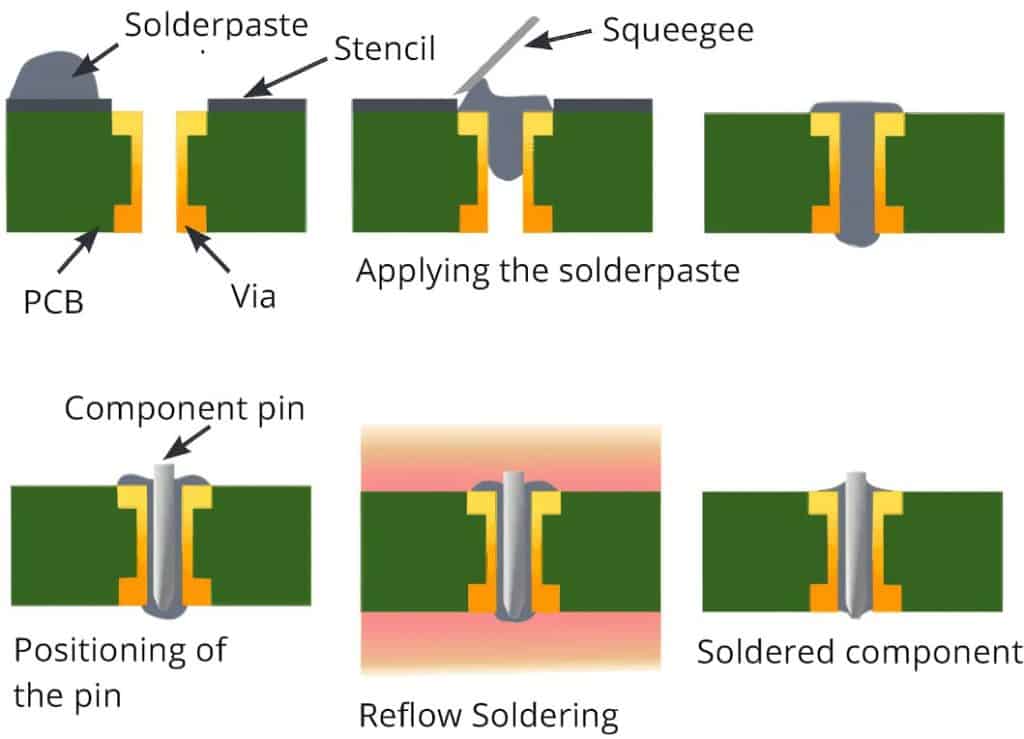

Solder Reflow Components . Reflow soldering involves several critical preparation and assembly steps to ensure precise placement and bonding of components. Reflow soldering is a type of soldering technique in which solder paste is applied over copper plates and melted to assemble electrical components on the board. The purpose of the reflow. In this, the board is subjected to controlled heat to prevent thermal shock. The pcb design and components’ layout. Reflow soldering is a pcb assembly and soldering technique that uses a convection air stream to create accurate and reliable soldering joints. Reflow soldering is a sophisticated and widely used technique in electronics manufacturing that facilitates the precise and. Knowing the reflow process and ways the oven effects soldering results is critical to consistent smt production. The components are placed on the pcb, where solder paste has been applied, and the assembly is then heated in a reflow oven. Reflow soldering is a process used to attach electronic components to pcb by melting solder paste. This article provides a detailed overview of the solder reflow process, types of reflow ovens, temperature profiles, solder paste.

from www.raypcb.com

The components are placed on the pcb, where solder paste has been applied, and the assembly is then heated in a reflow oven. Reflow soldering is a process used to attach electronic components to pcb by melting solder paste. The pcb design and components’ layout. This article provides a detailed overview of the solder reflow process, types of reflow ovens, temperature profiles, solder paste. Reflow soldering involves several critical preparation and assembly steps to ensure precise placement and bonding of components. Reflow soldering is a type of soldering technique in which solder paste is applied over copper plates and melted to assemble electrical components on the board. Reflow soldering is a pcb assembly and soldering technique that uses a convection air stream to create accurate and reliable soldering joints. Reflow soldering is a sophisticated and widely used technique in electronics manufacturing that facilitates the precise and. Knowing the reflow process and ways the oven effects soldering results is critical to consistent smt production. The purpose of the reflow.

What is Pin in Paste (PiP) Soldering Technology RAYPCB

Solder Reflow Components Reflow soldering is a type of soldering technique in which solder paste is applied over copper plates and melted to assemble electrical components on the board. Reflow soldering is a process used to attach electronic components to pcb by melting solder paste. Reflow soldering is a sophisticated and widely used technique in electronics manufacturing that facilitates the precise and. Knowing the reflow process and ways the oven effects soldering results is critical to consistent smt production. Reflow soldering involves several critical preparation and assembly steps to ensure precise placement and bonding of components. In this, the board is subjected to controlled heat to prevent thermal shock. The purpose of the reflow. The pcb design and components’ layout. This article provides a detailed overview of the solder reflow process, types of reflow ovens, temperature profiles, solder paste. The components are placed on the pcb, where solder paste has been applied, and the assembly is then heated in a reflow oven. Reflow soldering is a pcb assembly and soldering technique that uses a convection air stream to create accurate and reliable soldering joints. Reflow soldering is a type of soldering technique in which solder paste is applied over copper plates and melted to assemble electrical components on the board.

From www.circuits-diy.com

SMT PCB Reflow Soldering Process Everything You need to Know Solder Reflow Components The purpose of the reflow. In this, the board is subjected to controlled heat to prevent thermal shock. The pcb design and components’ layout. The components are placed on the pcb, where solder paste has been applied, and the assembly is then heated in a reflow oven. Reflow soldering is a pcb assembly and soldering technique that uses a convection. Solder Reflow Components.

From www.cambridge-sensotec.co.uk

Detecting residual oxygen within solder reflow Cambridge Sensotec Solder Reflow Components This article provides a detailed overview of the solder reflow process, types of reflow ovens, temperature profiles, solder paste. Reflow soldering is a pcb assembly and soldering technique that uses a convection air stream to create accurate and reliable soldering joints. Reflow soldering is a process used to attach electronic components to pcb by melting solder paste. The purpose of. Solder Reflow Components.

From www.pcbaaa.com

3 SMT Welding Processes Reflow Soldering, Wave Soldering and Through Solder Reflow Components Reflow soldering involves several critical preparation and assembly steps to ensure precise placement and bonding of components. This article provides a detailed overview of the solder reflow process, types of reflow ovens, temperature profiles, solder paste. Reflow soldering is a process used to attach electronic components to pcb by melting solder paste. Reflow soldering is a pcb assembly and soldering. Solder Reflow Components.

From www.youtube.com

SMD Soldering using Soldering Iron Tutorial How to Solder SMD Solder Reflow Components The pcb design and components’ layout. Reflow soldering is a pcb assembly and soldering technique that uses a convection air stream to create accurate and reliable soldering joints. In this, the board is subjected to controlled heat to prevent thermal shock. Reflow soldering involves several critical preparation and assembly steps to ensure precise placement and bonding of components. Reflow soldering. Solder Reflow Components.

From www.youtube.com

Reflow soldering of QFP leads Surface Mount Process YouTube Solder Reflow Components Reflow soldering is a pcb assembly and soldering technique that uses a convection air stream to create accurate and reliable soldering joints. Reflow soldering is a sophisticated and widely used technique in electronics manufacturing that facilitates the precise and. Reflow soldering is a type of soldering technique in which solder paste is applied over copper plates and melted to assemble. Solder Reflow Components.

From www.ptr-hartmann.com

Reflow Soldering PTR HARTMANN Solder Reflow Components Reflow soldering is a process used to attach electronic components to pcb by melting solder paste. The purpose of the reflow. Knowing the reflow process and ways the oven effects soldering results is critical to consistent smt production. Reflow soldering involves several critical preparation and assembly steps to ensure precise placement and bonding of components. In this, the board is. Solder Reflow Components.

From www.pcbaaa.com

Reflow Soldering vs Wave Soldering An Indepth Guide IBE Electronics Solder Reflow Components Reflow soldering is a process used to attach electronic components to pcb by melting solder paste. The pcb design and components’ layout. Reflow soldering is a sophisticated and widely used technique in electronics manufacturing that facilitates the precise and. In this, the board is subjected to controlled heat to prevent thermal shock. The purpose of the reflow. Reflow soldering is. Solder Reflow Components.

From www.linkedin.com

Through Hole Component Soldering with the eCreflow Mate Solder Reflow Components The components are placed on the pcb, where solder paste has been applied, and the assembly is then heated in a reflow oven. Reflow soldering is a sophisticated and widely used technique in electronics manufacturing that facilitates the precise and. Reflow soldering is a pcb assembly and soldering technique that uses a convection air stream to create accurate and reliable. Solder Reflow Components.

From www.7pcb.com

How the modern solder reflow oven works? Bittele Solder Reflow Components Reflow soldering is a pcb assembly and soldering technique that uses a convection air stream to create accurate and reliable soldering joints. Knowing the reflow process and ways the oven effects soldering results is critical to consistent smt production. The purpose of the reflow. Reflow soldering is a type of soldering technique in which solder paste is applied over copper. Solder Reflow Components.

From www.techspray.com

Repairing PCBA by Adjusting Solder Reflow Profile & Other Process Solder Reflow Components Reflow soldering involves several critical preparation and assembly steps to ensure precise placement and bonding of components. The components are placed on the pcb, where solder paste has been applied, and the assembly is then heated in a reflow oven. Reflow soldering is a type of soldering technique in which solder paste is applied over copper plates and melted to. Solder Reflow Components.

From www.mokotechnology.com

Everything You Need To Know About PCB Soldering MOKO Technology Solder Reflow Components The purpose of the reflow. Reflow soldering involves several critical preparation and assembly steps to ensure precise placement and bonding of components. Knowing the reflow process and ways the oven effects soldering results is critical to consistent smt production. The pcb design and components’ layout. In this, the board is subjected to controlled heat to prevent thermal shock. The components. Solder Reflow Components.

From www.dreamstime.com

Solder Reflow Furnace Attaching Many Tiny Electrical Components To Solder Reflow Components Reflow soldering is a sophisticated and widely used technique in electronics manufacturing that facilitates the precise and. Reflow soldering is a type of soldering technique in which solder paste is applied over copper plates and melted to assemble electrical components on the board. Reflow soldering is a process used to attach electronic components to pcb by melting solder paste. The. Solder Reflow Components.

From www.youtube.com

SMD Soldering 1 QFN and Reflow Components YouTube Solder Reflow Components Reflow soldering is a process used to attach electronic components to pcb by melting solder paste. The pcb design and components’ layout. In this, the board is subjected to controlled heat to prevent thermal shock. This article provides a detailed overview of the solder reflow process, types of reflow ovens, temperature profiles, solder paste. Reflow soldering is a type of. Solder Reflow Components.

From www.smt11.com

Smt Reflow Solder Oven For Soldering Components Buy Reflow Oven,Smt Solder Reflow Components This article provides a detailed overview of the solder reflow process, types of reflow ovens, temperature profiles, solder paste. The purpose of the reflow. Reflow soldering is a pcb assembly and soldering technique that uses a convection air stream to create accurate and reliable soldering joints. Reflow soldering is a type of soldering technique in which solder paste is applied. Solder Reflow Components.

From www.reed-sensor.com

Reflow Soldering of Reed Switches Solder Reflow Components Knowing the reflow process and ways the oven effects soldering results is critical to consistent smt production. Reflow soldering is a type of soldering technique in which solder paste is applied over copper plates and melted to assemble electrical components on the board. Reflow soldering is a sophisticated and widely used technique in electronics manufacturing that facilitates the precise and.. Solder Reflow Components.

From www.researchgate.net

Procedure for assembling a single BGA structure solder joint by Solder Reflow Components This article provides a detailed overview of the solder reflow process, types of reflow ovens, temperature profiles, solder paste. Reflow soldering involves several critical preparation and assembly steps to ensure precise placement and bonding of components. In this, the board is subjected to controlled heat to prevent thermal shock. Reflow soldering is a sophisticated and widely used technique in electronics. Solder Reflow Components.

From globalhac.weebly.com

Reflow solder globalhac Solder Reflow Components The components are placed on the pcb, where solder paste has been applied, and the assembly is then heated in a reflow oven. The pcb design and components’ layout. Reflow soldering is a sophisticated and widely used technique in electronics manufacturing that facilitates the precise and. Reflow soldering is a process used to attach electronic components to pcb by melting. Solder Reflow Components.

From experience.molex.com

Application and the Solder Processes Solder Reflow Components Reflow soldering is a sophisticated and widely used technique in electronics manufacturing that facilitates the precise and. Knowing the reflow process and ways the oven effects soldering results is critical to consistent smt production. The components are placed on the pcb, where solder paste has been applied, and the assembly is then heated in a reflow oven. Reflow soldering involves. Solder Reflow Components.

From www.electronicsandyou.com

Basic Soldering Guide How to Solder Electronic Components Solder Reflow Components Reflow soldering is a pcb assembly and soldering technique that uses a convection air stream to create accurate and reliable soldering joints. Knowing the reflow process and ways the oven effects soldering results is critical to consistent smt production. The pcb design and components’ layout. Reflow soldering is a type of soldering technique in which solder paste is applied over. Solder Reflow Components.

From www.davidhaillant.com

How to Hand Solder SMD Electronic things… and stuff Solder Reflow Components The pcb design and components’ layout. In this, the board is subjected to controlled heat to prevent thermal shock. Knowing the reflow process and ways the oven effects soldering results is critical to consistent smt production. Reflow soldering is a process used to attach electronic components to pcb by melting solder paste. Reflow soldering is a sophisticated and widely used. Solder Reflow Components.

From www.finepowertools.com

Reflow Soldering Guide. Process, Oven and Advantages Solder Reflow Components Reflow soldering is a sophisticated and widely used technique in electronics manufacturing that facilitates the precise and. In this, the board is subjected to controlled heat to prevent thermal shock. Reflow soldering is a pcb assembly and soldering technique that uses a convection air stream to create accurate and reliable soldering joints. Reflow soldering involves several critical preparation and assembly. Solder Reflow Components.

From www.acd-gruppe.de

Reflow Soldering And More Our Soldering Processes For SMT Soldering Solder Reflow Components Reflow soldering is a process used to attach electronic components to pcb by melting solder paste. This article provides a detailed overview of the solder reflow process, types of reflow ovens, temperature profiles, solder paste. The pcb design and components’ layout. Knowing the reflow process and ways the oven effects soldering results is critical to consistent smt production. Reflow soldering. Solder Reflow Components.

From www.mokotechnology.com

9 Common SMD Components You Must Know Solder Reflow Components This article provides a detailed overview of the solder reflow process, types of reflow ovens, temperature profiles, solder paste. Reflow soldering is a pcb assembly and soldering technique that uses a convection air stream to create accurate and reliable soldering joints. Reflow soldering is a sophisticated and widely used technique in electronics manufacturing that facilitates the precise and. Reflow soldering. Solder Reflow Components.

From in.pinterest.com

Reflow soldering is a process in which a solder paste (a sticky mixture Solder Reflow Components The purpose of the reflow. This article provides a detailed overview of the solder reflow process, types of reflow ovens, temperature profiles, solder paste. Reflow soldering is a process used to attach electronic components to pcb by melting solder paste. The pcb design and components’ layout. The components are placed on the pcb, where solder paste has been applied, and. Solder Reflow Components.

From amadaweldtech.com

Hot Bar Soldering Machine Reflow Soldering AMADA WELD TECH Solder Reflow Components Reflow soldering is a sophisticated and widely used technique in electronics manufacturing that facilitates the precise and. In this, the board is subjected to controlled heat to prevent thermal shock. The purpose of the reflow. Reflow soldering is a process used to attach electronic components to pcb by melting solder paste. Reflow soldering involves several critical preparation and assembly steps. Solder Reflow Components.

From www.newburyelectronics.co.uk

What Is Reflow Soldering? News Newbury Electronics Solder Reflow Components The purpose of the reflow. This article provides a detailed overview of the solder reflow process, types of reflow ovens, temperature profiles, solder paste. The pcb design and components’ layout. Reflow soldering is a type of soldering technique in which solder paste is applied over copper plates and melted to assemble electrical components on the board. Reflow soldering is a. Solder Reflow Components.

From www.wevolver.com

Solder Reflow An InDepth Guide to the Process and Techniques Solder Reflow Components Reflow soldering involves several critical preparation and assembly steps to ensure precise placement and bonding of components. The pcb design and components’ layout. Reflow soldering is a type of soldering technique in which solder paste is applied over copper plates and melted to assemble electrical components on the board. The components are placed on the pcb, where solder paste has. Solder Reflow Components.

From piektraining.com

Wave and Reflow Soldering PIEK Solder Reflow Components The pcb design and components’ layout. This article provides a detailed overview of the solder reflow process, types of reflow ovens, temperature profiles, solder paste. Knowing the reflow process and ways the oven effects soldering results is critical to consistent smt production. Reflow soldering is a type of soldering technique in which solder paste is applied over copper plates and. Solder Reflow Components.

From www.youtube.com

How to do SMD Reflow Soldering properly! Hot Air VS Sand VS Reflow Solder Reflow Components Knowing the reflow process and ways the oven effects soldering results is critical to consistent smt production. Reflow soldering is a sophisticated and widely used technique in electronics manufacturing that facilitates the precise and. Reflow soldering is a pcb assembly and soldering technique that uses a convection air stream to create accurate and reliable soldering joints. The purpose of the. Solder Reflow Components.

From www.mintecinno.com

Mastering Reflow Soldering A Comprehensive Guide Mintec Solder Reflow Components The purpose of the reflow. Reflow soldering is a sophisticated and widely used technique in electronics manufacturing that facilitates the precise and. Reflow soldering is a type of soldering technique in which solder paste is applied over copper plates and melted to assemble electrical components on the board. The components are placed on the pcb, where solder paste has been. Solder Reflow Components.

From fctsolder.com

reflow Solder Paste, Solder Flux FCT Solder Solder Reflow Components In this, the board is subjected to controlled heat to prevent thermal shock. Reflow soldering is a pcb assembly and soldering technique that uses a convection air stream to create accurate and reliable soldering joints. Knowing the reflow process and ways the oven effects soldering results is critical to consistent smt production. Reflow soldering involves several critical preparation and assembly. Solder Reflow Components.

From dokumen.tips

(PDF) Solder Reflow Failures in Electronic Components during Solder Reflow Components The purpose of the reflow. The components are placed on the pcb, where solder paste has been applied, and the assembly is then heated in a reflow oven. In this, the board is subjected to controlled heat to prevent thermal shock. The pcb design and components’ layout. Reflow soldering is a type of soldering technique in which solder paste is. Solder Reflow Components.

From www.pinterest.com

What is Reflow Soldering and Wave Soldering? Soldering, Circuit board Solder Reflow Components Reflow soldering is a sophisticated and widely used technique in electronics manufacturing that facilitates the precise and. This article provides a detailed overview of the solder reflow process, types of reflow ovens, temperature profiles, solder paste. Reflow soldering is a process used to attach electronic components to pcb by melting solder paste. The purpose of the reflow. Reflow soldering involves. Solder Reflow Components.

From www.wevolver.com

Solder Reflow An InDepth Guide to the Process and Techniques Solder Reflow Components Reflow soldering is a pcb assembly and soldering technique that uses a convection air stream to create accurate and reliable soldering joints. Reflow soldering is a process used to attach electronic components to pcb by melting solder paste. Reflow soldering is a type of soldering technique in which solder paste is applied over copper plates and melted to assemble electrical. Solder Reflow Components.

From www.raypcb.com

What is Pin in Paste (PiP) Soldering Technology RAYPCB Solder Reflow Components Reflow soldering involves several critical preparation and assembly steps to ensure precise placement and bonding of components. This article provides a detailed overview of the solder reflow process, types of reflow ovens, temperature profiles, solder paste. Reflow soldering is a process used to attach electronic components to pcb by melting solder paste. Reflow soldering is a pcb assembly and soldering. Solder Reflow Components.