Laser Ablation Tool . Laser ablation, commonly referred to as laser cleaning, is a proven method for surface cleaning and preparation, coating removal, and surface roughness modification for manufacturing,. Norton sandblasting offers equipment utilizing an innovative laser ablation technology for industrial surface treatment, cleaning and paint removal. Laser cleaning — also known as laser ablation — uses thousands of focused laser light pulses per second to remove contaminants from products. Laser cleaning effectively removes surface contaminants by directing a focused laser beam onto a targeted area to ablate unwanted. Specializing in custom laser processing solutions, we use advanced pulsed laser technology for superior surface treatment and material ablation. Laser ablation works by sending nanosecond laser pulses into a surface, creating shockwaves that eject contaminants or turn them into gas.

from news.europawire.eu

Laser cleaning — also known as laser ablation — uses thousands of focused laser light pulses per second to remove contaminants from products. Laser ablation, commonly referred to as laser cleaning, is a proven method for surface cleaning and preparation, coating removal, and surface roughness modification for manufacturing,. Norton sandblasting offers equipment utilizing an innovative laser ablation technology for industrial surface treatment, cleaning and paint removal. Laser cleaning effectively removes surface contaminants by directing a focused laser beam onto a targeted area to ablate unwanted. Specializing in custom laser processing solutions, we use advanced pulsed laser technology for superior surface treatment and material ablation. Laser ablation works by sending nanosecond laser pulses into a surface, creating shockwaves that eject contaminants or turn them into gas.

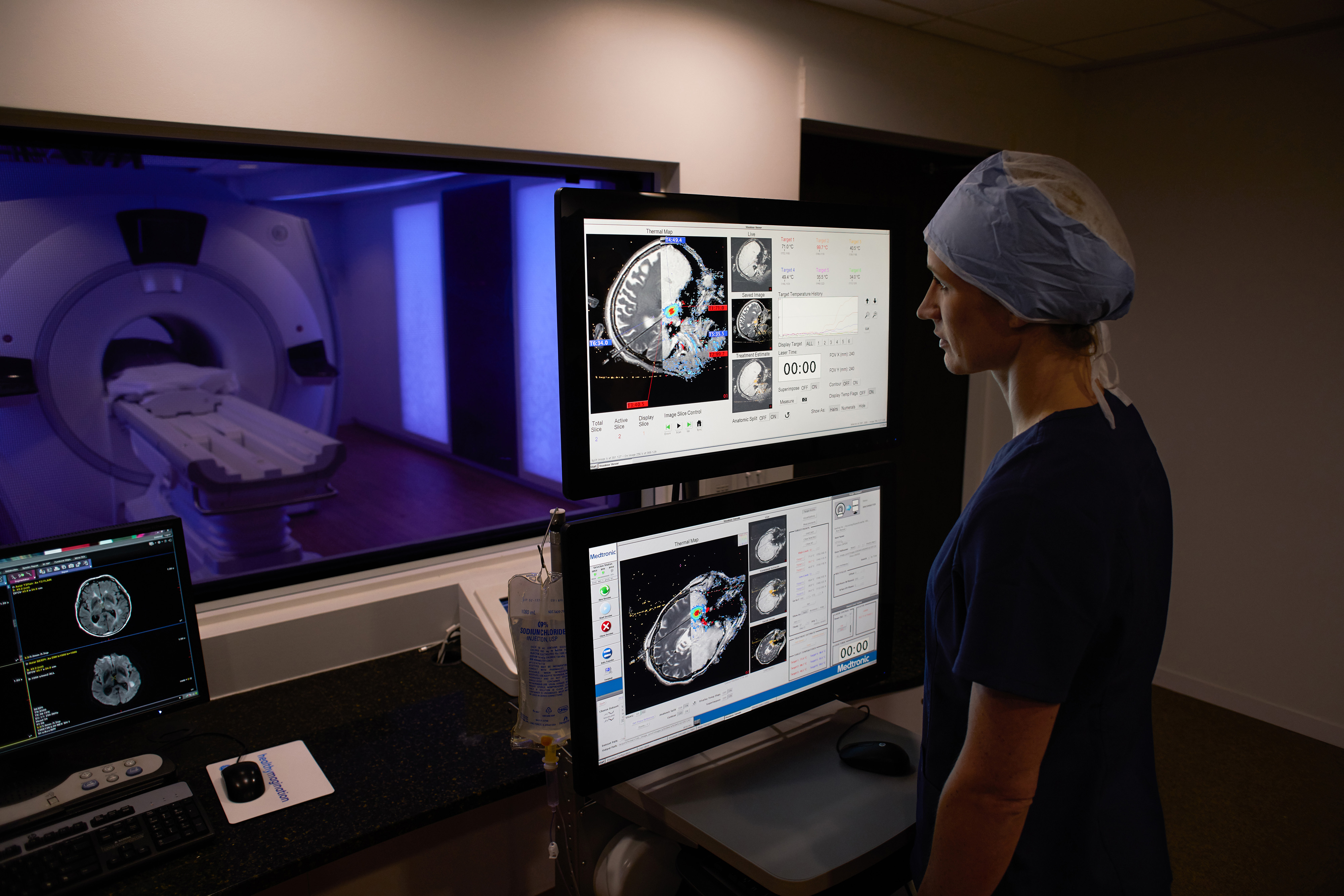

Medtronic announces first procedure using Visualase(TM) MRIGuided

Laser Ablation Tool Specializing in custom laser processing solutions, we use advanced pulsed laser technology for superior surface treatment and material ablation. Laser cleaning — also known as laser ablation — uses thousands of focused laser light pulses per second to remove contaminants from products. Laser cleaning effectively removes surface contaminants by directing a focused laser beam onto a targeted area to ablate unwanted. Specializing in custom laser processing solutions, we use advanced pulsed laser technology for superior surface treatment and material ablation. Laser ablation, commonly referred to as laser cleaning, is a proven method for surface cleaning and preparation, coating removal, and surface roughness modification for manufacturing,. Norton sandblasting offers equipment utilizing an innovative laser ablation technology for industrial surface treatment, cleaning and paint removal. Laser ablation works by sending nanosecond laser pulses into a surface, creating shockwaves that eject contaminants or turn them into gas.

From www.researchgate.net

Figure S6. Laser ablation tool configuration including source, beam Laser Ablation Tool Laser ablation works by sending nanosecond laser pulses into a surface, creating shockwaves that eject contaminants or turn them into gas. Laser ablation, commonly referred to as laser cleaning, is a proven method for surface cleaning and preparation, coating removal, and surface roughness modification for manufacturing,. Laser cleaning effectively removes surface contaminants by directing a focused laser beam onto a. Laser Ablation Tool.

From www.ramstar.net

How Laser Ablation Leads to Tight Tolerances & Custom Solutions Laser Ablation Tool Laser cleaning — also known as laser ablation — uses thousands of focused laser light pulses per second to remove contaminants from products. Norton sandblasting offers equipment utilizing an innovative laser ablation technology for industrial surface treatment, cleaning and paint removal. Laser ablation, commonly referred to as laser cleaning, is a proven method for surface cleaning and preparation, coating removal,. Laser Ablation Tool.

From mellowpine.com

Laser Ablation Explained Advantages & Disadvantages MellowPine Laser Ablation Tool Norton sandblasting offers equipment utilizing an innovative laser ablation technology for industrial surface treatment, cleaning and paint removal. Specializing in custom laser processing solutions, we use advanced pulsed laser technology for superior surface treatment and material ablation. Laser ablation works by sending nanosecond laser pulses into a surface, creating shockwaves that eject contaminants or turn them into gas. Laser cleaning. Laser Ablation Tool.

From www.coherent.com

What is Laser Ablation? Definition and Meaning Coherent Laser Ablation Tool Specializing in custom laser processing solutions, we use advanced pulsed laser technology for superior surface treatment and material ablation. Laser cleaning effectively removes surface contaminants by directing a focused laser beam onto a targeted area to ablate unwanted. Laser ablation works by sending nanosecond laser pulses into a surface, creating shockwaves that eject contaminants or turn them into gas. Norton. Laser Ablation Tool.

From staubinc.com

Clean Laser Ablation System CL 1000 Staub Precision Machine Laser Ablation Tool Laser ablation, commonly referred to as laser cleaning, is a proven method for surface cleaning and preparation, coating removal, and surface roughness modification for manufacturing,. Laser cleaning — also known as laser ablation — uses thousands of focused laser light pulses per second to remove contaminants from products. Laser ablation works by sending nanosecond laser pulses into a surface, creating. Laser Ablation Tool.

From www.hylax.com

Laser ablation Hylax Technology Laser Solution Provider Laser Ablation Tool Laser cleaning — also known as laser ablation — uses thousands of focused laser light pulses per second to remove contaminants from products. Specializing in custom laser processing solutions, we use advanced pulsed laser technology for superior surface treatment and material ablation. Laser ablation works by sending nanosecond laser pulses into a surface, creating shockwaves that eject contaminants or turn. Laser Ablation Tool.

From www.researchgate.net

Laser ablation principle. Download Scientific Diagram Laser Ablation Tool Laser cleaning effectively removes surface contaminants by directing a focused laser beam onto a targeted area to ablate unwanted. Laser cleaning — also known as laser ablation — uses thousands of focused laser light pulses per second to remove contaminants from products. Specializing in custom laser processing solutions, we use advanced pulsed laser technology for superior surface treatment and material. Laser Ablation Tool.

From staubinc.com

CL Clean Laser Ablation_2 Staub Precision Machine, Inc. Laser Ablation Tool Laser cleaning effectively removes surface contaminants by directing a focused laser beam onto a targeted area to ablate unwanted. Laser cleaning — also known as laser ablation — uses thousands of focused laser light pulses per second to remove contaminants from products. Laser ablation works by sending nanosecond laser pulses into a surface, creating shockwaves that eject contaminants or turn. Laser Ablation Tool.

From www.grinding.com

Tool Laser Ablation UNITED GRINDING North America Laser Ablation Tool Laser cleaning — also known as laser ablation — uses thousands of focused laser light pulses per second to remove contaminants from products. Specializing in custom laser processing solutions, we use advanced pulsed laser technology for superior surface treatment and material ablation. Laser cleaning effectively removes surface contaminants by directing a focused laser beam onto a targeted area to ablate. Laser Ablation Tool.

From www.researchgate.net

1 Laser Ablation Process Download Scientific Diagram Laser Ablation Tool Laser ablation, commonly referred to as laser cleaning, is a proven method for surface cleaning and preparation, coating removal, and surface roughness modification for manufacturing,. Laser cleaning effectively removes surface contaminants by directing a focused laser beam onto a targeted area to ablate unwanted. Norton sandblasting offers equipment utilizing an innovative laser ablation technology for industrial surface treatment, cleaning and. Laser Ablation Tool.

From www.heatsign.com

What is Industrial Laser Ablation? Heatsign Laser Ablation Tool Laser cleaning effectively removes surface contaminants by directing a focused laser beam onto a targeted area to ablate unwanted. Norton sandblasting offers equipment utilizing an innovative laser ablation technology for industrial surface treatment, cleaning and paint removal. Laser ablation works by sending nanosecond laser pulses into a surface, creating shockwaves that eject contaminants or turn them into gas. Laser ablation,. Laser Ablation Tool.

From www.youtube.com

CL1000 Clean Laser Ablation Tool Paint Removal Deburring Laser Ablation Tool Specializing in custom laser processing solutions, we use advanced pulsed laser technology for superior surface treatment and material ablation. Laser cleaning effectively removes surface contaminants by directing a focused laser beam onto a targeted area to ablate unwanted. Laser ablation works by sending nanosecond laser pulses into a surface, creating shockwaves that eject contaminants or turn them into gas. Laser. Laser Ablation Tool.

From www.iqsdirectory.com

Laser Marking & Engraving Machinery What Is It? Types, Uses Laser Ablation Tool Laser ablation, commonly referred to as laser cleaning, is a proven method for surface cleaning and preparation, coating removal, and surface roughness modification for manufacturing,. Laser cleaning — also known as laser ablation — uses thousands of focused laser light pulses per second to remove contaminants from products. Laser ablation works by sending nanosecond laser pulses into a surface, creating. Laser Ablation Tool.

From staubinc.com

Clean Laser Ablation System CL 1000 Staub Precision Machine Laser Ablation Tool Laser cleaning effectively removes surface contaminants by directing a focused laser beam onto a targeted area to ablate unwanted. Laser ablation, commonly referred to as laser cleaning, is a proven method for surface cleaning and preparation, coating removal, and surface roughness modification for manufacturing,. Laser ablation works by sending nanosecond laser pulses into a surface, creating shockwaves that eject contaminants. Laser Ablation Tool.

From stock.adobe.com

Step by step Visualase is an MRIguided laser ablation system used to Laser Ablation Tool Norton sandblasting offers equipment utilizing an innovative laser ablation technology for industrial surface treatment, cleaning and paint removal. Laser cleaning effectively removes surface contaminants by directing a focused laser beam onto a targeted area to ablate unwanted. Laser cleaning — also known as laser ablation — uses thousands of focused laser light pulses per second to remove contaminants from products.. Laser Ablation Tool.

From www.youtube.com

Laser Ablation in Tool Manufacturing A DMG MORI Success Story with our Laser Ablation Tool Laser ablation works by sending nanosecond laser pulses into a surface, creating shockwaves that eject contaminants or turn them into gas. Laser ablation, commonly referred to as laser cleaning, is a proven method for surface cleaning and preparation, coating removal, and surface roughness modification for manufacturing,. Laser cleaning — also known as laser ablation — uses thousands of focused laser. Laser Ablation Tool.

From www.researchgate.net

Laser ablation setup [43]. Download Scientific Diagram Laser Ablation Tool Laser cleaning effectively removes surface contaminants by directing a focused laser beam onto a targeted area to ablate unwanted. Norton sandblasting offers equipment utilizing an innovative laser ablation technology for industrial surface treatment, cleaning and paint removal. Specializing in custom laser processing solutions, we use advanced pulsed laser technology for superior surface treatment and material ablation. Laser ablation works by. Laser Ablation Tool.

From www.monteris.com

The NeuroBlate® Laser Ablation System Monteris Laser Ablation Tool Norton sandblasting offers equipment utilizing an innovative laser ablation technology for industrial surface treatment, cleaning and paint removal. Laser ablation, commonly referred to as laser cleaning, is a proven method for surface cleaning and preparation, coating removal, and surface roughness modification for manufacturing,. Laser cleaning effectively removes surface contaminants by directing a focused laser beam onto a targeted area to. Laser Ablation Tool.

From www.mdpi.com

JCM Free FullText Cold Ablation RobotGuided Laser Osteotome Laser Ablation Tool Laser ablation, commonly referred to as laser cleaning, is a proven method for surface cleaning and preparation, coating removal, and surface roughness modification for manufacturing,. Laser cleaning — also known as laser ablation — uses thousands of focused laser light pulses per second to remove contaminants from products. Specializing in custom laser processing solutions, we use advanced pulsed laser technology. Laser Ablation Tool.

From www.researchgate.net

Schematic diagram of laser ablation experimental setup. Inset shows the Laser Ablation Tool Laser ablation, commonly referred to as laser cleaning, is a proven method for surface cleaning and preparation, coating removal, and surface roughness modification for manufacturing,. Laser cleaning effectively removes surface contaminants by directing a focused laser beam onto a targeted area to ablate unwanted. Norton sandblasting offers equipment utilizing an innovative laser ablation technology for industrial surface treatment, cleaning and. Laser Ablation Tool.

From www.mdpi.com

Materials Free FullText Effect of Femtosecond Laser Processing Laser Ablation Tool Laser ablation works by sending nanosecond laser pulses into a surface, creating shockwaves that eject contaminants or turn them into gas. Laser cleaning — also known as laser ablation — uses thousands of focused laser light pulses per second to remove contaminants from products. Laser ablation, commonly referred to as laser cleaning, is a proven method for surface cleaning and. Laser Ablation Tool.

From www.alliedscientificpro.com

Laser Ablation and Laser Cleaning Allied Scientific Pro Laser Ablation Tool Laser cleaning — also known as laser ablation — uses thousands of focused laser light pulses per second to remove contaminants from products. Laser cleaning effectively removes surface contaminants by directing a focused laser beam onto a targeted area to ablate unwanted. Laser ablation works by sending nanosecond laser pulses into a surface, creating shockwaves that eject contaminants or turn. Laser Ablation Tool.

From www.hylax.com

Laser ablation Hylax Technology Laser Solution Provider Laser Ablation Tool Norton sandblasting offers equipment utilizing an innovative laser ablation technology for industrial surface treatment, cleaning and paint removal. Laser ablation works by sending nanosecond laser pulses into a surface, creating shockwaves that eject contaminants or turn them into gas. Specializing in custom laser processing solutions, we use advanced pulsed laser technology for superior surface treatment and material ablation. Laser cleaning. Laser Ablation Tool.

From staubinc.com

CL Clean Laser Ablation_3 Staub Precision Machine, Inc. Laser Ablation Tool Specializing in custom laser processing solutions, we use advanced pulsed laser technology for superior surface treatment and material ablation. Laser ablation works by sending nanosecond laser pulses into a surface, creating shockwaves that eject contaminants or turn them into gas. Laser ablation, commonly referred to as laser cleaning, is a proven method for surface cleaning and preparation, coating removal, and. Laser Ablation Tool.

From www.youtube.com

CL1000 Clean Laser Ablation Tool Paint Removal 2 Deburring Laser Ablation Tool Laser ablation works by sending nanosecond laser pulses into a surface, creating shockwaves that eject contaminants or turn them into gas. Norton sandblasting offers equipment utilizing an innovative laser ablation technology for industrial surface treatment, cleaning and paint removal. Specializing in custom laser processing solutions, we use advanced pulsed laser technology for superior surface treatment and material ablation. Laser cleaning. Laser Ablation Tool.

From fgga.univie.ac.at

Laser Ablation System Laser Ablation Tool Specializing in custom laser processing solutions, we use advanced pulsed laser technology for superior surface treatment and material ablation. Laser cleaning effectively removes surface contaminants by directing a focused laser beam onto a targeted area to ablate unwanted. Laser cleaning — also known as laser ablation — uses thousands of focused laser light pulses per second to remove contaminants from. Laser Ablation Tool.

From danyelaser.en.made-in-china.com

Stationary Fractional CO2 Laser Ablation Equipment Laser to Remove Acne Laser Ablation Tool Norton sandblasting offers equipment utilizing an innovative laser ablation technology for industrial surface treatment, cleaning and paint removal. Laser ablation, commonly referred to as laser cleaning, is a proven method for surface cleaning and preparation, coating removal, and surface roughness modification for manufacturing,. Laser cleaning — also known as laser ablation — uses thousands of focused laser light pulses per. Laser Ablation Tool.

From www.frontiersin.org

Frontiers Stereotactic Laser Ablation for Medically Intractable Laser Ablation Tool Specializing in custom laser processing solutions, we use advanced pulsed laser technology for superior surface treatment and material ablation. Laser ablation works by sending nanosecond laser pulses into a surface, creating shockwaves that eject contaminants or turn them into gas. Laser cleaning — also known as laser ablation — uses thousands of focused laser light pulses per second to remove. Laser Ablation Tool.

From sigmatech.com.ph

Analyte HE High Energy Excimer Laser Ablation System Laser Ablation Tool Laser cleaning effectively removes surface contaminants by directing a focused laser beam onto a targeted area to ablate unwanted. Specializing in custom laser processing solutions, we use advanced pulsed laser technology for superior surface treatment and material ablation. Norton sandblasting offers equipment utilizing an innovative laser ablation technology for industrial surface treatment, cleaning and paint removal. Laser ablation works by. Laser Ablation Tool.

From www.researchgate.net

Picture of the laser ablation setup. Download Scientific Diagram Laser Ablation Tool Laser cleaning effectively removes surface contaminants by directing a focused laser beam onto a targeted area to ablate unwanted. Laser cleaning — also known as laser ablation — uses thousands of focused laser light pulses per second to remove contaminants from products. Laser ablation, commonly referred to as laser cleaning, is a proven method for surface cleaning and preparation, coating. Laser Ablation Tool.

From www.youtube.com

MRIGuided Laser Ablation Using the Visualase® HCA Healthcare UK Laser Ablation Tool Laser cleaning effectively removes surface contaminants by directing a focused laser beam onto a targeted area to ablate unwanted. Laser cleaning — also known as laser ablation — uses thousands of focused laser light pulses per second to remove contaminants from products. Norton sandblasting offers equipment utilizing an innovative laser ablation technology for industrial surface treatment, cleaning and paint removal.. Laser Ablation Tool.

From senstech.ch

New femtosecond laser secures production Laser Ablation Tool Laser cleaning — also known as laser ablation — uses thousands of focused laser light pulses per second to remove contaminants from products. Laser ablation, commonly referred to as laser cleaning, is a proven method for surface cleaning and preparation, coating removal, and surface roughness modification for manufacturing,. Laser ablation works by sending nanosecond laser pulses into a surface, creating. Laser Ablation Tool.

From opli.net

Laser Ablation for Automatic Hypotube Coating Removal and Advanced Laser Ablation Tool Laser cleaning effectively removes surface contaminants by directing a focused laser beam onto a targeted area to ablate unwanted. Laser ablation works by sending nanosecond laser pulses into a surface, creating shockwaves that eject contaminants or turn them into gas. Specializing in custom laser processing solutions, we use advanced pulsed laser technology for superior surface treatment and material ablation. Laser. Laser Ablation Tool.

From news.europawire.eu

Medtronic announces first procedure using Visualase(TM) MRIGuided Laser Ablation Tool Laser cleaning effectively removes surface contaminants by directing a focused laser beam onto a targeted area to ablate unwanted. Laser cleaning — also known as laser ablation — uses thousands of focused laser light pulses per second to remove contaminants from products. Norton sandblasting offers equipment utilizing an innovative laser ablation technology for industrial surface treatment, cleaning and paint removal.. Laser Ablation Tool.

From www.kenelec.com.au

ESL NWRFemto Laser Ablation System Kenelec Scientific Laser Ablation Tool Laser cleaning effectively removes surface contaminants by directing a focused laser beam onto a targeted area to ablate unwanted. Laser ablation, commonly referred to as laser cleaning, is a proven method for surface cleaning and preparation, coating removal, and surface roughness modification for manufacturing,. Laser cleaning — also known as laser ablation — uses thousands of focused laser light pulses. Laser Ablation Tool.