Honing Of Stone . Silicon carbide, aluminum oxide, and diamond. Definition, operations, and uses in machining. Not to be confused with lapping, honing is a machining process that involves the use of an abrasive material to grind down a workpiece’s surface. It’s performed in conjunction with a stone, known as a honing stone, to manipulate the shape and texture of a workpiece’s surface. Three types of abrasives are available and in general use for honing: Honing is an abrasive machining process that produces a precision surface on a metal workpiece by scrubbing an abrasive grinding. The honing finish process offers many advantages. Here, a leading honing equipment manufacturer answers a few commonly. Honing is typically performed to bring bores to a precise size or achieve a specific surface finish. Between tool and workpiece a change in direction of the longitudinal movement takes place. Honing is an abrasive machining process that uses an abrasive grinding stone or wheel to produce a precise surface on a metal.

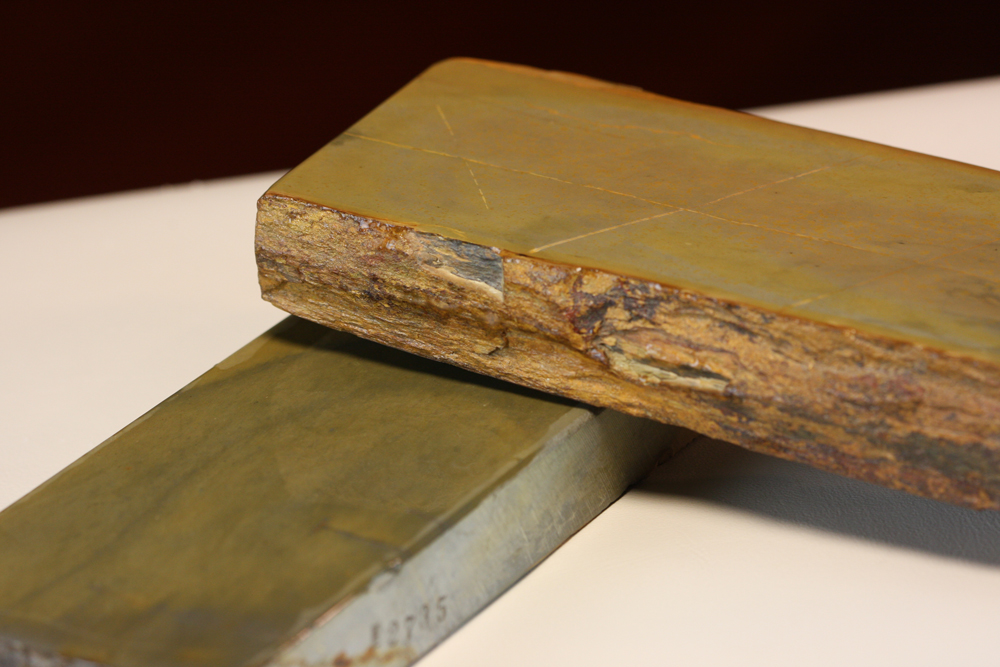

from www.asharperrazor.com

It’s performed in conjunction with a stone, known as a honing stone, to manipulate the shape and texture of a workpiece’s surface. Honing is an abrasive machining process that produces a precision surface on a metal workpiece by scrubbing an abrasive grinding. Honing is typically performed to bring bores to a precise size or achieve a specific surface finish. Silicon carbide, aluminum oxide, and diamond. Between tool and workpiece a change in direction of the longitudinal movement takes place. Honing is an abrasive machining process that uses an abrasive grinding stone or wheel to produce a precise surface on a metal. Not to be confused with lapping, honing is a machining process that involves the use of an abrasive material to grind down a workpiece’s surface. Definition, operations, and uses in machining. Three types of abrasives are available and in general use for honing: Here, a leading honing equipment manufacturer answers a few commonly.

Natural Honing Stones A Sharper Razor

Honing Of Stone Between tool and workpiece a change in direction of the longitudinal movement takes place. The honing finish process offers many advantages. Honing is an abrasive machining process that produces a precision surface on a metal workpiece by scrubbing an abrasive grinding. Silicon carbide, aluminum oxide, and diamond. Between tool and workpiece a change in direction of the longitudinal movement takes place. Not to be confused with lapping, honing is a machining process that involves the use of an abrasive material to grind down a workpiece’s surface. Here, a leading honing equipment manufacturer answers a few commonly. It’s performed in conjunction with a stone, known as a honing stone, to manipulate the shape and texture of a workpiece’s surface. Three types of abrasives are available and in general use for honing: Honing is an abrasive machining process that uses an abrasive grinding stone or wheel to produce a precise surface on a metal. Honing is typically performed to bring bores to a precise size or achieve a specific surface finish. Definition, operations, and uses in machining.

From stonerestorationworks.sb-core.com

Sep 2020 Stone Restoration Works Blog Honing Of Stone Honing is typically performed to bring bores to a precise size or achieve a specific surface finish. Here, a leading honing equipment manufacturer answers a few commonly. It’s performed in conjunction with a stone, known as a honing stone, to manipulate the shape and texture of a workpiece’s surface. Silicon carbide, aluminum oxide, and diamond. Between tool and workpiece a. Honing Of Stone.

From dayacipta.co.id

Jual Honing Stone King Sharpening Stone S1 Honing Of Stone Three types of abrasives are available and in general use for honing: Between tool and workpiece a change in direction of the longitudinal movement takes place. Honing is an abrasive machining process that uses an abrasive grinding stone or wheel to produce a precise surface on a metal. Silicon carbide, aluminum oxide, and diamond. Definition, operations, and uses in machining.. Honing Of Stone.

From knifeup.com

How to Use a Sharpening Stone Supreme Guide & Pro Tips Honing Of Stone Honing is an abrasive machining process that uses an abrasive grinding stone or wheel to produce a precise surface on a metal. Honing is an abrasive machining process that produces a precision surface on a metal workpiece by scrubbing an abrasive grinding. Definition, operations, and uses in machining. Silicon carbide, aluminum oxide, and diamond. The honing finish process offers many. Honing Of Stone.

From hfoplant.blogspot.com

CYLINDER LINER HONING (PURPOSE, HONING TEXTURE, ANGLE & PROCEDURE Honing Of Stone It’s performed in conjunction with a stone, known as a honing stone, to manipulate the shape and texture of a workpiece’s surface. The honing finish process offers many advantages. Definition, operations, and uses in machining. Three types of abrasives are available and in general use for honing: Honing is an abrasive machining process that uses an abrasive grinding stone or. Honing Of Stone.

From www.bosonabrasives.com

Honing ToolsZhengzhou Boson Abrasives Co.,Ltd. Honing Of Stone Not to be confused with lapping, honing is a machining process that involves the use of an abrasive material to grind down a workpiece’s surface. Between tool and workpiece a change in direction of the longitudinal movement takes place. Honing is an abrasive machining process that produces a precision surface on a metal workpiece by scrubbing an abrasive grinding. Definition,. Honing Of Stone.

From www.youtube.com

How to sharpen knives using honing stones YouTube Honing Of Stone It’s performed in conjunction with a stone, known as a honing stone, to manipulate the shape and texture of a workpiece’s surface. Not to be confused with lapping, honing is a machining process that involves the use of an abrasive material to grind down a workpiece’s surface. Between tool and workpiece a change in direction of the longitudinal movement takes. Honing Of Stone.

From surfacemasteraustralia.com.au

Stone Honing Services Natural Stone Honing Sydney Honing Of Stone Honing is an abrasive machining process that uses an abrasive grinding stone or wheel to produce a precise surface on a metal. Honing is an abrasive machining process that produces a precision surface on a metal workpiece by scrubbing an abrasive grinding. Here, a leading honing equipment manufacturer answers a few commonly. The honing finish process offers many advantages. Between. Honing Of Stone.

From www.mscdirect.com

Kennametal Honing Stone for Indexable Tools MSC Direct Honing Of Stone It’s performed in conjunction with a stone, known as a honing stone, to manipulate the shape and texture of a workpiece’s surface. Definition, operations, and uses in machining. Honing is an abrasive machining process that produces a precision surface on a metal workpiece by scrubbing an abrasive grinding. Silicon carbide, aluminum oxide, and diamond. Honing is typically performed to bring. Honing Of Stone.

From isharp.en.made-in-china.com

Diamond Honing Stone Be Used for The Honing Process of Materials Honing Of Stone Between tool and workpiece a change in direction of the longitudinal movement takes place. Here, a leading honing equipment manufacturer answers a few commonly. Not to be confused with lapping, honing is a machining process that involves the use of an abrasive material to grind down a workpiece’s surface. Silicon carbide, aluminum oxide, and diamond. The honing finish process offers. Honing Of Stone.

From www.kaysongreen.co.uk

Honing Stones Diamond Hone Honing Tools for Cylinder Honing Of Stone Not to be confused with lapping, honing is a machining process that involves the use of an abrasive material to grind down a workpiece’s surface. The honing finish process offers many advantages. Honing is an abrasive machining process that uses an abrasive grinding stone or wheel to produce a precise surface on a metal. Three types of abrasives are available. Honing Of Stone.

From seanhellman.com

Diamond sharpening stones Sean Hellman Honing Of Stone Three types of abrasives are available and in general use for honing: It’s performed in conjunction with a stone, known as a honing stone, to manipulate the shape and texture of a workpiece’s surface. Here, a leading honing equipment manufacturer answers a few commonly. Definition, operations, and uses in machining. Not to be confused with lapping, honing is a machining. Honing Of Stone.

From fantasticservicesgroup.com.au

Stone Honing and Polishing Service Fantastic Services Group Honing Of Stone Between tool and workpiece a change in direction of the longitudinal movement takes place. The honing finish process offers many advantages. Honing is an abrasive machining process that produces a precision surface on a metal workpiece by scrubbing an abrasive grinding. Silicon carbide, aluminum oxide, and diamond. It’s performed in conjunction with a stone, known as a honing stone, to. Honing Of Stone.

From www.researchgate.net

Honing stone specifications used in experiments. Download Scientific Honing Of Stone Between tool and workpiece a change in direction of the longitudinal movement takes place. It’s performed in conjunction with a stone, known as a honing stone, to manipulate the shape and texture of a workpiece’s surface. Honing is typically performed to bring bores to a precise size or achieve a specific surface finish. Three types of abrasives are available and. Honing Of Stone.

From goodson.com

Sunnen Honing Stones for CR1900 & Larger Mandrels GOODSON Goodson Honing Of Stone Here, a leading honing equipment manufacturer answers a few commonly. Between tool and workpiece a change in direction of the longitudinal movement takes place. Silicon carbide, aluminum oxide, and diamond. Not to be confused with lapping, honing is a machining process that involves the use of an abrasive material to grind down a workpiece’s surface. Honing is typically performed to. Honing Of Stone.

From chris-marine.com

Honing Stones ChrisMarine Honing Of Stone Honing is an abrasive machining process that produces a precision surface on a metal workpiece by scrubbing an abrasive grinding. The honing finish process offers many advantages. Honing is typically performed to bring bores to a precise size or achieve a specific surface finish. Here, a leading honing equipment manufacturer answers a few commonly. Three types of abrasives are available. Honing Of Stone.

From www.harborfreight.com

Combination Sharpening Stone Honing Of Stone Three types of abrasives are available and in general use for honing: Definition, operations, and uses in machining. Honing is typically performed to bring bores to a precise size or achieve a specific surface finish. Silicon carbide, aluminum oxide, and diamond. Honing is an abrasive machining process that produces a precision surface on a metal workpiece by scrubbing an abrasive. Honing Of Stone.

From waykenrm.com

Honing Process Definition, Operations, and Uses in Machining WayKen Honing Of Stone Here, a leading honing equipment manufacturer answers a few commonly. The honing finish process offers many advantages. Not to be confused with lapping, honing is a machining process that involves the use of an abrasive material to grind down a workpiece’s surface. Honing is an abrasive machining process that uses an abrasive grinding stone or wheel to produce a precise. Honing Of Stone.

From www.superabrasivetools.com

How to correctly choose honing stick stone Newdiamondtools Honing Of Stone Honing is an abrasive machining process that produces a precision surface on a metal workpiece by scrubbing an abrasive grinding. Here, a leading honing equipment manufacturer answers a few commonly. The honing finish process offers many advantages. It’s performed in conjunction with a stone, known as a honing stone, to manipulate the shape and texture of a workpiece’s surface. Silicon. Honing Of Stone.

From www.asharperrazor.com

Natural Honing Stones A Sharper Razor Honing Of Stone The honing finish process offers many advantages. Honing is an abrasive machining process that produces a precision surface on a metal workpiece by scrubbing an abrasive grinding. Here, a leading honing equipment manufacturer answers a few commonly. Three types of abrasives are available and in general use for honing: It’s performed in conjunction with a stone, known as a honing. Honing Of Stone.

From www.bosonabrasives.com

P28 Honing Stones Boson Abrasives Co Honing Of Stone Between tool and workpiece a change in direction of the longitudinal movement takes place. Here, a leading honing equipment manufacturer answers a few commonly. Definition, operations, and uses in machining. The honing finish process offers many advantages. Honing is an abrasive machining process that uses an abrasive grinding stone or wheel to produce a precise surface on a metal. It’s. Honing Of Stone.

From www.youtube.com

Stone Floor Honing YouTube Honing Of Stone Honing is typically performed to bring bores to a precise size or achieve a specific surface finish. Not to be confused with lapping, honing is a machining process that involves the use of an abrasive material to grind down a workpiece’s surface. Between tool and workpiece a change in direction of the longitudinal movement takes place. Honing is an abrasive. Honing Of Stone.

From isharp.en.made-in-china.com

Diamond Honing Stone China Super Hard Honing Stones and Diamond Honing Of Stone The honing finish process offers many advantages. Definition, operations, and uses in machining. Honing is an abrasive machining process that uses an abrasive grinding stone or wheel to produce a precise surface on a metal. It’s performed in conjunction with a stone, known as a honing stone, to manipulate the shape and texture of a workpiece’s surface. Three types of. Honing Of Stone.

From oldschooltools.co.uk

Honing Stones Product categories Old School Tools Honing Of Stone Definition, operations, and uses in machining. It’s performed in conjunction with a stone, known as a honing stone, to manipulate the shape and texture of a workpiece’s surface. Not to be confused with lapping, honing is a machining process that involves the use of an abrasive material to grind down a workpiece’s surface. Between tool and workpiece a change in. Honing Of Stone.

From www.asharperrazor.com

Natural Honing Stones A Sharper Razor Honing Of Stone Three types of abrasives are available and in general use for honing: Here, a leading honing equipment manufacturer answers a few commonly. Between tool and workpiece a change in direction of the longitudinal movement takes place. Silicon carbide, aluminum oxide, and diamond. Not to be confused with lapping, honing is a machining process that involves the use of an abrasive. Honing Of Stone.

From www.finewoodworking.com

A Look At OfftheStone Honing Guides FineWoodworking Honing Of Stone Honing is typically performed to bring bores to a precise size or achieve a specific surface finish. Definition, operations, and uses in machining. Silicon carbide, aluminum oxide, and diamond. Three types of abrasives are available and in general use for honing: Honing is an abrasive machining process that produces a precision surface on a metal workpiece by scrubbing an abrasive. Honing Of Stone.

From profloorsavers.com

Natural Stone Honing Services A&D Floor Restoration Honing Of Stone Honing is typically performed to bring bores to a precise size or achieve a specific surface finish. Three types of abrasives are available and in general use for honing: It’s performed in conjunction with a stone, known as a honing stone, to manipulate the shape and texture of a workpiece’s surface. Definition, operations, and uses in machining. Silicon carbide, aluminum. Honing Of Stone.

From www.youtube.com

Smith's 6 Inch Natural Arkansas Sharpening Stone YouTube Honing Of Stone Not to be confused with lapping, honing is a machining process that involves the use of an abrasive material to grind down a workpiece’s surface. It’s performed in conjunction with a stone, known as a honing stone, to manipulate the shape and texture of a workpiece’s surface. Silicon carbide, aluminum oxide, and diamond. Three types of abrasives are available and. Honing Of Stone.

From bosondia.en.made-in-china.com

Diamond CBN Honing Stones for Sunnen Mbb Honing Machines Honing Honing Of Stone Between tool and workpiece a change in direction of the longitudinal movement takes place. Honing is typically performed to bring bores to a precise size or achieve a specific surface finish. Honing is an abrasive machining process that produces a precision surface on a metal workpiece by scrubbing an abrasive grinding. The honing finish process offers many advantages. Definition, operations,. Honing Of Stone.

From www.dreamstime.com

Honing Oil Being Applied To a Sharpening Stone Stock Photo Image of Honing Of Stone Honing is typically performed to bring bores to a precise size or achieve a specific surface finish. Between tool and workpiece a change in direction of the longitudinal movement takes place. Silicon carbide, aluminum oxide, and diamond. Three types of abrasives are available and in general use for honing: Not to be confused with lapping, honing is a machining process. Honing Of Stone.

From oldschooltools.co.uk

Honing Stones Product categories Old School Tools Honing Of Stone Honing is an abrasive machining process that produces a precision surface on a metal workpiece by scrubbing an abrasive grinding. Silicon carbide, aluminum oxide, and diamond. Honing is an abrasive machining process that uses an abrasive grinding stone or wheel to produce a precise surface on a metal. Honing is typically performed to bring bores to a precise size or. Honing Of Stone.

From travertinepowerclean.com

Stone Floor Honing Definition Bakers Travertine Power Clean Honing Of Stone It’s performed in conjunction with a stone, known as a honing stone, to manipulate the shape and texture of a workpiece’s surface. Honing is an abrasive machining process that uses an abrasive grinding stone or wheel to produce a precise surface on a metal. Honing is an abrasive machining process that produces a precision surface on a metal workpiece by. Honing Of Stone.

From www.alamy.com

Grinding stone hires stock photography and images Alamy Honing Of Stone Honing is an abrasive machining process that produces a precision surface on a metal workpiece by scrubbing an abrasive grinding. The honing finish process offers many advantages. Honing is an abrasive machining process that uses an abrasive grinding stone or wheel to produce a precise surface on a metal. Three types of abrasives are available and in general use for. Honing Of Stone.

From www.indiamart.com

Honing Stone at Rs 5.75/piece Honing Stones ID 13364667748 Honing Of Stone Definition, operations, and uses in machining. Honing is an abrasive machining process that produces a precision surface on a metal workpiece by scrubbing an abrasive grinding. Silicon carbide, aluminum oxide, and diamond. Three types of abrasives are available and in general use for honing: The honing finish process offers many advantages. Between tool and workpiece a change in direction of. Honing Of Stone.

From www.youtube.com

One Stone Honing The Only Natural Whetstone You Need 1080p HD YouTube Honing Of Stone Between tool and workpiece a change in direction of the longitudinal movement takes place. Here, a leading honing equipment manufacturer answers a few commonly. The honing finish process offers many advantages. Honing is an abrasive machining process that produces a precision surface on a metal workpiece by scrubbing an abrasive grinding. It’s performed in conjunction with a stone, known as. Honing Of Stone.

From www.made-in-china.com

H70 Honing Stones and Guide Sets, Diamond CBN Honing Stone Sets China Honing Of Stone Silicon carbide, aluminum oxide, and diamond. Honing is an abrasive machining process that produces a precision surface on a metal workpiece by scrubbing an abrasive grinding. Honing is typically performed to bring bores to a precise size or achieve a specific surface finish. Here, a leading honing equipment manufacturer answers a few commonly. Not to be confused with lapping, honing. Honing Of Stone.