Rolling Load Formula . P= pblp = ob r∆h σ' where the roll pressure. Calculate the roll force and the power required. T rm = rolling torque which is converted to motor shaft taking into account the gear ratio between motor shaft and the rolls. Roll = mw since p roll >5 mw (the available power), the rolling mill is not adequate for the operation. T fm = torque for. Equations are derived for the normal roll pressure, specific roll load and torque in hot rolling mills, using the condition for plastic deformation in. For annealed copper, it has a true stress of about 80 mpa in the unstrained condition and at a true. Rolling load p moves along the circumference of a circle equal to 2π.a since there are two work rolls involved, the work done is equal to work done. In the case of no friction situation , the rolling load (p) is given by the roll pressure (p) times the area of contact between the metal and the rolls (bl p).

from pressbooks.library.upei.ca

Rolling load p moves along the circumference of a circle equal to 2π.a since there are two work rolls involved, the work done is equal to work done. Calculate the roll force and the power required. In the case of no friction situation , the rolling load (p) is given by the roll pressure (p) times the area of contact between the metal and the rolls (bl p). P= pblp = ob r∆h σ' where the roll pressure. Roll = mw since p roll >5 mw (the available power), the rolling mill is not adequate for the operation. Equations are derived for the normal roll pressure, specific roll load and torque in hot rolling mills, using the condition for plastic deformation in. For annealed copper, it has a true stress of about 80 mpa in the unstrained condition and at a true. T fm = torque for. T rm = rolling torque which is converted to motor shaft taking into account the gear ratio between motor shaft and the rolls.

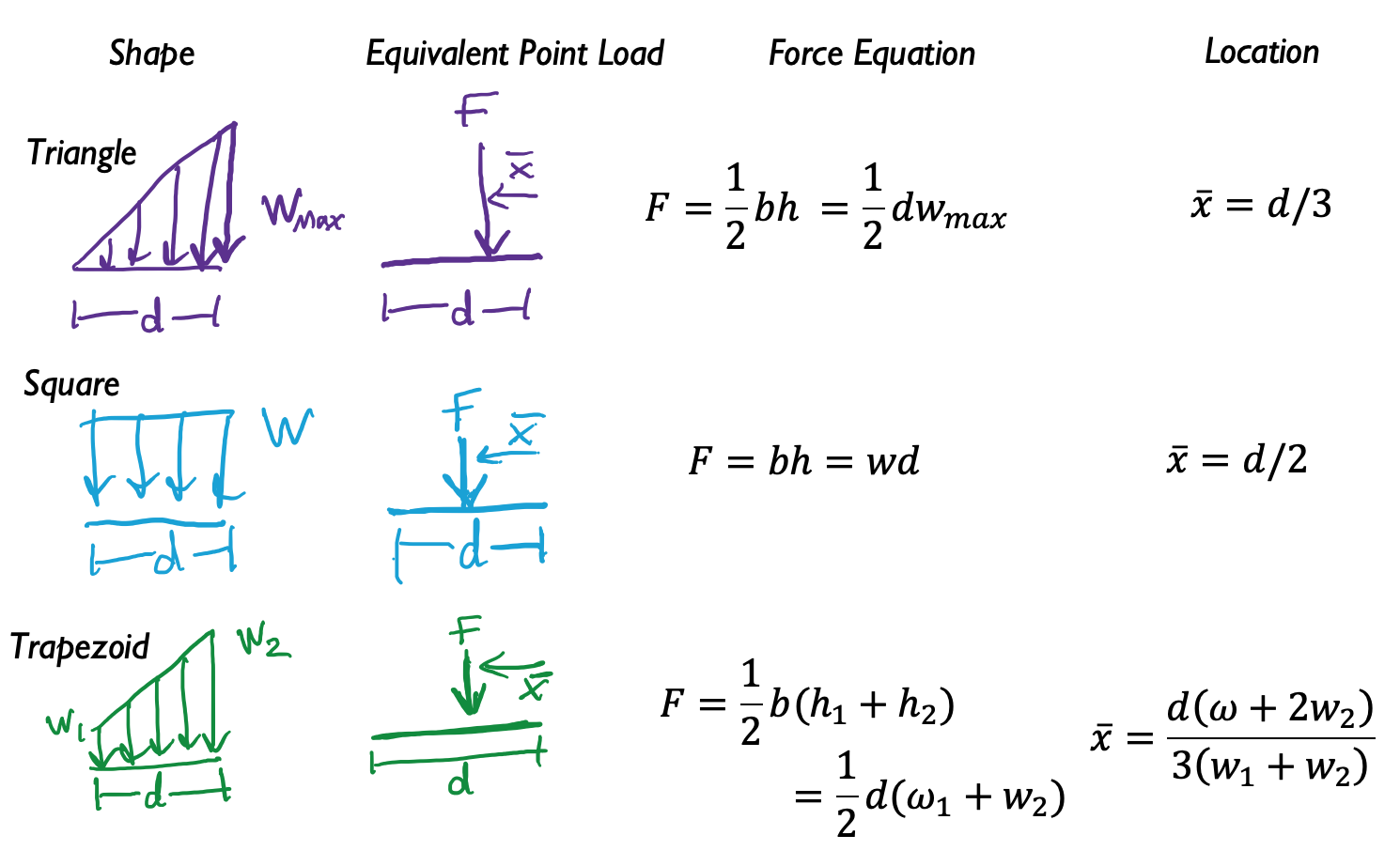

3.3 Distributed Loads Engineering Mechanics Statics

Rolling Load Formula For annealed copper, it has a true stress of about 80 mpa in the unstrained condition and at a true. Calculate the roll force and the power required. T rm = rolling torque which is converted to motor shaft taking into account the gear ratio between motor shaft and the rolls. For annealed copper, it has a true stress of about 80 mpa in the unstrained condition and at a true. In the case of no friction situation , the rolling load (p) is given by the roll pressure (p) times the area of contact between the metal and the rolls (bl p). Roll = mw since p roll >5 mw (the available power), the rolling mill is not adequate for the operation. Equations are derived for the normal roll pressure, specific roll load and torque in hot rolling mills, using the condition for plastic deformation in. T fm = torque for. P= pblp = ob r∆h σ' where the roll pressure. Rolling load p moves along the circumference of a circle equal to 2π.a since there are two work rolls involved, the work done is equal to work done.

From www.studocu.com

Rolling Loads UNIT I ROLLING LOADS Rolling loads are those loads Rolling Load Formula T fm = torque for. T rm = rolling torque which is converted to motor shaft taking into account the gear ratio between motor shaft and the rolls. In the case of no friction situation , the rolling load (p) is given by the roll pressure (p) times the area of contact between the metal and the rolls (bl p).. Rolling Load Formula.

From www.chegg.com

Solved The simply supported beam of length L is subjected to Rolling Load Formula For annealed copper, it has a true stress of about 80 mpa in the unstrained condition and at a true. T fm = torque for. Roll = mw since p roll >5 mw (the available power), the rolling mill is not adequate for the operation. Calculate the roll force and the power required. T rm = rolling torque which is. Rolling Load Formula.

From mechguru.com

Wheel Rolling Radius Calculation and Reading Tire Spec Rolling Load Formula Equations are derived for the normal roll pressure, specific roll load and torque in hot rolling mills, using the condition for plastic deformation in. T rm = rolling torque which is converted to motor shaft taking into account the gear ratio between motor shaft and the rolls. Roll = mw since p roll >5 mw (the available power), the rolling. Rolling Load Formula.

From koyo.jtekt.co.jp

Calculation of loads Basic Bearing Knowledge Koyo Bearings /JTEKT Rolling Load Formula Equations are derived for the normal roll pressure, specific roll load and torque in hot rolling mills, using the condition for plastic deformation in. Roll = mw since p roll >5 mw (the available power), the rolling mill is not adequate for the operation. T rm = rolling torque which is converted to motor shaft taking into account the gear. Rolling Load Formula.

From passionatemechanicalengineer.substack.com

The Fundamentals of Mechanical Engineering Part 2 Rolling Load Formula P= pblp = ob r∆h σ' where the roll pressure. For annealed copper, it has a true stress of about 80 mpa in the unstrained condition and at a true. Equations are derived for the normal roll pressure, specific roll load and torque in hot rolling mills, using the condition for plastic deformation in. In the case of no friction. Rolling Load Formula.

From www.youtube.com

Strength of Materials Moving Loads (2wheeled) Part 1 of 2 YouTube Rolling Load Formula Rolling load p moves along the circumference of a circle equal to 2π.a since there are two work rolls involved, the work done is equal to work done. P= pblp = ob r∆h σ' where the roll pressure. T rm = rolling torque which is converted to motor shaft taking into account the gear ratio between motor shaft and the. Rolling Load Formula.

From www.collegesearch.in

What is Rolling Friction Definition, Diagram, Formula, Coefficient Rolling Load Formula T rm = rolling torque which is converted to motor shaft taking into account the gear ratio between motor shaft and the rolls. P= pblp = ob r∆h σ' where the roll pressure. Equations are derived for the normal roll pressure, specific roll load and torque in hot rolling mills, using the condition for plastic deformation in. Rolling load p. Rolling Load Formula.

From www.slideserve.com

PPT rolling PowerPoint Presentation, free download ID2343161 Rolling Load Formula Equations are derived for the normal roll pressure, specific roll load and torque in hot rolling mills, using the condition for plastic deformation in. For annealed copper, it has a true stress of about 80 mpa in the unstrained condition and at a true. In the case of no friction situation , the rolling load (p) is given by the. Rolling Load Formula.

From www.chegg.com

Solved Calculate the rolling load needed to reduce a steel Rolling Load Formula For annealed copper, it has a true stress of about 80 mpa in the unstrained condition and at a true. Calculate the roll force and the power required. T rm = rolling torque which is converted to motor shaft taking into account the gear ratio between motor shaft and the rolls. Rolling load p moves along the circumference of a. Rolling Load Formula.

From www.researchgate.net

Rolling loadradius of groove top fillet R. Download Scientific Diagram Rolling Load Formula T rm = rolling torque which is converted to motor shaft taking into account the gear ratio between motor shaft and the rolls. Calculate the roll force and the power required. P= pblp = ob r∆h σ' where the roll pressure. T fm = torque for. For annealed copper, it has a true stress of about 80 mpa in the. Rolling Load Formula.

From www.slideserve.com

PPT Road Loads PowerPoint Presentation, free download ID5569012 Rolling Load Formula Calculate the roll force and the power required. Equations are derived for the normal roll pressure, specific roll load and torque in hot rolling mills, using the condition for plastic deformation in. For annealed copper, it has a true stress of about 80 mpa in the unstrained condition and at a true. Rolling load p moves along the circumference of. Rolling Load Formula.

From www.youtube.com

How to Calculate the value of Rolling radius ? YouTube Rolling Load Formula T fm = torque for. T rm = rolling torque which is converted to motor shaft taking into account the gear ratio between motor shaft and the rolls. Calculate the roll force and the power required. Roll = mw since p roll >5 mw (the available power), the rolling mill is not adequate for the operation. For annealed copper, it. Rolling Load Formula.

From www.collegesearch.in

What is Rolling Friction Definition, Diagram, Formula, Coefficient Rolling Load Formula Equations are derived for the normal roll pressure, specific roll load and torque in hot rolling mills, using the condition for plastic deformation in. T rm = rolling torque which is converted to motor shaft taking into account the gear ratio between motor shaft and the rolls. Rolling load p moves along the circumference of a circle equal to 2π.a. Rolling Load Formula.

From www.engineersedge.com

Vehicle Forces For Driving Up Slope Equations and Calculator Rolling Load Formula Rolling load p moves along the circumference of a circle equal to 2π.a since there are two work rolls involved, the work done is equal to work done. Calculate the roll force and the power required. Roll = mw since p roll >5 mw (the available power), the rolling mill is not adequate for the operation. For annealed copper, it. Rolling Load Formula.

From www.slideserve.com

PPT Rolling mill PowerPoint Presentation, free download ID687371 Rolling Load Formula T fm = torque for. For annealed copper, it has a true stress of about 80 mpa in the unstrained condition and at a true. In the case of no friction situation , the rolling load (p) is given by the roll pressure (p) times the area of contact between the metal and the rolls (bl p). Calculate the roll. Rolling Load Formula.

From www.youtube.com

I L D for Simply Supported Beam Rolling Loads and Influence Line Rolling Load Formula Roll = mw since p roll >5 mw (the available power), the rolling mill is not adequate for the operation. In the case of no friction situation , the rolling load (p) is given by the roll pressure (p) times the area of contact between the metal and the rolls (bl p). For annealed copper, it has a true stress. Rolling Load Formula.

From www.youtube.com

Calculating Linear and Angular Velocity for a Drum or Barrel Rolling Rolling Load Formula T fm = torque for. For annealed copper, it has a true stress of about 80 mpa in the unstrained condition and at a true. In the case of no friction situation , the rolling load (p) is given by the roll pressure (p) times the area of contact between the metal and the rolls (bl p). P= pblp =. Rolling Load Formula.

From www.studocu.com

Moving Loads mechanics Moving Loads From the previous discussion Rolling Load Formula T fm = torque for. T rm = rolling torque which is converted to motor shaft taking into account the gear ratio between motor shaft and the rolls. For annealed copper, it has a true stress of about 80 mpa in the unstrained condition and at a true. Equations are derived for the normal roll pressure, specific roll load and. Rolling Load Formula.

From www.studypool.com

SOLUTION Mechanics of rolling operation rolling force formula Studypool Rolling Load Formula T rm = rolling torque which is converted to motor shaft taking into account the gear ratio between motor shaft and the rolls. Roll = mw since p roll >5 mw (the available power), the rolling mill is not adequate for the operation. P= pblp = ob r∆h σ' where the roll pressure. In the case of no friction situation. Rolling Load Formula.

From www.youtube.com

Shear Force and Bending Moment diagram of Beam with Triangular Load Rolling Load Formula For annealed copper, it has a true stress of about 80 mpa in the unstrained condition and at a true. T fm = torque for. Roll = mw since p roll >5 mw (the available power), the rolling mill is not adequate for the operation. Rolling load p moves along the circumference of a circle equal to 2π.a since there. Rolling Load Formula.

From www.academia.edu

(PDF) Methodology for Calculation of Rolling Load and Forces Acting On Rolling Load Formula Rolling load p moves along the circumference of a circle equal to 2π.a since there are two work rolls involved, the work done is equal to work done. T rm = rolling torque which is converted to motor shaft taking into account the gear ratio between motor shaft and the rolls. For annealed copper, it has a true stress of. Rolling Load Formula.

From pressbooks.library.upei.ca

3.3 Distributed Loads Engineering Mechanics Statics Rolling Load Formula Calculate the roll force and the power required. T fm = torque for. In the case of no friction situation , the rolling load (p) is given by the roll pressure (p) times the area of contact between the metal and the rolls (bl p). T rm = rolling torque which is converted to motor shaft taking into account the. Rolling Load Formula.

From www.youtube.com

Moving Loads(Rolling Loads) Singly Concentrated Load YouTube Rolling Load Formula Roll = mw since p roll >5 mw (the available power), the rolling mill is not adequate for the operation. T rm = rolling torque which is converted to motor shaft taking into account the gear ratio between motor shaft and the rolls. Calculate the roll force and the power required. For annealed copper, it has a true stress of. Rolling Load Formula.

From www.electricalengineering.xyz

Load Factor Formula, Definition and Applications with Solved Rolling Load Formula T rm = rolling torque which is converted to motor shaft taking into account the gear ratio between motor shaft and the rolls. In the case of no friction situation , the rolling load (p) is given by the roll pressure (p) times the area of contact between the metal and the rolls (bl p). Rolling load p moves along. Rolling Load Formula.

From mungfali.com

Rolling Calculation Rolling Load Formula Calculate the roll force and the power required. In the case of no friction situation , the rolling load (p) is given by the roll pressure (p) times the area of contact between the metal and the rolls (bl p). For annealed copper, it has a true stress of about 80 mpa in the unstrained condition and at a true.. Rolling Load Formula.

From civiconcepts.com

Load Calculation On Column, Beam & Slab Column Design Calculations Rolling Load Formula In the case of no friction situation , the rolling load (p) is given by the roll pressure (p) times the area of contact between the metal and the rolls (bl p). Roll = mw since p roll >5 mw (the available power), the rolling mill is not adequate for the operation. T rm = rolling torque which is converted. Rolling Load Formula.

From x-engineer.org

How to calculate rolling resistance Rolling Load Formula T fm = torque for. T rm = rolling torque which is converted to motor shaft taking into account the gear ratio between motor shaft and the rolls. Roll = mw since p roll >5 mw (the available power), the rolling mill is not adequate for the operation. Rolling load p moves along the circumference of a circle equal to. Rolling Load Formula.

From www.animalia-life.club

Rolling Friction Diagram Rolling Load Formula Equations are derived for the normal roll pressure, specific roll load and torque in hot rolling mills, using the condition for plastic deformation in. P= pblp = ob r∆h σ' where the roll pressure. T fm = torque for. Rolling load p moves along the circumference of a circle equal to 2π.a since there are two work rolls involved, the. Rolling Load Formula.

From www.toppr.com

A body is rolling without slipping on a horizontal plane. The Rolling Load Formula For annealed copper, it has a true stress of about 80 mpa in the unstrained condition and at a true. Equations are derived for the normal roll pressure, specific roll load and torque in hot rolling mills, using the condition for plastic deformation in. Calculate the roll force and the power required. In the case of no friction situation ,. Rolling Load Formula.

From byjus.com

DerivAtion of energy of rolling motion Rolling Load Formula Rolling load p moves along the circumference of a circle equal to 2π.a since there are two work rolls involved, the work done is equal to work done. Equations are derived for the normal roll pressure, specific roll load and torque in hot rolling mills, using the condition for plastic deformation in. Calculate the roll force and the power required.. Rolling Load Formula.

From www.youtube.com

What is the total value of Yaw and Roll moment on vehicle Rolling Load Formula Calculate the roll force and the power required. For annealed copper, it has a true stress of about 80 mpa in the unstrained condition and at a true. In the case of no friction situation , the rolling load (p) is given by the roll pressure (p) times the area of contact between the metal and the rolls (bl p).. Rolling Load Formula.

From www.slideserve.com

PPT rolling PowerPoint Presentation, free download ID2343161 Rolling Load Formula Roll = mw since p roll >5 mw (the available power), the rolling mill is not adequate for the operation. For annealed copper, it has a true stress of about 80 mpa in the unstrained condition and at a true. Equations are derived for the normal roll pressure, specific roll load and torque in hot rolling mills, using the condition. Rolling Load Formula.

From www.semanticscholar.org

Figure 3 from Methods of calculation of load modes of roughing stand Rolling Load Formula Calculate the roll force and the power required. For annealed copper, it has a true stress of about 80 mpa in the unstrained condition and at a true. Roll = mw since p roll >5 mw (the available power), the rolling mill is not adequate for the operation. T rm = rolling torque which is converted to motor shaft taking. Rolling Load Formula.

From www.innovaltec.com

The calculation of rolling force Innoval Technology Rolling Load Formula T fm = torque for. Rolling load p moves along the circumference of a circle equal to 2π.a since there are two work rolls involved, the work done is equal to work done. T rm = rolling torque which is converted to motor shaft taking into account the gear ratio between motor shaft and the rolls. Roll = mw since. Rolling Load Formula.

From www.youtube.com

I L D for Cantilever Beam Rolling Loads and Influence Line Diagrams Rolling Load Formula Equations are derived for the normal roll pressure, specific roll load and torque in hot rolling mills, using the condition for plastic deformation in. T rm = rolling torque which is converted to motor shaft taking into account the gear ratio between motor shaft and the rolls. P= pblp = ob r∆h σ' where the roll pressure. For annealed copper,. Rolling Load Formula.