Plastic Dip Coating Process . Conversely, 3d objects can simply be. The dip coating process is a method used to apply a uniform layer of material, typically a polymer or paint, onto a substrate by immersing it into a. The most common technique for plastic dip coating is the hot dip method, resulting in coatings from about 1/16 to 1/4 thick. Applying liquid polymers or plastics to a workpiece through methods like dipping or immersion is known as plastic coating. It results in a durable, rubbery, flexible protective layer in varying thicknesses depending on the needs of your project. In brief, dip coating involves immersing a preheated part in a liquified plastisol and heat curing it to set the coating. Plastic dip coating is a process that involves immersing a preheated part into liquid plastisol to form a plastic coating that can add protection and aesthetics to most metal.

from www.slideserve.com

Plastic dip coating is a process that involves immersing a preheated part into liquid plastisol to form a plastic coating that can add protection and aesthetics to most metal. Applying liquid polymers or plastics to a workpiece through methods like dipping or immersion is known as plastic coating. It results in a durable, rubbery, flexible protective layer in varying thicknesses depending on the needs of your project. Conversely, 3d objects can simply be. The dip coating process is a method used to apply a uniform layer of material, typically a polymer or paint, onto a substrate by immersing it into a. In brief, dip coating involves immersing a preheated part in a liquified plastisol and heat curing it to set the coating. The most common technique for plastic dip coating is the hot dip method, resulting in coatings from about 1/16 to 1/4 thick.

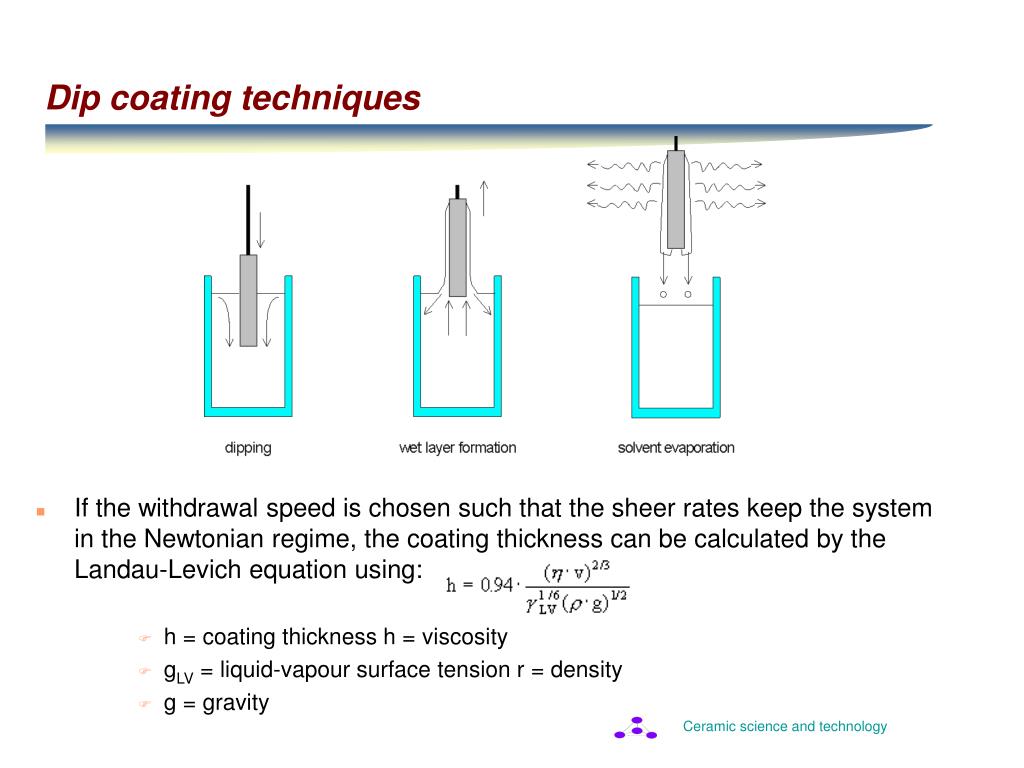

PPT Dip coating techniques PowerPoint Presentation, free download

Plastic Dip Coating Process It results in a durable, rubbery, flexible protective layer in varying thicknesses depending on the needs of your project. The dip coating process is a method used to apply a uniform layer of material, typically a polymer or paint, onto a substrate by immersing it into a. Applying liquid polymers or plastics to a workpiece through methods like dipping or immersion is known as plastic coating. It results in a durable, rubbery, flexible protective layer in varying thicknesses depending on the needs of your project. The most common technique for plastic dip coating is the hot dip method, resulting in coatings from about 1/16 to 1/4 thick. Plastic dip coating is a process that involves immersing a preheated part into liquid plastisol to form a plastic coating that can add protection and aesthetics to most metal. In brief, dip coating involves immersing a preheated part in a liquified plastisol and heat curing it to set the coating. Conversely, 3d objects can simply be.

From www.iqsdirectory.com

Plastic Coating What Is It? How Does It Work? Process Plastic Dip Coating Process The most common technique for plastic dip coating is the hot dip method, resulting in coatings from about 1/16 to 1/4 thick. In brief, dip coating involves immersing a preheated part in a liquified plastisol and heat curing it to set the coating. It results in a durable, rubbery, flexible protective layer in varying thicknesses depending on the needs of. Plastic Dip Coating Process.

From www.precisiondipcoating.com

The Process Of Plastic Dip Coating Precision Dip Coating Plastic Dip Coating Process The most common technique for plastic dip coating is the hot dip method, resulting in coatings from about 1/16 to 1/4 thick. Applying liquid polymers or plastics to a workpiece through methods like dipping or immersion is known as plastic coating. It results in a durable, rubbery, flexible protective layer in varying thicknesses depending on the needs of your project.. Plastic Dip Coating Process.

From www.researchgate.net

Sequential dipcoating process in preparing CsPbBr films Download Plastic Dip Coating Process Applying liquid polymers or plastics to a workpiece through methods like dipping or immersion is known as plastic coating. Plastic dip coating is a process that involves immersing a preheated part into liquid plastisol to form a plastic coating that can add protection and aesthetics to most metal. It results in a durable, rubbery, flexible protective layer in varying thicknesses. Plastic Dip Coating Process.

From www.researchgate.net

Schematic of dip coating [124] Download Scientific Diagram Plastic Dip Coating Process It results in a durable, rubbery, flexible protective layer in varying thicknesses depending on the needs of your project. The most common technique for plastic dip coating is the hot dip method, resulting in coatings from about 1/16 to 1/4 thick. In brief, dip coating involves immersing a preheated part in a liquified plastisol and heat curing it to set. Plastic Dip Coating Process.

From www.researchgate.net

Schematic of dipcoating process Download Scientific Diagram Plastic Dip Coating Process In brief, dip coating involves immersing a preheated part in a liquified plastisol and heat curing it to set the coating. The most common technique for plastic dip coating is the hot dip method, resulting in coatings from about 1/16 to 1/4 thick. Applying liquid polymers or plastics to a workpiece through methods like dipping or immersion is known as. Plastic Dip Coating Process.

From mwrco.com

Dip Molding & Dip Coating Which Process Suits You? MWRCO Plastic Dip Coating Process It results in a durable, rubbery, flexible protective layer in varying thicknesses depending on the needs of your project. The dip coating process is a method used to apply a uniform layer of material, typically a polymer or paint, onto a substrate by immersing it into a. The most common technique for plastic dip coating is the hot dip method,. Plastic Dip Coating Process.

From www.precisiondipcoating.com

The Process Of Plastic Dip Coating Plastic Dip Coating Process Plastic dip coating is a process that involves immersing a preheated part into liquid plastisol to form a plastic coating that can add protection and aesthetics to most metal. The most common technique for plastic dip coating is the hot dip method, resulting in coatings from about 1/16 to 1/4 thick. It results in a durable, rubbery, flexible protective layer. Plastic Dip Coating Process.

From www.slideserve.com

PPT DIP COATING PowerPoint Presentation, free download ID618468 Plastic Dip Coating Process Applying liquid polymers or plastics to a workpiece through methods like dipping or immersion is known as plastic coating. In brief, dip coating involves immersing a preheated part in a liquified plastisol and heat curing it to set the coating. It results in a durable, rubbery, flexible protective layer in varying thicknesses depending on the needs of your project. The. Plastic Dip Coating Process.

From www.researchgate.net

The dipcoating process and the considerable electrostatic Plastic Dip Coating Process In brief, dip coating involves immersing a preheated part in a liquified plastisol and heat curing it to set the coating. The dip coating process is a method used to apply a uniform layer of material, typically a polymer or paint, onto a substrate by immersing it into a. Plastic dip coating is a process that involves immersing a preheated. Plastic Dip Coating Process.

From www.iqsdirectory.com

Plastic Coating What Is It? How Does It Work? Process Plastic Dip Coating Process The most common technique for plastic dip coating is the hot dip method, resulting in coatings from about 1/16 to 1/4 thick. Applying liquid polymers or plastics to a workpiece through methods like dipping or immersion is known as plastic coating. The dip coating process is a method used to apply a uniform layer of material, typically a polymer or. Plastic Dip Coating Process.

From www.youtube.com

Thermoplastic dipping coating process YouTube Plastic Dip Coating Process Applying liquid polymers or plastics to a workpiece through methods like dipping or immersion is known as plastic coating. The dip coating process is a method used to apply a uniform layer of material, typically a polymer or paint, onto a substrate by immersing it into a. It results in a durable, rubbery, flexible protective layer in varying thicknesses depending. Plastic Dip Coating Process.

From www.dipmoldedplastics.com

Dip Coating Companies Dip Coating Services Plastic Dip Coating Process Applying liquid polymers or plastics to a workpiece through methods like dipping or immersion is known as plastic coating. Conversely, 3d objects can simply be. The dip coating process is a method used to apply a uniform layer of material, typically a polymer or paint, onto a substrate by immersing it into a. It results in a durable, rubbery, flexible. Plastic Dip Coating Process.

From www.researchgate.net

Schematic representation of dip coating process for synthesizing thin Plastic Dip Coating Process Applying liquid polymers or plastics to a workpiece through methods like dipping or immersion is known as plastic coating. Plastic dip coating is a process that involves immersing a preheated part into liquid plastisol to form a plastic coating that can add protection and aesthetics to most metal. Conversely, 3d objects can simply be. The most common technique for plastic. Plastic Dip Coating Process.

From www.dipmoldedplastics.com

Dip Coating Companies Dip Coating Services Plastic Dip Coating Process The dip coating process is a method used to apply a uniform layer of material, typically a polymer or paint, onto a substrate by immersing it into a. In brief, dip coating involves immersing a preheated part in a liquified plastisol and heat curing it to set the coating. It results in a durable, rubbery, flexible protective layer in varying. Plastic Dip Coating Process.

From www.iqsdirectory.com

Plastic Coating What Is It? How Does It Work? Process Plastic Dip Coating Process The dip coating process is a method used to apply a uniform layer of material, typically a polymer or paint, onto a substrate by immersing it into a. Plastic dip coating is a process that involves immersing a preheated part into liquid plastisol to form a plastic coating that can add protection and aesthetics to most metal. Applying liquid polymers. Plastic Dip Coating Process.

From www.researchgate.net

4 Schematic diagram of the dipcoating process Download Scientific Plastic Dip Coating Process The dip coating process is a method used to apply a uniform layer of material, typically a polymer or paint, onto a substrate by immersing it into a. Applying liquid polymers or plastics to a workpiece through methods like dipping or immersion is known as plastic coating. The most common technique for plastic dip coating is the hot dip method,. Plastic Dip Coating Process.

From www.researchgate.net

The schematic representation of the dipcoating process. (a) Dipping Plastic Dip Coating Process In brief, dip coating involves immersing a preheated part in a liquified plastisol and heat curing it to set the coating. Plastic dip coating is a process that involves immersing a preheated part into liquid plastisol to form a plastic coating that can add protection and aesthetics to most metal. Conversely, 3d objects can simply be. The dip coating process. Plastic Dip Coating Process.

From www.piper-plastics.com

Dip Coating & Plastisol Coating Process Piper Plastics Corp. Plastic Dip Coating Process The dip coating process is a method used to apply a uniform layer of material, typically a polymer or paint, onto a substrate by immersing it into a. In brief, dip coating involves immersing a preheated part in a liquified plastisol and heat curing it to set the coating. Applying liquid polymers or plastics to a workpiece through methods like. Plastic Dip Coating Process.

From www.piper-plastics.com

Vinyl Plastisol Dip Molding & Coating Overview Piper Plastics Corp. Plastic Dip Coating Process Conversely, 3d objects can simply be. The most common technique for plastic dip coating is the hot dip method, resulting in coatings from about 1/16 to 1/4 thick. Plastic dip coating is a process that involves immersing a preheated part into liquid plastisol to form a plastic coating that can add protection and aesthetics to most metal. Applying liquid polymers. Plastic Dip Coating Process.

From www.iqsdirectory.com

Plastic Coating What Is It? How Does It Work? Process Plastic Dip Coating Process The dip coating process is a method used to apply a uniform layer of material, typically a polymer or paint, onto a substrate by immersing it into a. Plastic dip coating is a process that involves immersing a preheated part into liquid plastisol to form a plastic coating that can add protection and aesthetics to most metal. Applying liquid polymers. Plastic Dip Coating Process.

From www.slideserve.com

PPT Dip coating techniques PowerPoint Presentation, free download Plastic Dip Coating Process Plastic dip coating is a process that involves immersing a preheated part into liquid plastisol to form a plastic coating that can add protection and aesthetics to most metal. The dip coating process is a method used to apply a uniform layer of material, typically a polymer or paint, onto a substrate by immersing it into a. It results in. Plastic Dip Coating Process.

From www.dipmoldedplastics.com

Plastic Dip Coating Companies Plastic Dip Coating Services Plastic Dip Coating Process It results in a durable, rubbery, flexible protective layer in varying thicknesses depending on the needs of your project. Applying liquid polymers or plastics to a workpiece through methods like dipping or immersion is known as plastic coating. Plastic dip coating is a process that involves immersing a preheated part into liquid plastisol to form a plastic coating that can. Plastic Dip Coating Process.

From www.researchgate.net

Schematic illustration of the solutionbased (dipcoating) process with Plastic Dip Coating Process It results in a durable, rubbery, flexible protective layer in varying thicknesses depending on the needs of your project. The most common technique for plastic dip coating is the hot dip method, resulting in coatings from about 1/16 to 1/4 thick. Applying liquid polymers or plastics to a workpiece through methods like dipping or immersion is known as plastic coating.. Plastic Dip Coating Process.

From www.iqsdirectory.com

Plastic Coating What Is It? How Does It Work? Process Plastic Dip Coating Process Plastic dip coating is a process that involves immersing a preheated part into liquid plastisol to form a plastic coating that can add protection and aesthetics to most metal. The dip coating process is a method used to apply a uniform layer of material, typically a polymer or paint, onto a substrate by immersing it into a. Conversely, 3d objects. Plastic Dip Coating Process.

From mwrco.com

One of the First Plastic Manufacturing Methods Vacuum Forming Plastic Dip Coating Process Conversely, 3d objects can simply be. It results in a durable, rubbery, flexible protective layer in varying thicknesses depending on the needs of your project. Plastic dip coating is a process that involves immersing a preheated part into liquid plastisol to form a plastic coating that can add protection and aesthetics to most metal. The dip coating process is a. Plastic Dip Coating Process.

From www.yzours.com

PLASTIC DIP COATING Plastic Dip Coating Process In brief, dip coating involves immersing a preheated part in a liquified plastisol and heat curing it to set the coating. The dip coating process is a method used to apply a uniform layer of material, typically a polymer or paint, onto a substrate by immersing it into a. Conversely, 3d objects can simply be. It results in a durable,. Plastic Dip Coating Process.

From www.researchgate.net

Dipcoating steps (1) immersion and dwell time, (2) deposition and Plastic Dip Coating Process In brief, dip coating involves immersing a preheated part in a liquified plastisol and heat curing it to set the coating. The most common technique for plastic dip coating is the hot dip method, resulting in coatings from about 1/16 to 1/4 thick. Applying liquid polymers or plastics to a workpiece through methods like dipping or immersion is known as. Plastic Dip Coating Process.

From www.youtube.com

See the Fluidized Bed Powder Coating Process YouTube Plastic Dip Coating Process It results in a durable, rubbery, flexible protective layer in varying thicknesses depending on the needs of your project. The most common technique for plastic dip coating is the hot dip method, resulting in coatings from about 1/16 to 1/4 thick. In brief, dip coating involves immersing a preheated part in a liquified plastisol and heat curing it to set. Plastic Dip Coating Process.

From www.youtube.com

Plastic Dip Coating Services and Industry Information YouTube Plastic Dip Coating Process Applying liquid polymers or plastics to a workpiece through methods like dipping or immersion is known as plastic coating. Conversely, 3d objects can simply be. In brief, dip coating involves immersing a preheated part in a liquified plastisol and heat curing it to set the coating. The most common technique for plastic dip coating is the hot dip method, resulting. Plastic Dip Coating Process.

From www.youtube.com

What is Dip Coating? YouTube Plastic Dip Coating Process Applying liquid polymers or plastics to a workpiece through methods like dipping or immersion is known as plastic coating. Plastic dip coating is a process that involves immersing a preheated part into liquid plastisol to form a plastic coating that can add protection and aesthetics to most metal. The most common technique for plastic dip coating is the hot dip. Plastic Dip Coating Process.

From www.researchgate.net

Schematics of the different stages of the dip coating process (30 Plastic Dip Coating Process It results in a durable, rubbery, flexible protective layer in varying thicknesses depending on the needs of your project. Applying liquid polymers or plastics to a workpiece through methods like dipping or immersion is known as plastic coating. In brief, dip coating involves immersing a preheated part in a liquified plastisol and heat curing it to set the coating. Conversely,. Plastic Dip Coating Process.

From www.youtube.com

Dip Coating Process YouTube Plastic Dip Coating Process Plastic dip coating is a process that involves immersing a preheated part into liquid plastisol to form a plastic coating that can add protection and aesthetics to most metal. It results in a durable, rubbery, flexible protective layer in varying thicknesses depending on the needs of your project. The most common technique for plastic dip coating is the hot dip. Plastic Dip Coating Process.

From www.iqsdirectory.com

Plastic Coating What Is It? How Does It Work? Process Plastic Dip Coating Process In brief, dip coating involves immersing a preheated part in a liquified plastisol and heat curing it to set the coating. Conversely, 3d objects can simply be. It results in a durable, rubbery, flexible protective layer in varying thicknesses depending on the needs of your project. The dip coating process is a method used to apply a uniform layer of. Plastic Dip Coating Process.

From www.iqsdirectory.com

Plastic Coating What Is It? How Does It Work? Process Plastic Dip Coating Process In brief, dip coating involves immersing a preheated part in a liquified plastisol and heat curing it to set the coating. It results in a durable, rubbery, flexible protective layer in varying thicknesses depending on the needs of your project. Plastic dip coating is a process that involves immersing a preheated part into liquid plastisol to form a plastic coating. Plastic Dip Coating Process.

From www.piper-plastics.com

Process of Dip Molded and Dip Coated Parts Piper Plastics Corp. Plastic Dip Coating Process Plastic dip coating is a process that involves immersing a preheated part into liquid plastisol to form a plastic coating that can add protection and aesthetics to most metal. The most common technique for plastic dip coating is the hot dip method, resulting in coatings from about 1/16 to 1/4 thick. Applying liquid polymers or plastics to a workpiece through. Plastic Dip Coating Process.