Welding Clamp Ground . 1m+ visitors in the past month You’re going to need a ground clamp to ground your welder. We’ll show the importance of welding ground for your safety and welds. The ground clamp (earth clamp) needs to be attached to the base material you’re welding. The first step is to make sure the power source for the welding machine is turned off. It needs to be close to where you’re. This move will help you complete the electric circuit and allow the welder to create an arc safely and effectively. Earth clamps play a vital role in preventing electrical accidents by safely diverting the welding current to the ground. Without the proper grounding provided by these clamps, there is a risk of electrical shock to the welder, as well as potential damage to the welding equipment. The ground clamp should be attached to a clean and unpainted metal surface, such as a nearby metal beam or an equipment grounding conductor. If you want to create quality welds, you need to know how to use a welding ground clamp. Then, locate the ground clamp attached to the welding machine. The article provides an overview of the best ground clamps for welding, highlighting a range of options such as magnetic, copper, and steel clamps.

from www.grainger.com

Without the proper grounding provided by these clamps, there is a risk of electrical shock to the welder, as well as potential damage to the welding equipment. If you want to create quality welds, you need to know how to use a welding ground clamp. The first step is to make sure the power source for the welding machine is turned off. This move will help you complete the electric circuit and allow the welder to create an arc safely and effectively. The ground clamp (earth clamp) needs to be attached to the base material you’re welding. You’re going to need a ground clamp to ground your welder. The article provides an overview of the best ground clamps for welding, highlighting a range of options such as magnetic, copper, and steel clamps. The ground clamp should be attached to a clean and unpainted metal surface, such as a nearby metal beam or an equipment grounding conductor. 1m+ visitors in the past month We’ll show the importance of welding ground for your safety and welds.

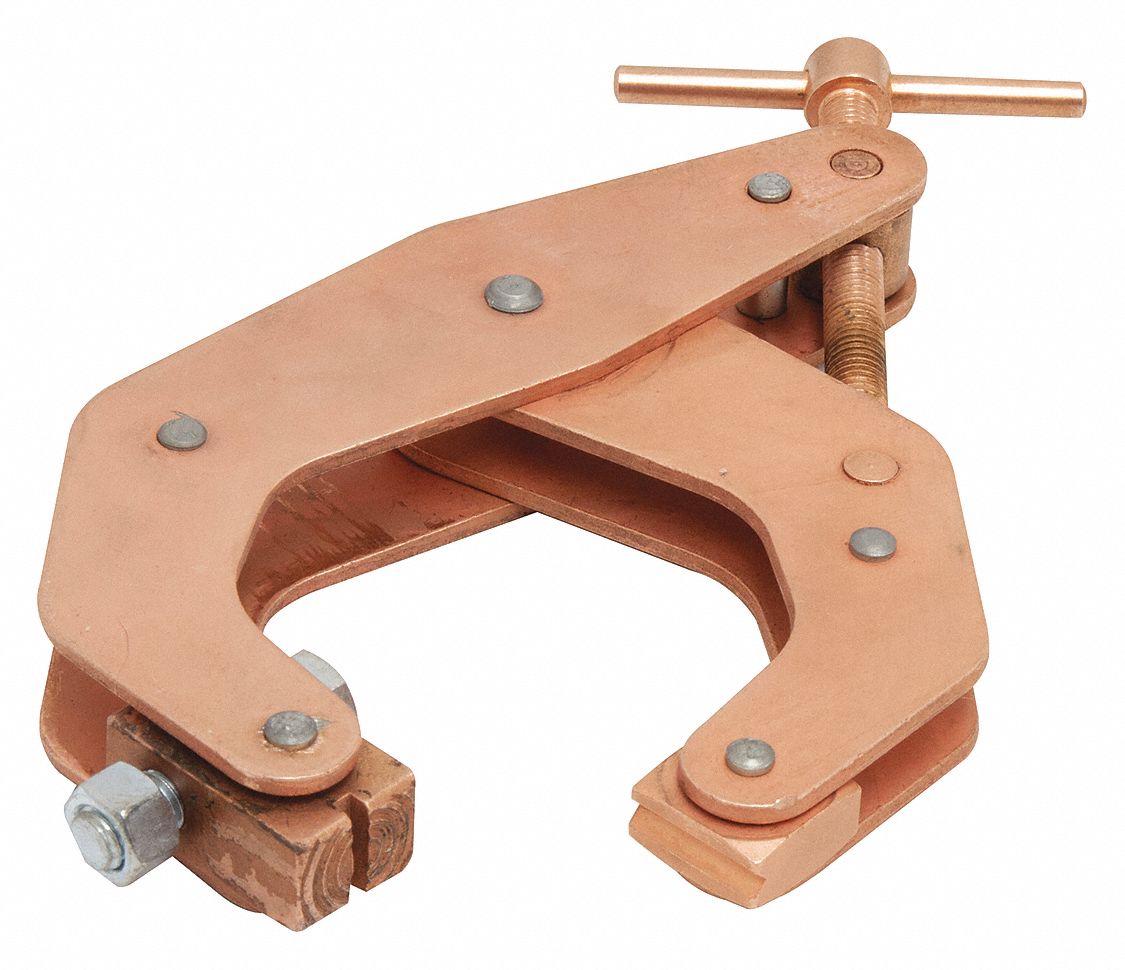

KANTTWIST Welding Ground Clamp, 400A 31HG56K045TGD Grainger

Welding Clamp Ground If you want to create quality welds, you need to know how to use a welding ground clamp. You’re going to need a ground clamp to ground your welder. We’ll show the importance of welding ground for your safety and welds. The ground clamp should be attached to a clean and unpainted metal surface, such as a nearby metal beam or an equipment grounding conductor. 1m+ visitors in the past month Earth clamps play a vital role in preventing electrical accidents by safely diverting the welding current to the ground. Then, locate the ground clamp attached to the welding machine. Without the proper grounding provided by these clamps, there is a risk of electrical shock to the welder, as well as potential damage to the welding equipment. If you want to create quality welds, you need to know how to use a welding ground clamp. The first step is to make sure the power source for the welding machine is turned off. It needs to be close to where you’re. The ground clamp (earth clamp) needs to be attached to the base material you’re welding. The article provides an overview of the best ground clamps for welding, highlighting a range of options such as magnetic, copper, and steel clamps. This move will help you complete the electric circuit and allow the welder to create an arc safely and effectively.

From

Welding Clamp Ground The ground clamp (earth clamp) needs to be attached to the base material you’re welding. We’ll show the importance of welding ground for your safety and welds. The ground clamp should be attached to a clean and unpainted metal surface, such as a nearby metal beam or an equipment grounding conductor. The first step is to make sure the power. Welding Clamp Ground.

From

Welding Clamp Ground The article provides an overview of the best ground clamps for welding, highlighting a range of options such as magnetic, copper, and steel clamps. Then, locate the ground clamp attached to the welding machine. You’re going to need a ground clamp to ground your welder. The ground clamp should be attached to a clean and unpainted metal surface, such as. Welding Clamp Ground.

From www.valkenpower.com

welding ground clamp 600A Valkenpower Welding Clamp Ground Earth clamps play a vital role in preventing electrical accidents by safely diverting the welding current to the ground. You’re going to need a ground clamp to ground your welder. Without the proper grounding provided by these clamps, there is a risk of electrical shock to the welder, as well as potential damage to the welding equipment. The first step. Welding Clamp Ground.

From

Welding Clamp Ground Earth clamps play a vital role in preventing electrical accidents by safely diverting the welding current to the ground. Without the proper grounding provided by these clamps, there is a risk of electrical shock to the welder, as well as potential damage to the welding equipment. This move will help you complete the electric circuit and allow the welder to. Welding Clamp Ground.

From www.dreamstime.com

Ground clamp for welding stock photo. Image of welding 88585402 Welding Clamp Ground Without the proper grounding provided by these clamps, there is a risk of electrical shock to the welder, as well as potential damage to the welding equipment. We’ll show the importance of welding ground for your safety and welds. The first step is to make sure the power source for the welding machine is turned off. The ground clamp (earth. Welding Clamp Ground.

From

Welding Clamp Ground You’re going to need a ground clamp to ground your welder. The ground clamp should be attached to a clean and unpainted metal surface, such as a nearby metal beam or an equipment grounding conductor. If you want to create quality welds, you need to know how to use a welding ground clamp. We’ll show the importance of welding ground. Welding Clamp Ground.

From

Welding Clamp Ground 1m+ visitors in the past month Earth clamps play a vital role in preventing electrical accidents by safely diverting the welding current to the ground. If you want to create quality welds, you need to know how to use a welding ground clamp. The first step is to make sure the power source for the welding machine is turned off.. Welding Clamp Ground.

From

Welding Clamp Ground 1m+ visitors in the past month Earth clamps play a vital role in preventing electrical accidents by safely diverting the welding current to the ground. The ground clamp (earth clamp) needs to be attached to the base material you’re welding. It needs to be close to where you’re. This move will help you complete the electric circuit and allow the. Welding Clamp Ground.

From

Welding Clamp Ground If you want to create quality welds, you need to know how to use a welding ground clamp. It needs to be close to where you’re. The ground clamp (earth clamp) needs to be attached to the base material you’re welding. The ground clamp should be attached to a clean and unpainted metal surface, such as a nearby metal beam. Welding Clamp Ground.

From

Welding Clamp Ground The ground clamp should be attached to a clean and unpainted metal surface, such as a nearby metal beam or an equipment grounding conductor. Without the proper grounding provided by these clamps, there is a risk of electrical shock to the welder, as well as potential damage to the welding equipment. We’ll show the importance of welding ground for your. Welding Clamp Ground.

From www.lencocanada.com

EG500 500 AMP GROUND CLAMP Lenco Welding Accessories Ltd. Welding Clamp Ground The first step is to make sure the power source for the welding machine is turned off. The article provides an overview of the best ground clamps for welding, highlighting a range of options such as magnetic, copper, and steel clamps. You’re going to need a ground clamp to ground your welder. This move will help you complete the electric. Welding Clamp Ground.

From

Welding Clamp Ground The first step is to make sure the power source for the welding machine is turned off. If you want to create quality welds, you need to know how to use a welding ground clamp. The article provides an overview of the best ground clamps for welding, highlighting a range of options such as magnetic, copper, and steel clamps. Earth. Welding Clamp Ground.

From

Welding Clamp Ground If you want to create quality welds, you need to know how to use a welding ground clamp. It needs to be close to where you’re. We’ll show the importance of welding ground for your safety and welds. Earth clamps play a vital role in preventing electrical accidents by safely diverting the welding current to the ground. You’re going to. Welding Clamp Ground.

From alexnld.com

MWGC1200 Welding Ground Clamp 200A Welding Clamp Ground We’ll show the importance of welding ground for your safety and welds. Without the proper grounding provided by these clamps, there is a risk of electrical shock to the welder, as well as potential damage to the welding equipment. It needs to be close to where you’re. If you want to create quality welds, you need to know how to. Welding Clamp Ground.

From

Welding Clamp Ground We’ll show the importance of welding ground for your safety and welds. If you want to create quality welds, you need to know how to use a welding ground clamp. It needs to be close to where you’re. Then, locate the ground clamp attached to the welding machine. Earth clamps play a vital role in preventing electrical accidents by safely. Welding Clamp Ground.

From clamps.welderguide.biz

400A C Welding Ground Clamp Solid Brass C Welding Clamp Ground You’re going to need a ground clamp to ground your welder. The first step is to make sure the power source for the welding machine is turned off. The article provides an overview of the best ground clamps for welding, highlighting a range of options such as magnetic, copper, and steel clamps. Then, locate the ground clamp attached to the. Welding Clamp Ground.

From www.harborfreight.com

300 Amp Welding Ground Clamp Welding Clamp Ground The ground clamp (earth clamp) needs to be attached to the base material you’re welding. It needs to be close to where you’re. The article provides an overview of the best ground clamps for welding, highlighting a range of options such as magnetic, copper, and steel clamps. If you want to create quality welds, you need to know how to. Welding Clamp Ground.

From

Welding Clamp Ground It needs to be close to where you’re. You’re going to need a ground clamp to ground your welder. Earth clamps play a vital role in preventing electrical accidents by safely diverting the welding current to the ground. This move will help you complete the electric circuit and allow the welder to create an arc safely and effectively. The ground. Welding Clamp Ground.

From

Welding Clamp Ground The ground clamp should be attached to a clean and unpainted metal surface, such as a nearby metal beam or an equipment grounding conductor. This move will help you complete the electric circuit and allow the welder to create an arc safely and effectively. If you want to create quality welds, you need to know how to use a welding. Welding Clamp Ground.

From

Welding Clamp Ground If you want to create quality welds, you need to know how to use a welding ground clamp. Without the proper grounding provided by these clamps, there is a risk of electrical shock to the welder, as well as potential damage to the welding equipment. We’ll show the importance of welding ground for your safety and welds. The ground clamp. Welding Clamp Ground.

From www.scnindustrial.com

WELDMATE HeavyDuty "CStyle" Ground Clamp, 600 Amperage Rating SCN Welding Clamp Ground The first step is to make sure the power source for the welding machine is turned off. This move will help you complete the electric circuit and allow the welder to create an arc safely and effectively. Then, locate the ground clamp attached to the welding machine. We’ll show the importance of welding ground for your safety and welds. Earth. Welding Clamp Ground.

From weldzone.org

6 Best Welding Ground Clamps Reviewed in Detail (Fall 2024) Welding Clamp Ground Earth clamps play a vital role in preventing electrical accidents by safely diverting the welding current to the ground. You’re going to need a ground clamp to ground your welder. The first step is to make sure the power source for the welding machine is turned off. We’ll show the importance of welding ground for your safety and welds. It. Welding Clamp Ground.

From

Welding Clamp Ground Without the proper grounding provided by these clamps, there is a risk of electrical shock to the welder, as well as potential damage to the welding equipment. We’ll show the importance of welding ground for your safety and welds. If you want to create quality welds, you need to know how to use a welding ground clamp. Then, locate the. Welding Clamp Ground.

From

Welding Clamp Ground We’ll show the importance of welding ground for your safety and welds. The ground clamp should be attached to a clean and unpainted metal surface, such as a nearby metal beam or an equipment grounding conductor. If you want to create quality welds, you need to know how to use a welding ground clamp. You’re going to need a ground. Welding Clamp Ground.

From

Welding Clamp Ground You’re going to need a ground clamp to ground your welder. If you want to create quality welds, you need to know how to use a welding ground clamp. Then, locate the ground clamp attached to the welding machine. 1m+ visitors in the past month The ground clamp (earth clamp) needs to be attached to the base material you’re welding.. Welding Clamp Ground.

From welderchoice.com

5 Best Welding Ground Clamps Reviews with Pros and Cons Welding Clamp Ground This move will help you complete the electric circuit and allow the welder to create an arc safely and effectively. If you want to create quality welds, you need to know how to use a welding ground clamp. We’ll show the importance of welding ground for your safety and welds. Without the proper grounding provided by these clamps, there is. Welding Clamp Ground.

From

Welding Clamp Ground The article provides an overview of the best ground clamps for welding, highlighting a range of options such as magnetic, copper, and steel clamps. Then, locate the ground clamp attached to the welding machine. Without the proper grounding provided by these clamps, there is a risk of electrical shock to the welder, as well as potential damage to the welding. Welding Clamp Ground.

From www.amazon.ca

FTVOGUE 500A Arc Weld Clamp Welding Clamps Welding Ground Clamp Welding Clamp Ground The article provides an overview of the best ground clamps for welding, highlighting a range of options such as magnetic, copper, and steel clamps. The ground clamp should be attached to a clean and unpainted metal surface, such as a nearby metal beam or an equipment grounding conductor. Earth clamps play a vital role in preventing electrical accidents by safely. Welding Clamp Ground.

From

Welding Clamp Ground We’ll show the importance of welding ground for your safety and welds. Then, locate the ground clamp attached to the welding machine. The ground clamp should be attached to a clean and unpainted metal surface, such as a nearby metal beam or an equipment grounding conductor. The ground clamp (earth clamp) needs to be attached to the base material you’re. Welding Clamp Ground.

From

Welding Clamp Ground We’ll show the importance of welding ground for your safety and welds. This move will help you complete the electric circuit and allow the welder to create an arc safely and effectively. The first step is to make sure the power source for the welding machine is turned off. The ground clamp (earth clamp) needs to be attached to the. Welding Clamp Ground.

From www.walmart.com

SÜA 300 AMP Welding Steel Ground Clamp Earth Clamp EG300 Style Welding Clamp Ground This move will help you complete the electric circuit and allow the welder to create an arc safely and effectively. The ground clamp (earth clamp) needs to be attached to the base material you’re welding. Without the proper grounding provided by these clamps, there is a risk of electrical shock to the welder, as well as potential damage to the. Welding Clamp Ground.

From

Welding Clamp Ground This move will help you complete the electric circuit and allow the welder to create an arc safely and effectively. The article provides an overview of the best ground clamps for welding, highlighting a range of options such as magnetic, copper, and steel clamps. 1m+ visitors in the past month It needs to be close to where you’re. The ground. Welding Clamp Ground.

From www.grainger.com

KANTTWIST Welding Ground Clamp, 400A 31HG56K045TGD Grainger Welding Clamp Ground Then, locate the ground clamp attached to the welding machine. You’re going to need a ground clamp to ground your welder. Without the proper grounding provided by these clamps, there is a risk of electrical shock to the welder, as well as potential damage to the welding equipment. The ground clamp should be attached to a clean and unpainted metal. Welding Clamp Ground.

From www.walmart.com

Arc Welding Ground Clamp 300A Grouding Earth Clamp for Welder Walmart Welding Clamp Ground It needs to be close to where you’re. Earth clamps play a vital role in preventing electrical accidents by safely diverting the welding current to the ground. If you want to create quality welds, you need to know how to use a welding ground clamp. The ground clamp (earth clamp) needs to be attached to the base material you’re welding.. Welding Clamp Ground.

From

Welding Clamp Ground The first step is to make sure the power source for the welding machine is turned off. We’ll show the importance of welding ground for your safety and welds. The ground clamp should be attached to a clean and unpainted metal surface, such as a nearby metal beam or an equipment grounding conductor. Then, locate the ground clamp attached to. Welding Clamp Ground.