Brinell Hardness Test Results . The brinell method is a static hardness testing method, which can be characterised as follows: A chart is then used to convert the averaged diameter measurement to a brinell hardness number. The brinell hardness hbw results from the quotient of the applied test force f (in newtons n) and the surface area of the residual indentation on the specimen (the projection of the indentation). Brinell hardness tester holds significant importance in today's industrial landscape, where understanding material properties is crucial for. In brinell hardness testing, a hard metal ball (carbide ball) is pressed into the material surface to be tested within approximately 10 seconds as the force increases. The brinell test uses a larger spherical indenter, usually made of steel or carbide, and applies a heavy load to the. Test forces range from 500 to 3000 kgf. It is one of the standardised procedures (iso.

from www.tec-science.com

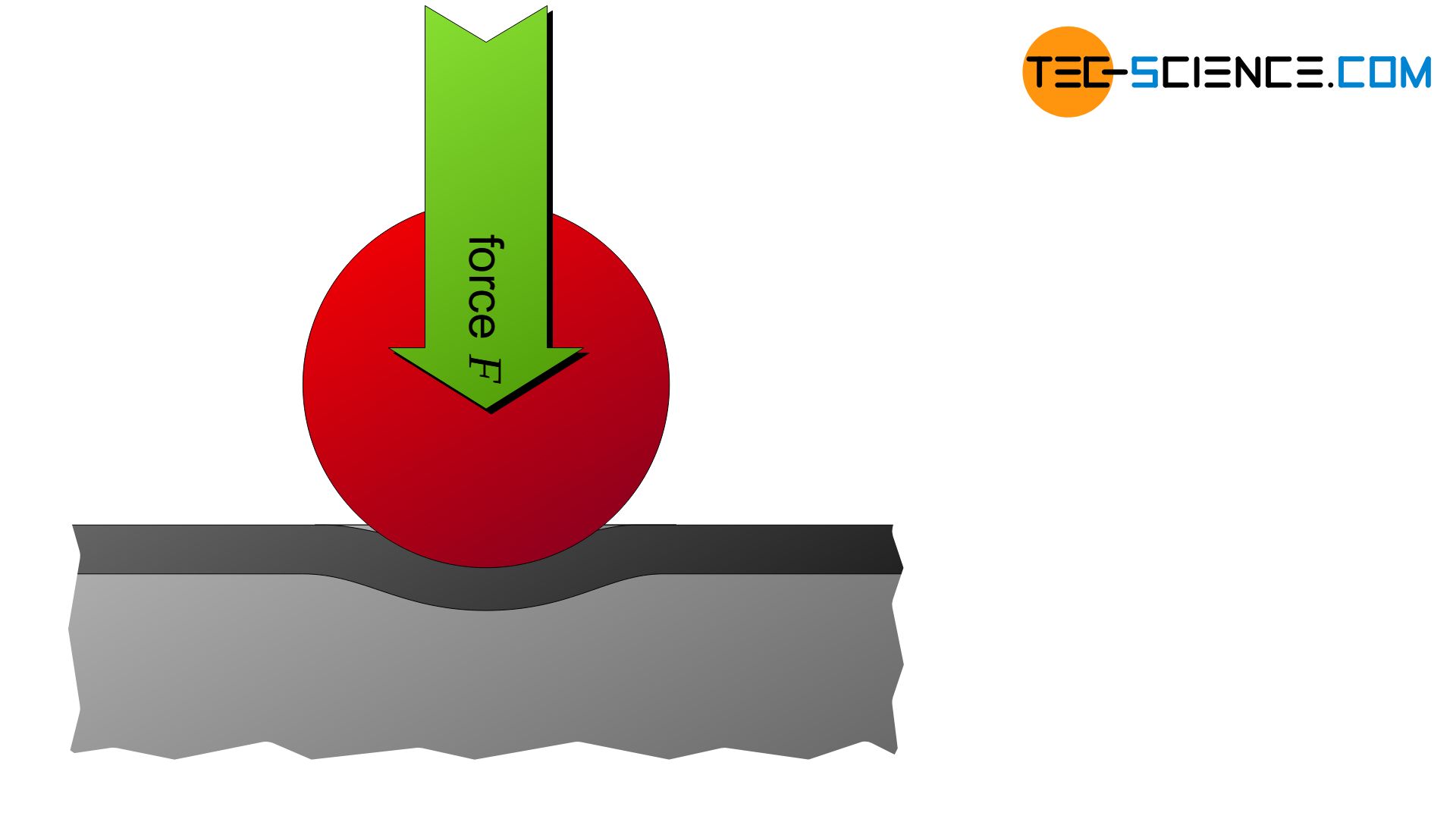

In brinell hardness testing, a hard metal ball (carbide ball) is pressed into the material surface to be tested within approximately 10 seconds as the force increases. A chart is then used to convert the averaged diameter measurement to a brinell hardness number. It is one of the standardised procedures (iso. The brinell hardness hbw results from the quotient of the applied test force f (in newtons n) and the surface area of the residual indentation on the specimen (the projection of the indentation). Test forces range from 500 to 3000 kgf. The brinell test uses a larger spherical indenter, usually made of steel or carbide, and applies a heavy load to the. Brinell hardness tester holds significant importance in today's industrial landscape, where understanding material properties is crucial for. The brinell method is a static hardness testing method, which can be characterised as follows:

Brinell hardness test tecscience

Brinell Hardness Test Results Brinell hardness tester holds significant importance in today's industrial landscape, where understanding material properties is crucial for. Test forces range from 500 to 3000 kgf. The brinell test uses a larger spherical indenter, usually made of steel or carbide, and applies a heavy load to the. A chart is then used to convert the averaged diameter measurement to a brinell hardness number. The brinell hardness hbw results from the quotient of the applied test force f (in newtons n) and the surface area of the residual indentation on the specimen (the projection of the indentation). It is one of the standardised procedures (iso. In brinell hardness testing, a hard metal ball (carbide ball) is pressed into the material surface to be tested within approximately 10 seconds as the force increases. The brinell method is a static hardness testing method, which can be characterised as follows: Brinell hardness tester holds significant importance in today's industrial landscape, where understanding material properties is crucial for.

From www.youtube.com

Brinell Hardness Test Explained Material Science YouTube Brinell Hardness Test Results The brinell method is a static hardness testing method, which can be characterised as follows: Test forces range from 500 to 3000 kgf. Brinell hardness tester holds significant importance in today's industrial landscape, where understanding material properties is crucial for. A chart is then used to convert the averaged diameter measurement to a brinell hardness number. In brinell hardness testing,. Brinell Hardness Test Results.

From www.tec-science.com

Brinell hardness test tecscience Brinell Hardness Test Results A chart is then used to convert the averaged diameter measurement to a brinell hardness number. The brinell hardness hbw results from the quotient of the applied test force f (in newtons n) and the surface area of the residual indentation on the specimen (the projection of the indentation). Brinell hardness tester holds significant importance in today's industrial landscape, where. Brinell Hardness Test Results.

From whatispiping.com

What is Brinell Hardness Test? Procedure, Formula, Standards What Is Brinell Hardness Test Results It is one of the standardised procedures (iso. The brinell method is a static hardness testing method, which can be characterised as follows: A chart is then used to convert the averaged diameter measurement to a brinell hardness number. The brinell test uses a larger spherical indenter, usually made of steel or carbide, and applies a heavy load to the.. Brinell Hardness Test Results.

From www.clemex.com

Microhardness (Brinell) Clemex Brinell Hardness Test Results It is one of the standardised procedures (iso. Brinell hardness tester holds significant importance in today's industrial landscape, where understanding material properties is crucial for. The brinell test uses a larger spherical indenter, usually made of steel or carbide, and applies a heavy load to the. Test forces range from 500 to 3000 kgf. A chart is then used to. Brinell Hardness Test Results.

From www.struers.com

Brinell Hardness Testing. Brinell Hardness Test Results In brinell hardness testing, a hard metal ball (carbide ball) is pressed into the material surface to be tested within approximately 10 seconds as the force increases. It is one of the standardised procedures (iso. The brinell method is a static hardness testing method, which can be characterised as follows: The brinell test uses a larger spherical indenter, usually made. Brinell Hardness Test Results.

From www.zwickroell.com

Brinell hardness testing ISO 6506, ASTM E10 ZwickRoell Brinell Hardness Test Results The brinell test uses a larger spherical indenter, usually made of steel or carbide, and applies a heavy load to the. It is one of the standardised procedures (iso. The brinell hardness hbw results from the quotient of the applied test force f (in newtons n) and the surface area of the residual indentation on the specimen (the projection of. Brinell Hardness Test Results.

From www.nextgentest.com

BrinGen Brinell Hardness Testing System Review Brinell Hardness Test Results The brinell method is a static hardness testing method, which can be characterised as follows: In brinell hardness testing, a hard metal ball (carbide ball) is pressed into the material surface to be tested within approximately 10 seconds as the force increases. The brinell hardness hbw results from the quotient of the applied test force f (in newtons n) and. Brinell Hardness Test Results.

From www.youtube.com

Brinell Hardness Test YouTube Brinell Hardness Test Results Brinell hardness tester holds significant importance in today's industrial landscape, where understanding material properties is crucial for. In brinell hardness testing, a hard metal ball (carbide ball) is pressed into the material surface to be tested within approximately 10 seconds as the force increases. Test forces range from 500 to 3000 kgf. The brinell hardness hbw results from the quotient. Brinell Hardness Test Results.

From www.tec-science.com

Brinell hardness test tecscience Brinell Hardness Test Results The brinell method is a static hardness testing method, which can be characterised as follows: Brinell hardness tester holds significant importance in today's industrial landscape, where understanding material properties is crucial for. In brinell hardness testing, a hard metal ball (carbide ball) is pressed into the material surface to be tested within approximately 10 seconds as the force increases. The. Brinell Hardness Test Results.

From www.chegg.com

SCOPE The Brinell Hardness Test measures the Brinell Hardness Test Results It is one of the standardised procedures (iso. Brinell hardness tester holds significant importance in today's industrial landscape, where understanding material properties is crucial for. Test forces range from 500 to 3000 kgf. A chart is then used to convert the averaged diameter measurement to a brinell hardness number. The brinell hardness hbw results from the quotient of the applied. Brinell Hardness Test Results.

From www.hardnessgauge.com

Brinell Hardness Testing Hardness Tester Brinell Hardness Test Results Test forces range from 500 to 3000 kgf. The brinell method is a static hardness testing method, which can be characterised as follows: The brinell test uses a larger spherical indenter, usually made of steel or carbide, and applies a heavy load to the. A chart is then used to convert the averaged diameter measurement to a brinell hardness number.. Brinell Hardness Test Results.

From www.scribd.com

Brinell Test Hardness Materials Science Brinell Hardness Test Results The brinell method is a static hardness testing method, which can be characterised as follows: Brinell hardness tester holds significant importance in today's industrial landscape, where understanding material properties is crucial for. In brinell hardness testing, a hard metal ball (carbide ball) is pressed into the material surface to be tested within approximately 10 seconds as the force increases. It. Brinell Hardness Test Results.

From www.alphamedicalmanagement.com

SOLVED Calculate The Depth Of (h) For The, 58 OFF Brinell Hardness Test Results In brinell hardness testing, a hard metal ball (carbide ball) is pressed into the material surface to be tested within approximately 10 seconds as the force increases. The brinell method is a static hardness testing method, which can be characterised as follows: A chart is then used to convert the averaged diameter measurement to a brinell hardness number. The brinell. Brinell Hardness Test Results.

From www.researchgate.net

Brinell hardness results for red sandstone using a modified NCB cone Brinell Hardness Test Results The brinell method is a static hardness testing method, which can be characterised as follows: In brinell hardness testing, a hard metal ball (carbide ball) is pressed into the material surface to be tested within approximately 10 seconds as the force increases. A chart is then used to convert the averaged diameter measurement to a brinell hardness number. Brinell hardness. Brinell Hardness Test Results.

From www.researchgate.net

Duncan's Test Results for Mean Values of Density and Brinell Hardness Brinell Hardness Test Results The brinell method is a static hardness testing method, which can be characterised as follows: In brinell hardness testing, a hard metal ball (carbide ball) is pressed into the material surface to be tested within approximately 10 seconds as the force increases. It is one of the standardised procedures (iso. The brinell hardness hbw results from the quotient of the. Brinell Hardness Test Results.

From www.struers.com

Brinell Hardness Testing. Brinell Hardness Test Results In brinell hardness testing, a hard metal ball (carbide ball) is pressed into the material surface to be tested within approximately 10 seconds as the force increases. The brinell method is a static hardness testing method, which can be characterised as follows: Test forces range from 500 to 3000 kgf. A chart is then used to convert the averaged diameter. Brinell Hardness Test Results.

From www.slideshare.net

Brinell Hardness Testing Method Brinell Hardness Test Results Test forces range from 500 to 3000 kgf. It is one of the standardised procedures (iso. The brinell hardness hbw results from the quotient of the applied test force f (in newtons n) and the surface area of the residual indentation on the specimen (the projection of the indentation). Brinell hardness tester holds significant importance in today's industrial landscape, where. Brinell Hardness Test Results.

From www.researchgate.net

Graph for the Brinell Hardness Test Download Scientific Diagram Brinell Hardness Test Results The brinell method is a static hardness testing method, which can be characterised as follows: Test forces range from 500 to 3000 kgf. The brinell test uses a larger spherical indenter, usually made of steel or carbide, and applies a heavy load to the. It is one of the standardised procedures (iso. Brinell hardness tester holds significant importance in today's. Brinell Hardness Test Results.

From www.researchgate.net

Results of ANOVA of Brinell Hardness Values Download Scientific Diagram Brinell Hardness Test Results Brinell hardness tester holds significant importance in today's industrial landscape, where understanding material properties is crucial for. In brinell hardness testing, a hard metal ball (carbide ball) is pressed into the material surface to be tested within approximately 10 seconds as the force increases. Test forces range from 500 to 3000 kgf. It is one of the standardised procedures (iso.. Brinell Hardness Test Results.

From www.enggstudy.com

Brinell Hardness Test Methods, advantages, disadvantages, applications Brinell Hardness Test Results The brinell method is a static hardness testing method, which can be characterised as follows: A chart is then used to convert the averaged diameter measurement to a brinell hardness number. It is one of the standardised procedures (iso. In brinell hardness testing, a hard metal ball (carbide ball) is pressed into the material surface to be tested within approximately. Brinell Hardness Test Results.

From mech.poriyaan.in

Brinell Hardness Test Arrangement, Procedure, Formula, Calculation Brinell Hardness Test Results It is one of the standardised procedures (iso. The brinell test uses a larger spherical indenter, usually made of steel or carbide, and applies a heavy load to the. The brinell hardness hbw results from the quotient of the applied test force f (in newtons n) and the surface area of the residual indentation on the specimen (the projection of. Brinell Hardness Test Results.

From extrudesign.com

How Brinell Hardness Test is conducted? ExtruDesign Brinell Hardness Test Results The brinell method is a static hardness testing method, which can be characterised as follows: The brinell hardness hbw results from the quotient of the applied test force f (in newtons n) and the surface area of the residual indentation on the specimen (the projection of the indentation). It is one of the standardised procedures (iso. A chart is then. Brinell Hardness Test Results.

From swissproficiency.com

Brinell Hardness Testing Proficiency tests Brinell Hardness Test Results Brinell hardness tester holds significant importance in today's industrial landscape, where understanding material properties is crucial for. Test forces range from 500 to 3000 kgf. The brinell hardness hbw results from the quotient of the applied test force f (in newtons n) and the surface area of the residual indentation on the specimen (the projection of the indentation). It is. Brinell Hardness Test Results.

From www.youtube.com

Determining Brinell Hardness Using a Standard Non Destructive Brinell Brinell Hardness Test Results The brinell test uses a larger spherical indenter, usually made of steel or carbide, and applies a heavy load to the. The brinell method is a static hardness testing method, which can be characterised as follows: It is one of the standardised procedures (iso. Test forces range from 500 to 3000 kgf. Brinell hardness tester holds significant importance in today's. Brinell Hardness Test Results.

From metaltechnology.co.za

Brinell Hardness Test Metal Technology Engineering Brinell Hardness Test Results In brinell hardness testing, a hard metal ball (carbide ball) is pressed into the material surface to be tested within approximately 10 seconds as the force increases. The brinell test uses a larger spherical indenter, usually made of steel or carbide, and applies a heavy load to the. The brinell method is a static hardness testing method, which can be. Brinell Hardness Test Results.

From www.struers.com

Brinell Hardness Testing. Brinell Hardness Test Results The brinell method is a static hardness testing method, which can be characterised as follows: It is one of the standardised procedures (iso. In brinell hardness testing, a hard metal ball (carbide ball) is pressed into the material surface to be tested within approximately 10 seconds as the force increases. Brinell hardness tester holds significant importance in today's industrial landscape,. Brinell Hardness Test Results.

From www.youtube.com

Calculate the hardness of material using Brinell Hardness Tester in Brinell Hardness Test Results The brinell hardness hbw results from the quotient of the applied test force f (in newtons n) and the surface area of the residual indentation on the specimen (the projection of the indentation). The brinell test uses a larger spherical indenter, usually made of steel or carbide, and applies a heavy load to the. In brinell hardness testing, a hard. Brinell Hardness Test Results.

From www.researchgate.net

Brinell hardness measurement along the simulated sample Download Brinell Hardness Test Results Test forces range from 500 to 3000 kgf. A chart is then used to convert the averaged diameter measurement to a brinell hardness number. It is one of the standardised procedures (iso. The brinell hardness hbw results from the quotient of the applied test force f (in newtons n) and the surface area of the residual indentation on the specimen. Brinell Hardness Test Results.

From www.researchgate.net

Brinell hardness test methods [64]. Download Scientific Diagram Brinell Hardness Test Results A chart is then used to convert the averaged diameter measurement to a brinell hardness number. The brinell method is a static hardness testing method, which can be characterised as follows: The brinell hardness hbw results from the quotient of the applied test force f (in newtons n) and the surface area of the residual indentation on the specimen (the. Brinell Hardness Test Results.

From www.chegg.com

Solved EXPERTIVIEN BRINELL HARDNESS TEST RESULTS Table 1 Brinell Hardness Test Results Test forces range from 500 to 3000 kgf. The brinell method is a static hardness testing method, which can be characterised as follows: A chart is then used to convert the averaged diameter measurement to a brinell hardness number. The brinell test uses a larger spherical indenter, usually made of steel or carbide, and applies a heavy load to the.. Brinell Hardness Test Results.

From www.tec-science.com

Brinell hardness test tecscience Brinell Hardness Test Results Test forces range from 500 to 3000 kgf. The brinell method is a static hardness testing method, which can be characterised as follows: The brinell test uses a larger spherical indenter, usually made of steel or carbide, and applies a heavy load to the. The brinell hardness hbw results from the quotient of the applied test force f (in newtons. Brinell Hardness Test Results.

From www.metalsupermarkets.com

What are Brinell and Rockwell Hardness Measurements? Metal Supermarkets Brinell Hardness Test Results Test forces range from 500 to 3000 kgf. The brinell test uses a larger spherical indenter, usually made of steel or carbide, and applies a heavy load to the. In brinell hardness testing, a hard metal ball (carbide ball) is pressed into the material surface to be tested within approximately 10 seconds as the force increases. A chart is then. Brinell Hardness Test Results.

From www.tec-science.com

Brinell hardness test tecscience Brinell Hardness Test Results The brinell hardness hbw results from the quotient of the applied test force f (in newtons n) and the surface area of the residual indentation on the specimen (the projection of the indentation). In brinell hardness testing, a hard metal ball (carbide ball) is pressed into the material surface to be tested within approximately 10 seconds as the force increases.. Brinell Hardness Test Results.

From www.youtube.com

Brinell Hardness Test YouTube Brinell Hardness Test Results The brinell hardness hbw results from the quotient of the applied test force f (in newtons n) and the surface area of the residual indentation on the specimen (the projection of the indentation). Test forces range from 500 to 3000 kgf. A chart is then used to convert the averaged diameter measurement to a brinell hardness number. It is one. Brinell Hardness Test Results.

From www.tec-science.com

Brinell hardness test tecscience Brinell Hardness Test Results Brinell hardness tester holds significant importance in today's industrial landscape, where understanding material properties is crucial for. The brinell hardness hbw results from the quotient of the applied test force f (in newtons n) and the surface area of the residual indentation on the specimen (the projection of the indentation). A chart is then used to convert the averaged diameter. Brinell Hardness Test Results.