How To Make Stator Core . By choosing the correct type of stator core. Motor core lamination stacking is a crucial step in the manufacturing of electric motors and generators. Manufacturing stator cores come with a unique set of challenges, from material selection to intricate coil winding. In general two types of stator slots are. The bonded cores show optimal thermal conductivity, no harmony noise, and do not breathe at temperature changes. Design of stator stator slots: Stator bonding eliminates the need for rivet points or welding of the magnetic stator cores, which in turn reduces interlaminar loss. Stator of an induction motor consists of stator core and stator slots. In this comprehensive guide, we’ll explore several methods of motor core lamination stacking commonly used in the. How does a standard core. The stator core typically consists of laminated iron or other magnetic materials arranged to facilitate the efficient generation of. Below, you will understand what stator core lamination is and discover its advantages for your equipment. It involves the assembly of thin, insulated steel sheets, called laminations, to create the core of the motor. Stator core laminations reduce eddy currents, minimize hysteresis loss, and help manage heat flow within motors and generators.

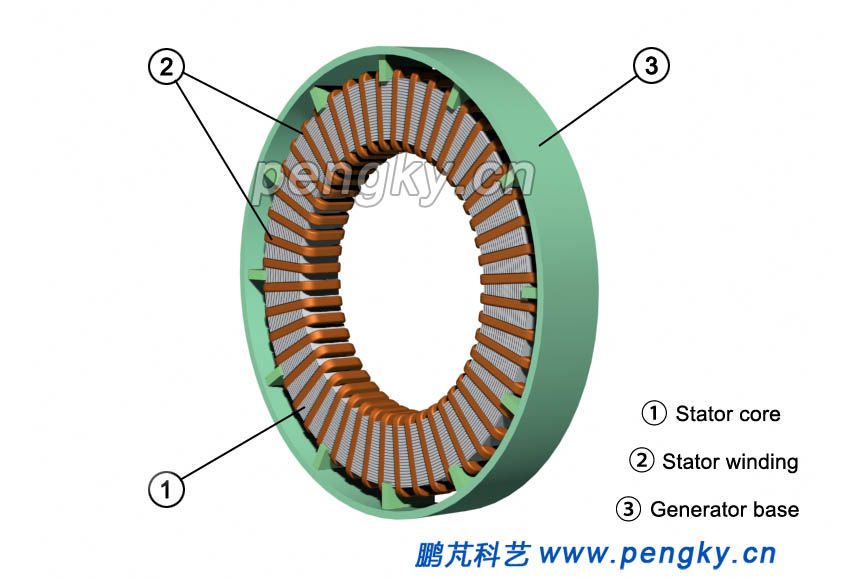

from www.pengky.cn

The stator core typically consists of laminated iron or other magnetic materials arranged to facilitate the efficient generation of. How does a standard core. Design of stator stator slots: Stator of an induction motor consists of stator core and stator slots. By choosing the correct type of stator core. Stator bonding eliminates the need for rivet points or welding of the magnetic stator cores, which in turn reduces interlaminar loss. In general two types of stator slots are. It involves the assembly of thin, insulated steel sheets, called laminations, to create the core of the motor. Manufacturing stator cores come with a unique set of challenges, from material selection to intricate coil winding. In this comprehensive guide, we’ll explore several methods of motor core lamination stacking commonly used in the.

Intermediate Stator Disc Generator Direct Drive Wind Turbine Pengky

How To Make Stator Core Stator bonding eliminates the need for rivet points or welding of the magnetic stator cores, which in turn reduces interlaminar loss. By choosing the correct type of stator core. In this comprehensive guide, we’ll explore several methods of motor core lamination stacking commonly used in the. Below, you will understand what stator core lamination is and discover its advantages for your equipment. Stator of an induction motor consists of stator core and stator slots. It involves the assembly of thin, insulated steel sheets, called laminations, to create the core of the motor. Manufacturing stator cores come with a unique set of challenges, from material selection to intricate coil winding. Design of stator stator slots: In general two types of stator slots are. Stator core laminations reduce eddy currents, minimize hysteresis loss, and help manage heat flow within motors and generators. Motor core lamination stacking is a crucial step in the manufacturing of electric motors and generators. How does a standard core. The stator core typically consists of laminated iron or other magnetic materials arranged to facilitate the efficient generation of. The bonded cores show optimal thermal conductivity, no harmony noise, and do not breathe at temperature changes. Stator bonding eliminates the need for rivet points or welding of the magnetic stator cores, which in turn reduces interlaminar loss.

From www.powerservicesgroup.com

Why is a Stator Core Made of Laminated Steel? Power Services Group How To Make Stator Core Motor core lamination stacking is a crucial step in the manufacturing of electric motors and generators. It involves the assembly of thin, insulated steel sheets, called laminations, to create the core of the motor. Design of stator stator slots: How does a standard core. Stator bonding eliminates the need for rivet points or welding of the magnetic stator cores, which. How To Make Stator Core.

From eureka.patsnap.com

Stator core assembling system and stator iron core assembling method How To Make Stator Core It involves the assembly of thin, insulated steel sheets, called laminations, to create the core of the motor. How does a standard core. Stator core laminations reduce eddy currents, minimize hysteresis loss, and help manage heat flow within motors and generators. Below, you will understand what stator core lamination is and discover its advantages for your equipment. Motor core lamination. How To Make Stator Core.

From www.aemservices.com

Special Projects Hydro Power Generation Associated ElectroMechanics How To Make Stator Core Stator of an induction motor consists of stator core and stator slots. In this comprehensive guide, we’ll explore several methods of motor core lamination stacking commonly used in the. Stator bonding eliminates the need for rivet points or welding of the magnetic stator cores, which in turn reduces interlaminar loss. The stator core typically consists of laminated iron or other. How To Make Stator Core.

From www.researchgate.net

Simplified motor lateral section and cooling air paths. A−Stator core How To Make Stator Core The bonded cores show optimal thermal conductivity, no harmony noise, and do not breathe at temperature changes. Motor core lamination stacking is a crucial step in the manufacturing of electric motors and generators. Stator bonding eliminates the need for rivet points or welding of the magnetic stator cores, which in turn reduces interlaminar loss. Design of stator stator slots: The. How To Make Stator Core.

From www.mdpi.com

Sensors Free FullText Stator Core Shape Design for Low Core Loss How To Make Stator Core Design of stator stator slots: The stator core typically consists of laminated iron or other magnetic materials arranged to facilitate the efficient generation of. Motor core lamination stacking is a crucial step in the manufacturing of electric motors and generators. In general two types of stator slots are. How does a standard core. Stator core laminations reduce eddy currents, minimize. How To Make Stator Core.

From www.researchgate.net

Stator core with 48 slots (a) and robot's point of view when removing How To Make Stator Core Motor core lamination stacking is a crucial step in the manufacturing of electric motors and generators. Design of stator stator slots: Stator of an induction motor consists of stator core and stator slots. In this comprehensive guide, we’ll explore several methods of motor core lamination stacking commonly used in the. The bonded cores show optimal thermal conductivity, no harmony noise,. How To Make Stator Core.

From www.researchgate.net

Slotted stator core for tubular machine. (a) Fabricated from Ishaped How To Make Stator Core By choosing the correct type of stator core. In general two types of stator slots are. The stator core typically consists of laminated iron or other magnetic materials arranged to facilitate the efficient generation of. In this comprehensive guide, we’ll explore several methods of motor core lamination stacking commonly used in the. Stator bonding eliminates the need for rivet points. How To Make Stator Core.

From www.backlack.com

motor stator and rotor coil winding manufacturer How To Make Stator Core In general two types of stator slots are. The bonded cores show optimal thermal conductivity, no harmony noise, and do not breathe at temperature changes. Stator core laminations reduce eddy currents, minimize hysteresis loss, and help manage heat flow within motors and generators. Manufacturing stator cores come with a unique set of challenges, from material selection to intricate coil winding.. How To Make Stator Core.

From www.pengky.cn

Intermediate Stator Disc Generator Direct Drive Wind Turbine Pengky How To Make Stator Core Design of stator stator slots: The bonded cores show optimal thermal conductivity, no harmony noise, and do not breathe at temperature changes. Manufacturing stator cores come with a unique set of challenges, from material selection to intricate coil winding. In general two types of stator slots are. Stator bonding eliminates the need for rivet points or welding of the magnetic. How To Make Stator Core.

From electricalgang.com

What Is Stator? Construction of Stator ElectricalGang How To Make Stator Core Manufacturing stator cores come with a unique set of challenges, from material selection to intricate coil winding. The bonded cores show optimal thermal conductivity, no harmony noise, and do not breathe at temperature changes. The stator core typically consists of laminated iron or other magnetic materials arranged to facilitate the efficient generation of. Stator core laminations reduce eddy currents, minimize. How To Make Stator Core.

From travelknowledge.org

The Basics of Stator Core Lamination in Your Equipment Travel Knowledge How To Make Stator Core Stator bonding eliminates the need for rivet points or welding of the magnetic stator cores, which in turn reduces interlaminar loss. How does a standard core. In this comprehensive guide, we’ll explore several methods of motor core lamination stacking commonly used in the. Design of stator stator slots: By choosing the correct type of stator core. Manufacturing stator cores come. How To Make Stator Core.

From www.powerservicesgroup.com

Why is a Stator Core Made of Laminated Steel? Power Services Group How To Make Stator Core In general two types of stator slots are. The bonded cores show optimal thermal conductivity, no harmony noise, and do not breathe at temperature changes. Design of stator stator slots: Stator bonding eliminates the need for rivet points or welding of the magnetic stator cores, which in turn reduces interlaminar loss. By choosing the correct type of stator core. The. How To Make Stator Core.

From electricalgang.com

What Is Stator? Construction of Stator ElectricalGang How To Make Stator Core It involves the assembly of thin, insulated steel sheets, called laminations, to create the core of the motor. Below, you will understand what stator core lamination is and discover its advantages for your equipment. Design of stator stator slots: Stator bonding eliminates the need for rivet points or welding of the magnetic stator cores, which in turn reduces interlaminar loss.. How To Make Stator Core.

From www.researchgate.net

Stator core manufacturing process and core shapes (a) Connected core How To Make Stator Core Stator bonding eliminates the need for rivet points or welding of the magnetic stator cores, which in turn reduces interlaminar loss. Manufacturing stator cores come with a unique set of challenges, from material selection to intricate coil winding. Stator core laminations reduce eddy currents, minimize hysteresis loss, and help manage heat flow within motors and generators. The bonded cores show. How To Make Stator Core.

From www.backlack.com

motor stator and rotor coil winding manufacturer How To Make Stator Core In general two types of stator slots are. By choosing the correct type of stator core. How does a standard core. Stator core laminations reduce eddy currents, minimize hysteresis loss, and help manage heat flow within motors and generators. Motor core lamination stacking is a crucial step in the manufacturing of electric motors and generators. In this comprehensive guide, we’ll. How To Make Stator Core.

From eureka.patsnap.com

Stator core, stator assembly, motor, food processor and air supply How To Make Stator Core Stator bonding eliminates the need for rivet points or welding of the magnetic stator cores, which in turn reduces interlaminar loss. Manufacturing stator cores come with a unique set of challenges, from material selection to intricate coil winding. Motor core lamination stacking is a crucial step in the manufacturing of electric motors and generators. In general two types of stator. How To Make Stator Core.

From www.researchgate.net

Stator core manufacturing process and core shapes (a) Connected core How To Make Stator Core The bonded cores show optimal thermal conductivity, no harmony noise, and do not breathe at temperature changes. How does a standard core. Below, you will understand what stator core lamination is and discover its advantages for your equipment. Motor core lamination stacking is a crucial step in the manufacturing of electric motors and generators. By choosing the correct type of. How To Make Stator Core.

From forum.allaboutcircuits.com

Making an inductor from an old motor stator core All About Circuits How To Make Stator Core It involves the assembly of thin, insulated steel sheets, called laminations, to create the core of the motor. Design of stator stator slots: Stator of an induction motor consists of stator core and stator slots. The stator core typically consists of laminated iron or other magnetic materials arranged to facilitate the efficient generation of. Below, you will understand what stator. How To Make Stator Core.

From www.ccj-online.com

Correcting statorcore looseness in generators for gas and steam How To Make Stator Core Stator of an induction motor consists of stator core and stator slots. In this comprehensive guide, we’ll explore several methods of motor core lamination stacking commonly used in the. It involves the assembly of thin, insulated steel sheets, called laminations, to create the core of the motor. Stator bonding eliminates the need for rivet points or welding of the magnetic. How To Make Stator Core.

From www.researchgate.net

Production of the AM core motor (a) LPBF process of the motor stator How To Make Stator Core Motor core lamination stacking is a crucial step in the manufacturing of electric motors and generators. Manufacturing stator cores come with a unique set of challenges, from material selection to intricate coil winding. Below, you will understand what stator core lamination is and discover its advantages for your equipment. The stator core typically consists of laminated iron or other magnetic. How To Make Stator Core.

From www.youtube.com

electric motor manufacturing processing,how to make stator housing How To Make Stator Core How does a standard core. The bonded cores show optimal thermal conductivity, no harmony noise, and do not breathe at temperature changes. It involves the assembly of thin, insulated steel sheets, called laminations, to create the core of the motor. The stator core typically consists of laminated iron or other magnetic materials arranged to facilitate the efficient generation of. Manufacturing. How To Make Stator Core.

From www.youtube.com

How to make a electric motor stator motor production assembly line How To Make Stator Core By choosing the correct type of stator core. Design of stator stator slots: It involves the assembly of thin, insulated steel sheets, called laminations, to create the core of the motor. Stator of an induction motor consists of stator core and stator slots. The bonded cores show optimal thermal conductivity, no harmony noise, and do not breathe at temperature changes.. How To Make Stator Core.

From water-to-wire.blogspot.com

Diary of a Powerspout installation Reduced core stator Part 1 How To Make Stator Core Stator of an induction motor consists of stator core and stator slots. By choosing the correct type of stator core. Stator bonding eliminates the need for rivet points or welding of the magnetic stator cores, which in turn reduces interlaminar loss. It involves the assembly of thin, insulated steel sheets, called laminations, to create the core of the motor. Stator. How To Make Stator Core.

From turbogentech.com

EL CID stator core test How To Make Stator Core Stator of an induction motor consists of stator core and stator slots. Below, you will understand what stator core lamination is and discover its advantages for your equipment. How does a standard core. In this comprehensive guide, we’ll explore several methods of motor core lamination stacking commonly used in the. Stator core laminations reduce eddy currents, minimize hysteresis loss, and. How To Make Stator Core.

From www.pengky.cn

Principle of Transverse Flux Permanent Generator Direct Drive How To Make Stator Core In this comprehensive guide, we’ll explore several methods of motor core lamination stacking commonly used in the. Design of stator stator slots: The stator core typically consists of laminated iron or other magnetic materials arranged to facilitate the efficient generation of. How does a standard core. The bonded cores show optimal thermal conductivity, no harmony noise, and do not breathe. How To Make Stator Core.

From www.researchgate.net

7 Typical stator core including stator winding bar. Download How To Make Stator Core In general two types of stator slots are. Stator bonding eliminates the need for rivet points or welding of the magnetic stator cores, which in turn reduces interlaminar loss. Manufacturing stator cores come with a unique set of challenges, from material selection to intricate coil winding. The bonded cores show optimal thermal conductivity, no harmony noise, and do not breathe. How To Make Stator Core.

From www.youtube.com

STATOR DIAGRAM YouTube How To Make Stator Core Below, you will understand what stator core lamination is and discover its advantages for your equipment. The stator core typically consists of laminated iron or other magnetic materials arranged to facilitate the efficient generation of. By choosing the correct type of stator core. In this comprehensive guide, we’ll explore several methods of motor core lamination stacking commonly used in the.. How To Make Stator Core.

From wirepartsarah.z19.web.core.windows.net

2 Pole Stator Wiring Diagram How To Make Stator Core Below, you will understand what stator core lamination is and discover its advantages for your equipment. Manufacturing stator cores come with a unique set of challenges, from material selection to intricate coil winding. Design of stator stator slots: The stator core typically consists of laminated iron or other magnetic materials arranged to facilitate the efficient generation of. How does a. How To Make Stator Core.

From electricalacademia.com

SYNCHRONOUS MOTOR CONSTRUCTION Electrical Academia How To Make Stator Core Manufacturing stator cores come with a unique set of challenges, from material selection to intricate coil winding. Below, you will understand what stator core lamination is and discover its advantages for your equipment. How does a standard core. The stator core typically consists of laminated iron or other magnetic materials arranged to facilitate the efficient generation of. Motor core lamination. How To Make Stator Core.

From guidepartfatteners.z13.web.core.windows.net

How To Make A Stator How To Make Stator Core Manufacturing stator cores come with a unique set of challenges, from material selection to intricate coil winding. In this comprehensive guide, we’ll explore several methods of motor core lamination stacking commonly used in the. It involves the assembly of thin, insulated steel sheets, called laminations, to create the core of the motor. Design of stator stator slots: How does a. How To Make Stator Core.

From www.researchgate.net

Stator (a) winding wiring, (b) sub‐module stator core, (c) module How To Make Stator Core Motor core lamination stacking is a crucial step in the manufacturing of electric motors and generators. It involves the assembly of thin, insulated steel sheets, called laminations, to create the core of the motor. The stator core typically consists of laminated iron or other magnetic materials arranged to facilitate the efficient generation of. Stator bonding eliminates the need for rivet. How To Make Stator Core.

From www.suncall.co.jp

Motor cores/stator cores How To Make Stator Core Motor core lamination stacking is a crucial step in the manufacturing of electric motors and generators. How does a standard core. The bonded cores show optimal thermal conductivity, no harmony noise, and do not breathe at temperature changes. Manufacturing stator cores come with a unique set of challenges, from material selection to intricate coil winding. In this comprehensive guide, we’ll. How To Make Stator Core.

From www.youtube.com

Design of stator core (3ph Induction Motor Design Course 10) YouTube How To Make Stator Core The stator core typically consists of laminated iron or other magnetic materials arranged to facilitate the efficient generation of. Stator of an induction motor consists of stator core and stator slots. Manufacturing stator cores come with a unique set of challenges, from material selection to intricate coil winding. How does a standard core. The bonded cores show optimal thermal conductivity,. How To Make Stator Core.

From www.researchgate.net

Laminated sheets of stator and rotor cores. Download Scientific Diagram How To Make Stator Core Design of stator stator slots: Manufacturing stator cores come with a unique set of challenges, from material selection to intricate coil winding. Stator bonding eliminates the need for rivet points or welding of the magnetic stator cores, which in turn reduces interlaminar loss. It involves the assembly of thin, insulated steel sheets, called laminations, to create the core of the. How To Make Stator Core.

From www.researchgate.net

Stator core structure Download Scientific Diagram How To Make Stator Core How does a standard core. Stator core laminations reduce eddy currents, minimize hysteresis loss, and help manage heat flow within motors and generators. Design of stator stator slots: In general two types of stator slots are. It involves the assembly of thin, insulated steel sheets, called laminations, to create the core of the motor. Manufacturing stator cores come with a. How To Make Stator Core.