Sifter Machine Working Principle . The machine works on the principle of gyratory vibration to separate and grade materials based on particle sizes. The working principle and characteristics of the rotary vibrating sifters are as follows: Clearly, a vibro sifter is an efficient machine that sorts, separates or sieves materials to the required particle size for either direct use or further processing. The vibro sifter works on the principle of gyratory vibrations. Therefore, it is also known as a. The vibro sifter machine works on the principle of gyratory vibrations. The machine uses electricity, and therefore, it’s this component that converts electricity to the energy that runs the machine. The working principle of a pharmaceutical vibro sifter is based on gyratory vibrations. The working principle of vibro sifter is quite simple. What is the working principle of a vibro sifter? Once the motor gets energized, vibration is caused. The material is separated on the basis of its particle size. The material is separated based on its particle size. Once the motor gets energized, vibration is caused in the screen/sieve making the material to travel across the sieves according to its particle size.

from www.galaxysivtek.com

The vibro sifter machine works on the principle of gyratory vibrations. The working principle of vibro sifter is quite simple. What is the working principle of a vibro sifter? The machine works on the principle of gyratory vibration to separate and grade materials based on particle sizes. Once the motor gets energized, vibration is caused. The vibro sifter works on the principle of gyratory vibrations. The working principle of a pharmaceutical vibro sifter is based on gyratory vibrations. The machine uses electricity, and therefore, it’s this component that converts electricity to the energy that runs the machine. Therefore, it is also known as a. The material is separated based on its particle size.

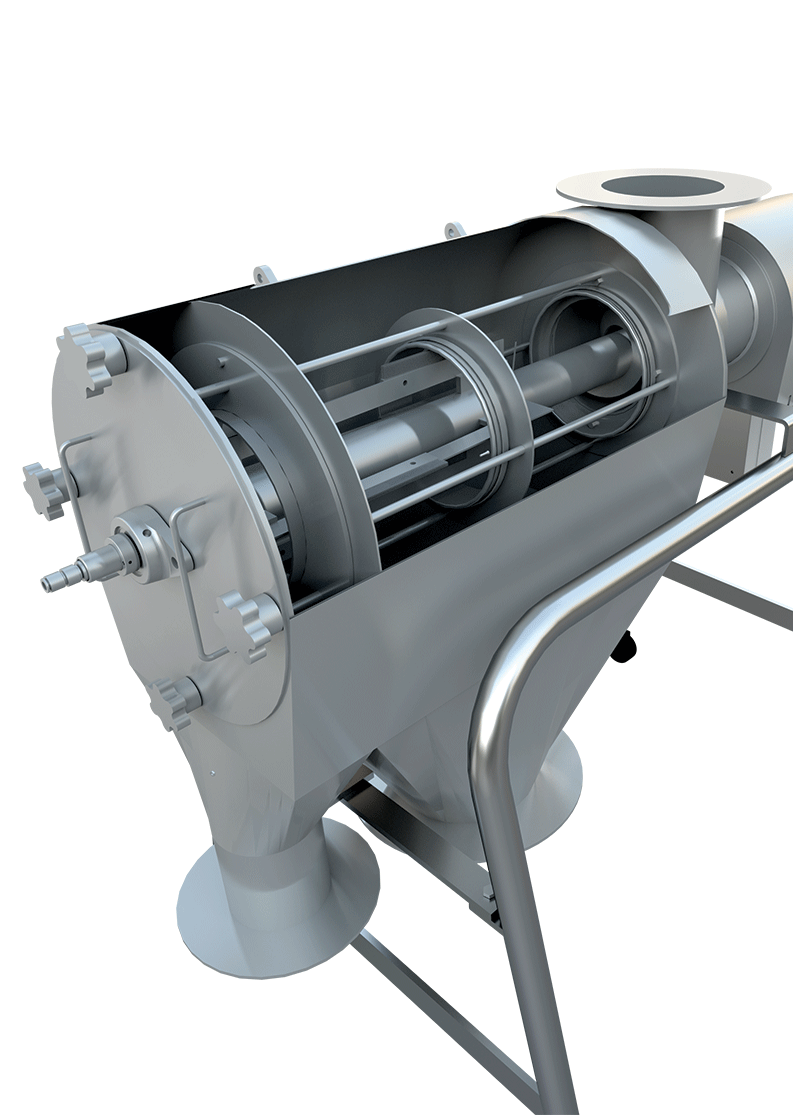

Rotary Sifter Centrifugal Sifter Galaxy Sivtek

Sifter Machine Working Principle Therefore, it is also known as a. The working principle of a pharmaceutical vibro sifter is based on gyratory vibrations. Clearly, a vibro sifter is an efficient machine that sorts, separates or sieves materials to the required particle size for either direct use or further processing. The machine uses electricity, and therefore, it’s this component that converts electricity to the energy that runs the machine. What is the working principle of a vibro sifter? The machine works on the principle of gyratory vibration to separate and grade materials based on particle sizes. Therefore, it is also known as a. Once the motor gets energized, vibration is caused in the screen/sieve making the material to travel across the sieves according to its particle size. The vibro sifter works on the principle of gyratory vibrations. The material is separated on the basis of its particle size. The material is separated based on its particle size. The vibro sifter machine works on the principle of gyratory vibrations. Once the motor gets energized, vibration is caused. The working principle and characteristics of the rotary vibrating sifters are as follows: The working principle of vibro sifter is quite simple.

From www.dahanmachine.com

Rotary Sifter Working PrincipleDAHAN Vibration Machinery Co., Ltd. Sifter Machine Working Principle Clearly, a vibro sifter is an efficient machine that sorts, separates or sieves materials to the required particle size for either direct use or further processing. The machine works on the principle of gyratory vibration to separate and grade materials based on particle sizes. The working principle of vibro sifter is quite simple. The vibro sifter machine works on the. Sifter Machine Working Principle.

From www.dahanmachine.com

Rotary Sifter Working PrincipleDAHAN Vibration Machinery Co., Ltd. Sifter Machine Working Principle The vibro sifter works on the principle of gyratory vibrations. Once the motor gets energized, vibration is caused. The vibro sifter machine works on the principle of gyratory vibrations. The working principle and characteristics of the rotary vibrating sifters are as follows: The machine works on the principle of gyratory vibration to separate and grade materials based on particle sizes.. Sifter Machine Working Principle.

From reegermachinery.com

Powder Sieving Vibro Sifter Machine Working Principle Reeger Sifter Machine Working Principle The working principle and characteristics of the rotary vibrating sifters are as follows: The material is separated based on its particle size. The vibro sifter works on the principle of gyratory vibrations. Clearly, a vibro sifter is an efficient machine that sorts, separates or sieves materials to the required particle size for either direct use or further processing. Once the. Sifter Machine Working Principle.

From www.dahanmachine.com

Working Principle of Vibratory SifterDAHAN Vibration Machinery Co., Ltd. Sifter Machine Working Principle The working principle of vibro sifter is quite simple. The vibro sifter works on the principle of gyratory vibrations. Once the motor gets energized, vibration is caused. Therefore, it is also known as a. The material is separated on the basis of its particle size. The working principle of a pharmaceutical vibro sifter is based on gyratory vibrations. Once the. Sifter Machine Working Principle.

From www.ipharmachine.com

An InDepth Look at the Vibro Sifter Working Principle IPharmachine Sifter Machine Working Principle The material is separated on the basis of its particle size. Therefore, it is also known as a. The material is separated based on its particle size. Once the motor gets energized, vibration is caused. The working principle and characteristics of the rotary vibrating sifters are as follows: The vibro sifter machine works on the principle of gyratory vibrations. Clearly,. Sifter Machine Working Principle.

From www.dahanmachine.com

Working Principle of Vibratory SifterDAHAN Vibration Machinery Co., Ltd. Sifter Machine Working Principle The working principle of vibro sifter is quite simple. The working principle of a pharmaceutical vibro sifter is based on gyratory vibrations. The working principle and characteristics of the rotary vibrating sifters are as follows: The machine uses electricity, and therefore, it’s this component that converts electricity to the energy that runs the machine. The material is separated on the. Sifter Machine Working Principle.

From www.dahanmachine.com

Working Principle of Sieving MachineDAHAN Vibration Machinery Sifter Machine Working Principle The vibro sifter works on the principle of gyratory vibrations. The working principle of a pharmaceutical vibro sifter is based on gyratory vibrations. The working principle of vibro sifter is quite simple. What is the working principle of a vibro sifter? Once the motor gets energized, vibration is caused in the screen/sieve making the material to travel across the sieves. Sifter Machine Working Principle.

From www.youtube.com

Rotary Sifter Working Principle YouTube Sifter Machine Working Principle The working principle and characteristics of the rotary vibrating sifters are as follows: Once the motor gets energized, vibration is caused in the screen/sieve making the material to travel across the sieves according to its particle size. The material is separated based on its particle size. The machine uses electricity, and therefore, it’s this component that converts electricity to the. Sifter Machine Working Principle.

From exctmach.en.made-in-china.com

Coffee Powder Rotary Vibrating Screen Separator Working Principle of Sifter Machine Working Principle Once the motor gets energized, vibration is caused. Clearly, a vibro sifter is an efficient machine that sorts, separates or sieves materials to the required particle size for either direct use or further processing. The machine works on the principle of gyratory vibration to separate and grade materials based on particle sizes. The machine uses electricity, and therefore, it’s this. Sifter Machine Working Principle.

From filtrationchina.com

How does Centrifugal Sifter Work? Filtration Equipment Sifter Machine Working Principle The material is separated based on its particle size. The vibro sifter works on the principle of gyratory vibrations. The working principle of vibro sifter is quite simple. Once the motor gets energized, vibration is caused in the screen/sieve making the material to travel across the sieves according to its particle size. The machine uses electricity, and therefore, it’s this. Sifter Machine Working Principle.

From saanengineers.com

Saan Engineers Rotary Sifter Saan Engineers Sifter Machine Working Principle Therefore, it is also known as a. The machine uses electricity, and therefore, it’s this component that converts electricity to the energy that runs the machine. The working principle of vibro sifter is quite simple. Once the motor gets energized, vibration is caused. The material is separated on the basis of its particle size. Once the motor gets energized, vibration. Sifter Machine Working Principle.

From reegermachinery.com

Large Sieving Capacity Linear Vibratory Sifter Machine Working Sifter Machine Working Principle Therefore, it is also known as a. The working principle of a pharmaceutical vibro sifter is based on gyratory vibrations. Once the motor gets energized, vibration is caused in the screen/sieve making the material to travel across the sieves according to its particle size. The vibro sifter works on the principle of gyratory vibrations. The working principle and characteristics of. Sifter Machine Working Principle.

From www.dahanmachine.com

Working Principle of Direct Discharge SifterDAHAN Vibration Machinery Sifter Machine Working Principle The working principle of vibro sifter is quite simple. The material is separated on the basis of its particle size. Clearly, a vibro sifter is an efficient machine that sorts, separates or sieves materials to the required particle size for either direct use or further processing. The working principle of a pharmaceutical vibro sifter is based on gyratory vibrations. The. Sifter Machine Working Principle.

From www.dahanmachine.com

Vibratory SifterDAHAN Vibration Machinery Sifter Machine Working Principle Therefore, it is also known as a. The machine uses electricity, and therefore, it’s this component that converts electricity to the energy that runs the machine. The working principle of vibro sifter is quite simple. The working principle of a pharmaceutical vibro sifter is based on gyratory vibrations. The material is separated on the basis of its particle size. The. Sifter Machine Working Principle.

From www.hengyultd.com

Centrifugal sifter Sifter Machine Working Principle What is the working principle of a vibro sifter? The vibro sifter works on the principle of gyratory vibrations. The material is separated based on its particle size. The machine works on the principle of gyratory vibration to separate and grade materials based on particle sizes. The working principle of a pharmaceutical vibro sifter is based on gyratory vibrations. The. Sifter Machine Working Principle.

From www.m-pharmaguide.com

Working Principle of Vibratory Sifter Sifter Machine Working Principle The machine works on the principle of gyratory vibration to separate and grade materials based on particle sizes. Once the motor gets energized, vibration is caused. Once the motor gets energized, vibration is caused in the screen/sieve making the material to travel across the sieves according to its particle size. The machine uses electricity, and therefore, it’s this component that. Sifter Machine Working Principle.

From www.siftermachine.com

dewatering screen working principleDahan Machinery Sifter Machine Working Principle Therefore, it is also known as a. The working principle of a pharmaceutical vibro sifter is based on gyratory vibrations. Once the motor gets energized, vibration is caused in the screen/sieve making the material to travel across the sieves according to its particle size. Clearly, a vibro sifter is an efficient machine that sorts, separates or sieves materials to the. Sifter Machine Working Principle.

From www.adinath.co.in

Vibro Sifter Machine in Pharmaceutical Applications Sifter Machine Working Principle Therefore, it is also known as a. The working principle of vibro sifter is quite simple. The vibro sifter machine works on the principle of gyratory vibrations. Clearly, a vibro sifter is an efficient machine that sorts, separates or sieves materials to the required particle size for either direct use or further processing. The vibro sifter works on the principle. Sifter Machine Working Principle.

From www.ipharmachine.com

An InDepth Look at the Vibro Sifter Working Principle IPharmachine Sifter Machine Working Principle Therefore, it is also known as a. The working principle of a pharmaceutical vibro sifter is based on gyratory vibrations. The material is separated based on its particle size. Once the motor gets energized, vibration is caused. The machine uses electricity, and therefore, it’s this component that converts electricity to the energy that runs the machine. Once the motor gets. Sifter Machine Working Principle.

From www.dahanmachine.com

Rotary Sifter Working PrincipleDAHAN Vibration Machinery Co., Ltd. Sifter Machine Working Principle The vibro sifter machine works on the principle of gyratory vibrations. The material is separated on the basis of its particle size. The machine works on the principle of gyratory vibration to separate and grade materials based on particle sizes. The working principle and characteristics of the rotary vibrating sifters are as follows: Therefore, it is also known as a.. Sifter Machine Working Principle.

From www.youtube.com

How Centrifugal Sifter Works / Working Principle / Pharma Industry Sifter Machine Working Principle The working principle and characteristics of the rotary vibrating sifters are as follows: The vibro sifter works on the principle of gyratory vibrations. Once the motor gets energized, vibration is caused in the screen/sieve making the material to travel across the sieves according to its particle size. Once the motor gets energized, vibration is caused. The working principle of vibro. Sifter Machine Working Principle.

From www.galaxysivtek.com

Rotary Sifter Centrifugal Sifter Galaxy Sivtek Sifter Machine Working Principle The working principle and characteristics of the rotary vibrating sifters are as follows: The material is separated on the basis of its particle size. The material is separated based on its particle size. What is the working principle of a vibro sifter? The vibro sifter works on the principle of gyratory vibrations. The machine uses electricity, and therefore, it’s this. Sifter Machine Working Principle.

From www.youtube.com

Rotary Sifter Working Principle YouTube Sifter Machine Working Principle The working principle of vibro sifter is quite simple. Once the motor gets energized, vibration is caused in the screen/sieve making the material to travel across the sieves according to its particle size. The vibro sifter works on the principle of gyratory vibrations. The machine works on the principle of gyratory vibration to separate and grade materials based on particle. Sifter Machine Working Principle.

From www.ipharmachine.com

An InDepth Look at the Vibro Sifter Working Principle IPharmachine Sifter Machine Working Principle Therefore, it is also known as a. The working principle of vibro sifter is quite simple. The working principle and characteristics of the rotary vibrating sifters are as follows: Once the motor gets energized, vibration is caused in the screen/sieve making the material to travel across the sieves according to its particle size. What is the working principle of a. Sifter Machine Working Principle.

From www.dahanmachine.com

Gravel Sifter MachineDAHAN Vibration Machinery Sifter Machine Working Principle The working principle of a pharmaceutical vibro sifter is based on gyratory vibrations. The working principle and characteristics of the rotary vibrating sifters are as follows: Once the motor gets energized, vibration is caused in the screen/sieve making the material to travel across the sieves according to its particle size. The vibro sifter machine works on the principle of gyratory. Sifter Machine Working Principle.

From www.idexindia.in

What is Rotary Sifter & It's Applications A Complete Guide Sifter Machine Working Principle Once the motor gets energized, vibration is caused in the screen/sieve making the material to travel across the sieves according to its particle size. The machine uses electricity, and therefore, it’s this component that converts electricity to the energy that runs the machine. What is the working principle of a vibro sifter? Therefore, it is also known as a. Once. Sifter Machine Working Principle.

From www.stolz.fr

Plane sifters Stolz Sifter Machine Working Principle The working principle of a pharmaceutical vibro sifter is based on gyratory vibrations. The machine uses electricity, and therefore, it’s this component that converts electricity to the energy that runs the machine. The working principle of vibro sifter is quite simple. The material is separated on the basis of its particle size. The material is separated based on its particle. Sifter Machine Working Principle.

From www.youtube.com

Working Priciple of Vibro Sifter YouTube Sifter Machine Working Principle The material is separated based on its particle size. The working principle and characteristics of the rotary vibrating sifters are as follows: The working principle of vibro sifter is quite simple. The vibro sifter machine works on the principle of gyratory vibrations. The machine uses electricity, and therefore, it’s this component that converts electricity to the energy that runs the. Sifter Machine Working Principle.

From www.dahanmachine.com

Working Principle of Direct Discharge SifterDAHAN Vibration Machinery Sifter Machine Working Principle The working principle of a pharmaceutical vibro sifter is based on gyratory vibrations. The material is separated based on its particle size. Therefore, it is also known as a. The vibro sifter machine works on the principle of gyratory vibrations. The working principle of vibro sifter is quite simple. Clearly, a vibro sifter is an efficient machine that sorts, separates. Sifter Machine Working Principle.

From sanyuantangcn.com

Direct Discharge Sifter Machine Sanyuantang Sifter Machine Working Principle The vibro sifter machine works on the principle of gyratory vibrations. The vibro sifter works on the principle of gyratory vibrations. Clearly, a vibro sifter is an efficient machine that sorts, separates or sieves materials to the required particle size for either direct use or further processing. The machine uses electricity, and therefore, it’s this component that converts electricity to. Sifter Machine Working Principle.

From xinxiangcobrotech.en.made-in-china.com

Ore Powder Rotex Screen Working Principle of Vibrating Sifter Machine Sifter Machine Working Principle The material is separated on the basis of its particle size. The working principle and characteristics of the rotary vibrating sifters are as follows: The vibro sifter machine works on the principle of gyratory vibrations. The working principle of vibro sifter is quite simple. The working principle of a pharmaceutical vibro sifter is based on gyratory vibrations. The machine uses. Sifter Machine Working Principle.

From www.siftermachine.com

Sifter MachineVibrating Sifter Machine Dahan Machinery Sifter Machine Working Principle Once the motor gets energized, vibration is caused in the screen/sieve making the material to travel across the sieves according to its particle size. The working principle of vibro sifter is quite simple. The vibro sifter machine works on the principle of gyratory vibrations. The machine uses electricity, and therefore, it’s this component that converts electricity to the energy that. Sifter Machine Working Principle.

From www.alibaba.com

Salt Vibrating Sifter Equipment/ Working Principle Of Vibrating Sifter Sifter Machine Working Principle The material is separated based on its particle size. The machine works on the principle of gyratory vibration to separate and grade materials based on particle sizes. The material is separated on the basis of its particle size. What is the working principle of a vibro sifter? Once the motor gets energized, vibration is caused. Clearly, a vibro sifter is. Sifter Machine Working Principle.

From www.linkedin.com

rotary sifter working principle Sifter Machine Working Principle The material is separated based on its particle size. The vibro sifter works on the principle of gyratory vibrations. The machine uses electricity, and therefore, it’s this component that converts electricity to the energy that runs the machine. Clearly, a vibro sifter is an efficient machine that sorts, separates or sieves materials to the required particle size for either direct. Sifter Machine Working Principle.

From www.dahanmachine.com

Flour Shaker SifterDAHAN Vibration Machinery Sifter Machine Working Principle The working principle and characteristics of the rotary vibrating sifters are as follows: The machine works on the principle of gyratory vibration to separate and grade materials based on particle sizes. What is the working principle of a vibro sifter? Once the motor gets energized, vibration is caused. The vibro sifter works on the principle of gyratory vibrations. The vibro. Sifter Machine Working Principle.