Gas Flow Rate For Mig Welding Lpm . The correct gas flow rate in mig welding ranges between 15 to 25 cfh. The diameter of the gas shroud. In mig welding, the gas flow rate refers to the volume of shielding gas (such as argon, carbon dioxide, or a mixture of gases) that is delivered through the welding gun to the weld. We occasionally get a question about converting cfh (cubic feet per hour) to psi (pounds per square inch). The correct gas flow rate for a mig will depend on a number of factors: Aim for a gas flow rate ranging from 25 to 30 cfh (12 to 15 lpm) when welding stainless steel. Also, take into account the suggested gas flow rates for metals like aluminum or stainless steel which also have a specific gas they should be used with. But make sure to take into account the different variables while selecting the flow rate. This increased shielding helps maintain the material’s corrosion resistance.

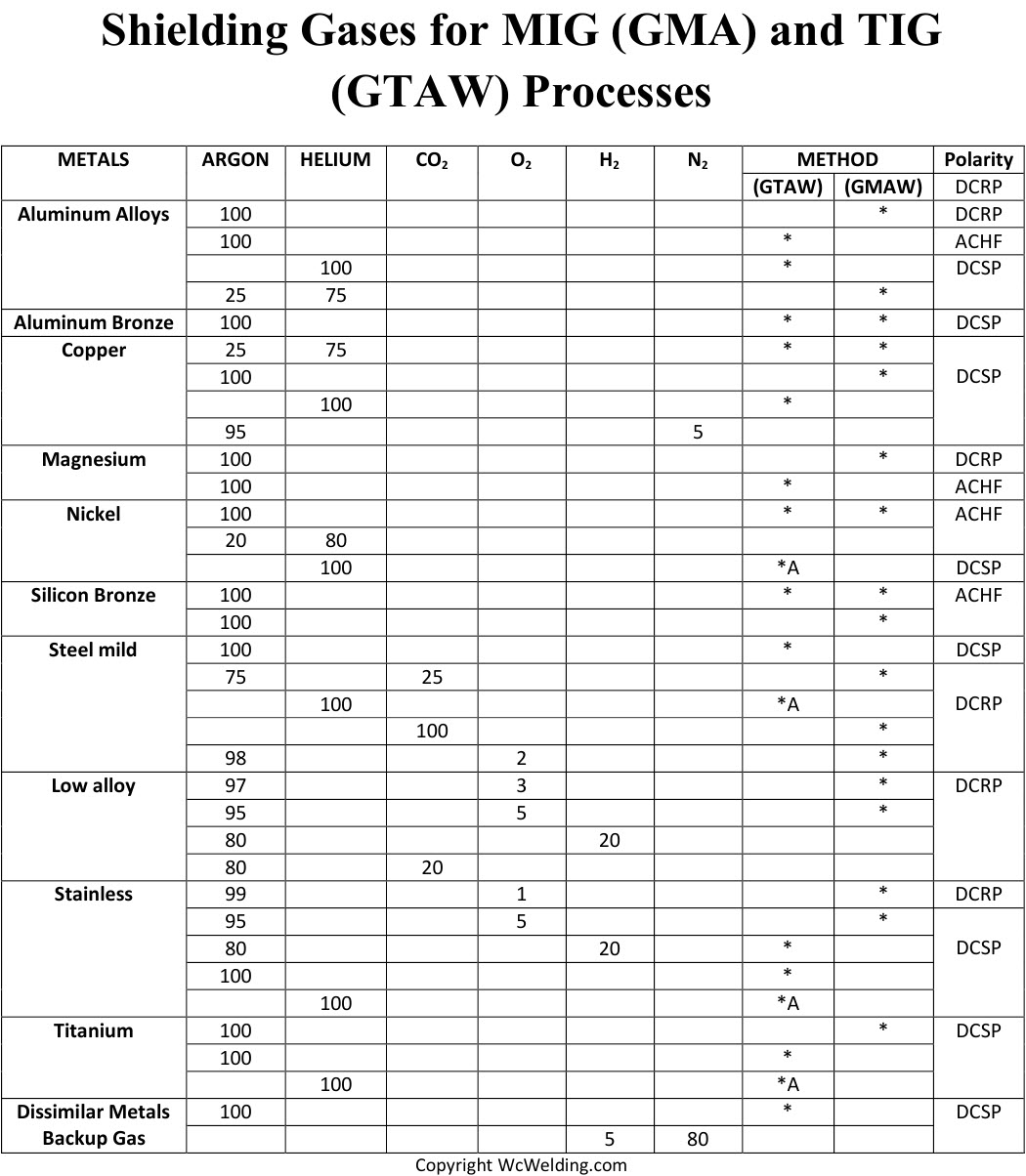

from www.wcwelding.com

The correct gas flow rate in mig welding ranges between 15 to 25 cfh. The correct gas flow rate for a mig will depend on a number of factors: Also, take into account the suggested gas flow rates for metals like aluminum or stainless steel which also have a specific gas they should be used with. But make sure to take into account the different variables while selecting the flow rate. This increased shielding helps maintain the material’s corrosion resistance. The diameter of the gas shroud. In mig welding, the gas flow rate refers to the volume of shielding gas (such as argon, carbon dioxide, or a mixture of gases) that is delivered through the welding gun to the weld. Aim for a gas flow rate ranging from 25 to 30 cfh (12 to 15 lpm) when welding stainless steel. We occasionally get a question about converting cfh (cubic feet per hour) to psi (pounds per square inch).

Shielding Gas Guide

Gas Flow Rate For Mig Welding Lpm The correct gas flow rate in mig welding ranges between 15 to 25 cfh. The diameter of the gas shroud. This increased shielding helps maintain the material’s corrosion resistance. The correct gas flow rate for a mig will depend on a number of factors: Aim for a gas flow rate ranging from 25 to 30 cfh (12 to 15 lpm) when welding stainless steel. In mig welding, the gas flow rate refers to the volume of shielding gas (such as argon, carbon dioxide, or a mixture of gases) that is delivered through the welding gun to the weld. We occasionally get a question about converting cfh (cubic feet per hour) to psi (pounds per square inch). The correct gas flow rate in mig welding ranges between 15 to 25 cfh. But make sure to take into account the different variables while selecting the flow rate. Also, take into account the suggested gas flow rates for metals like aluminum or stainless steel which also have a specific gas they should be used with.

From reg.globaltextileexpo.com

Argon CO2 Gas Flow Meter Flow Rate Gas Shielding Welding Tool Flowmeter Gas Flow Rate For Mig Welding Lpm Also, take into account the suggested gas flow rates for metals like aluminum or stainless steel which also have a specific gas they should be used with. The diameter of the gas shroud. We occasionally get a question about converting cfh (cubic feet per hour) to psi (pounds per square inch). But make sure to take into account the different. Gas Flow Rate For Mig Welding Lpm.

From weldguru.com

MIG Welding Gas Pressure Settings (with Charts) Gas Flow Rate For Mig Welding Lpm We occasionally get a question about converting cfh (cubic feet per hour) to psi (pounds per square inch). The diameter of the gas shroud. This increased shielding helps maintain the material’s corrosion resistance. The correct gas flow rate for a mig will depend on a number of factors: Aim for a gas flow rate ranging from 25 to 30 cfh. Gas Flow Rate For Mig Welding Lpm.

From mavink.com

Mig Welding Gas Flow Chart Gas Flow Rate For Mig Welding Lpm But make sure to take into account the different variables while selecting the flow rate. We occasionally get a question about converting cfh (cubic feet per hour) to psi (pounds per square inch). In mig welding, the gas flow rate refers to the volume of shielding gas (such as argon, carbon dioxide, or a mixture of gases) that is delivered. Gas Flow Rate For Mig Welding Lpm.

From rst-web.com

Selecting the Right Shielding Gas For Your Welding Process RonSon's Gas Flow Rate For Mig Welding Lpm The diameter of the gas shroud. The correct gas flow rate for a mig will depend on a number of factors: This increased shielding helps maintain the material’s corrosion resistance. In mig welding, the gas flow rate refers to the volume of shielding gas (such as argon, carbon dioxide, or a mixture of gases) that is delivered through the welding. Gas Flow Rate For Mig Welding Lpm.

From abbywalsh.z19.web.core.windows.net

Mig Welding Gas Flow Rate Chart Lpm Gas Flow Rate For Mig Welding Lpm But make sure to take into account the different variables while selecting the flow rate. The diameter of the gas shroud. The correct gas flow rate for a mig will depend on a number of factors: In mig welding, the gas flow rate refers to the volume of shielding gas (such as argon, carbon dioxide, or a mixture of gases). Gas Flow Rate For Mig Welding Lpm.

From mavink.com

Mig Welding Gas Flow Chart Gas Flow Rate For Mig Welding Lpm The diameter of the gas shroud. We occasionally get a question about converting cfh (cubic feet per hour) to psi (pounds per square inch). The correct gas flow rate in mig welding ranges between 15 to 25 cfh. This increased shielding helps maintain the material’s corrosion resistance. In mig welding, the gas flow rate refers to the volume of shielding. Gas Flow Rate For Mig Welding Lpm.

From giodbuxra.blob.core.windows.net

Gas Flow Rate For Tig Welding at Manuel Carlton blog Gas Flow Rate For Mig Welding Lpm This increased shielding helps maintain the material’s corrosion resistance. The diameter of the gas shroud. The correct gas flow rate in mig welding ranges between 15 to 25 cfh. Also, take into account the suggested gas flow rates for metals like aluminum or stainless steel which also have a specific gas they should be used with. But make sure to. Gas Flow Rate For Mig Welding Lpm.

From gowelding.org

MIG Welding Gases Choices and Options for Most Metals Gas Flow Rate For Mig Welding Lpm In mig welding, the gas flow rate refers to the volume of shielding gas (such as argon, carbon dioxide, or a mixture of gases) that is delivered through the welding gun to the weld. This increased shielding helps maintain the material’s corrosion resistance. Aim for a gas flow rate ranging from 25 to 30 cfh (12 to 15 lpm) when. Gas Flow Rate For Mig Welding Lpm.

From weldguru.com

Best Gas for MIG Welding What to Use (with Chart) Gas Flow Rate For Mig Welding Lpm This increased shielding helps maintain the material’s corrosion resistance. The correct gas flow rate in mig welding ranges between 15 to 25 cfh. The diameter of the gas shroud. Aim for a gas flow rate ranging from 25 to 30 cfh (12 to 15 lpm) when welding stainless steel. We occasionally get a question about converting cfh (cubic feet per. Gas Flow Rate For Mig Welding Lpm.

From sophiemetcalfe.z13.web.core.windows.net

Mig Welding Gas Flow Rate Chart Gas Flow Rate For Mig Welding Lpm In mig welding, the gas flow rate refers to the volume of shielding gas (such as argon, carbon dioxide, or a mixture of gases) that is delivered through the welding gun to the weld. Also, take into account the suggested gas flow rates for metals like aluminum or stainless steel which also have a specific gas they should be used. Gas Flow Rate For Mig Welding Lpm.

From localrevive.com

Gas Metal Arc Welding (GMAW) MIG Welding Guide (2022) Gas Flow Rate For Mig Welding Lpm But make sure to take into account the different variables while selecting the flow rate. The correct gas flow rate for a mig will depend on a number of factors: The diameter of the gas shroud. Also, take into account the suggested gas flow rates for metals like aluminum or stainless steel which also have a specific gas they should. Gas Flow Rate For Mig Welding Lpm.

From giojdcouz.blob.core.windows.net

Correct Gas Flow For Mig Welding at Eric Glenn blog Gas Flow Rate For Mig Welding Lpm Aim for a gas flow rate ranging from 25 to 30 cfh (12 to 15 lpm) when welding stainless steel. Also, take into account the suggested gas flow rates for metals like aluminum or stainless steel which also have a specific gas they should be used with. The diameter of the gas shroud. The correct gas flow rate for a. Gas Flow Rate For Mig Welding Lpm.

From www.wcwelding.com

Shielding Gas Guide Gas Flow Rate For Mig Welding Lpm But make sure to take into account the different variables while selecting the flow rate. The correct gas flow rate in mig welding ranges between 15 to 25 cfh. In mig welding, the gas flow rate refers to the volume of shielding gas (such as argon, carbon dioxide, or a mixture of gases) that is delivered through the welding gun. Gas Flow Rate For Mig Welding Lpm.

From makemoneywelding.com

Explained Best MIG Welding Shielding Gas To Use Gas Flow Rate For Mig Welding Lpm We occasionally get a question about converting cfh (cubic feet per hour) to psi (pounds per square inch). In mig welding, the gas flow rate refers to the volume of shielding gas (such as argon, carbon dioxide, or a mixture of gases) that is delivered through the welding gun to the weld. The diameter of the gas shroud. The correct. Gas Flow Rate For Mig Welding Lpm.

From www.scribd.com

MIG Flow Rate Chart Welding Gases Gas Flow Rate For Mig Welding Lpm This increased shielding helps maintain the material’s corrosion resistance. But make sure to take into account the different variables while selecting the flow rate. Also, take into account the suggested gas flow rates for metals like aluminum or stainless steel which also have a specific gas they should be used with. Aim for a gas flow rate ranging from 25. Gas Flow Rate For Mig Welding Lpm.

From weldingzilla.com

MIG Welding Gas Pressure Settings (with Charts) Gas Flow Rate For Mig Welding Lpm We occasionally get a question about converting cfh (cubic feet per hour) to psi (pounds per square inch). The diameter of the gas shroud. In mig welding, the gas flow rate refers to the volume of shielding gas (such as argon, carbon dioxide, or a mixture of gases) that is delivered through the welding gun to the weld. The correct. Gas Flow Rate For Mig Welding Lpm.

From makemoneywelding.com

MIG Welding Gas Pressure Settings Gas Flow Rate For Mig Welding Lpm The diameter of the gas shroud. The correct gas flow rate in mig welding ranges between 15 to 25 cfh. Aim for a gas flow rate ranging from 25 to 30 cfh (12 to 15 lpm) when welding stainless steel. This increased shielding helps maintain the material’s corrosion resistance. Also, take into account the suggested gas flow rates for metals. Gas Flow Rate For Mig Welding Lpm.

From weldguru.com

MIG Welding Gas Pressure Settings (with Charts) Gas Flow Rate For Mig Welding Lpm Also, take into account the suggested gas flow rates for metals like aluminum or stainless steel which also have a specific gas they should be used with. We occasionally get a question about converting cfh (cubic feet per hour) to psi (pounds per square inch). The correct gas flow rate for a mig will depend on a number of factors:. Gas Flow Rate For Mig Welding Lpm.

From flavored.ph

Flowmeter 014 LPM Welding Gas Bottle Flow Metre Gauge Welder Argon MIG Gas Flow Rate For Mig Welding Lpm This increased shielding helps maintain the material’s corrosion resistance. The diameter of the gas shroud. But make sure to take into account the different variables while selecting the flow rate. The correct gas flow rate for a mig will depend on a number of factors: Aim for a gas flow rate ranging from 25 to 30 cfh (12 to 15. Gas Flow Rate For Mig Welding Lpm.

From weldguru.com

What Gas Should You Use for TIG Welding? (with Chart) Gas Flow Rate For Mig Welding Lpm We occasionally get a question about converting cfh (cubic feet per hour) to psi (pounds per square inch). Aim for a gas flow rate ranging from 25 to 30 cfh (12 to 15 lpm) when welding stainless steel. In mig welding, the gas flow rate refers to the volume of shielding gas (such as argon, carbon dioxide, or a mixture. Gas Flow Rate For Mig Welding Lpm.

From www.youtube.com

Gas Flow Settings for MIG & TIG Welding YouTube Gas Flow Rate For Mig Welding Lpm Also, take into account the suggested gas flow rates for metals like aluminum or stainless steel which also have a specific gas they should be used with. We occasionally get a question about converting cfh (cubic feet per hour) to psi (pounds per square inch). But make sure to take into account the different variables while selecting the flow rate.. Gas Flow Rate For Mig Welding Lpm.

From weldempire.com

What Should Be the Gas Pressure for MIG Welding? Weld Empire Gas Flow Rate For Mig Welding Lpm The diameter of the gas shroud. Aim for a gas flow rate ranging from 25 to 30 cfh (12 to 15 lpm) when welding stainless steel. But make sure to take into account the different variables while selecting the flow rate. The correct gas flow rate for a mig will depend on a number of factors: The correct gas flow. Gas Flow Rate For Mig Welding Lpm.

From makemoneywelding.com

MIG Welding Gas Pressure Settings Gas Flow Rate For Mig Welding Lpm In mig welding, the gas flow rate refers to the volume of shielding gas (such as argon, carbon dioxide, or a mixture of gases) that is delivered through the welding gun to the weld. The diameter of the gas shroud. But make sure to take into account the different variables while selecting the flow rate. Aim for a gas flow. Gas Flow Rate For Mig Welding Lpm.

From kemele.labbyag.es

Tig Welding Gases Chart Kemele Gas Flow Rate For Mig Welding Lpm The correct gas flow rate for a mig will depend on a number of factors: Also, take into account the suggested gas flow rates for metals like aluminum or stainless steel which also have a specific gas they should be used with. In mig welding, the gas flow rate refers to the volume of shielding gas (such as argon, carbon. Gas Flow Rate For Mig Welding Lpm.

From mavink.com

Mig Welding Gas Flow Rate Chart Gas Flow Rate For Mig Welding Lpm Aim for a gas flow rate ranging from 25 to 30 cfh (12 to 15 lpm) when welding stainless steel. Also, take into account the suggested gas flow rates for metals like aluminum or stainless steel which also have a specific gas they should be used with. But make sure to take into account the different variables while selecting the. Gas Flow Rate For Mig Welding Lpm.

From weldingblos.netlify.app

Gas Flow Rate For Mig Welding Lpm Gas Flow Rate For Mig Welding Lpm The correct gas flow rate for a mig will depend on a number of factors: Aim for a gas flow rate ranging from 25 to 30 cfh (12 to 15 lpm) when welding stainless steel. In mig welding, the gas flow rate refers to the volume of shielding gas (such as argon, carbon dioxide, or a mixture of gases) that. Gas Flow Rate For Mig Welding Lpm.

From weldingmastermind.com

MIG Gas Settings How to Set Gas on MIG Welder Welding Mastermind Gas Flow Rate For Mig Welding Lpm In mig welding, the gas flow rate refers to the volume of shielding gas (such as argon, carbon dioxide, or a mixture of gases) that is delivered through the welding gun to the weld. Also, take into account the suggested gas flow rates for metals like aluminum or stainless steel which also have a specific gas they should be used. Gas Flow Rate For Mig Welding Lpm.

From makemoneywelding.com

MIG Welding Gas Pressure Settings Gas Flow Rate For Mig Welding Lpm Also, take into account the suggested gas flow rates for metals like aluminum or stainless steel which also have a specific gas they should be used with. The correct gas flow rate for a mig will depend on a number of factors: This increased shielding helps maintain the material’s corrosion resistance. Aim for a gas flow rate ranging from 25. Gas Flow Rate For Mig Welding Lpm.

From rst-web.com

Selecting the Right Shielding Gas For Your Welding Process RonSon's Gas Flow Rate For Mig Welding Lpm Also, take into account the suggested gas flow rates for metals like aluminum or stainless steel which also have a specific gas they should be used with. Aim for a gas flow rate ranging from 25 to 30 cfh (12 to 15 lpm) when welding stainless steel. The correct gas flow rate in mig welding ranges between 15 to 25. Gas Flow Rate For Mig Welding Lpm.

From flavored.ph

Flowmeter 014 LPM Welding Gas Bottle Flow Metre Gauge Welder Argon MIG Gas Flow Rate For Mig Welding Lpm Also, take into account the suggested gas flow rates for metals like aluminum or stainless steel which also have a specific gas they should be used with. The correct gas flow rate for a mig will depend on a number of factors: The correct gas flow rate in mig welding ranges between 15 to 25 cfh. The diameter of the. Gas Flow Rate For Mig Welding Lpm.

From weldguru.com

Best Gas for MIG Welding What to Use (with Chart) Gas Flow Rate For Mig Welding Lpm But make sure to take into account the different variables while selecting the flow rate. In mig welding, the gas flow rate refers to the volume of shielding gas (such as argon, carbon dioxide, or a mixture of gases) that is delivered through the welding gun to the weld. The correct gas flow rate in mig welding ranges between 15. Gas Flow Rate For Mig Welding Lpm.

From www.perfectwelders.com

How To Optimize MIG Welding Shielding Gas Pressure PERFECT POWER Gas Flow Rate For Mig Welding Lpm The diameter of the gas shroud. The correct gas flow rate in mig welding ranges between 15 to 25 cfh. But make sure to take into account the different variables while selecting the flow rate. This increased shielding helps maintain the material’s corrosion resistance. Also, take into account the suggested gas flow rates for metals like aluminum or stainless steel. Gas Flow Rate For Mig Welding Lpm.

From itstillruns.com

How to Set the Gas on an MIG Welder It Still Runs Gas Flow Rate For Mig Welding Lpm The correct gas flow rate in mig welding ranges between 15 to 25 cfh. This increased shielding helps maintain the material’s corrosion resistance. We occasionally get a question about converting cfh (cubic feet per hour) to psi (pounds per square inch). Also, take into account the suggested gas flow rates for metals like aluminum or stainless steel which also have. Gas Flow Rate For Mig Welding Lpm.

From www.hampdon.com.au

Harris Argon / Co2 Flow Meter Welding Gauge 015Lpm MIG TIG Gas Flow Rate For Mig Welding Lpm Aim for a gas flow rate ranging from 25 to 30 cfh (12 to 15 lpm) when welding stainless steel. The correct gas flow rate for a mig will depend on a number of factors: The diameter of the gas shroud. But make sure to take into account the different variables while selecting the flow rate. In mig welding, the. Gas Flow Rate For Mig Welding Lpm.

From www.artofit.org

Mig welding gas pressure settings with charts Artofit Gas Flow Rate For Mig Welding Lpm Also, take into account the suggested gas flow rates for metals like aluminum or stainless steel which also have a specific gas they should be used with. The correct gas flow rate in mig welding ranges between 15 to 25 cfh. The correct gas flow rate for a mig will depend on a number of factors: But make sure to. Gas Flow Rate For Mig Welding Lpm.