Worm Pitch Diameter . Divide number of teeth in worm gear (n) by number of worm threads (t) n ratio =. A crownless worm gear results when it is made by using a hob that has. Pitch diameter of worm is determined by (eq. The pitch line velocity is ideally up to 30. Tooth data (addendum, full depth, etc.). D = np / π = n π ε / π. Cut worm gear with a hob cutter of greater pitch diameter than the worm. Gear engineering and design data. Efficiency grows with increasing pitch angle (for. Pitch angle is one of the key parameters of worm gearing closely related to worm dimensions and transmission efficiency.

from www.chegg.com

Tooth data (addendum, full depth, etc.). Pitch angle is one of the key parameters of worm gearing closely related to worm dimensions and transmission efficiency. Gear engineering and design data. Cut worm gear with a hob cutter of greater pitch diameter than the worm. The pitch line velocity is ideally up to 30. Efficiency grows with increasing pitch angle (for. D = np / π = n π ε / π. Pitch diameter of worm is determined by (eq. Divide number of teeth in worm gear (n) by number of worm threads (t) n ratio =. A crownless worm gear results when it is made by using a hob that has.

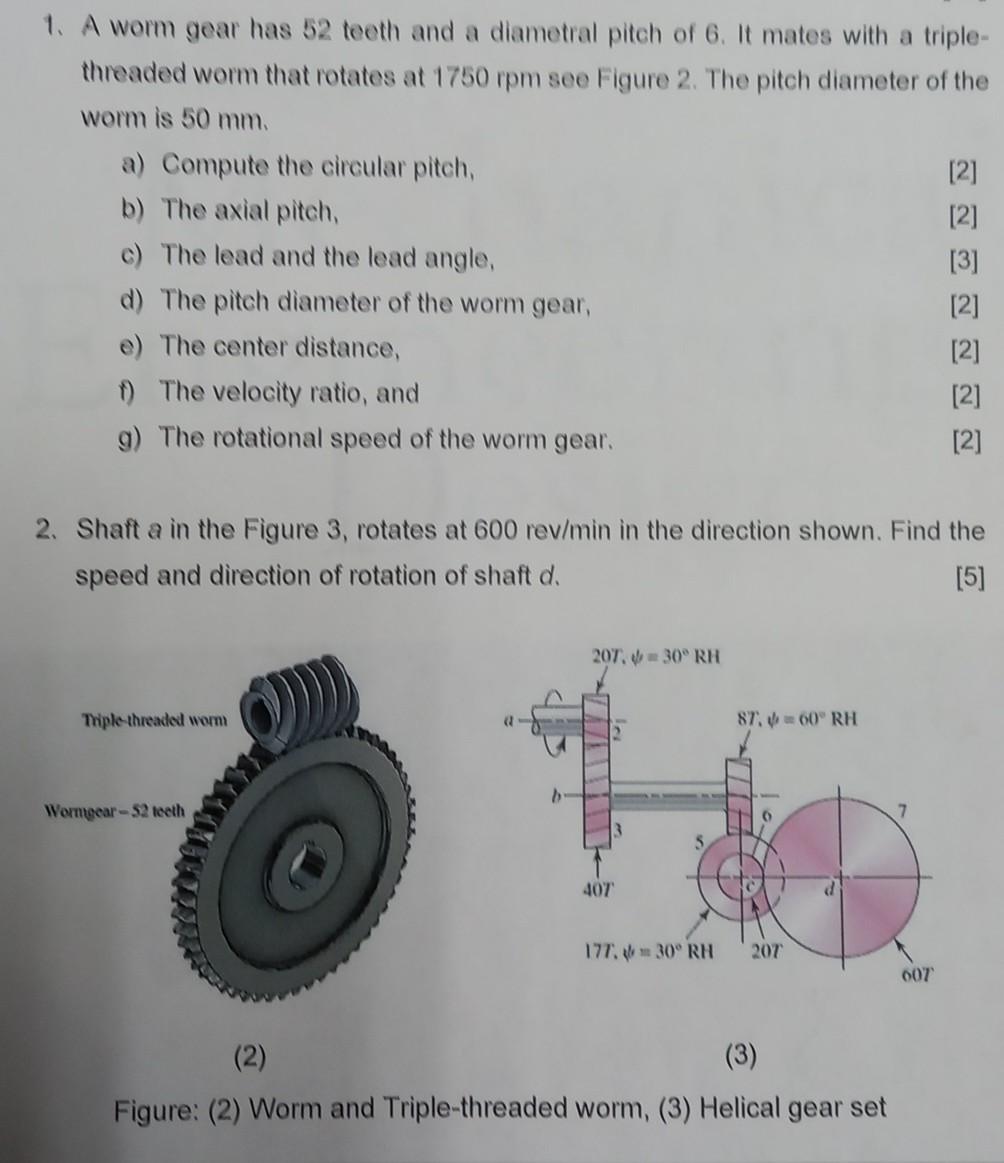

Solved 1. A worm gear has 52 teeth and a diametral pitch of

Worm Pitch Diameter A crownless worm gear results when it is made by using a hob that has. Efficiency grows with increasing pitch angle (for. Gear engineering and design data. Cut worm gear with a hob cutter of greater pitch diameter than the worm. Tooth data (addendum, full depth, etc.). Pitch angle is one of the key parameters of worm gearing closely related to worm dimensions and transmission efficiency. A crownless worm gear results when it is made by using a hob that has. Pitch diameter of worm is determined by (eq. Divide number of teeth in worm gear (n) by number of worm threads (t) n ratio =. The pitch line velocity is ideally up to 30. D = np / π = n π ε / π.

From www.chegg.com

Solved Problem 8 A triplethread worm has a pitch diameter Worm Pitch Diameter Cut worm gear with a hob cutter of greater pitch diameter than the worm. Efficiency grows with increasing pitch angle (for. The pitch line velocity is ideally up to 30. A crownless worm gear results when it is made by using a hob that has. Pitch diameter of worm is determined by (eq. Tooth data (addendum, full depth, etc.). Pitch. Worm Pitch Diameter.

From www.chegg.com

Solved 1. A worm gear has 52 teeth and a diametral pitch of Worm Pitch Diameter The pitch line velocity is ideally up to 30. Gear engineering and design data. Efficiency grows with increasing pitch angle (for. Pitch diameter of worm is determined by (eq. Tooth data (addendum, full depth, etc.). A crownless worm gear results when it is made by using a hob that has. Cut worm gear with a hob cutter of greater pitch. Worm Pitch Diameter.

From www.tessshebaylo.com

Gear Ratio Equation Teeth Tessshebaylo Worm Pitch Diameter Efficiency grows with increasing pitch angle (for. Gear engineering and design data. Divide number of teeth in worm gear (n) by number of worm threads (t) n ratio =. Pitch diameter of worm is determined by (eq. The pitch line velocity is ideally up to 30. D = np / π = n π ε / π. Tooth data (addendum,. Worm Pitch Diameter.

From gear.com.my

Worm Gear Malaysia, Worm Gear Supplier Malaysia Worm Pitch Diameter Pitch diameter of worm is determined by (eq. Efficiency grows with increasing pitch angle (for. Divide number of teeth in worm gear (n) by number of worm threads (t) n ratio =. Cut worm gear with a hob cutter of greater pitch diameter than the worm. Tooth data (addendum, full depth, etc.). D = np / π = n π. Worm Pitch Diameter.

From www.hexagon.de

ZAR3 Worm Gear Calculation Worm Pitch Diameter Divide number of teeth in worm gear (n) by number of worm threads (t) n ratio =. Pitch diameter of worm is determined by (eq. Pitch angle is one of the key parameters of worm gearing closely related to worm dimensions and transmission efficiency. Efficiency grows with increasing pitch angle (for. Cut worm gear with a hob cutter of greater. Worm Pitch Diameter.

From azgardsci.weebly.com

Pitch Diameter Gear Calculator azgardsci Worm Pitch Diameter Pitch diameter of worm is determined by (eq. Tooth data (addendum, full depth, etc.). Pitch angle is one of the key parameters of worm gearing closely related to worm dimensions and transmission efficiency. D = np / π = n π ε / π. Cut worm gear with a hob cutter of greater pitch diameter than the worm. Efficiency grows. Worm Pitch Diameter.

From www.brighthubengineering.com

Worm Gear Box Design Tutorial Pitch Diameter of Worm Gear and Other Worm Pitch Diameter Efficiency grows with increasing pitch angle (for. D = np / π = n π ε / π. Pitch angle is one of the key parameters of worm gearing closely related to worm dimensions and transmission efficiency. Gear engineering and design data. Divide number of teeth in worm gear (n) by number of worm threads (t) n ratio =. A. Worm Pitch Diameter.

From www.numerade.com

SOLVEDA singlethreaded steel worm rotates at 1725 revimin, meshing Worm Pitch Diameter Tooth data (addendum, full depth, etc.). Gear engineering and design data. The pitch line velocity is ideally up to 30. Efficiency grows with increasing pitch angle (for. A crownless worm gear results when it is made by using a hob that has. D = np / π = n π ε / π. Pitch diameter of worm is determined by. Worm Pitch Diameter.

From www.slideserve.com

PPT Chapter 15 Helical, Bevel, and Worm Gears PowerPoint Worm Pitch Diameter Cut worm gear with a hob cutter of greater pitch diameter than the worm. Efficiency grows with increasing pitch angle (for. D = np / π = n π ε / π. Pitch angle is one of the key parameters of worm gearing closely related to worm dimensions and transmission efficiency. A crownless worm gear results when it is made. Worm Pitch Diameter.

From www.numerade.com

SOLVED 1. A worm gear has 52 teeth and a diametral pitch of 6. It Worm Pitch Diameter Divide number of teeth in worm gear (n) by number of worm threads (t) n ratio =. Gear engineering and design data. D = np / π = n π ε / π. Cut worm gear with a hob cutter of greater pitch diameter than the worm. A crownless worm gear results when it is made by using a hob. Worm Pitch Diameter.

From www.chegg.com

Solved In the figure, a righthand singletooth worm gear Worm Pitch Diameter Efficiency grows with increasing pitch angle (for. Pitch diameter of worm is determined by (eq. A crownless worm gear results when it is made by using a hob that has. Tooth data (addendum, full depth, etc.). Pitch angle is one of the key parameters of worm gearing closely related to worm dimensions and transmission efficiency. Cut worm gear with a. Worm Pitch Diameter.

From www.chegg.com

Solved Problem 13.51 A righthand singletooth Worm Pitch Diameter Pitch diameter of worm is determined by (eq. Cut worm gear with a hob cutter of greater pitch diameter than the worm. The pitch line velocity is ideally up to 30. A crownless worm gear results when it is made by using a hob that has. Gear engineering and design data. D = np / π = n π ε. Worm Pitch Diameter.

From www.omniamfg.com

Determination of the Best Pitch Diameter and Thread Class for Your Worm Pitch Diameter Gear engineering and design data. Cut worm gear with a hob cutter of greater pitch diameter than the worm. A crownless worm gear results when it is made by using a hob that has. Divide number of teeth in worm gear (n) by number of worm threads (t) n ratio =. Efficiency grows with increasing pitch angle (for. The pitch. Worm Pitch Diameter.

From www.chegg.com

Solved 5. Figure 5 shows that a 2tooth lefthand worm Worm Pitch Diameter Divide number of teeth in worm gear (n) by number of worm threads (t) n ratio =. D = np / π = n π ε / π. Gear engineering and design data. Tooth data (addendum, full depth, etc.). The pitch line velocity is ideally up to 30. A crownless worm gear results when it is made by using a. Worm Pitch Diameter.

From rarecomponents.com

Plastic Worm Gear 4mm D Shape Bore Worm Pitch Diameter A crownless worm gear results when it is made by using a hob that has. Efficiency grows with increasing pitch angle (for. Gear engineering and design data. The pitch line velocity is ideally up to 30. Pitch diameter of worm is determined by (eq. Pitch angle is one of the key parameters of worm gearing closely related to worm dimensions. Worm Pitch Diameter.

From www.researchgate.net

The impact of the pitch adjustment DB under the force of the worm's Worm Pitch Diameter Gear engineering and design data. Pitch diameter of worm is determined by (eq. Pitch angle is one of the key parameters of worm gearing closely related to worm dimensions and transmission efficiency. Divide number of teeth in worm gear (n) by number of worm threads (t) n ratio =. Cut worm gear with a hob cutter of greater pitch diameter. Worm Pitch Diameter.

From www.chegg.com

Solved Question 3 [181 A 2start worm transmits 0.75 hp at Worm Pitch Diameter Cut worm gear with a hob cutter of greater pitch diameter than the worm. Divide number of teeth in worm gear (n) by number of worm threads (t) n ratio =. A crownless worm gear results when it is made by using a hob that has. D = np / π = n π ε / π. Tooth data (addendum,. Worm Pitch Diameter.

From khkgears.net

Technical Information of Worm Gear KHK Gears Worm Pitch Diameter Pitch angle is one of the key parameters of worm gearing closely related to worm dimensions and transmission efficiency. Gear engineering and design data. A crownless worm gear results when it is made by using a hob that has. Tooth data (addendum, full depth, etc.). Pitch diameter of worm is determined by (eq. D = np / π = n. Worm Pitch Diameter.

From www.numerade.com

SOLVED a double thread worm gear having a pitch of 1in is used to Worm Pitch Diameter The pitch line velocity is ideally up to 30. A crownless worm gear results when it is made by using a hob that has. Efficiency grows with increasing pitch angle (for. D = np / π = n π ε / π. Tooth data (addendum, full depth, etc.). Cut worm gear with a hob cutter of greater pitch diameter than. Worm Pitch Diameter.

From www.chegg.com

A 1start righthand worm transmits 1.5 hp at 1200 Worm Pitch Diameter A crownless worm gear results when it is made by using a hob that has. Divide number of teeth in worm gear (n) by number of worm threads (t) n ratio =. Pitch diameter of worm is determined by (eq. Cut worm gear with a hob cutter of greater pitch diameter than the worm. D = np / π =. Worm Pitch Diameter.

From www.chegg.com

Solved 4. The 3tooth worm has a pitch diameter of 2 in and Worm Pitch Diameter Pitch angle is one of the key parameters of worm gearing closely related to worm dimensions and transmission efficiency. Tooth data (addendum, full depth, etc.). Divide number of teeth in worm gear (n) by number of worm threads (t) n ratio =. The pitch line velocity is ideally up to 30. Cut worm gear with a hob cutter of greater. Worm Pitch Diameter.

From brainsherof.weebly.com

Worm gear design calculation download brainsherofMy Site Worm Pitch Diameter Pitch angle is one of the key parameters of worm gearing closely related to worm dimensions and transmission efficiency. D = np / π = n π ε / π. Tooth data (addendum, full depth, etc.). Efficiency grows with increasing pitch angle (for. Pitch diameter of worm is determined by (eq. Cut worm gear with a hob cutter of greater. Worm Pitch Diameter.

From www.numerade.com

SOLVEDA wormgear set has a fourthreaded worm with a normal pressure Worm Pitch Diameter Cut worm gear with a hob cutter of greater pitch diameter than the worm. A crownless worm gear results when it is made by using a hob that has. Pitch angle is one of the key parameters of worm gearing closely related to worm dimensions and transmission efficiency. Divide number of teeth in worm gear (n) by number of worm. Worm Pitch Diameter.

From klamqmbbt.blob.core.windows.net

Worm Gear Design Calculation at Virginia Kilburn blog Worm Pitch Diameter D = np / π = n π ε / π. Pitch diameter of worm is determined by (eq. Pitch angle is one of the key parameters of worm gearing closely related to worm dimensions and transmission efficiency. A crownless worm gear results when it is made by using a hob that has. Tooth data (addendum, full depth, etc.). Efficiency. Worm Pitch Diameter.

From www.chegg.com

Solved A 2tooth righthand worm transmits l hp at 1200 Worm Pitch Diameter D = np / π = n π ε / π. Cut worm gear with a hob cutter of greater pitch diameter than the worm. A crownless worm gear results when it is made by using a hob that has. Gear engineering and design data. Efficiency grows with increasing pitch angle (for. Pitch angle is one of the key parameters. Worm Pitch Diameter.

From www.vlr.eng.br

Worm Gear What Is It? How Is It Made? Types Of, Uses vlr.eng.br Worm Pitch Diameter A crownless worm gear results when it is made by using a hob that has. The pitch line velocity is ideally up to 30. Gear engineering and design data. Efficiency grows with increasing pitch angle (for. Pitch diameter of worm is determined by (eq. D = np / π = n π ε / π. Divide number of teeth in. Worm Pitch Diameter.

From www.youtube.com

Bevel Gears and Worm Gears Part IV YouTube Worm Pitch Diameter Divide number of teeth in worm gear (n) by number of worm threads (t) n ratio =. The pitch line velocity is ideally up to 30. A crownless worm gear results when it is made by using a hob that has. Pitch diameter of worm is determined by (eq. Efficiency grows with increasing pitch angle (for. Pitch angle is one. Worm Pitch Diameter.

From www.chegg.com

Solved 5. A worm transmitting 6 kW at 1200 RPM drives a worm Worm Pitch Diameter The pitch line velocity is ideally up to 30. A crownless worm gear results when it is made by using a hob that has. Cut worm gear with a hob cutter of greater pitch diameter than the worm. Tooth data (addendum, full depth, etc.). Pitch diameter of worm is determined by (eq. Gear engineering and design data. Pitch angle is. Worm Pitch Diameter.

From rangmillionaire.weebly.com

Worm Gear Design Calculation Pdf File rangmillionaire Worm Pitch Diameter Pitch diameter of worm is determined by (eq. Cut worm gear with a hob cutter of greater pitch diameter than the worm. A crownless worm gear results when it is made by using a hob that has. Pitch angle is one of the key parameters of worm gearing closely related to worm dimensions and transmission efficiency. Efficiency grows with increasing. Worm Pitch Diameter.

From grabcad.com

How to Calculate the Centre to CentreDistance between Worm and Wrom Worm Pitch Diameter Divide number of teeth in worm gear (n) by number of worm threads (t) n ratio =. Gear engineering and design data. The pitch line velocity is ideally up to 30. Pitch diameter of worm is determined by (eq. A crownless worm gear results when it is made by using a hob that has. D = np / π =. Worm Pitch Diameter.

From www.chegg.com

Solved 5. A worm rotating at 1150 rpm drives a worm gear Worm Pitch Diameter A crownless worm gear results when it is made by using a hob that has. Gear engineering and design data. Pitch diameter of worm is determined by (eq. The pitch line velocity is ideally up to 30. Tooth data (addendum, full depth, etc.). Efficiency grows with increasing pitch angle (for. D = np / π = n π ε /. Worm Pitch Diameter.

From fyosxrcsr.blob.core.windows.net

Worm Shaft Traduccion at Dave Green blog Worm Pitch Diameter The pitch line velocity is ideally up to 30. Pitch diameter of worm is determined by (eq. Efficiency grows with increasing pitch angle (for. Gear engineering and design data. A crownless worm gear results when it is made by using a hob that has. Tooth data (addendum, full depth, etc.). Cut worm gear with a hob cutter of greater pitch. Worm Pitch Diameter.

From evolventdesign.com

Worm Measurement over Pins Calculator Evolvent Design Worm Pitch Diameter Divide number of teeth in worm gear (n) by number of worm threads (t) n ratio =. Pitch diameter of worm is determined by (eq. Pitch angle is one of the key parameters of worm gearing closely related to worm dimensions and transmission efficiency. Cut worm gear with a hob cutter of greater pitch diameter than the worm. A crownless. Worm Pitch Diameter.

From www.researchgate.net

Coordinate system of globoid worm drive. Download Scientific Diagram Worm Pitch Diameter Cut worm gear with a hob cutter of greater pitch diameter than the worm. Efficiency grows with increasing pitch angle (for. The pitch line velocity is ideally up to 30. Gear engineering and design data. D = np / π = n π ε / π. A crownless worm gear results when it is made by using a hob that. Worm Pitch Diameter.

From www.chegg.com

Solved Problem 1 A wormgear has 50 teeth and a transverse Worm Pitch Diameter Tooth data (addendum, full depth, etc.). D = np / π = n π ε / π. A crownless worm gear results when it is made by using a hob that has. The pitch line velocity is ideally up to 30. Pitch diameter of worm is determined by (eq. Pitch angle is one of the key parameters of worm gearing. Worm Pitch Diameter.