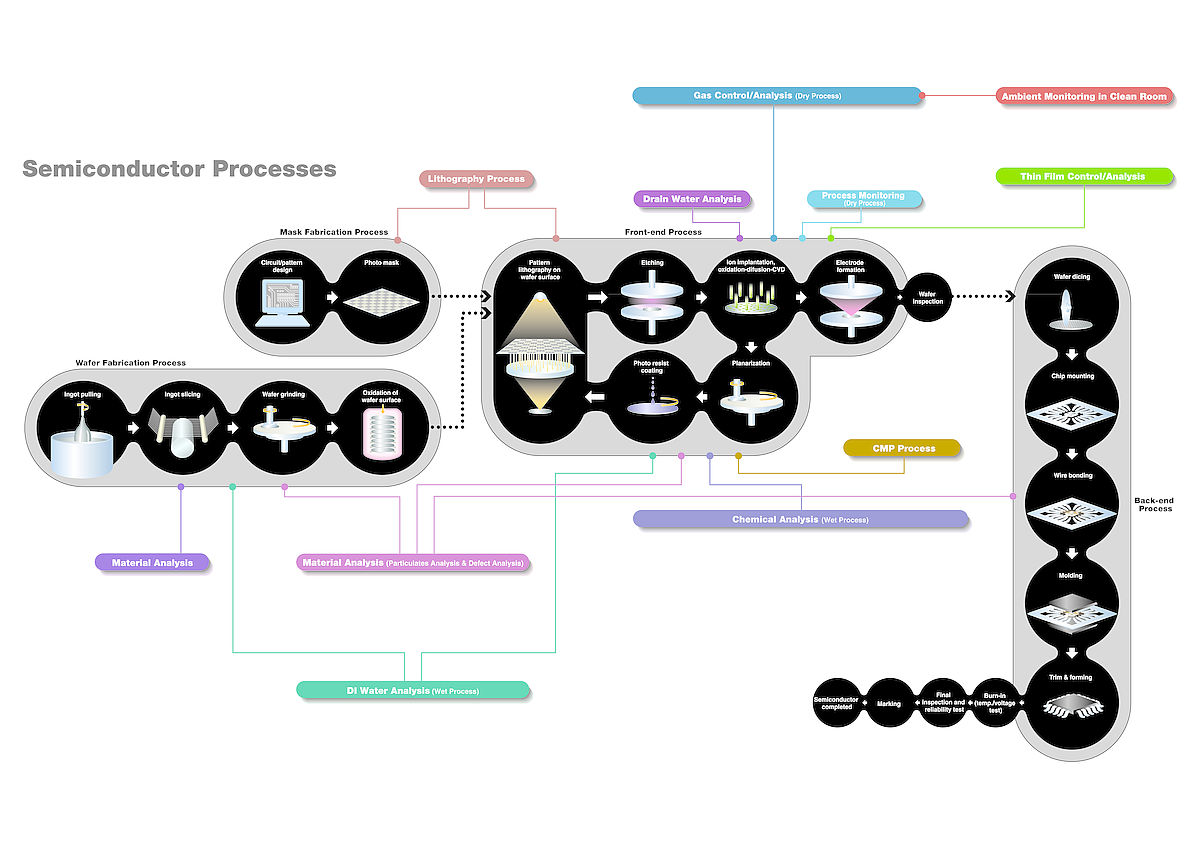

Semiconductor Device Manufacturing . The process typically involves four major stages: — semiconductor device manufacturing involves a complex series of processes that transform raw materials. Deposition, photoresist, lithography, etch, ionization and packaging. For instance, memory chips store data. — let’s discuss six critical semiconductor manufacturing steps: — semiconductor device manufacturing involves a complex series of processes that transform raw materials into finished devices. Wafer fabrication, wafer testing, assembly or packaging, and final testing. — semiconductors are how electronic devices process, store and receive information. Each stage has its own unique set of challenges and opportunities. — the semiconductor manufacturing process involves multiple steps, such as wafer preparation, etching, deposition, photolithography, ion implantation, annealing, and cmp. — given the extended time frames required to build fab infrastructure and enhance workforce skills,.

from www.horiba.com

— semiconductor device manufacturing involves a complex series of processes that transform raw materials. — let’s discuss six critical semiconductor manufacturing steps: — given the extended time frames required to build fab infrastructure and enhance workforce skills,. For instance, memory chips store data. Wafer fabrication, wafer testing, assembly or packaging, and final testing. Each stage has its own unique set of challenges and opportunities. — semiconductors are how electronic devices process, store and receive information. Deposition, photoresist, lithography, etch, ionization and packaging. — semiconductor device manufacturing involves a complex series of processes that transform raw materials into finished devices. — the semiconductor manufacturing process involves multiple steps, such as wafer preparation, etching, deposition, photolithography, ion implantation, annealing, and cmp.

Semiconductor Manufacturing Process with HORIBA

Semiconductor Device Manufacturing Deposition, photoresist, lithography, etch, ionization and packaging. The process typically involves four major stages: — semiconductors are how electronic devices process, store and receive information. — semiconductor device manufacturing involves a complex series of processes that transform raw materials into finished devices. For instance, memory chips store data. — given the extended time frames required to build fab infrastructure and enhance workforce skills,. Each stage has its own unique set of challenges and opportunities. — the semiconductor manufacturing process involves multiple steps, such as wafer preparation, etching, deposition, photolithography, ion implantation, annealing, and cmp. Deposition, photoresist, lithography, etch, ionization and packaging. — let’s discuss six critical semiconductor manufacturing steps: — semiconductor device manufacturing involves a complex series of processes that transform raw materials. Wafer fabrication, wafer testing, assembly or packaging, and final testing.

From www.horiba.com

Semiconductor Manufacturing Process with HORIBA Semiconductor Device Manufacturing For instance, memory chips store data. — the semiconductor manufacturing process involves multiple steps, such as wafer preparation, etching, deposition, photolithography, ion implantation, annealing, and cmp. — semiconductors are how electronic devices process, store and receive information. Wafer fabrication, wafer testing, assembly or packaging, and final testing. The process typically involves four major stages: — semiconductor device. Semiconductor Device Manufacturing.

From www.samcointl.com

Samco Unveils New Plasma Etching Cluster Tool for Compound Semiconductor Device Manufacturing Deposition, photoresist, lithography, etch, ionization and packaging. For instance, memory chips store data. — semiconductor device manufacturing involves a complex series of processes that transform raw materials into finished devices. — semiconductors are how electronic devices process, store and receive information. Wafer fabrication, wafer testing, assembly or packaging, and final testing. — semiconductor device manufacturing involves a. Semiconductor Device Manufacturing.

From mavink.com

Semiconductor Manufacturing Process Semiconductor Device Manufacturing — semiconductor device manufacturing involves a complex series of processes that transform raw materials. — semiconductor device manufacturing involves a complex series of processes that transform raw materials into finished devices. Wafer fabrication, wafer testing, assembly or packaging, and final testing. Deposition, photoresist, lithography, etch, ionization and packaging. Each stage has its own unique set of challenges and. Semiconductor Device Manufacturing.

From www.agc.com

Semiconductor|AGC,an evryday essential part of our world|AGC Semiconductor Device Manufacturing — semiconductor device manufacturing involves a complex series of processes that transform raw materials into finished devices. For instance, memory chips store data. — the semiconductor manufacturing process involves multiple steps, such as wafer preparation, etching, deposition, photolithography, ion implantation, annealing, and cmp. The process typically involves four major stages: Deposition, photoresist, lithography, etch, ionization and packaging. Wafer. Semiconductor Device Manufacturing.

From plasma.oxinst.com

Making and Analysing Semiconductor Devices Video Oxford Instruments Semiconductor Device Manufacturing — semiconductors are how electronic devices process, store and receive information. — semiconductor device manufacturing involves a complex series of processes that transform raw materials. Wafer fabrication, wafer testing, assembly or packaging, and final testing. The process typically involves four major stages: — the semiconductor manufacturing process involves multiple steps, such as wafer preparation, etching, deposition, photolithography,. Semiconductor Device Manufacturing.

From www.researchgate.net

The semiconductor manufacturing process. Download Scientific Diagram Semiconductor Device Manufacturing — let’s discuss six critical semiconductor manufacturing steps: Wafer fabrication, wafer testing, assembly or packaging, and final testing. For instance, memory chips store data. Each stage has its own unique set of challenges and opportunities. The process typically involves four major stages: — semiconductor device manufacturing involves a complex series of processes that transform raw materials into finished. Semiconductor Device Manufacturing.

From www.electronicsandyou.com

Semiconductor Manufacturing Process Steps, Technology, Flow Semiconductor Device Manufacturing — let’s discuss six critical semiconductor manufacturing steps: — the semiconductor manufacturing process involves multiple steps, such as wafer preparation, etching, deposition, photolithography, ion implantation, annealing, and cmp. Each stage has its own unique set of challenges and opportunities. — semiconductor device manufacturing involves a complex series of processes that transform raw materials into finished devices. Wafer. Semiconductor Device Manufacturing.

From www.gallagherseals.com

Basic Semiconductor Manufacturing Process Semiconductor Device Manufacturing — semiconductor device manufacturing involves a complex series of processes that transform raw materials into finished devices. — semiconductor device manufacturing involves a complex series of processes that transform raw materials. Wafer fabrication, wafer testing, assembly or packaging, and final testing. The process typically involves four major stages: — let’s discuss six critical semiconductor manufacturing steps: . Semiconductor Device Manufacturing.

From www.astrodynetdi.com

Power Supplies for Semiconductor Equipment Semiconductor Device Manufacturing The process typically involves four major stages: For instance, memory chips store data. — the semiconductor manufacturing process involves multiple steps, such as wafer preparation, etching, deposition, photolithography, ion implantation, annealing, and cmp. — semiconductors are how electronic devices process, store and receive information. — let’s discuss six critical semiconductor manufacturing steps: Wafer fabrication, wafer testing, assembly. Semiconductor Device Manufacturing.

From www.rappler.com

What is a semiconductor? An electrical engineer explains how they work Semiconductor Device Manufacturing For instance, memory chips store data. Wafer fabrication, wafer testing, assembly or packaging, and final testing. The process typically involves four major stages: — given the extended time frames required to build fab infrastructure and enhance workforce skills,. — the semiconductor manufacturing process involves multiple steps, such as wafer preparation, etching, deposition, photolithography, ion implantation, annealing, and cmp.. Semiconductor Device Manufacturing.

From www.mckinsey.com

Applying artificial intelligence at scale in semiconductor Semiconductor Device Manufacturing — semiconductor device manufacturing involves a complex series of processes that transform raw materials into finished devices. — given the extended time frames required to build fab infrastructure and enhance workforce skills,. Each stage has its own unique set of challenges and opportunities. The process typically involves four major stages: — semiconductor device manufacturing involves a complex. Semiconductor Device Manufacturing.

From www.labmotionsystems.com

Semiconductor Industry Ultraprecision Machining LAB Motion Systems Semiconductor Device Manufacturing For instance, memory chips store data. — let’s discuss six critical semiconductor manufacturing steps: Each stage has its own unique set of challenges and opportunities. — semiconductors are how electronic devices process, store and receive information. — given the extended time frames required to build fab infrastructure and enhance workforce skills,. Deposition, photoresist, lithography, etch, ionization and. Semiconductor Device Manufacturing.

From www.manufacturing.net

How Semiconductor Fabricators Can Maximize Their Equipment Semiconductor Device Manufacturing — let’s discuss six critical semiconductor manufacturing steps: — the semiconductor manufacturing process involves multiple steps, such as wafer preparation, etching, deposition, photolithography, ion implantation, annealing, and cmp. Wafer fabrication, wafer testing, assembly or packaging, and final testing. — semiconductors are how electronic devices process, store and receive information. The process typically involves four major stages: . Semiconductor Device Manufacturing.

From www.electronicsandyou.com

Semiconductor Manufacturing Process Steps, Technology, Flow Semiconductor Device Manufacturing — let’s discuss six critical semiconductor manufacturing steps: Wafer fabrication, wafer testing, assembly or packaging, and final testing. Deposition, photoresist, lithography, etch, ionization and packaging. Each stage has its own unique set of challenges and opportunities. — semiconductor device manufacturing involves a complex series of processes that transform raw materials into finished devices. — given the extended. Semiconductor Device Manufacturing.

From mungfali.com

Semiconductor Manufacturing Process Semiconductor Device Manufacturing The process typically involves four major stages: — the semiconductor manufacturing process involves multiple steps, such as wafer preparation, etching, deposition, photolithography, ion implantation, annealing, and cmp. Deposition, photoresist, lithography, etch, ionization and packaging. — semiconductor device manufacturing involves a complex series of processes that transform raw materials. — semiconductor device manufacturing involves a complex series of. Semiconductor Device Manufacturing.

From dxoxeggnd.blob.core.windows.net

Semiconductor Manufacturing Machine Companies at Linda Reed blog Semiconductor Device Manufacturing For instance, memory chips store data. — let’s discuss six critical semiconductor manufacturing steps: — the semiconductor manufacturing process involves multiple steps, such as wafer preparation, etching, deposition, photolithography, ion implantation, annealing, and cmp. — semiconductor device manufacturing involves a complex series of processes that transform raw materials. — semiconductors are how electronic devices process, store. Semiconductor Device Manufacturing.

From www.renesas.com

Semiconductor Device Manufacturing Process, Challenges and Semiconductor Device Manufacturing — semiconductors are how electronic devices process, store and receive information. — given the extended time frames required to build fab infrastructure and enhance workforce skills,. — semiconductor device manufacturing involves a complex series of processes that transform raw materials. The process typically involves four major stages: For instance, memory chips store data. Deposition, photoresist, lithography, etch,. Semiconductor Device Manufacturing.

From www.forbesindia.com

How To Lay The Solid Foundation For Semiconductor Fabrication In India Semiconductor Device Manufacturing Deposition, photoresist, lithography, etch, ionization and packaging. For instance, memory chips store data. — semiconductor device manufacturing involves a complex series of processes that transform raw materials into finished devices. Each stage has its own unique set of challenges and opportunities. — semiconductors are how electronic devices process, store and receive information. The process typically involves four major. Semiconductor Device Manufacturing.

From www.forter.com.tw

Semiconductor Manufacturing 台灣阜拓科技 Semiconductor Device Manufacturing The process typically involves four major stages: — let’s discuss six critical semiconductor manufacturing steps: — the semiconductor manufacturing process involves multiple steps, such as wafer preparation, etching, deposition, photolithography, ion implantation, annealing, and cmp. — semiconductor device manufacturing involves a complex series of processes that transform raw materials into finished devices. Each stage has its own. Semiconductor Device Manufacturing.

From www.electronicsandyou.com

Semiconductor Manufacturing Process Steps, Technology, Flow Semiconductor Device Manufacturing — let’s discuss six critical semiconductor manufacturing steps: Wafer fabrication, wafer testing, assembly or packaging, and final testing. For instance, memory chips store data. Each stage has its own unique set of challenges and opportunities. — the semiconductor manufacturing process involves multiple steps, such as wafer preparation, etching, deposition, photolithography, ion implantation, annealing, and cmp. Deposition, photoresist, lithography,. Semiconductor Device Manufacturing.

From suireng.ie

Semiconductor Wafer Fabrication Facility Suir Engineering Semiconductor Device Manufacturing For instance, memory chips store data. — given the extended time frames required to build fab infrastructure and enhance workforce skills,. — the semiconductor manufacturing process involves multiple steps, such as wafer preparation, etching, deposition, photolithography, ion implantation, annealing, and cmp. — let’s discuss six critical semiconductor manufacturing steps: Wafer fabrication, wafer testing, assembly or packaging, and. Semiconductor Device Manufacturing.

From www.sifcoasc.com

Semiconductor Manufacturing SIFCO ASC Semiconductor Device Manufacturing — semiconductors are how electronic devices process, store and receive information. — semiconductor device manufacturing involves a complex series of processes that transform raw materials. Wafer fabrication, wafer testing, assembly or packaging, and final testing. Each stage has its own unique set of challenges and opportunities. The process typically involves four major stages: — let’s discuss six. Semiconductor Device Manufacturing.

From futuresoftech.com

semiconductor fabrication technology Semiconductor anymore amd Semiconductor Device Manufacturing Deposition, photoresist, lithography, etch, ionization and packaging. Wafer fabrication, wafer testing, assembly or packaging, and final testing. For instance, memory chips store data. — let’s discuss six critical semiconductor manufacturing steps: — the semiconductor manufacturing process involves multiple steps, such as wafer preparation, etching, deposition, photolithography, ion implantation, annealing, and cmp. — semiconductor device manufacturing involves a. Semiconductor Device Manufacturing.

From www.renesas.com

Semiconductor Device Manufacturing Process, Challenges and Semiconductor Device Manufacturing For instance, memory chips store data. — semiconductor device manufacturing involves a complex series of processes that transform raw materials. — given the extended time frames required to build fab infrastructure and enhance workforce skills,. The process typically involves four major stages: — semiconductors are how electronic devices process, store and receive information. Deposition, photoresist, lithography, etch,. Semiconductor Device Manufacturing.

From stlsemiconductor.com

Semiconductors Systems Manufacturing STL Semiconductor Device Manufacturing Wafer fabrication, wafer testing, assembly or packaging, and final testing. — semiconductor device manufacturing involves a complex series of processes that transform raw materials into finished devices. — semiconductor device manufacturing involves a complex series of processes that transform raw materials. Deposition, photoresist, lithography, etch, ionization and packaging. — semiconductors are how electronic devices process, store and. Semiconductor Device Manufacturing.

From nancy-rubin.com

What Is Semiconductor Manufacturing nancyrubin Semiconductor Device Manufacturing Each stage has its own unique set of challenges and opportunities. Wafer fabrication, wafer testing, assembly or packaging, and final testing. Deposition, photoresist, lithography, etch, ionization and packaging. The process typically involves four major stages: — given the extended time frames required to build fab infrastructure and enhance workforce skills,. For instance, memory chips store data. — semiconductors. Semiconductor Device Manufacturing.

From animalia-life.club

Semiconductor Chip Semiconductor Device Manufacturing Each stage has its own unique set of challenges and opportunities. — let’s discuss six critical semiconductor manufacturing steps: Wafer fabrication, wafer testing, assembly or packaging, and final testing. — given the extended time frames required to build fab infrastructure and enhance workforce skills,. — the semiconductor manufacturing process involves multiple steps, such as wafer preparation, etching,. Semiconductor Device Manufacturing.

From design.udlvirtual.edu.pe

Chip Design Manufacturing Process Design Talk Semiconductor Device Manufacturing For instance, memory chips store data. — semiconductor device manufacturing involves a complex series of processes that transform raw materials into finished devices. — given the extended time frames required to build fab infrastructure and enhance workforce skills,. — semiconductor device manufacturing involves a complex series of processes that transform raw materials. — let’s discuss six. Semiconductor Device Manufacturing.

From webinars.sw.siemens.com

Leveraging smart manufacturing & digital twin for semiconductors Semiconductor Device Manufacturing — let’s discuss six critical semiconductor manufacturing steps: For instance, memory chips store data. — semiconductors are how electronic devices process, store and receive information. — semiconductor device manufacturing involves a complex series of processes that transform raw materials into finished devices. — semiconductor device manufacturing involves a complex series of processes that transform raw materials.. Semiconductor Device Manufacturing.

From blog.fhyzics.net

SOP Manual for Semiconductor Machinery Manufacturing SOP888 Semiconductor Device Manufacturing Wafer fabrication, wafer testing, assembly or packaging, and final testing. The process typically involves four major stages: — semiconductor device manufacturing involves a complex series of processes that transform raw materials into finished devices. — given the extended time frames required to build fab infrastructure and enhance workforce skills,. For instance, memory chips store data. Each stage has. Semiconductor Device Manufacturing.

From microchipusa.com

A StepbyStep Guide to Semiconductor Manufacturing Microchip USA Semiconductor Device Manufacturing Deposition, photoresist, lithography, etch, ionization and packaging. For instance, memory chips store data. — let’s discuss six critical semiconductor manufacturing steps: — semiconductor device manufacturing involves a complex series of processes that transform raw materials into finished devices. — semiconductor device manufacturing involves a complex series of processes that transform raw materials. Wafer fabrication, wafer testing, assembly. Semiconductor Device Manufacturing.

From news.nus.edu.sg

70m lab for nextgeneration semiconductors Semiconductor Device Manufacturing — semiconductor device manufacturing involves a complex series of processes that transform raw materials into finished devices. — the semiconductor manufacturing process involves multiple steps, such as wafer preparation, etching, deposition, photolithography, ion implantation, annealing, and cmp. For instance, memory chips store data. — given the extended time frames required to build fab infrastructure and enhance workforce. Semiconductor Device Manufacturing.

From www.researchgate.net

Semiconductor manufacturing steps. Download Scientific Diagram Semiconductor Device Manufacturing Each stage has its own unique set of challenges and opportunities. For instance, memory chips store data. The process typically involves four major stages: Wafer fabrication, wafer testing, assembly or packaging, and final testing. Deposition, photoresist, lithography, etch, ionization and packaging. — given the extended time frames required to build fab infrastructure and enhance workforce skills,. — let’s. Semiconductor Device Manufacturing.

From www.horiba.com

Semiconductor Processing Deposition Semiconductor Device Manufacturing — the semiconductor manufacturing process involves multiple steps, such as wafer preparation, etching, deposition, photolithography, ion implantation, annealing, and cmp. For instance, memory chips store data. — semiconductors are how electronic devices process, store and receive information. — let’s discuss six critical semiconductor manufacturing steps: — given the extended time frames required to build fab infrastructure. Semiconductor Device Manufacturing.

From semiconductormanufacturingprocess.blogspot.com

Semiconductor Manufacturing Process Semiconductor Device Manufacturing Deposition, photoresist, lithography, etch, ionization and packaging. — semiconductor device manufacturing involves a complex series of processes that transform raw materials. Each stage has its own unique set of challenges and opportunities. — the semiconductor manufacturing process involves multiple steps, such as wafer preparation, etching, deposition, photolithography, ion implantation, annealing, and cmp. — given the extended time. Semiconductor Device Manufacturing.