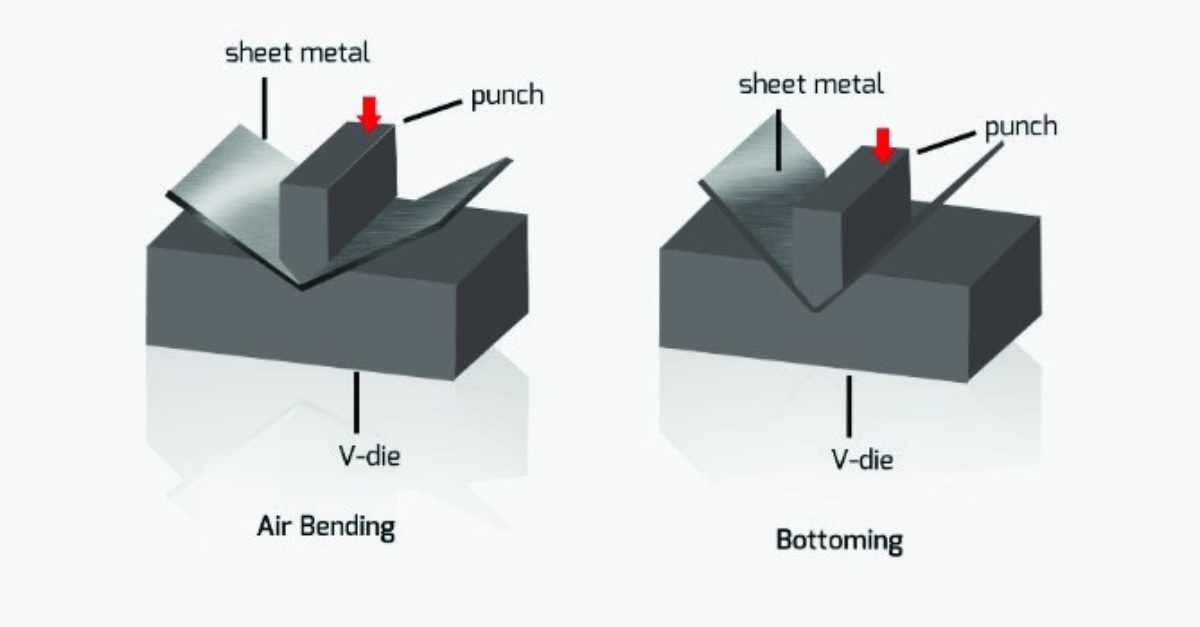

Brake Press Air Forming . press brake guru steve benson answers questions about air forming and bump bending, including the many variables involved in each application. this article explores six types of press brake bending processes—folding, wiping, air bending, bottoming, coining, and. Press brakes are indispensable machines in the metal fabrication industry, enabling precise bending and forming of sheet metal to create a wide range of structures and components. Mechanical, hydraulic, and electric press brakes. press brake forming is one of the oldest ways to shape metal mechanically. press brake bending involves leveraging force to shape sheet metal into desired geometries. The leap again changed how the radius. press brake fundamentals. so, what exactly is air forming (or air bending), and how does it work compared to bottom bending? These versatile tools are classified into three main categories:

from www.komaspec.com

press brake fundamentals. These versatile tools are classified into three main categories: press brake forming is one of the oldest ways to shape metal mechanically. press brake guru steve benson answers questions about air forming and bump bending, including the many variables involved in each application. press brake bending involves leveraging force to shape sheet metal into desired geometries. so, what exactly is air forming (or air bending), and how does it work compared to bottom bending? Mechanical, hydraulic, and electric press brakes. this article explores six types of press brake bending processes—folding, wiping, air bending, bottoming, coining, and. Press brakes are indispensable machines in the metal fabrication industry, enabling precise bending and forming of sheet metal to create a wide range of structures and components. The leap again changed how the radius.

Air Bending and Bottom Bending Sheet Metal Komaspec

Brake Press Air Forming press brake fundamentals. press brake bending involves leveraging force to shape sheet metal into desired geometries. These versatile tools are classified into three main categories: so, what exactly is air forming (or air bending), and how does it work compared to bottom bending? Press brakes are indispensable machines in the metal fabrication industry, enabling precise bending and forming of sheet metal to create a wide range of structures and components. this article explores six types of press brake bending processes—folding, wiping, air bending, bottoming, coining, and. press brake forming is one of the oldest ways to shape metal mechanically. press brake guru steve benson answers questions about air forming and bump bending, including the many variables involved in each application. Mechanical, hydraulic, and electric press brakes. The leap again changed how the radius. press brake fundamentals.

From www.southernfabsales.com

The 3 Types of Bending in Press Brakes Brake Press Air Forming The leap again changed how the radius. press brake guru steve benson answers questions about air forming and bump bending, including the many variables involved in each application. press brake bending involves leveraging force to shape sheet metal into desired geometries. These versatile tools are classified into three main categories: press brake forming is one of the. Brake Press Air Forming.

From www.machines4u.com.au

New cmt tooling RADIUS PUNCH BARS LARGE 15MM Press Brakes in SEVENTEEN Brake Press Air Forming The leap again changed how the radius. so, what exactly is air forming (or air bending), and how does it work compared to bottom bending? Mechanical, hydraulic, and electric press brakes. Press brakes are indispensable machines in the metal fabrication industry, enabling precise bending and forming of sheet metal to create a wide range of structures and components. These. Brake Press Air Forming.

From owenmetalsgroup.com

Owen Industries Utilizes a Fleet of Hydraulic Press Brakes and Other Brake Press Air Forming press brake guru steve benson answers questions about air forming and bump bending, including the many variables involved in each application. press brake bending involves leveraging force to shape sheet metal into desired geometries. this article explores six types of press brake bending processes—folding, wiping, air bending, bottoming, coining, and. These versatile tools are classified into three. Brake Press Air Forming.

From www.youtube.com

Gapped Hem in Two Hits with One Tool in the Press Brake Application Brake Press Air Forming press brake bending involves leveraging force to shape sheet metal into desired geometries. this article explores six types of press brake bending processes—folding, wiping, air bending, bottoming, coining, and. so, what exactly is air forming (or air bending), and how does it work compared to bottom bending? press brake fundamentals. Press brakes are indispensable machines in. Brake Press Air Forming.

From www.komaspec.com

Air Bending and Bottom Bending Sheet Metal Komaspec Brake Press Air Forming this article explores six types of press brake bending processes—folding, wiping, air bending, bottoming, coining, and. press brake guru steve benson answers questions about air forming and bump bending, including the many variables involved in each application. press brake fundamentals. The leap again changed how the radius. These versatile tools are classified into three main categories: . Brake Press Air Forming.

From www.youtube.com

Step bending with Bystronic Brake Press full automatic YouTube Brake Press Air Forming The leap again changed how the radius. These versatile tools are classified into three main categories: press brake guru steve benson answers questions about air forming and bump bending, including the many variables involved in each application. press brake forming is one of the oldest ways to shape metal mechanically. press brake fundamentals. so, what exactly. Brake Press Air Forming.

From www.andersenmp.com

CNC Press Brake Forming Multi Axis Press Brake Bending Brake Press Air Forming press brake guru steve benson answers questions about air forming and bump bending, including the many variables involved in each application. press brake bending involves leveraging force to shape sheet metal into desired geometries. Press brakes are indispensable machines in the metal fabrication industry, enabling precise bending and forming of sheet metal to create a wide range of. Brake Press Air Forming.

From www.thefabricator.com

Getting back to air forming and bending basics on the press brake Brake Press Air Forming Press brakes are indispensable machines in the metal fabrication industry, enabling precise bending and forming of sheet metal to create a wide range of structures and components. so, what exactly is air forming (or air bending), and how does it work compared to bottom bending? press brake bending involves leveraging force to shape sheet metal into desired geometries.. Brake Press Air Forming.

From www.genmet.com

Forming Press Brakes GenMet Brake Press Air Forming press brake fundamentals. The leap again changed how the radius. press brake guru steve benson answers questions about air forming and bump bending, including the many variables involved in each application. press brake bending involves leveraging force to shape sheet metal into desired geometries. Press brakes are indispensable machines in the metal fabrication industry, enabling precise bending. Brake Press Air Forming.

From www.canadianmetalworking.com

Turning the press brake into a forming machine Brake Press Air Forming These versatile tools are classified into three main categories: this article explores six types of press brake bending processes—folding, wiping, air bending, bottoming, coining, and. press brake guru steve benson answers questions about air forming and bump bending, including the many variables involved in each application. press brake bending involves leveraging force to shape sheet metal into. Brake Press Air Forming.

From www.trscraftservices.com

4 things you need to know about a brake press operator job TRS Craft Brake Press Air Forming this article explores six types of press brake bending processes—folding, wiping, air bending, bottoming, coining, and. press brake fundamentals. so, what exactly is air forming (or air bending), and how does it work compared to bottom bending? Press brakes are indispensable machines in the metal fabrication industry, enabling precise bending and forming of sheet metal to create. Brake Press Air Forming.

From fractory.com

Press Brake Tooling Fractory Brake Press Air Forming Press brakes are indispensable machines in the metal fabrication industry, enabling precise bending and forming of sheet metal to create a wide range of structures and components. Mechanical, hydraulic, and electric press brakes. this article explores six types of press brake bending processes—folding, wiping, air bending, bottoming, coining, and. press brake forming is one of the oldest ways. Brake Press Air Forming.

From www.kzell.com

CNC Press Brake Air Bending KZell Metals Brake Press Air Forming this article explores six types of press brake bending processes—folding, wiping, air bending, bottoming, coining, and. press brake fundamentals. press brake bending involves leveraging force to shape sheet metal into desired geometries. These versatile tools are classified into three main categories: so, what exactly is air forming (or air bending), and how does it work compared. Brake Press Air Forming.

From www.youtube.com

Curling Press Brake Tools,Hinges and Curls Bending Punch,RADIUS FORMING Brake Press Air Forming The leap again changed how the radius. Press brakes are indispensable machines in the metal fabrication industry, enabling precise bending and forming of sheet metal to create a wide range of structures and components. These versatile tools are classified into three main categories: press brake guru steve benson answers questions about air forming and bump bending, including the many. Brake Press Air Forming.

From precisionmc.net

Press Brake Roll Forming Precision M/C Manufacturing, Inc. Brake Press Air Forming Mechanical, hydraulic, and electric press brakes. so, what exactly is air forming (or air bending), and how does it work compared to bottom bending? The leap again changed how the radius. Press brakes are indispensable machines in the metal fabrication industry, enabling precise bending and forming of sheet metal to create a wide range of structures and components. . Brake Press Air Forming.

From www.thefabricator.com

Yield, tensile, and bending small metal parts on the press brake Brake Press Air Forming press brake guru steve benson answers questions about air forming and bump bending, including the many variables involved in each application. These versatile tools are classified into three main categories: so, what exactly is air forming (or air bending), and how does it work compared to bottom bending? Mechanical, hydraulic, and electric press brakes. press brake fundamentals.. Brake Press Air Forming.

From cefabrication.com

Press Brake Forming and Bending Cutting Edge Fabrication Brake Press Air Forming Press brakes are indispensable machines in the metal fabrication industry, enabling precise bending and forming of sheet metal to create a wide range of structures and components. These versatile tools are classified into three main categories: so, what exactly is air forming (or air bending), and how does it work compared to bottom bending? The leap again changed how. Brake Press Air Forming.

From www.canadianmetalworking.com

Lighten the Load of Dealing With Heavy Press Brake Tooling Brake Press Air Forming Mechanical, hydraulic, and electric press brakes. press brake forming is one of the oldest ways to shape metal mechanically. so, what exactly is air forming (or air bending), and how does it work compared to bottom bending? Press brakes are indispensable machines in the metal fabrication industry, enabling precise bending and forming of sheet metal to create a. Brake Press Air Forming.

From midwestpressbrake.com

90 Degree Forming Midwest Press Brake Dies Inc. Brake Press Air Forming Press brakes are indispensable machines in the metal fabrication industry, enabling precise bending and forming of sheet metal to create a wide range of structures and components. press brake guru steve benson answers questions about air forming and bump bending, including the many variables involved in each application. press brake bending involves leveraging force to shape sheet metal. Brake Press Air Forming.

From yafei-machinery.en.made-in-china.com

Special Forming Press Brake Tooling for Bending Machine China Special Brake Press Air Forming press brake bending involves leveraging force to shape sheet metal into desired geometries. press brake fundamentals. press brake guru steve benson answers questions about air forming and bump bending, including the many variables involved in each application. Mechanical, hydraulic, and electric press brakes. The leap again changed how the radius. These versatile tools are classified into three. Brake Press Air Forming.

From microhydrotechnic.co.in

The Advantages and Disadvantages of Press Brake Forming Techniques Brake Press Air Forming Mechanical, hydraulic, and electric press brakes. press brake bending involves leveraging force to shape sheet metal into desired geometries. The leap again changed how the radius. this article explores six types of press brake bending processes—folding, wiping, air bending, bottoming, coining, and. Press brakes are indispensable machines in the metal fabrication industry, enabling precise bending and forming of. Brake Press Air Forming.

From www.thefabricator.com

Airbending sharp on the press brake A fight not worth fighting Brake Press Air Forming press brake fundamentals. press brake bending involves leveraging force to shape sheet metal into desired geometries. Mechanical, hydraulic, and electric press brakes. These versatile tools are classified into three main categories: so, what exactly is air forming (or air bending), and how does it work compared to bottom bending? press brake guru steve benson answers questions. Brake Press Air Forming.

From spikeelectric.com

CNC Press Brake Forming Spike Controls Brake Press Air Forming press brake fundamentals. so, what exactly is air forming (or air bending), and how does it work compared to bottom bending? press brake forming is one of the oldest ways to shape metal mechanically. this article explores six types of press brake bending processes—folding, wiping, air bending, bottoming, coining, and. press brake guru steve benson. Brake Press Air Forming.

From www.rnrd.com

Metal Forming & Bending Press Brake Forming Custom Fabrication Brake Press Air Forming The leap again changed how the radius. press brake forming is one of the oldest ways to shape metal mechanically. press brake fundamentals. Press brakes are indispensable machines in the metal fabrication industry, enabling precise bending and forming of sheet metal to create a wide range of structures and components. this article explores six types of press. Brake Press Air Forming.

From www.thefabricator.com

Radius types formed by air bending on a press brake Brake Press Air Forming Mechanical, hydraulic, and electric press brakes. press brake forming is one of the oldest ways to shape metal mechanically. Press brakes are indispensable machines in the metal fabrication industry, enabling precise bending and forming of sheet metal to create a wide range of structures and components. this article explores six types of press brake bending processes—folding, wiping, air. Brake Press Air Forming.

From www.metalsupplies.com

Sheet Metal Forming / Bending Press Brake Forming Metal Supplies™ Brake Press Air Forming press brake bending involves leveraging force to shape sheet metal into desired geometries. this article explores six types of press brake bending processes—folding, wiping, air bending, bottoming, coining, and. The leap again changed how the radius. press brake fundamentals. Press brakes are indispensable machines in the metal fabrication industry, enabling precise bending and forming of sheet metal. Brake Press Air Forming.

From www.machinerfq.com

What Is Press Brake Forming Explained Intro, Materials & More Brake Press Air Forming press brake forming is one of the oldest ways to shape metal mechanically. The leap again changed how the radius. Mechanical, hydraulic, and electric press brakes. press brake fundamentals. These versatile tools are classified into three main categories: this article explores six types of press brake bending processes—folding, wiping, air bending, bottoming, coining, and. press brake. Brake Press Air Forming.

From www.surewaymetal.com

Press Brake / Steel Forming Brake Press Air Forming press brake bending involves leveraging force to shape sheet metal into desired geometries. press brake forming is one of the oldest ways to shape metal mechanically. Press brakes are indispensable machines in the metal fabrication industry, enabling precise bending and forming of sheet metal to create a wide range of structures and components. so, what exactly is. Brake Press Air Forming.

From www.shearform.com.au

Press Brake Forming Shearform Brake Press Air Forming press brake fundamentals. press brake guru steve benson answers questions about air forming and bump bending, including the many variables involved in each application. press brake bending involves leveraging force to shape sheet metal into desired geometries. this article explores six types of press brake bending processes—folding, wiping, air bending, bottoming, coining, and. Mechanical, hydraulic, and. Brake Press Air Forming.

From bermo.com

Press Brake Forming A Surprising Fabrication Process BERMO Brake Press Air Forming press brake guru steve benson answers questions about air forming and bump bending, including the many variables involved in each application. The leap again changed how the radius. press brake forming is one of the oldest ways to shape metal mechanically. press brake fundamentals. so, what exactly is air forming (or air bending), and how does. Brake Press Air Forming.

From www.southernfabsales.com

What You Need to Know About Press Brake Forming Technology Brake Press Air Forming press brake forming is one of the oldest ways to shape metal mechanically. press brake bending involves leveraging force to shape sheet metal into desired geometries. press brake guru steve benson answers questions about air forming and bump bending, including the many variables involved in each application. The leap again changed how the radius. Press brakes are. Brake Press Air Forming.

From msplaser.com

Press Brake & Forming Mississippi Laser Stockton, IA Brake Press Air Forming Press brakes are indispensable machines in the metal fabrication industry, enabling precise bending and forming of sheet metal to create a wide range of structures and components. press brake forming is one of the oldest ways to shape metal mechanically. press brake fundamentals. Mechanical, hydraulic, and electric press brakes. this article explores six types of press brake. Brake Press Air Forming.

From www.southernfabsales.com

What You Need to Know About Press Brake Forming Technology Brake Press Air Forming press brake fundamentals. press brake guru steve benson answers questions about air forming and bump bending, including the many variables involved in each application. press brake bending involves leveraging force to shape sheet metal into desired geometries. so, what exactly is air forming (or air bending), and how does it work compared to bottom bending? These. Brake Press Air Forming.

From www.harsle.com

PRESS BRAKE MACHINE FORMING HARSLE Brake Press Air Forming Mechanical, hydraulic, and electric press brakes. this article explores six types of press brake bending processes—folding, wiping, air bending, bottoming, coining, and. press brake forming is one of the oldest ways to shape metal mechanically. The leap again changed how the radius. These versatile tools are classified into three main categories: press brake guru steve benson answers. Brake Press Air Forming.

From quapin.en.made-in-china.com

CNC Press Brake Tooling Louver Tool Punch Die for Bending Forming Brake Press Air Forming press brake forming is one of the oldest ways to shape metal mechanically. These versatile tools are classified into three main categories: press brake guru steve benson answers questions about air forming and bump bending, including the many variables involved in each application. The leap again changed how the radius. press brake fundamentals. press brake bending. Brake Press Air Forming.