Best Countersink Angle . Note that in the case of the 90° countersink, this callout is the same. What is the best countersink angle? The most common countersink angles are 82°, 90° or 100°. Choosing the correct angle ensures fasteners sit flush with. For american inch screws, an 82° angle is common, while for iso metric screws, a 90° angle is typical. Common angles include 60 degrees, 82 degrees, and 90. Countersink angles vary depending on the application and fastener type. The angle of the countersink is crucial and should be carefully determined based on the type of fastener and the material being used. Selecting the right countersink angle: Common countersink angles include 82°, 90°, and 100°. Gather a drill, countersink bit (which combines a drill bit and a countersink cutter), screws, and a screwdriver. In the aerospace industry, a 100°. The angle of the countersink bit should match the angle of the screw head. The most common angles for countersink holes are 82 degrees and 90 degrees, though other angles.

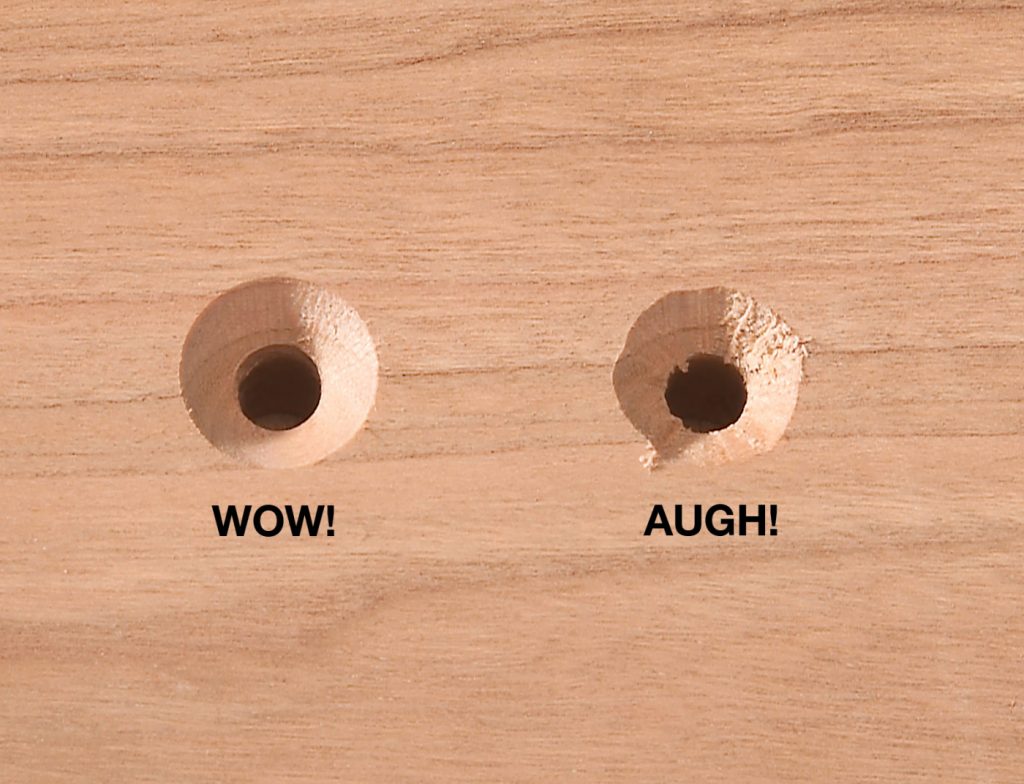

from www.popularwoodworking.com

Countersink angles vary depending on the application and fastener type. The most common angles for countersink holes are 82 degrees and 90 degrees, though other angles. The most common countersink angles are 82°, 90° or 100°. The angle of the countersink is crucial and should be carefully determined based on the type of fastener and the material being used. Common countersink angles include 82°, 90°, and 100°. For american inch screws, an 82° angle is common, while for iso metric screws, a 90° angle is typical. Gather a drill, countersink bit (which combines a drill bit and a countersink cutter), screws, and a screwdriver. What is the best countersink angle? In the aerospace industry, a 100°. Note that in the case of the 90° countersink, this callout is the same.

How to Make A Perfect Countersink Popular Woodworking

Best Countersink Angle Countersink angles vary depending on the application and fastener type. Gather a drill, countersink bit (which combines a drill bit and a countersink cutter), screws, and a screwdriver. The angle of the countersink bit should match the angle of the screw head. The most common countersink angles are 82°, 90° or 100°. Countersink angles vary depending on the application and fastener type. For american inch screws, an 82° angle is common, while for iso metric screws, a 90° angle is typical. Common countersink angles include 82°, 90°, and 100°. Common angles include 60 degrees, 82 degrees, and 90. Note that in the case of the 90° countersink, this callout is the same. What is the best countersink angle? Selecting the right countersink angle: In the aerospace industry, a 100°. The angle of the countersink is crucial and should be carefully determined based on the type of fastener and the material being used. Choosing the correct angle ensures fasteners sit flush with. The most common angles for countersink holes are 82 degrees and 90 degrees, though other angles.

From www.grainger.com

KEO Countersink Set, 82 ° Countersink Angle, Number of Pieces 5, High Best Countersink Angle Common angles include 60 degrees, 82 degrees, and 90. The angle of the countersink bit should match the angle of the screw head. Selecting the right countersink angle: The most common countersink angles are 82°, 90° or 100°. What is the best countersink angle? Common countersink angles include 82°, 90°, and 100°. The most common angles for countersink holes are. Best Countersink Angle.

From www.gistgear.com

Best Countersinks Buying Guide Gistgear Best Countersink Angle Common countersink angles include 82°, 90°, and 100°. Note that in the case of the 90° countersink, this callout is the same. Selecting the right countersink angle: For american inch screws, an 82° angle is common, while for iso metric screws, a 90° angle is typical. The angle of the countersink is crucial and should be carefully determined based on. Best Countersink Angle.

From www.walter.com

VP™ Countersinks Walter Surface Technologies Best Countersink Angle Selecting the right countersink angle: Countersink angles vary depending on the application and fastener type. Choosing the correct angle ensures fasteners sit flush with. In the aerospace industry, a 100°. Common angles include 60 degrees, 82 degrees, and 90. For american inch screws, an 82° angle is common, while for iso metric screws, a 90° angle is typical. The most. Best Countersink Angle.

From www.grainger.com

KEO Countersink Set, 100 ° Countersink Angle, Number of Pieces 7, High Best Countersink Angle What is the best countersink angle? In the aerospace industry, a 100°. Note that in the case of the 90° countersink, this callout is the same. Common countersink angles include 82°, 90°, and 100°. The most common countersink angles are 82°, 90° or 100°. Common angles include 60 degrees, 82 degrees, and 90. Gather a drill, countersink bit (which combines. Best Countersink Angle.

From www.straight.com

Top 5 Best Countersink Bits in 2024 Best Countersink Angle Common angles include 60 degrees, 82 degrees, and 90. What is the best countersink angle? Gather a drill, countersink bit (which combines a drill bit and a countersink cutter), screws, and a screwdriver. The most common countersink angles are 82°, 90° or 100°. For american inch screws, an 82° angle is common, while for iso metric screws, a 90° angle. Best Countersink Angle.

From drillbitguru.com

We Review The 6 Best Countersink Bits (2024) Best Countersink Angle The angle of the countersink bit should match the angle of the screw head. Common angles include 60 degrees, 82 degrees, and 90. Selecting the right countersink angle: Choosing the correct angle ensures fasteners sit flush with. Note that in the case of the 90° countersink, this callout is the same. For american inch screws, an 82° angle is common,. Best Countersink Angle.

From www.popularwoodworking.com

How to Make A Perfect Countersink Popular Woodworking Best Countersink Angle Common countersink angles include 82°, 90°, and 100°. Note that in the case of the 90° countersink, this callout is the same. Common angles include 60 degrees, 82 degrees, and 90. The most common angles for countersink holes are 82 degrees and 90 degrees, though other angles. For american inch screws, an 82° angle is common, while for iso metric. Best Countersink Angle.

From forums.autodesk.com

Measure a countersink angle? Autodesk Community Best Countersink Angle The most common countersink angles are 82°, 90° or 100°. Gather a drill, countersink bit (which combines a drill bit and a countersink cutter), screws, and a screwdriver. Common angles include 60 degrees, 82 degrees, and 90. Choosing the correct angle ensures fasteners sit flush with. What is the best countersink angle? The angle of the countersink is crucial and. Best Countersink Angle.

From www.novacam.com

3D countersink measurement noncontact and automated Novacam Best Countersink Angle For american inch screws, an 82° angle is common, while for iso metric screws, a 90° angle is typical. The most common angles for countersink holes are 82 degrees and 90 degrees, though other angles. Common angles include 60 degrees, 82 degrees, and 90. Gather a drill, countersink bit (which combines a drill bit and a countersink cutter), screws, and. Best Countersink Angle.

From www.grainger.com

CLEVELAND Countersink Set, 82 ° Countersink Angle, Number of Pieces 5 Best Countersink Angle The most common countersink angles are 82°, 90° or 100°. What is the best countersink angle? The most common angles for countersink holes are 82 degrees and 90 degrees, though other angles. Common angles include 60 degrees, 82 degrees, and 90. Gather a drill, countersink bit (which combines a drill bit and a countersink cutter), screws, and a screwdriver. In. Best Countersink Angle.

From engineersbible.com

Countersunk Hole Size for Machine Screw (ANSI Metric) Best Countersink Angle Choosing the correct angle ensures fasteners sit flush with. Note that in the case of the 90° countersink, this callout is the same. Countersink angles vary depending on the application and fastener type. Common countersink angles include 82°, 90°, and 100°. The angle of the countersink bit should match the angle of the screw head. The most common countersink angles. Best Countersink Angle.

From www.grainger.com

KEO Countersink Set, 110 ° Countersink Angle, Number of Pieces 5, High Best Countersink Angle What is the best countersink angle? The angle of the countersink bit should match the angle of the screw head. The most common countersink angles are 82°, 90° or 100°. Common countersink angles include 82°, 90°, and 100°. For american inch screws, an 82° angle is common, while for iso metric screws, a 90° angle is typical. The most common. Best Countersink Angle.

From www.grainger.com

KEO Countersink Set, 82 ° Countersink Angle, Number of Pieces 5, High Best Countersink Angle Countersink angles vary depending on the application and fastener type. Selecting the right countersink angle: In the aerospace industry, a 100°. Common angles include 60 degrees, 82 degrees, and 90. The most common countersink angles are 82°, 90° or 100°. The angle of the countersink bit should match the angle of the screw head. Gather a drill, countersink bit (which. Best Countersink Angle.

From www.grainger.com

KEO Countersink Set, 82 ° Countersink Angle, Number of Pieces 5, Cobalt Best Countersink Angle The most common angles for countersink holes are 82 degrees and 90 degrees, though other angles. The angle of the countersink is crucial and should be carefully determined based on the type of fastener and the material being used. In the aerospace industry, a 100°. The angle of the countersink bit should match the angle of the screw head. Gather. Best Countersink Angle.

From teletalkbd.com

Best Countersink Drill Bit For Every Job Best Countersink Angle Countersink angles vary depending on the application and fastener type. The angle of the countersink is crucial and should be carefully determined based on the type of fastener and the material being used. Common countersink angles include 82°, 90°, and 100°. What is the best countersink angle? Gather a drill, countersink bit (which combines a drill bit and a countersink. Best Countersink Angle.

From www.finepowertools.com

Countersink Angles Common Angles and Their Applications Best Countersink Angle For american inch screws, an 82° angle is common, while for iso metric screws, a 90° angle is typical. The angle of the countersink is crucial and should be carefully determined based on the type of fastener and the material being used. In the aerospace industry, a 100°. Choosing the correct angle ensures fasteners sit flush with. Selecting the right. Best Countersink Angle.

From carpentrify.com

Best Countersink Bit for Wood Pros, Cons and Best Use Best Countersink Angle The angle of the countersink bit should match the angle of the screw head. For american inch screws, an 82° angle is common, while for iso metric screws, a 90° angle is typical. In the aerospace industry, a 100°. Selecting the right countersink angle: Countersink angles vary depending on the application and fastener type. Note that in the case of. Best Countersink Angle.

From 10bestreviewz.com

Top 10 Best Countersink For Steel in 2024 Reviews by Experts Best Countersink Angle Gather a drill, countersink bit (which combines a drill bit and a countersink cutter), screws, and a screwdriver. Common angles include 60 degrees, 82 degrees, and 90. Selecting the right countersink angle: The angle of the countersink is crucial and should be carefully determined based on the type of fastener and the material being used. Common countersink angles include 82°,. Best Countersink Angle.

From www.gdandtbasics.com

Countersink GD&T Basics Best Countersink Angle The most common countersink angles are 82°, 90° or 100°. The angle of the countersink is crucial and should be carefully determined based on the type of fastener and the material being used. Choosing the correct angle ensures fasteners sit flush with. Countersink angles vary depending on the application and fastener type. For american inch screws, an 82° angle is. Best Countersink Angle.

From www.johnrocker.net

Top 10 Best Countersink For Steel Reviews (2023) Best Countersink Angle In the aerospace industry, a 100°. Countersink angles vary depending on the application and fastener type. For american inch screws, an 82° angle is common, while for iso metric screws, a 90° angle is typical. What is the best countersink angle? The angle of the countersink bit should match the angle of the screw head. Common angles include 60 degrees,. Best Countersink Angle.

From sendcutsend.com

Countersink Design Best Practices SendCutSend Best Countersink Angle The angle of the countersink bit should match the angle of the screw head. Choosing the correct angle ensures fasteners sit flush with. For american inch screws, an 82° angle is common, while for iso metric screws, a 90° angle is typical. What is the best countersink angle? The angle of the countersink is crucial and should be carefully determined. Best Countersink Angle.

From sendcutsend.com

Countersink Design Best Practices SendCutSend Best Countersink Angle What is the best countersink angle? Common angles include 60 degrees, 82 degrees, and 90. Common countersink angles include 82°, 90°, and 100°. Selecting the right countersink angle: Countersink angles vary depending on the application and fastener type. In the aerospace industry, a 100°. The most common angles for countersink holes are 82 degrees and 90 degrees, though other angles.. Best Countersink Angle.

From www.tenyutool.com

Steel Countersink Bit HSS4241 Round Shank Countersink Best Countersink Angle Selecting the right countersink angle: The most common countersink angles are 82°, 90° or 100°. Choosing the correct angle ensures fasteners sit flush with. The most common angles for countersink holes are 82 degrees and 90 degrees, though other angles. Common angles include 60 degrees, 82 degrees, and 90. For american inch screws, an 82° angle is common, while for. Best Countersink Angle.

From gadgetssai.com

Top 10 Best Countersink For Stainless Steel Review In 2022 GadgetsSai Best Countersink Angle In the aerospace industry, a 100°. The most common countersink angles are 82°, 90° or 100°. For american inch screws, an 82° angle is common, while for iso metric screws, a 90° angle is typical. The angle of the countersink bit should match the angle of the screw head. The most common angles for countersink holes are 82 degrees and. Best Countersink Angle.

From www.finepowertools.com

Countersink Angles Common Angles and Their Applications Best Countersink Angle What is the best countersink angle? The most common countersink angles are 82°, 90° or 100°. Choosing the correct angle ensures fasteners sit flush with. Common countersink angles include 82°, 90°, and 100°. For american inch screws, an 82° angle is common, while for iso metric screws, a 90° angle is typical. Selecting the right countersink angle: The angle of. Best Countersink Angle.

From www.mathscinotes.com

Measuring Countersink Angle Using Gage Balls Math Encounters Blog Best Countersink Angle What is the best countersink angle? Common angles include 60 degrees, 82 degrees, and 90. Common countersink angles include 82°, 90°, and 100°. Selecting the right countersink angle: Choosing the correct angle ensures fasteners sit flush with. The most common angles for countersink holes are 82 degrees and 90 degrees, though other angles. Note that in the case of the. Best Countersink Angle.

From www.amazon.com

KEO 53512 Cobalt Steel SingleEnd Countersink, Uncoated (Bright) Finish Best Countersink Angle Choosing the correct angle ensures fasteners sit flush with. The most common angles for countersink holes are 82 degrees and 90 degrees, though other angles. What is the best countersink angle? Selecting the right countersink angle: For american inch screws, an 82° angle is common, while for iso metric screws, a 90° angle is typical. The angle of the countersink. Best Countersink Angle.

From carpentrify.com

Best Countersink Bit for Wood Pros, Cons and Best Use Best Countersink Angle What is the best countersink angle? Countersink angles vary depending on the application and fastener type. Note that in the case of the 90° countersink, this callout is the same. For american inch screws, an 82° angle is common, while for iso metric screws, a 90° angle is typical. Gather a drill, countersink bit (which combines a drill bit and. Best Countersink Angle.

From bdteletalk.com

Selecting The Best Countersink Bit For Metal What To Consider And Tips Best Countersink Angle Countersink angles vary depending on the application and fastener type. Note that in the case of the 90° countersink, this callout is the same. What is the best countersink angle? The angle of the countersink bit should match the angle of the screw head. The most common angles for countersink holes are 82 degrees and 90 degrees, though other angles.. Best Countersink Angle.

From www.walter.com

VP™ Countersinks Walter Surface Technologies Best Countersink Angle In the aerospace industry, a 100°. Selecting the right countersink angle: Countersink angles vary depending on the application and fastener type. The most common angles for countersink holes are 82 degrees and 90 degrees, though other angles. Common countersink angles include 82°, 90°, and 100°. The angle of the countersink is crucial and should be carefully determined based on the. Best Countersink Angle.

From www.grainger.com

CLEVELAND Countersink Set, 90 ° Countersink Angle, Number of Pieces 5 Best Countersink Angle Common countersink angles include 82°, 90°, and 100°. What is the best countersink angle? Countersink angles vary depending on the application and fastener type. The most common countersink angles are 82°, 90° or 100°. Gather a drill, countersink bit (which combines a drill bit and a countersink cutter), screws, and a screwdriver. For american inch screws, an 82° angle is. Best Countersink Angle.

From forums.autodesk.com

Measure a countersink angle? Autodesk Community Best Countersink Angle The most common angles for countersink holes are 82 degrees and 90 degrees, though other angles. Gather a drill, countersink bit (which combines a drill bit and a countersink cutter), screws, and a screwdriver. In the aerospace industry, a 100°. The angle of the countersink bit should match the angle of the screw head. Countersink angles vary depending on the. Best Countersink Angle.

From www.reddit.com

How to calculate countersink angle from hole diameter and countersink Best Countersink Angle Countersink angles vary depending on the application and fastener type. The most common angles for countersink holes are 82 degrees and 90 degrees, though other angles. Choosing the correct angle ensures fasteners sit flush with. Gather a drill, countersink bit (which combines a drill bit and a countersink cutter), screws, and a screwdriver. For american inch screws, an 82° angle. Best Countersink Angle.

From sendcutsend.com

Countersink Design Best Practices SendCutSend Best Countersink Angle The angle of the countersink is crucial and should be carefully determined based on the type of fastener and the material being used. What is the best countersink angle? Selecting the right countersink angle: The angle of the countersink bit should match the angle of the screw head. Note that in the case of the 90° countersink, this callout is. Best Countersink Angle.

From thatcrazyoillady.com

Top 10 Best Countersink For Aluminum Based On Customer Ratings That Best Countersink Angle What is the best countersink angle? Choosing the correct angle ensures fasteners sit flush with. For american inch screws, an 82° angle is common, while for iso metric screws, a 90° angle is typical. Gather a drill, countersink bit (which combines a drill bit and a countersink cutter), screws, and a screwdriver. The most common angles for countersink holes are. Best Countersink Angle.