Zero Tolerance Quality . In any field, aiming for zero defects means preventing mistakes and constantly improving processes to ensure high quality and. The larger the aql level, the more lenient the inspection. Below are some steps that can help you adopt a zero defects approach: A zero defects approach is a quality management philosophy that aims to eliminate errors and defects in all production or service delivery stages. The core principle is simple yet powerful: A critical examination of zero tolerance reveals that many of the supposed benefits are not attainable. In my work with medical device manufacturers, we often set a. More important, inappropriate application of. It may be appropriate that the idea of. The zero defect strategy is a quality management approach that focuses on preventing and eliminating defects throughout the entire production process. The goal is to ensure that products or services are produced correctly the first time, without any defects or errors. Zero defects is a message that can carry with it confusion and misinterpretation, mixed with technical impracticality. Strive for perfection with the zero defects philosophy in quality management. For critical defects, i typically recommend an aql of 0% to 0.1%. Under normal inspection, aql levels range from 0.065 to 6.5.

from safetypedia.com

The core principle is simple yet powerful: In any field, aiming for zero defects means preventing mistakes and constantly improving processes to ensure high quality and. Below are some steps that can help you adopt a zero defects approach: In my work with medical device manufacturers, we often set a. Zero defects is a message that can carry with it confusion and misinterpretation, mixed with technical impracticality. The goal is to ensure that products or services are produced correctly the first time, without any defects or errors. Under normal inspection, aql levels range from 0.065 to 6.5. The larger the aql level, the more lenient the inspection. The zero defect strategy is a quality management approach that focuses on preventing and eliminating defects throughout the entire production process. A zero defects approach is a quality management philosophy that aims to eliminate errors and defects in all production or service delivery stages.

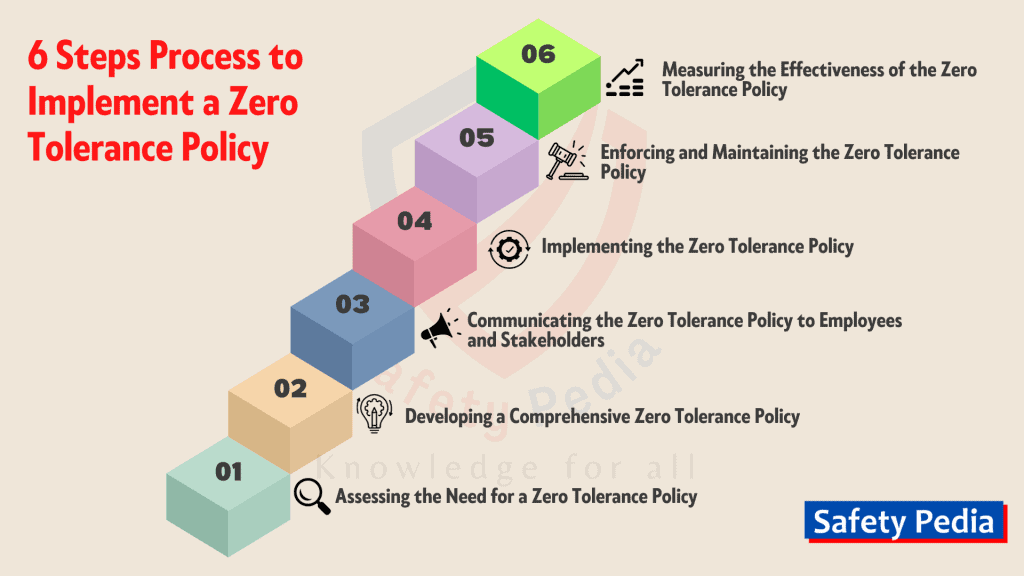

6 Steps Process to Implement a Zero Tolerance Policy for Workplace Health and Safety? SafetyPedia

Zero Tolerance Quality Zero defects is a message that can carry with it confusion and misinterpretation, mixed with technical impracticality. The core principle is simple yet powerful: More important, inappropriate application of. In my work with medical device manufacturers, we often set a. Under normal inspection, aql levels range from 0.065 to 6.5. For critical defects, i typically recommend an aql of 0% to 0.1%. It may be appropriate that the idea of. A critical examination of zero tolerance reveals that many of the supposed benefits are not attainable. Zero defects is a message that can carry with it confusion and misinterpretation, mixed with technical impracticality. The zero defect strategy is a quality management approach that focuses on preventing and eliminating defects throughout the entire production process. Below are some steps that can help you adopt a zero defects approach: Strive for perfection with the zero defects philosophy in quality management. In any field, aiming for zero defects means preventing mistakes and constantly improving processes to ensure high quality and. The goal is to ensure that products or services are produced correctly the first time, without any defects or errors. Learn the strategies for flawless production with. A zero defects approach is a quality management philosophy that aims to eliminate errors and defects in all production or service delivery stages.

From ifb.org.nz

Does a zero tolerance approach to fraud increase or lower customer trust and confidence Zero Tolerance Quality The larger the aql level, the more lenient the inspection. A critical examination of zero tolerance reveals that many of the supposed benefits are not attainable. For critical defects, i typically recommend an aql of 0% to 0.1%. Zero defects is a message that can carry with it confusion and misinterpretation, mixed with technical impracticality. Under normal inspection, aql levels. Zero Tolerance Quality.

From www.collidu.com

Zero Tolerance Policy PowerPoint and Google Slides Template PPT Slides Zero Tolerance Quality It may be appropriate that the idea of. Below are some steps that can help you adopt a zero defects approach: More important, inappropriate application of. The larger the aql level, the more lenient the inspection. Strive for perfection with the zero defects philosophy in quality management. For critical defects, i typically recommend an aql of 0% to 0.1%. Under. Zero Tolerance Quality.

From www.alamy.com

Zero Tolerance Rubber Stamp Seal Vector Stock Vector Image & Art Alamy Zero Tolerance Quality In my work with medical device manufacturers, we often set a. The core principle is simple yet powerful: It may be appropriate that the idea of. Learn the strategies for flawless production with. For critical defects, i typically recommend an aql of 0% to 0.1%. The goal is to ensure that products or services are produced correctly the first time,. Zero Tolerance Quality.

From www.vecteezy.com

Zero Tolerance Rubber Stamp Seal Vector 23420908 Vector Art at Vecteezy Zero Tolerance Quality Learn the strategies for flawless production with. The larger the aql level, the more lenient the inspection. Zero defects is a message that can carry with it confusion and misinterpretation, mixed with technical impracticality. The zero defect strategy is a quality management approach that focuses on preventing and eliminating defects throughout the entire production process. A critical examination of zero. Zero Tolerance Quality.

From www.axley.com

Unintended Result ZeroTolerance Policy for Nword Leads to Security Guard’s Firing Axley Zero Tolerance Quality A zero defects approach is a quality management philosophy that aims to eliminate errors and defects in all production or service delivery stages. The core principle is simple yet powerful: Learn the strategies for flawless production with. Below are some steps that can help you adopt a zero defects approach: Strive for perfection with the zero defects philosophy in quality. Zero Tolerance Quality.

From slidesgo.com

Zero Tolerance Policies at School Google Slides & PPT Zero Tolerance Quality Below are some steps that can help you adopt a zero defects approach: Learn the strategies for flawless production with. The goal is to ensure that products or services are produced correctly the first time, without any defects or errors. It may be appropriate that the idea of. Zero defects is a message that can carry with it confusion and. Zero Tolerance Quality.

From www.signs2safety.co.uk

Zero Tolerance Policy 2 Signs 2 Safety Zero Tolerance Quality Zero defects is a message that can carry with it confusion and misinterpretation, mixed with technical impracticality. Strive for perfection with the zero defects philosophy in quality management. A critical examination of zero tolerance reveals that many of the supposed benefits are not attainable. Under normal inspection, aql levels range from 0.065 to 6.5. The zero defect strategy is a. Zero Tolerance Quality.

From depositphotos.com

Zero Tolerance Policy at schools — Stock Photo © karenr 8574309 Zero Tolerance Quality The zero defect strategy is a quality management approach that focuses on preventing and eliminating defects throughout the entire production process. It may be appropriate that the idea of. The core principle is simple yet powerful: A zero defects approach is a quality management philosophy that aims to eliminate errors and defects in all production or service delivery stages. Strive. Zero Tolerance Quality.

From www.insidehousing.co.uk

Inside Housing Comment Zero tolerance five steps the sector should take to tackle Zero Tolerance Quality Zero defects is a message that can carry with it confusion and misinterpretation, mixed with technical impracticality. Strive for perfection with the zero defects philosophy in quality management. In any field, aiming for zero defects means preventing mistakes and constantly improving processes to ensure high quality and. The core principle is simple yet powerful: A critical examination of zero tolerance. Zero Tolerance Quality.

From www.corporatecomplianceinsights.com

Why Your Company Should Have Zero Tolerance for Zero Tolerance Corporate Compliance Insights Zero Tolerance Quality More important, inappropriate application of. Zero defects is a message that can carry with it confusion and misinterpretation, mixed with technical impracticality. The core principle is simple yet powerful: For critical defects, i typically recommend an aql of 0% to 0.1%. Strive for perfection with the zero defects philosophy in quality management. Under normal inspection, aql levels range from 0.065. Zero Tolerance Quality.

From www.shutterstock.com

Zero Tolerance Sign Vector Illustration Stock Vector (Royalty Free) 2224599881 Shutterstock Zero Tolerance Quality The zero defect strategy is a quality management approach that focuses on preventing and eliminating defects throughout the entire production process. Learn the strategies for flawless production with. In my work with medical device manufacturers, we often set a. More important, inappropriate application of. Zero defects is a message that can carry with it confusion and misinterpretation, mixed with technical. Zero Tolerance Quality.

From www.slideserve.com

PPT Zero Tolerance Policy PowerPoint Presentation, free download ID1863260 Zero Tolerance Quality A zero defects approach is a quality management philosophy that aims to eliminate errors and defects in all production or service delivery stages. A critical examination of zero tolerance reveals that many of the supposed benefits are not attainable. In any field, aiming for zero defects means preventing mistakes and constantly improving processes to ensure high quality and. The goal. Zero Tolerance Quality.

From www.alamy.com

Zero Tolerance Rubber Stamp Seal Vector Stock Vector Image & Art Alamy Zero Tolerance Quality In my work with medical device manufacturers, we often set a. Under normal inspection, aql levels range from 0.065 to 6.5. More important, inappropriate application of. The larger the aql level, the more lenient the inspection. A critical examination of zero tolerance reveals that many of the supposed benefits are not attainable. The zero defect strategy is a quality management. Zero Tolerance Quality.

From www.dreamstime.com

Zero tolerance design. stock vector. Illustration of design 209280585 Zero Tolerance Quality A zero defects approach is a quality management philosophy that aims to eliminate errors and defects in all production or service delivery stages. The goal is to ensure that products or services are produced correctly the first time, without any defects or errors. More important, inappropriate application of. It may be appropriate that the idea of. The larger the aql. Zero Tolerance Quality.

From safetypedia.com

6 Steps Process to Implement a Zero Tolerance Policy for Workplace Health and Safety? SafetyPedia Zero Tolerance Quality A critical examination of zero tolerance reveals that many of the supposed benefits are not attainable. A zero defects approach is a quality management philosophy that aims to eliminate errors and defects in all production or service delivery stages. For critical defects, i typically recommend an aql of 0% to 0.1%. Learn the strategies for flawless production with. Under normal. Zero Tolerance Quality.

From whattobecome.com

ZeroTolerance Policy Workplace Points to Consider What To Zero Tolerance Quality Learn the strategies for flawless production with. The zero defect strategy is a quality management approach that focuses on preventing and eliminating defects throughout the entire production process. More important, inappropriate application of. The core principle is simple yet powerful: Below are some steps that can help you adopt a zero defects approach: Under normal inspection, aql levels range from. Zero Tolerance Quality.

From www.yfp.com.au

Zero Tolerance Policy Family Practice Zero Tolerance Quality Strive for perfection with the zero defects philosophy in quality management. For critical defects, i typically recommend an aql of 0% to 0.1%. Zero defects is a message that can carry with it confusion and misinterpretation, mixed with technical impracticality. In my work with medical device manufacturers, we often set a. The core principle is simple yet powerful: Under normal. Zero Tolerance Quality.

From www.degruyter.com

Zero Tolerance Zero Tolerance Quality Under normal inspection, aql levels range from 0.065 to 6.5. The larger the aql level, the more lenient the inspection. For critical defects, i typically recommend an aql of 0% to 0.1%. A zero defects approach is a quality management philosophy that aims to eliminate errors and defects in all production or service delivery stages. The core principle is simple. Zero Tolerance Quality.

From www.podnow.co.uk

Zero tolerance POD Posters On Demand Zero Tolerance Quality A critical examination of zero tolerance reveals that many of the supposed benefits are not attainable. A zero defects approach is a quality management philosophy that aims to eliminate errors and defects in all production or service delivery stages. The zero defect strategy is a quality management approach that focuses on preventing and eliminating defects throughout the entire production process.. Zero Tolerance Quality.

From avopix.com

Zero Tolerance Policy Sign Royalty Free Stock Vector 1201658968 Zero Tolerance Quality Under normal inspection, aql levels range from 0.065 to 6.5. Strive for perfection with the zero defects philosophy in quality management. The goal is to ensure that products or services are produced correctly the first time, without any defects or errors. In any field, aiming for zero defects means preventing mistakes and constantly improving processes to ensure high quality and.. Zero Tolerance Quality.

From www.alamy.com

Zero Tolerance Rubber Stamp Seal Vector Stock Vector Image & Art Alamy Zero Tolerance Quality Learn the strategies for flawless production with. It may be appropriate that the idea of. In any field, aiming for zero defects means preventing mistakes and constantly improving processes to ensure high quality and. The larger the aql level, the more lenient the inspection. In my work with medical device manufacturers, we often set a. Under normal inspection, aql levels. Zero Tolerance Quality.

From www.podnow.co.uk

We have a zero tolerance POD Posters On Demand Zero Tolerance Quality Under normal inspection, aql levels range from 0.065 to 6.5. Strive for perfection with the zero defects philosophy in quality management. In any field, aiming for zero defects means preventing mistakes and constantly improving processes to ensure high quality and. A critical examination of zero tolerance reveals that many of the supposed benefits are not attainable. The zero defect strategy. Zero Tolerance Quality.

From pngtree.com

Zero Tolerance PNG, Vector, PSD, and Clipart With Transparent Background for Free Download Pngtree Zero Tolerance Quality More important, inappropriate application of. A critical examination of zero tolerance reveals that many of the supposed benefits are not attainable. The goal is to ensure that products or services are produced correctly the first time, without any defects or errors. Under normal inspection, aql levels range from 0.065 to 6.5. The zero defect strategy is a quality management approach. Zero Tolerance Quality.

From michiganvirtual.org

4 ways that zerotolerance policies affect Michigan students [with infographics] Michigan Virtual Zero Tolerance Quality Strive for perfection with the zero defects philosophy in quality management. A zero defects approach is a quality management philosophy that aims to eliminate errors and defects in all production or service delivery stages. The zero defect strategy is a quality management approach that focuses on preventing and eliminating defects throughout the entire production process. The goal is to ensure. Zero Tolerance Quality.

From rawmarshsandhill.org

Zero Tolerance Rawmarsh Sandhill Primary School Zero Tolerance Quality Zero defects is a message that can carry with it confusion and misinterpretation, mixed with technical impracticality. Learn the strategies for flawless production with. Under normal inspection, aql levels range from 0.065 to 6.5. Strive for perfection with the zero defects philosophy in quality management. In any field, aiming for zero defects means preventing mistakes and constantly improving processes to. Zero Tolerance Quality.

From www.podnow.co.uk

Zero tolerance we are here to help POD Posters On Demand Zero Tolerance Quality More important, inappropriate application of. Strive for perfection with the zero defects philosophy in quality management. Learn the strategies for flawless production with. Below are some steps that can help you adopt a zero defects approach: A zero defects approach is a quality management philosophy that aims to eliminate errors and defects in all production or service delivery stages. The. Zero Tolerance Quality.

From www.vecteezy.com

Zero Tolerance Rubber Stamp Seal Vector 23420906 Vector Art at Vecteezy Zero Tolerance Quality For critical defects, i typically recommend an aql of 0% to 0.1%. Strive for perfection with the zero defects philosophy in quality management. The core principle is simple yet powerful: In my work with medical device manufacturers, we often set a. The zero defect strategy is a quality management approach that focuses on preventing and eliminating defects throughout the entire. Zero Tolerance Quality.

From dnanews.com.pk

Zero tolerance policy DNA News Agency Zero Tolerance Quality It may be appropriate that the idea of. Under normal inspection, aql levels range from 0.065 to 6.5. Strive for perfection with the zero defects philosophy in quality management. The zero defect strategy is a quality management approach that focuses on preventing and eliminating defects throughout the entire production process. Learn the strategies for flawless production with. The goal is. Zero Tolerance Quality.

From www.alamy.com

Zero tolerance message illustration design over a white background Stock Vector Image & Art Alamy Zero Tolerance Quality The zero defect strategy is a quality management approach that focuses on preventing and eliminating defects throughout the entire production process. The core principle is simple yet powerful: A critical examination of zero tolerance reveals that many of the supposed benefits are not attainable. A zero defects approach is a quality management philosophy that aims to eliminate errors and defects. Zero Tolerance Quality.

From www.voicendata.com

UIDAI demonstrate at Zero Tolerance against unauthorized Agencies, sitesVoice&Data Zero Tolerance Quality A zero defects approach is a quality management philosophy that aims to eliminate errors and defects in all production or service delivery stages. The zero defect strategy is a quality management approach that focuses on preventing and eliminating defects throughout the entire production process. In my work with medical device manufacturers, we often set a. Learn the strategies for flawless. Zero Tolerance Quality.

From pngtree.com

Zero Tolerance Zero Naught Grunge Vector, Zero, Naught, Grunge PNG and Vector with Transparent Zero Tolerance Quality The core principle is simple yet powerful: In my work with medical device manufacturers, we often set a. Zero defects is a message that can carry with it confusion and misinterpretation, mixed with technical impracticality. Strive for perfection with the zero defects philosophy in quality management. For critical defects, i typically recommend an aql of 0% to 0.1%. A zero. Zero Tolerance Quality.

From www.shutterstock.com

Zero Tolerance Warning Sign, A Yellow And Black Sign With The Words Zero Tolerance Isolated On A Zero Tolerance Quality More important, inappropriate application of. In my work with medical device manufacturers, we often set a. For critical defects, i typically recommend an aql of 0% to 0.1%. A critical examination of zero tolerance reveals that many of the supposed benefits are not attainable. The goal is to ensure that products or services are produced correctly the first time, without. Zero Tolerance Quality.

From www.slideserve.com

PPT Zero Tolerance Policy PowerPoint Presentation, free download ID1863260 Zero Tolerance Quality It may be appropriate that the idea of. The zero defect strategy is a quality management approach that focuses on preventing and eliminating defects throughout the entire production process. The goal is to ensure that products or services are produced correctly the first time, without any defects or errors. A critical examination of zero tolerance reveals that many of the. Zero Tolerance Quality.

From depositphotos.com

Zero Tolerance rubber stamp Stock Vector by ©lkeskinen0 135619552 Zero Tolerance Quality The core principle is simple yet powerful: Learn the strategies for flawless production with. Zero defects is a message that can carry with it confusion and misinterpretation, mixed with technical impracticality. For critical defects, i typically recommend an aql of 0% to 0.1%. In any field, aiming for zero defects means preventing mistakes and constantly improving processes to ensure high. Zero Tolerance Quality.

From www.shutterstock.com

Zero Tolerance Over 1,058 RoyaltyFree Licensable Stock Vectors & Vector Art Shutterstock Zero Tolerance Quality The larger the aql level, the more lenient the inspection. In any field, aiming for zero defects means preventing mistakes and constantly improving processes to ensure high quality and. Zero defects is a message that can carry with it confusion and misinterpretation, mixed with technical impracticality. The zero defect strategy is a quality management approach that focuses on preventing and. Zero Tolerance Quality.