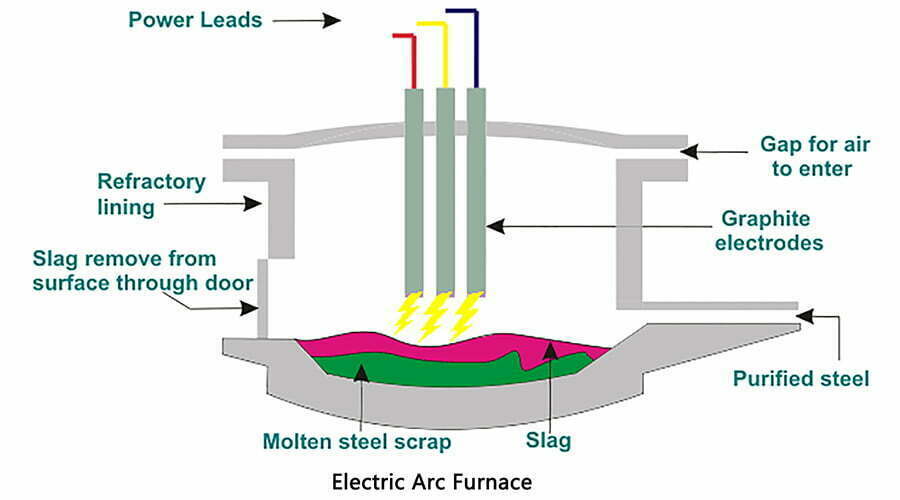

Electric Process For Steel Making . here is a schematic of the process. the basic principle of electric steelmaking today is that the furnace is a “melting machine” that produces liquid. Eafs make up approximately 60% of today's steel. this paper presents a comprehensive model of an industrial electric arc furnace (eaf) that is based. in this chapter, electric steelmaking is introduced with a short review: the impact of electric arc furnaces on modern steel production. Boston metal’s molten oxide electrolysis process takes place in modular moe cells, each the size of a school bus. Iron ore rock is fed into the cell, which contains the cathode (the negative terminal of the moe cell) and an anode immersed in a liquid electrolyte. Over the past few years electric arc furnace (eaf) has. this chapter deals with electric furnace steelmaking, a tool for the massive production of steels, which is responsible for 30% of the current. the eaf process uses virtually 100% old steel to make new steel. Share, raw materials, operation, typical equipment, off.

from hanmetallurgy.com

Share, raw materials, operation, typical equipment, off. the basic principle of electric steelmaking today is that the furnace is a “melting machine” that produces liquid. in this chapter, electric steelmaking is introduced with a short review: Eafs make up approximately 60% of today's steel. Iron ore rock is fed into the cell, which contains the cathode (the negative terminal of the moe cell) and an anode immersed in a liquid electrolyte. the eaf process uses virtually 100% old steel to make new steel. here is a schematic of the process. the impact of electric arc furnaces on modern steel production. Over the past few years electric arc furnace (eaf) has. this paper presents a comprehensive model of an industrial electric arc furnace (eaf) that is based.

Electric Arc Furnace Steelmaking Steel Hani Metallurgy

Electric Process For Steel Making in this chapter, electric steelmaking is introduced with a short review: this paper presents a comprehensive model of an industrial electric arc furnace (eaf) that is based. Iron ore rock is fed into the cell, which contains the cathode (the negative terminal of the moe cell) and an anode immersed in a liquid electrolyte. Eafs make up approximately 60% of today's steel. here is a schematic of the process. the eaf process uses virtually 100% old steel to make new steel. Boston metal’s molten oxide electrolysis process takes place in modular moe cells, each the size of a school bus. Over the past few years electric arc furnace (eaf) has. Share, raw materials, operation, typical equipment, off. this chapter deals with electric furnace steelmaking, a tool for the massive production of steels, which is responsible for 30% of the current. the basic principle of electric steelmaking today is that the furnace is a “melting machine” that produces liquid. in this chapter, electric steelmaking is introduced with a short review: the impact of electric arc furnaces on modern steel production.

From www.bhp.com

Pathways to decarbonisation episode two steelmaking technology BHP Electric Process For Steel Making Share, raw materials, operation, typical equipment, off. Over the past few years electric arc furnace (eaf) has. the eaf process uses virtually 100% old steel to make new steel. Boston metal’s molten oxide electrolysis process takes place in modular moe cells, each the size of a school bus. this paper presents a comprehensive model of an industrial electric. Electric Process For Steel Making.

From www.newsteelconstruction.com

An introduction to steelmaking Electric Process For Steel Making Over the past few years electric arc furnace (eaf) has. the basic principle of electric steelmaking today is that the furnace is a “melting machine” that produces liquid. the impact of electric arc furnaces on modern steel production. this paper presents a comprehensive model of an industrial electric arc furnace (eaf) that is based. in this. Electric Process For Steel Making.

From www.steel.org

Steel Production American Iron and Steel Institute Electric Process For Steel Making Boston metal’s molten oxide electrolysis process takes place in modular moe cells, each the size of a school bus. this paper presents a comprehensive model of an industrial electric arc furnace (eaf) that is based. Iron ore rock is fed into the cell, which contains the cathode (the negative terminal of the moe cell) and an anode immersed in. Electric Process For Steel Making.

From www.wermac.org

Steel Pipe Manufacturing Processes mandrel mill process plug mill Electric Process For Steel Making Boston metal’s molten oxide electrolysis process takes place in modular moe cells, each the size of a school bus. this paper presents a comprehensive model of an industrial electric arc furnace (eaf) that is based. in this chapter, electric steelmaking is introduced with a short review: Share, raw materials, operation, typical equipment, off. Over the past few years. Electric Process For Steel Making.

From mavink.com

Steel Detailing Process Flow Chart Electric Process For Steel Making here is a schematic of the process. Share, raw materials, operation, typical equipment, off. Eafs make up approximately 60% of today's steel. Over the past few years electric arc furnace (eaf) has. this chapter deals with electric furnace steelmaking, a tool for the massive production of steels, which is responsible for 30% of the current. the impact. Electric Process For Steel Making.

From www.eurofer.eu

What is steel and how is steel made? Electric Process For Steel Making this paper presents a comprehensive model of an industrial electric arc furnace (eaf) that is based. Iron ore rock is fed into the cell, which contains the cathode (the negative terminal of the moe cell) and an anode immersed in a liquid electrolyte. the basic principle of electric steelmaking today is that the furnace is a “melting machine”. Electric Process For Steel Making.

From www.survivaltech.club

Steelmaking Part 1 42 Electric Process For Steel Making the basic principle of electric steelmaking today is that the furnace is a “melting machine” that produces liquid. Over the past few years electric arc furnace (eaf) has. the impact of electric arc furnaces on modern steel production. Eafs make up approximately 60% of today's steel. here is a schematic of the process. Boston metal’s molten oxide. Electric Process For Steel Making.

From www.steels-supplier.com

Steel Plate and Steel Pipe Production Process Flowchart Electric Process For Steel Making Over the past few years electric arc furnace (eaf) has. this paper presents a comprehensive model of an industrial electric arc furnace (eaf) that is based. here is a schematic of the process. the basic principle of electric steelmaking today is that the furnace is a “melting machine” that produces liquid. Share, raw materials, operation, typical equipment,. Electric Process For Steel Making.

From www.cwbgroup.org

The Story of Steel Part 2. The Creation of Steel CWB Group Electric Process For Steel Making here is a schematic of the process. the eaf process uses virtually 100% old steel to make new steel. Eafs make up approximately 60% of today's steel. Share, raw materials, operation, typical equipment, off. Iron ore rock is fed into the cell, which contains the cathode (the negative terminal of the moe cell) and an anode immersed in. Electric Process For Steel Making.

From www.eurofer.eu

What is steel and how is steel made? Electric Process For Steel Making this paper presents a comprehensive model of an industrial electric arc furnace (eaf) that is based. this chapter deals with electric furnace steelmaking, a tool for the massive production of steels, which is responsible for 30% of the current. Share, raw materials, operation, typical equipment, off. Iron ore rock is fed into the cell, which contains the cathode. Electric Process For Steel Making.

From www.slideserve.com

PPT IRON AND STEEL MAKING PowerPoint Presentation, free download ID Electric Process For Steel Making Boston metal’s molten oxide electrolysis process takes place in modular moe cells, each the size of a school bus. this paper presents a comprehensive model of an industrial electric arc furnace (eaf) that is based. the basic principle of electric steelmaking today is that the furnace is a “melting machine” that produces liquid. Over the past few years. Electric Process For Steel Making.

From www.sustainableinsteel.eu

Production routes for steel Electric Process For Steel Making the impact of electric arc furnaces on modern steel production. here is a schematic of the process. Share, raw materials, operation, typical equipment, off. Boston metal’s molten oxide electrolysis process takes place in modular moe cells, each the size of a school bus. Over the past few years electric arc furnace (eaf) has. the eaf process uses. Electric Process For Steel Making.

From mavink.com

Blast Furnace Process Flow Diagram Electric Process For Steel Making this paper presents a comprehensive model of an industrial electric arc furnace (eaf) that is based. Share, raw materials, operation, typical equipment, off. this chapter deals with electric furnace steelmaking, a tool for the massive production of steels, which is responsible for 30% of the current. the eaf process uses virtually 100% old steel to make new. Electric Process For Steel Making.

From www.nzsteel.co.nz

Steel Making New Zealand Steel Electric Process For Steel Making this chapter deals with electric furnace steelmaking, a tool for the massive production of steels, which is responsible for 30% of the current. Boston metal’s molten oxide electrolysis process takes place in modular moe cells, each the size of a school bus. Over the past few years electric arc furnace (eaf) has. Iron ore rock is fed into the. Electric Process For Steel Making.

From metallurgymaterial.blogspot.com

Current Steel Manufacturing Process Metallurgy Materials Electric Process For Steel Making Share, raw materials, operation, typical equipment, off. Boston metal’s molten oxide electrolysis process takes place in modular moe cells, each the size of a school bus. this paper presents a comprehensive model of an industrial electric arc furnace (eaf) that is based. the impact of electric arc furnaces on modern steel production. in this chapter, electric steelmaking. Electric Process For Steel Making.

From www.researchgate.net

Steel making process. Download Scientific Diagram Electric Process For Steel Making this paper presents a comprehensive model of an industrial electric arc furnace (eaf) that is based. the basic principle of electric steelmaking today is that the furnace is a “melting machine” that produces liquid. in this chapter, electric steelmaking is introduced with a short review: Iron ore rock is fed into the cell, which contains the cathode. Electric Process For Steel Making.

From www.chartersteel.com

Charter Steel EAF vs. BOF Furnaces in Sustainable Steelmaking Electric Process For Steel Making the eaf process uses virtually 100% old steel to make new steel. the basic principle of electric steelmaking today is that the furnace is a “melting machine” that produces liquid. in this chapter, electric steelmaking is introduced with a short review: here is a schematic of the process. Over the past few years electric arc furnace. Electric Process For Steel Making.

From mechanicstips.blogspot.com

Steel Making & Processing MechanicsTips Electric Process For Steel Making Over the past few years electric arc furnace (eaf) has. this chapter deals with electric furnace steelmaking, a tool for the massive production of steels, which is responsible for 30% of the current. the eaf process uses virtually 100% old steel to make new steel. Iron ore rock is fed into the cell, which contains the cathode (the. Electric Process For Steel Making.

From allsteelchoices.blogspot.com

Stainless Steel Manufacturing Process Steel Choices Electric Process For Steel Making here is a schematic of the process. the impact of electric arc furnaces on modern steel production. the eaf process uses virtually 100% old steel to make new steel. Share, raw materials, operation, typical equipment, off. the basic principle of electric steelmaking today is that the furnace is a “melting machine” that produces liquid. Over the. Electric Process For Steel Making.

From www.millconsteel.com

Steel Process MILLCON Electric Process For Steel Making Iron ore rock is fed into the cell, which contains the cathode (the negative terminal of the moe cell) and an anode immersed in a liquid electrolyte. here is a schematic of the process. Eafs make up approximately 60% of today's steel. this paper presents a comprehensive model of an industrial electric arc furnace (eaf) that is based.. Electric Process For Steel Making.

From gbu-presnenskij.ru

Steel Making Process Complete Overview With Flowchart, 42 OFF Electric Process For Steel Making in this chapter, electric steelmaking is introduced with a short review: Over the past few years electric arc furnace (eaf) has. the basic principle of electric steelmaking today is that the furnace is a “melting machine” that produces liquid. Boston metal’s molten oxide electrolysis process takes place in modular moe cells, each the size of a school bus.. Electric Process For Steel Making.

From www.researchgate.net

The overview of ironmaking and steelmaking processes Download Electric Process For Steel Making the impact of electric arc furnaces on modern steel production. the eaf process uses virtually 100% old steel to make new steel. Iron ore rock is fed into the cell, which contains the cathode (the negative terminal of the moe cell) and an anode immersed in a liquid electrolyte. here is a schematic of the process. Eafs. Electric Process For Steel Making.

From www.jfe-steel.co.jp

JFE Steel CorporationJFE Steel Corporation Electrical Steel Sheets Electric Process For Steel Making in this chapter, electric steelmaking is introduced with a short review: Over the past few years electric arc furnace (eaf) has. here is a schematic of the process. this paper presents a comprehensive model of an industrial electric arc furnace (eaf) that is based. Eafs make up approximately 60% of today's steel. Boston metal’s molten oxide electrolysis. Electric Process For Steel Making.

From www.lmmgroupcn.com

Direct reduced iron process Electric Process For Steel Making Boston metal’s molten oxide electrolysis process takes place in modular moe cells, each the size of a school bus. Eafs make up approximately 60% of today's steel. the eaf process uses virtually 100% old steel to make new steel. in this chapter, electric steelmaking is introduced with a short review: this chapter deals with electric furnace steelmaking,. Electric Process For Steel Making.

From www.metallurgyfordummies.com

Steel Production Technology Metallurgy for Dummies Electric Process For Steel Making Share, raw materials, operation, typical equipment, off. Boston metal’s molten oxide electrolysis process takes place in modular moe cells, each the size of a school bus. Iron ore rock is fed into the cell, which contains the cathode (the negative terminal of the moe cell) and an anode immersed in a liquid electrolyte. Eafs make up approximately 60% of today's. Electric Process For Steel Making.

From hanmetallurgy.com

Electric Arc Furnace Steelmaking Steel Hani Metallurgy Electric Process For Steel Making Iron ore rock is fed into the cell, which contains the cathode (the negative terminal of the moe cell) and an anode immersed in a liquid electrolyte. this chapter deals with electric furnace steelmaking, a tool for the massive production of steels, which is responsible for 30% of the current. this paper presents a comprehensive model of an. Electric Process For Steel Making.

From www.uky.edu

Coal to Make Coke and Steel, Kentucky Geological Survey, University of Electric Process For Steel Making this paper presents a comprehensive model of an industrial electric arc furnace (eaf) that is based. in this chapter, electric steelmaking is introduced with a short review: Share, raw materials, operation, typical equipment, off. this chapter deals with electric furnace steelmaking, a tool for the massive production of steels, which is responsible for 30% of the current.. Electric Process For Steel Making.

From www.mdpi.com

Metals Free FullText Data Driven Performance Prediction in Steel Electric Process For Steel Making Boston metal’s molten oxide electrolysis process takes place in modular moe cells, each the size of a school bus. this paper presents a comprehensive model of an industrial electric arc furnace (eaf) that is based. Eafs make up approximately 60% of today's steel. the impact of electric arc furnaces on modern steel production. Share, raw materials, operation, typical. Electric Process For Steel Making.

From blog.dixonvalve.com

6 Steps of the Steel Manufacturing Process Electric Process For Steel Making in this chapter, electric steelmaking is introduced with a short review: Iron ore rock is fed into the cell, which contains the cathode (the negative terminal of the moe cell) and an anode immersed in a liquid electrolyte. Boston metal’s molten oxide electrolysis process takes place in modular moe cells, each the size of a school bus. here. Electric Process For Steel Making.

From www.nzsteel.co.nz

Iron Making New Zealand Steel Electric Process For Steel Making Iron ore rock is fed into the cell, which contains the cathode (the negative terminal of the moe cell) and an anode immersed in a liquid electrolyte. here is a schematic of the process. Boston metal’s molten oxide electrolysis process takes place in modular moe cells, each the size of a school bus. in this chapter, electric steelmaking. Electric Process For Steel Making.

From mavink.com

Manufacturing Process Flow Chart For Steel Electric Process For Steel Making the eaf process uses virtually 100% old steel to make new steel. Share, raw materials, operation, typical equipment, off. Eafs make up approximately 60% of today's steel. Iron ore rock is fed into the cell, which contains the cathode (the negative terminal of the moe cell) and an anode immersed in a liquid electrolyte. in this chapter, electric. Electric Process For Steel Making.

From www.dreamstime.com

Metallurgy. the Iron and Steel Production. the Electric Arc Furnace Electric Process For Steel Making this paper presents a comprehensive model of an industrial electric arc furnace (eaf) that is based. Iron ore rock is fed into the cell, which contains the cathode (the negative terminal of the moe cell) and an anode immersed in a liquid electrolyte. Over the past few years electric arc furnace (eaf) has. the impact of electric arc. Electric Process For Steel Making.

From econ243.academic.wlu.edu

BOF and EAF Steels What are the Differences? Economics 243 Fall 2018 Electric Process For Steel Making Over the past few years electric arc furnace (eaf) has. Iron ore rock is fed into the cell, which contains the cathode (the negative terminal of the moe cell) and an anode immersed in a liquid electrolyte. this chapter deals with electric furnace steelmaking, a tool for the massive production of steels, which is responsible for 30% of the. Electric Process For Steel Making.

From hxeuirofd.blob.core.windows.net

Electric Arc Furnace Taphole at Melissa Hawley blog Electric Process For Steel Making the impact of electric arc furnaces on modern steel production. this paper presents a comprehensive model of an industrial electric arc furnace (eaf) that is based. Share, raw materials, operation, typical equipment, off. the eaf process uses virtually 100% old steel to make new steel. here is a schematic of the process. Over the past few. Electric Process For Steel Making.

From steelmuseum.org

Steelmaking Process Electric Process For Steel Making Iron ore rock is fed into the cell, which contains the cathode (the negative terminal of the moe cell) and an anode immersed in a liquid electrolyte. this chapter deals with electric furnace steelmaking, a tool for the massive production of steels, which is responsible for 30% of the current. Share, raw materials, operation, typical equipment, off. Boston metal’s. Electric Process For Steel Making.