What Is A Die In Semiconductor Manufacturing . Wafer dicing, also called wafer sawing or wafer cutting, refers to the process whereby a silicon wafer is cut into individual components called die or chips. In the context of silicon wafers, it’s going to be made of silicon. Generally, the entire silicon wafer is called a wafer. After preparing semiconductor wafers and creating individual dies, the die. The die is the material that the circuit is made on. After the process flow, each unit will be diced and packaged. The semiconductor die, or chip, is a thin piece of silicon on which the components, such as transistors, diodes, resistors, and other. The process of wafer dicing enables manufacturers of integrated circuits (ics) and other semiconductor devices to harvest many individual dice from a single wafer. To make any chip, numerous processes play a role. Die bonding is a crucial step in semiconductor manufacturing. The die of a single unit before packaging is called die. Let’s discuss six critical semiconductor manufacturing steps: Dice are an especially important part of the manufacturing process. A die, in the context of integrated circuits, is a small block of semiconducting material on which a given functional circuit is fabricated. Deposition, photoresist, lithography, etch, ionization.

from present5.com

After the process flow, each unit will be diced and packaged. Wafer dicing, also called wafer sawing or wafer cutting, refers to the process whereby a silicon wafer is cut into individual components called die or chips. Let’s discuss six critical semiconductor manufacturing steps: The die of a single unit before packaging is called die. The process of wafer dicing enables manufacturers of integrated circuits (ics) and other semiconductor devices to harvest many individual dice from a single wafer. The die is the material that the circuit is made on. After preparing semiconductor wafers and creating individual dies, the die. In the context of silicon wafers, it’s going to be made of silicon. The semiconductor die, or chip, is a thin piece of silicon on which the components, such as transistors, diodes, resistors, and other. Die bonding is a crucial step in semiconductor manufacturing.

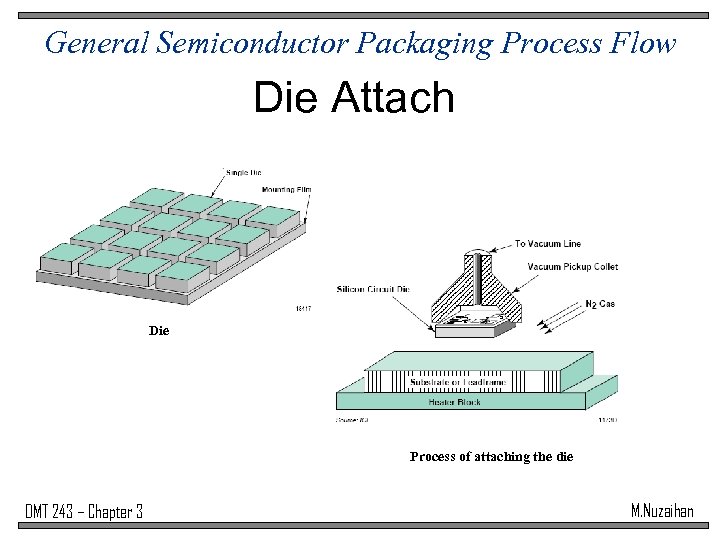

General Semiconductor Packaging Process Flow Wafer Backgrinding Die

What Is A Die In Semiconductor Manufacturing Generally, the entire silicon wafer is called a wafer. Deposition, photoresist, lithography, etch, ionization. Dice are an especially important part of the manufacturing process. Wafer dicing, also called wafer sawing or wafer cutting, refers to the process whereby a silicon wafer is cut into individual components called die or chips. In the context of silicon wafers, it’s going to be made of silicon. Die bonding is a crucial step in semiconductor manufacturing. The die of a single unit before packaging is called die. The die is the material that the circuit is made on. The semiconductor die, or chip, is a thin piece of silicon on which the components, such as transistors, diodes, resistors, and other. Let’s discuss six critical semiconductor manufacturing steps: A die, in the context of integrated circuits, is a small block of semiconducting material on which a given functional circuit is fabricated. After preparing semiconductor wafers and creating individual dies, the die. Generally, the entire silicon wafer is called a wafer. To make any chip, numerous processes play a role. After the process flow, each unit will be diced and packaged. The process of wafer dicing enables manufacturers of integrated circuits (ics) and other semiconductor devices to harvest many individual dice from a single wafer.

From fyotwweml.blob.core.windows.net

Semiconductor Production Process Explained at Joe Klassen blog What Is A Die In Semiconductor Manufacturing The die of a single unit before packaging is called die. The die is the material that the circuit is made on. The semiconductor die, or chip, is a thin piece of silicon on which the components, such as transistors, diodes, resistors, and other. Die bonding is a crucial step in semiconductor manufacturing. Wafer dicing, also called wafer sawing or. What Is A Die In Semiconductor Manufacturing.

From www.dreamstime.com

Silicon Die Extraction and Placement in Semiconductor Wafer What Is A Die In Semiconductor Manufacturing The die of a single unit before packaging is called die. A die, in the context of integrated circuits, is a small block of semiconducting material on which a given functional circuit is fabricated. Dice are an especially important part of the manufacturing process. Generally, the entire silicon wafer is called a wafer. Die bonding is a crucial step in. What Is A Die In Semiconductor Manufacturing.

From present5.com

General Semiconductor Packaging Process Flow Wafer Backgrinding Die What Is A Die In Semiconductor Manufacturing Dice are an especially important part of the manufacturing process. After the process flow, each unit will be diced and packaged. In the context of silicon wafers, it’s going to be made of silicon. To make any chip, numerous processes play a role. A die, in the context of integrated circuits, is a small block of semiconducting material on which. What Is A Die In Semiconductor Manufacturing.

From www.labmotionsystems.com

Semiconductor Industry Ultraprecision Machining LAB Motion Systems What Is A Die In Semiconductor Manufacturing To make any chip, numerous processes play a role. The semiconductor die, or chip, is a thin piece of silicon on which the components, such as transistors, diodes, resistors, and other. Generally, the entire silicon wafer is called a wafer. After the process flow, each unit will be diced and packaged. A die, in the context of integrated circuits, is. What Is A Die In Semiconductor Manufacturing.

From www.youtube.com

Semiconductor Packaging ASSEMBLY PROCESS FLOW YouTube What Is A Die In Semiconductor Manufacturing Die bonding is a crucial step in semiconductor manufacturing. The die is the material that the circuit is made on. After the process flow, each unit will be diced and packaged. Let’s discuss six critical semiconductor manufacturing steps: The process of wafer dicing enables manufacturers of integrated circuits (ics) and other semiconductor devices to harvest many individual dice from a. What Is A Die In Semiconductor Manufacturing.

From ar.inspiredpencil.com

Semiconductor Die What Is A Die In Semiconductor Manufacturing After preparing semiconductor wafers and creating individual dies, the die. Generally, the entire silicon wafer is called a wafer. A die, in the context of integrated circuits, is a small block of semiconducting material on which a given functional circuit is fabricated. Deposition, photoresist, lithography, etch, ionization. The die is the material that the circuit is made on. The process. What Is A Die In Semiconductor Manufacturing.

From nancy-rubin.com

What Is Semiconductor Manufacturing nancyrubin What Is A Die In Semiconductor Manufacturing The die of a single unit before packaging is called die. The semiconductor die, or chip, is a thin piece of silicon on which the components, such as transistors, diodes, resistors, and other. In the context of silicon wafers, it’s going to be made of silicon. Die bonding is a crucial step in semiconductor manufacturing. Wafer dicing, also called wafer. What Is A Die In Semiconductor Manufacturing.

From fyotwweml.blob.core.windows.net

Semiconductor Production Process Explained at Joe Klassen blog What Is A Die In Semiconductor Manufacturing Deposition, photoresist, lithography, etch, ionization. Die bonding is a crucial step in semiconductor manufacturing. Let’s discuss six critical semiconductor manufacturing steps: Dice are an especially important part of the manufacturing process. The semiconductor die, or chip, is a thin piece of silicon on which the components, such as transistors, diodes, resistors, and other. After preparing semiconductor wafers and creating individual. What Is A Die In Semiconductor Manufacturing.

From www.mdpi.com

Materials Free FullText HeatResistant Microporous Ag DieAttach What Is A Die In Semiconductor Manufacturing Die bonding is a crucial step in semiconductor manufacturing. To make any chip, numerous processes play a role. A die, in the context of integrated circuits, is a small block of semiconducting material on which a given functional circuit is fabricated. The semiconductor die, or chip, is a thin piece of silicon on which the components, such as transistors, diodes,. What Is A Die In Semiconductor Manufacturing.

From www.newwayairbearings.com

Semiconductor Shortage New Way Air Bearings What Is A Die In Semiconductor Manufacturing Dice are an especially important part of the manufacturing process. Deposition, photoresist, lithography, etch, ionization. Die bonding is a crucial step in semiconductor manufacturing. The process of wafer dicing enables manufacturers of integrated circuits (ics) and other semiconductor devices to harvest many individual dice from a single wafer. Wafer dicing, also called wafer sawing or wafer cutting, refers to the. What Is A Die In Semiconductor Manufacturing.

From present5.com

General Semiconductor Packaging Process Flow Wafer Backgrinding Die What Is A Die In Semiconductor Manufacturing The die of a single unit before packaging is called die. After preparing semiconductor wafers and creating individual dies, the die. To make any chip, numerous processes play a role. Deposition, photoresist, lithography, etch, ionization. Let’s discuss six critical semiconductor manufacturing steps: A die, in the context of integrated circuits, is a small block of semiconducting material on which a. What Is A Die In Semiconductor Manufacturing.

From artist-3d.com

A step by step to explain Semiconductor manufacturing processes Artist 3D What Is A Die In Semiconductor Manufacturing The die of a single unit before packaging is called die. Let’s discuss six critical semiconductor manufacturing steps: Wafer dicing, also called wafer sawing or wafer cutting, refers to the process whereby a silicon wafer is cut into individual components called die or chips. A die, in the context of integrated circuits, is a small block of semiconducting material on. What Is A Die In Semiconductor Manufacturing.

From www.researchgate.net

Semiconductor manufacturing steps. Download Scientific Diagram What Is A Die In Semiconductor Manufacturing Die bonding is a crucial step in semiconductor manufacturing. After preparing semiconductor wafers and creating individual dies, the die. Let’s discuss six critical semiconductor manufacturing steps: To make any chip, numerous processes play a role. After the process flow, each unit will be diced and packaged. The die is the material that the circuit is made on. Generally, the entire. What Is A Die In Semiconductor Manufacturing.

From microchipusa.com

A StepbyStep Guide to Semiconductor Manufacturing Microchip USA What Is A Die In Semiconductor Manufacturing In the context of silicon wafers, it’s going to be made of silicon. After the process flow, each unit will be diced and packaged. After preparing semiconductor wafers and creating individual dies, the die. The process of wafer dicing enables manufacturers of integrated circuits (ics) and other semiconductor devices to harvest many individual dice from a single wafer. A die,. What Is A Die In Semiconductor Manufacturing.

From news.samsung.com

Eight Major Steps to Semiconductor Fabrication, Part 8 Electrical Die What Is A Die In Semiconductor Manufacturing After preparing semiconductor wafers and creating individual dies, the die. Dice are an especially important part of the manufacturing process. In the context of silicon wafers, it’s going to be made of silicon. The semiconductor die, or chip, is a thin piece of silicon on which the components, such as transistors, diodes, resistors, and other. The die is the material. What Is A Die In Semiconductor Manufacturing.

From sst.semiconductor-digest.com

Perfecting yield with proactive optimization throughout the process and What Is A Die In Semiconductor Manufacturing The semiconductor die, or chip, is a thin piece of silicon on which the components, such as transistors, diodes, resistors, and other. A die, in the context of integrated circuits, is a small block of semiconducting material on which a given functional circuit is fabricated. The die of a single unit before packaging is called die. The die is the. What Is A Die In Semiconductor Manufacturing.

From thors.com

Semiconductor Basics Course What Is A Die In Semiconductor Manufacturing A die, in the context of integrated circuits, is a small block of semiconducting material on which a given functional circuit is fabricated. The semiconductor die, or chip, is a thin piece of silicon on which the components, such as transistors, diodes, resistors, and other. The process of wafer dicing enables manufacturers of integrated circuits (ics) and other semiconductor devices. What Is A Die In Semiconductor Manufacturing.

From www.gallagherseals.com

Basic Semiconductor Manufacturing Process What Is A Die In Semiconductor Manufacturing To make any chip, numerous processes play a role. The process of wafer dicing enables manufacturers of integrated circuits (ics) and other semiconductor devices to harvest many individual dice from a single wafer. The die of a single unit before packaging is called die. Die bonding is a crucial step in semiconductor manufacturing. Wafer dicing, also called wafer sawing or. What Is A Die In Semiconductor Manufacturing.

From news.skhynix.com

Semiconductor FrontEnd Process Episode 2 Oxidation What Is A Die In Semiconductor Manufacturing After the process flow, each unit will be diced and packaged. After preparing semiconductor wafers and creating individual dies, the die. Let’s discuss six critical semiconductor manufacturing steps: Deposition, photoresist, lithography, etch, ionization. A die, in the context of integrated circuits, is a small block of semiconducting material on which a given functional circuit is fabricated. The semiconductor die, or. What Is A Die In Semiconductor Manufacturing.

From news.samsung.com

Eight Major Steps to Semiconductor Fabrication, Part 1 Creating the What Is A Die In Semiconductor Manufacturing Generally, the entire silicon wafer is called a wafer. Deposition, photoresist, lithography, etch, ionization. After the process flow, each unit will be diced and packaged. After preparing semiconductor wafers and creating individual dies, the die. A die, in the context of integrated circuits, is a small block of semiconducting material on which a given functional circuit is fabricated. Let’s discuss. What Is A Die In Semiconductor Manufacturing.

From www.newport.com.cn

Semiconductor Manufacturing What Is A Die In Semiconductor Manufacturing Wafer dicing, also called wafer sawing or wafer cutting, refers to the process whereby a silicon wafer is cut into individual components called die or chips. Die bonding is a crucial step in semiconductor manufacturing. Let’s discuss six critical semiconductor manufacturing steps: Dice are an especially important part of the manufacturing process. The die of a single unit before packaging. What Is A Die In Semiconductor Manufacturing.

From www.researchgate.net

Comparison between semiconductor packaging molding processes (a What Is A Die In Semiconductor Manufacturing After preparing semiconductor wafers and creating individual dies, the die. The die of a single unit before packaging is called die. Wafer dicing, also called wafer sawing or wafer cutting, refers to the process whereby a silicon wafer is cut into individual components called die or chips. Dice are an especially important part of the manufacturing process. To make any. What Is A Die In Semiconductor Manufacturing.

From www.waferworld.com

The Process of Die Preparation in Wafer Manufacturing What Is A Die In Semiconductor Manufacturing The die is the material that the circuit is made on. The process of wafer dicing enables manufacturers of integrated circuits (ics) and other semiconductor devices to harvest many individual dice from a single wafer. Deposition, photoresist, lithography, etch, ionization. In the context of silicon wafers, it’s going to be made of silicon. Dice are an especially important part of. What Is A Die In Semiconductor Manufacturing.

From www.electronicsandyou.com

Semiconductor Manufacturing Process Steps, Technology, Flow What Is A Die In Semiconductor Manufacturing Let’s discuss six critical semiconductor manufacturing steps: In the context of silicon wafers, it’s going to be made of silicon. Deposition, photoresist, lithography, etch, ionization. After the process flow, each unit will be diced and packaged. A die, in the context of integrated circuits, is a small block of semiconducting material on which a given functional circuit is fabricated. The. What Is A Die In Semiconductor Manufacturing.

From www.theengineerspost.com

10 Types of Dies Used in Manufacturing, Its Components (PDF) What Is A Die In Semiconductor Manufacturing In the context of silicon wafers, it’s going to be made of silicon. Wafer dicing, also called wafer sawing or wafer cutting, refers to the process whereby a silicon wafer is cut into individual components called die or chips. Deposition, photoresist, lithography, etch, ionization. Let’s discuss six critical semiconductor manufacturing steps: The die is the material that the circuit is. What Is A Die In Semiconductor Manufacturing.

From semiconductor.samsung.com

A short introduction to semiconductor fabrication Samsung What Is A Die In Semiconductor Manufacturing Die bonding is a crucial step in semiconductor manufacturing. A die, in the context of integrated circuits, is a small block of semiconducting material on which a given functional circuit is fabricated. Wafer dicing, also called wafer sawing or wafer cutting, refers to the process whereby a silicon wafer is cut into individual components called die or chips. The semiconductor. What Is A Die In Semiconductor Manufacturing.

From www.renesas.com

Semiconductor Device Manufacturing Process, Challenges and What Is A Die In Semiconductor Manufacturing After the process flow, each unit will be diced and packaged. Dice are an especially important part of the manufacturing process. A die, in the context of integrated circuits, is a small block of semiconducting material on which a given functional circuit is fabricated. Generally, the entire silicon wafer is called a wafer. The die is the material that the. What Is A Die In Semiconductor Manufacturing.

From www.swissfinancialtime.com

Multidie systems define the future of semiconductors What Is A Die In Semiconductor Manufacturing After preparing semiconductor wafers and creating individual dies, the die. After the process flow, each unit will be diced and packaged. The die of a single unit before packaging is called die. The die is the material that the circuit is made on. To make any chip, numerous processes play a role. Dice are an especially important part of the. What Is A Die In Semiconductor Manufacturing.

From www.istockphoto.com

Silicon Wafer In Die Attach Machine In Semiconductor Manufacturing What Is A Die In Semiconductor Manufacturing Deposition, photoresist, lithography, etch, ionization. Generally, the entire silicon wafer is called a wafer. The die of a single unit before packaging is called die. A die, in the context of integrated circuits, is a small block of semiconducting material on which a given functional circuit is fabricated. The process of wafer dicing enables manufacturers of integrated circuits (ics) and. What Is A Die In Semiconductor Manufacturing.

From stock.adobe.com

Fotografia do Stock Semiconductor Wafer after Dicing Process. Silicon What Is A Die In Semiconductor Manufacturing Wafer dicing, also called wafer sawing or wafer cutting, refers to the process whereby a silicon wafer is cut into individual components called die or chips. Generally, the entire silicon wafer is called a wafer. Die bonding is a crucial step in semiconductor manufacturing. A die, in the context of integrated circuits, is a small block of semiconducting material on. What Is A Die In Semiconductor Manufacturing.

From waferdies.com

Die Prep Process Overview Wafer Dies Microelectronic Device What Is A Die In Semiconductor Manufacturing Wafer dicing, also called wafer sawing or wafer cutting, refers to the process whereby a silicon wafer is cut into individual components called die or chips. Let’s discuss six critical semiconductor manufacturing steps: To make any chip, numerous processes play a role. Generally, the entire silicon wafer is called a wafer. The die of a single unit before packaging is. What Is A Die In Semiconductor Manufacturing.

From www.youtube.com

Semiconductor Manufacturing Process Flow Chart YouTube What Is A Die In Semiconductor Manufacturing The die of a single unit before packaging is called die. The semiconductor die, or chip, is a thin piece of silicon on which the components, such as transistors, diodes, resistors, and other. The process of wafer dicing enables manufacturers of integrated circuits (ics) and other semiconductor devices to harvest many individual dice from a single wafer. Die bonding is. What Is A Die In Semiconductor Manufacturing.

From mungfali.com

Semiconductor Assembly Process What Is A Die In Semiconductor Manufacturing The die is the material that the circuit is made on. After the process flow, each unit will be diced and packaged. Die bonding is a crucial step in semiconductor manufacturing. The die of a single unit before packaging is called die. To make any chip, numerous processes play a role. In the context of silicon wafers, it’s going to. What Is A Die In Semiconductor Manufacturing.

From www.wevolver.com

Wafer Thinning Investigating an essential part of semiconductor What Is A Die In Semiconductor Manufacturing To make any chip, numerous processes play a role. Generally, the entire silicon wafer is called a wafer. Die bonding is a crucial step in semiconductor manufacturing. Deposition, photoresist, lithography, etch, ionization. Dice are an especially important part of the manufacturing process. Wafer dicing, also called wafer sawing or wafer cutting, refers to the process whereby a silicon wafer is. What Is A Die In Semiconductor Manufacturing.

From microchipusa.com

A StepbyStep Guide to Semiconductor Manufacturing Microchip USA What Is A Die In Semiconductor Manufacturing After the process flow, each unit will be diced and packaged. The semiconductor die, or chip, is a thin piece of silicon on which the components, such as transistors, diodes, resistors, and other. In the context of silicon wafers, it’s going to be made of silicon. After preparing semiconductor wafers and creating individual dies, the die. The die of a. What Is A Die In Semiconductor Manufacturing.