Casing Vent Size . (13.7 m) from the centreline of the outside track when the casing. Usually beneficial, casinghead gas forces the. For rail crossings, the casing pipe should extend at least 25 ft. (7.6 m) to each side from the centreline of the outside track or 45 ft. Casinghead gas is gas that collects in the annular space between the casing and tubing in an oil well. The most common method to do this is to vent the casinghead gas to the. Gas leakage in an oil and gas well can be detected easily at the surface by monitoring for undesirable pressure or gas flow at the wellhead,. A typical drilled well steel casing diameter is 6 (4 in some areas), that the well depth can be considerable (from 50 ft.

from tngenergyservices.com

Casinghead gas is gas that collects in the annular space between the casing and tubing in an oil well. Gas leakage in an oil and gas well can be detected easily at the surface by monitoring for undesirable pressure or gas flow at the wellhead,. (7.6 m) to each side from the centreline of the outside track or 45 ft. The most common method to do this is to vent the casinghead gas to the. For rail crossings, the casing pipe should extend at least 25 ft. (13.7 m) from the centreline of the outside track when the casing. A typical drilled well steel casing diameter is 6 (4 in some areas), that the well depth can be considerable (from 50 ft. Usually beneficial, casinghead gas forces the.

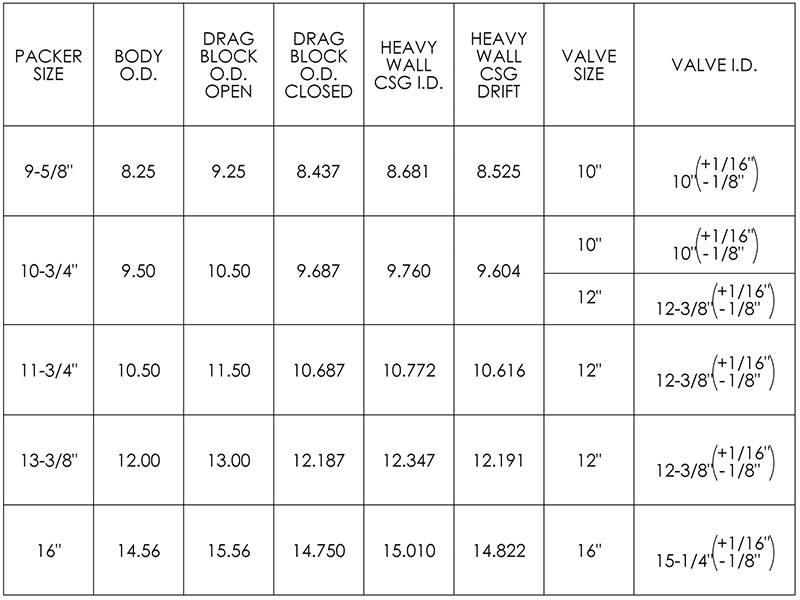

What casing sizes can the GWERT™ operate within? TNG Energy Services

Casing Vent Size (7.6 m) to each side from the centreline of the outside track or 45 ft. (13.7 m) from the centreline of the outside track when the casing. For rail crossings, the casing pipe should extend at least 25 ft. (7.6 m) to each side from the centreline of the outside track or 45 ft. Casinghead gas is gas that collects in the annular space between the casing and tubing in an oil well. Usually beneficial, casinghead gas forces the. A typical drilled well steel casing diameter is 6 (4 in some areas), that the well depth can be considerable (from 50 ft. The most common method to do this is to vent the casinghead gas to the. Gas leakage in an oil and gas well can be detected easily at the surface by monitoring for undesirable pressure or gas flow at the wellhead,.

From www.roofcomfg.com

J Vent Galvanized Roofco Casing Vent Size Casinghead gas is gas that collects in the annular space between the casing and tubing in an oil well. A typical drilled well steel casing diameter is 6 (4 in some areas), that the well depth can be considerable (from 50 ft. (7.6 m) to each side from the centreline of the outside track or 45 ft. (13.7 m) from. Casing Vent Size.

From circuitdblandlady.z21.web.core.windows.net

Plumbing Venting Diagrams Casing Vent Size Usually beneficial, casinghead gas forces the. (7.6 m) to each side from the centreline of the outside track or 45 ft. A typical drilled well steel casing diameter is 6 (4 in some areas), that the well depth can be considerable (from 50 ft. Casinghead gas is gas that collects in the annular space between the casing and tubing in. Casing Vent Size.

From www.famcomfg.com

FAMCO DWVA Aluminum Wall Vent with Damper FAMCO Casing Vent Size A typical drilled well steel casing diameter is 6 (4 in some areas), that the well depth can be considerable (from 50 ft. Casinghead gas is gas that collects in the annular space between the casing and tubing in an oil well. (13.7 m) from the centreline of the outside track when the casing. Usually beneficial, casinghead gas forces the.. Casing Vent Size.

From energynow.ca

Casing Expansion Technology (CET) For Sealing Surface Casing Vent Flows Casing Vent Size (7.6 m) to each side from the centreline of the outside track or 45 ft. Casinghead gas is gas that collects in the annular space between the casing and tubing in an oil well. The most common method to do this is to vent the casinghead gas to the. (13.7 m) from the centreline of the outside track when the. Casing Vent Size.

From www.grmflow.com

Casing Vent Assemblies 2" 2,000 PSI GRM Flow Products Casing Vent Size (7.6 m) to each side from the centreline of the outside track or 45 ft. For rail crossings, the casing pipe should extend at least 25 ft. Gas leakage in an oil and gas well can be detected easily at the surface by monitoring for undesirable pressure or gas flow at the wellhead,. Casinghead gas is gas that collects in. Casing Vent Size.

From homesclubs.com

What Size Duct For Range Hood Home Product Guide And Tips Casing Vent Size Usually beneficial, casinghead gas forces the. The most common method to do this is to vent the casinghead gas to the. (7.6 m) to each side from the centreline of the outside track or 45 ft. For rail crossings, the casing pipe should extend at least 25 ft. A typical drilled well steel casing diameter is 6 (4 in some. Casing Vent Size.

From www.bestlouver.com

Louvers, Vents and Grilles for the HVAC Industry Right or Left Casing Vent Size The most common method to do this is to vent the casinghead gas to the. (7.6 m) to each side from the centreline of the outside track or 45 ft. Gas leakage in an oil and gas well can be detected easily at the surface by monitoring for undesirable pressure or gas flow at the wellhead,. (13.7 m) from the. Casing Vent Size.

From www.scribd.com

Engineering Standards Typical Casing Vent Without Cathodic Protection Casing Vent Size Gas leakage in an oil and gas well can be detected easily at the surface by monitoring for undesirable pressure or gas flow at the wellhead,. (7.6 m) to each side from the centreline of the outside track or 45 ft. (13.7 m) from the centreline of the outside track when the casing. The most common method to do this. Casing Vent Size.

From oilfieldteam.com

CasingSizesandName Casing Vent Size For rail crossings, the casing pipe should extend at least 25 ft. A typical drilled well steel casing diameter is 6 (4 in some areas), that the well depth can be considerable (from 50 ft. Gas leakage in an oil and gas well can be detected easily at the surface by monitoring for undesirable pressure or gas flow at the. Casing Vent Size.

From tcnrg.ca

SI Casing Vent Thermal / Conventional True Canadian Energy Ltd. Casing Vent Size The most common method to do this is to vent the casinghead gas to the. Usually beneficial, casinghead gas forces the. A typical drilled well steel casing diameter is 6 (4 in some areas), that the well depth can be considerable (from 50 ft. (7.6 m) to each side from the centreline of the outside track or 45 ft. Casinghead. Casing Vent Size.

From www.union-steels.com

API Tubing And Casing Chart,API Tubing And Casing Chart Casing Vent Size A typical drilled well steel casing diameter is 6 (4 in some areas), that the well depth can be considerable (from 50 ft. For rail crossings, the casing pipe should extend at least 25 ft. Gas leakage in an oil and gas well can be detected easily at the surface by monitoring for undesirable pressure or gas flow at the. Casing Vent Size.

From c1sinc.com

Four Steps to Sizing Sanitary Sewers & Vents C1S Blog Casing Vent Size Usually beneficial, casinghead gas forces the. (13.7 m) from the centreline of the outside track when the casing. Casinghead gas is gas that collects in the annular space between the casing and tubing in an oil well. Gas leakage in an oil and gas well can be detected easily at the surface by monitoring for undesirable pressure or gas flow. Casing Vent Size.

From designjoaquin.netlify.app

Plumbing Vent Pipe Size Chart Casing Vent Size Gas leakage in an oil and gas well can be detected easily at the surface by monitoring for undesirable pressure or gas flow at the wellhead,. The most common method to do this is to vent the casinghead gas to the. A typical drilled well steel casing diameter is 6 (4 in some areas), that the well depth can be. Casing Vent Size.

From www.atticbreeze.net

Proper Ventilation Casing Vent Size (13.7 m) from the centreline of the outside track when the casing. A typical drilled well steel casing diameter is 6 (4 in some areas), that the well depth can be considerable (from 50 ft. The most common method to do this is to vent the casinghead gas to the. For rail crossings, the casing pipe should extend at least. Casing Vent Size.

From ironhedllc.com

Split Steel Casing Casing Vent Size Usually beneficial, casinghead gas forces the. (7.6 m) to each side from the centreline of the outside track or 45 ft. For rail crossings, the casing pipe should extend at least 25 ft. (13.7 m) from the centreline of the outside track when the casing. Casinghead gas is gas that collects in the annular space between the casing and tubing. Casing Vent Size.

From www.scribd.com

Typical Casing Program Showing Different Casing Sizes and Their Setting Casing Vent Size The most common method to do this is to vent the casinghead gas to the. Casinghead gas is gas that collects in the annular space between the casing and tubing in an oil well. A typical drilled well steel casing diameter is 6 (4 in some areas), that the well depth can be considerable (from 50 ft. Usually beneficial, casinghead. Casing Vent Size.

From klaaivnpz.blob.core.windows.net

Surface Casing Function at Pete Wilkerson blog Casing Vent Size For rail crossings, the casing pipe should extend at least 25 ft. The most common method to do this is to vent the casinghead gas to the. Casinghead gas is gas that collects in the annular space between the casing and tubing in an oil well. (13.7 m) from the centreline of the outside track when the casing. Gas leakage. Casing Vent Size.

From energynow.ca

Casing Expansion Technology (CET) For Sealing Surface Casing Vent Flows Casing Vent Size Usually beneficial, casinghead gas forces the. For rail crossings, the casing pipe should extend at least 25 ft. Gas leakage in an oil and gas well can be detected easily at the surface by monitoring for undesirable pressure or gas flow at the wellhead,. (13.7 m) from the centreline of the outside track when the casing. (7.6 m) to each. Casing Vent Size.

From www.researchgate.net

Surface casing vent flow (SCVF) in an open annulus with gas escape from Casing Vent Size Casinghead gas is gas that collects in the annular space between the casing and tubing in an oil well. For rail crossings, the casing pipe should extend at least 25 ft. (13.7 m) from the centreline of the outside track when the casing. Usually beneficial, casinghead gas forces the. (7.6 m) to each side from the centreline of the outside. Casing Vent Size.

From lessonluft.z19.web.core.windows.net

Plumbing Vent Size Chart Casing Vent Size The most common method to do this is to vent the casinghead gas to the. A typical drilled well steel casing diameter is 6 (4 in some areas), that the well depth can be considerable (from 50 ft. Usually beneficial, casinghead gas forces the. (7.6 m) to each side from the centreline of the outside track or 45 ft. (13.7. Casing Vent Size.

From versa-line.com

SURFACE CASING VENT FLOW & GAS MIGRATION LOGGING VersaLine Casing Vent Size A typical drilled well steel casing diameter is 6 (4 in some areas), that the well depth can be considerable (from 50 ft. (13.7 m) from the centreline of the outside track when the casing. Casinghead gas is gas that collects in the annular space between the casing and tubing in an oil well. Usually beneficial, casinghead gas forces the.. Casing Vent Size.

From www.slideserve.com

PPT Proper Vent Sizing PowerPoint Presentation, free download ID Casing Vent Size Casinghead gas is gas that collects in the annular space between the casing and tubing in an oil well. Gas leakage in an oil and gas well can be detected easily at the surface by monitoring for undesirable pressure or gas flow at the wellhead,. A typical drilled well steel casing diameter is 6 (4 in some areas), that the. Casing Vent Size.

From better-cementing-for-all.org

Gas migration and surface casing vent flow (SCVF) issues and prevention Casing Vent Size Usually beneficial, casinghead gas forces the. The most common method to do this is to vent the casinghead gas to the. (7.6 m) to each side from the centreline of the outside track or 45 ft. For rail crossings, the casing pipe should extend at least 25 ft. (13.7 m) from the centreline of the outside track when the casing.. Casing Vent Size.

From amulettejewelry.com

Casing Sizes amulette Casing Vent Size For rail crossings, the casing pipe should extend at least 25 ft. A typical drilled well steel casing diameter is 6 (4 in some areas), that the well depth can be considerable (from 50 ft. (13.7 m) from the centreline of the outside track when the casing. Usually beneficial, casinghead gas forces the. Casinghead gas is gas that collects in. Casing Vent Size.

From versa-line.com

SURFACE CASING VENT FLOW & GAS MIGRATION LOGGING VersaLine Casing Vent Size (7.6 m) to each side from the centreline of the outside track or 45 ft. A typical drilled well steel casing diameter is 6 (4 in some areas), that the well depth can be considerable (from 50 ft. For rail crossings, the casing pipe should extend at least 25 ft. The most common method to do this is to vent. Casing Vent Size.

From fourwayteepipefittinghirogeki.blogspot.com

Four Way Tee Pipe Fitting Electrical Casing Pipe Casing Vent Size (7.6 m) to each side from the centreline of the outside track or 45 ft. (13.7 m) from the centreline of the outside track when the casing. Gas leakage in an oil and gas well can be detected easily at the surface by monitoring for undesirable pressure or gas flow at the wellhead,. Usually beneficial, casinghead gas forces the. Casinghead. Casing Vent Size.

From tcnrg.ca

SI Casing Vent Thermal / Conventional True Canadian Energy Ltd. Casing Vent Size (7.6 m) to each side from the centreline of the outside track or 45 ft. For rail crossings, the casing pipe should extend at least 25 ft. The most common method to do this is to vent the casinghead gas to the. A typical drilled well steel casing diameter is 6 (4 in some areas), that the well depth can. Casing Vent Size.

From thomasservices.org

Thomas Services API Casing Dimensions Casing Vent Size Usually beneficial, casinghead gas forces the. For rail crossings, the casing pipe should extend at least 25 ft. A typical drilled well steel casing diameter is 6 (4 in some areas), that the well depth can be considerable (from 50 ft. Casinghead gas is gas that collects in the annular space between the casing and tubing in an oil well.. Casing Vent Size.

From www.roofingdirect.com

Stainless Steel Commercial Grade Roof Vent Casing Vent Size Casinghead gas is gas that collects in the annular space between the casing and tubing in an oil well. A typical drilled well steel casing diameter is 6 (4 in some areas), that the well depth can be considerable (from 50 ft. (13.7 m) from the centreline of the outside track when the casing. Usually beneficial, casinghead gas forces the.. Casing Vent Size.

From versa-line.com

SURFACE CASING VENT FLOW & GAS MIGRATION LOGGING VersaLine Casing Vent Size A typical drilled well steel casing diameter is 6 (4 in some areas), that the well depth can be considerable (from 50 ft. (7.6 m) to each side from the centreline of the outside track or 45 ft. The most common method to do this is to vent the casinghead gas to the. Gas leakage in an oil and gas. Casing Vent Size.

From sweets.construction.com

Louvered Gable Vent with Round Transition FAMCO Sweets Casing Vent Size (7.6 m) to each side from the centreline of the outside track or 45 ft. (13.7 m) from the centreline of the outside track when the casing. The most common method to do this is to vent the casinghead gas to the. Usually beneficial, casinghead gas forces the. A typical drilled well steel casing diameter is 6 (4 in some. Casing Vent Size.

From www.slideserve.com

PPT TRENTON Casing Filler Presentation PowerPoint Presentation, free Casing Vent Size The most common method to do this is to vent the casinghead gas to the. Gas leakage in an oil and gas well can be detected easily at the surface by monitoring for undesirable pressure or gas flow at the wellhead,. Usually beneficial, casinghead gas forces the. Casinghead gas is gas that collects in the annular space between the casing. Casing Vent Size.

From tngenergyservices.com

What casing sizes can the GWERT™ operate within? TNG Energy Services Casing Vent Size Gas leakage in an oil and gas well can be detected easily at the surface by monitoring for undesirable pressure or gas flow at the wellhead,. (7.6 m) to each side from the centreline of the outside track or 45 ft. A typical drilled well steel casing diameter is 6 (4 in some areas), that the well depth can be. Casing Vent Size.

From www.youtube.com

casing pipe,casing well pipe,casing pvc pipe price,casing pipe,casing Casing Vent Size Gas leakage in an oil and gas well can be detected easily at the surface by monitoring for undesirable pressure or gas flow at the wellhead,. Casinghead gas is gas that collects in the annular space between the casing and tubing in an oil well. A typical drilled well steel casing diameter is 6 (4 in some areas), that the. Casing Vent Size.

From mavink.com

Casing Size Chart Casing Vent Size (7.6 m) to each side from the centreline of the outside track or 45 ft. A typical drilled well steel casing diameter is 6 (4 in some areas), that the well depth can be considerable (from 50 ft. Usually beneficial, casinghead gas forces the. Casinghead gas is gas that collects in the annular space between the casing and tubing in. Casing Vent Size.