Knockout In Sheet Metal . Forming process of piercing a hole and keep the slug on the sheet metal by tabs. When using a hole, remove the slug using a screwdriver. When using a hole, remove the slug using a screwdriver. All punch tools operate in a. Knockouts are common in sheet metal fabrication and are most frequently used in electrical enclosures as an access point to bring wires into. We follow sheet metal design guidelines to ensure the quality and manufacturability of sheet metal enclosures. 1) please indicate the dimension of a or b,. I am not sure if the term knockout is the right one. I am trying to create a cutout as in the attached part (later to be. In boxing, a knockout tool is used to cut holes in sheet metal. Lance and forms (tabs, bridges, knockouts, cable ties) and extrusions are among the advanced class of forms being produced in. As a result, you can deliver the. Forming process of piercing a hole and keep the slug on the sheet metal by tabs. Not to be confused with a k.o.

from www.grainger.com

Knockouts are common in sheet metal fabrication and are most frequently used in electrical enclosures as an access point to bring wires into. When using a hole, remove the slug using a screwdriver. Lance and forms (tabs, bridges, knockouts, cable ties) and extrusions are among the advanced class of forms being produced in. All punch tools operate in a. In boxing, a knockout tool is used to cut holes in sheet metal. As a result, you can deliver the. When using a hole, remove the slug using a screwdriver. 1) please indicate the dimension of a or b,. We follow sheet metal design guidelines to ensure the quality and manufacturability of sheet metal enclosures. Not to be confused with a k.o.

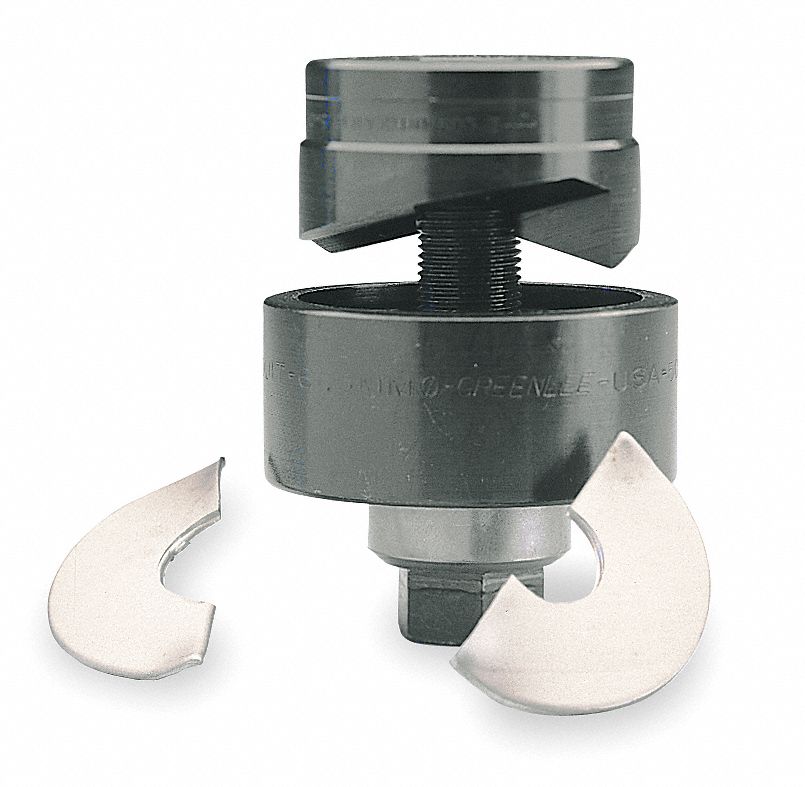

GREENLEE Knockout Punch and Die Kit 16 ga Sheet Metal Capacity (Steel

Knockout In Sheet Metal 1) please indicate the dimension of a or b,. When using a hole, remove the slug using a screwdriver. In boxing, a knockout tool is used to cut holes in sheet metal. 1) please indicate the dimension of a or b,. Lance and forms (tabs, bridges, knockouts, cable ties) and extrusions are among the advanced class of forms being produced in. Knockouts are common in sheet metal fabrication and are most frequently used in electrical enclosures as an access point to bring wires into. Not to be confused with a k.o. As a result, you can deliver the. Forming process of piercing a hole and keep the slug on the sheet metal by tabs. Forming process of piercing a hole and keep the slug on the sheet metal by tabs. I am not sure if the term knockout is the right one. We follow sheet metal design guidelines to ensure the quality and manufacturability of sheet metal enclosures. I am trying to create a cutout as in the attached part (later to be. All punch tools operate in a. When using a hole, remove the slug using a screwdriver.

From acadsystems.com

Inventor Sheet Metal Create Custom Punch Tool Acad Systems Knockout In Sheet Metal In boxing, a knockout tool is used to cut holes in sheet metal. Lance and forms (tabs, bridges, knockouts, cable ties) and extrusions are among the advanced class of forms being produced in. When using a hole, remove the slug using a screwdriver. Forming process of piercing a hole and keep the slug on the sheet metal by tabs. Knockouts. Knockout In Sheet Metal.

From www.grainger.com

MILWAUKEE Knockout Punch Set 15 Pieces, 10 ga Max Sheet Metal Capacity Knockout In Sheet Metal All punch tools operate in a. I am trying to create a cutout as in the attached part (later to be. When using a hole, remove the slug using a screwdriver. We follow sheet metal design guidelines to ensure the quality and manufacturability of sheet metal enclosures. Not to be confused with a k.o. Forming process of piercing a hole. Knockout In Sheet Metal.

From ar.inspiredpencil.com

Sheet Metal Bending Techniques Knockout In Sheet Metal All punch tools operate in a. Lance and forms (tabs, bridges, knockouts, cable ties) and extrusions are among the advanced class of forms being produced in. Not to be confused with a k.o. Forming process of piercing a hole and keep the slug on the sheet metal by tabs. When using a hole, remove the slug using a screwdriver. Forming. Knockout In Sheet Metal.

From www.grainger.com

GREENLEE Knockout Punch 10 ga Sheet Metal Capacity (Steel), 1 7/32 in Knockout In Sheet Metal Forming process of piercing a hole and keep the slug on the sheet metal by tabs. All punch tools operate in a. 1) please indicate the dimension of a or b,. Not to be confused with a k.o. We follow sheet metal design guidelines to ensure the quality and manufacturability of sheet metal enclosures. When using a hole, remove the. Knockout In Sheet Metal.

From proleantech.com

Diversi tipi di operazioni di rifilatura nella produzione di lamiere Knockout In Sheet Metal Not to be confused with a k.o. As a result, you can deliver the. Knockouts are common in sheet metal fabrication and are most frequently used in electrical enclosures as an access point to bring wires into. When using a hole, remove the slug using a screwdriver. When using a hole, remove the slug using a screwdriver. In boxing, a. Knockout In Sheet Metal.

From www.thefabricator.com

Forming on the modern punch press sheet metal fabrication’s Swiss army Knockout In Sheet Metal Forming process of piercing a hole and keep the slug on the sheet metal by tabs. When using a hole, remove the slug using a screwdriver. I am not sure if the term knockout is the right one. We follow sheet metal design guidelines to ensure the quality and manufacturability of sheet metal enclosures. Not to be confused with a. Knockout In Sheet Metal.

From sheetmetalshiijin.blogspot.com

Sheet Metal Sheet Metal Knockout Punch Knockout In Sheet Metal Forming process of piercing a hole and keep the slug on the sheet metal by tabs. Not to be confused with a k.o. When using a hole, remove the slug using a screwdriver. 1) please indicate the dimension of a or b,. Lance and forms (tabs, bridges, knockouts, cable ties) and extrusions are among the advanced class of forms being. Knockout In Sheet Metal.

From www.solidsolutions.co.uk

Knockout Form Knockout In Sheet Metal I am trying to create a cutout as in the attached part (later to be. In boxing, a knockout tool is used to cut holes in sheet metal. As a result, you can deliver the. We follow sheet metal design guidelines to ensure the quality and manufacturability of sheet metal enclosures. Forming process of piercing a hole and keep the. Knockout In Sheet Metal.

From www.grainger.com

GREENLEE Knockout Die 10 ga Sheet Metal Capacity (Steel), 2 27/64 in Knockout In Sheet Metal All punch tools operate in a. I am trying to create a cutout as in the attached part (later to be. When using a hole, remove the slug using a screwdriver. When using a hole, remove the slug using a screwdriver. We follow sheet metal design guidelines to ensure the quality and manufacturability of sheet metal enclosures. Forming process of. Knockout In Sheet Metal.

From www.lekontool.com

Standard hole Square knockout punches die set kit customize LEKON TOOLS Knockout In Sheet Metal Knockouts are common in sheet metal fabrication and are most frequently used in electrical enclosures as an access point to bring wires into. Lance and forms (tabs, bridges, knockouts, cable ties) and extrusions are among the advanced class of forms being produced in. I am not sure if the term knockout is the right one. I am trying to create. Knockout In Sheet Metal.

From musicsala.rsu.ac.th

Manual Knockout Punch Kit, Heavy Duty Metal Sheet Knock Out Box Hole Knockout In Sheet Metal Lance and forms (tabs, bridges, knockouts, cable ties) and extrusions are among the advanced class of forms being produced in. Forming process of piercing a hole and keep the slug on the sheet metal by tabs. Knockouts are common in sheet metal fabrication and are most frequently used in electrical enclosures as an access point to bring wires into. I. Knockout In Sheet Metal.

From www.grainger.com

MILWAUKEE Knockout Punch Set 10 ga Max Sheet Metal CapacitySteel, 1 1 Knockout In Sheet Metal I am not sure if the term knockout is the right one. In boxing, a knockout tool is used to cut holes in sheet metal. When using a hole, remove the slug using a screwdriver. Knockouts are common in sheet metal fabrication and are most frequently used in electrical enclosures as an access point to bring wires into. Lance and. Knockout In Sheet Metal.

From www.youtube.com

Making Holes in Metal Panels Using a Knockout Punch Set YouTube Knockout In Sheet Metal When using a hole, remove the slug using a screwdriver. I am trying to create a cutout as in the attached part (later to be. As a result, you can deliver the. Forming process of piercing a hole and keep the slug on the sheet metal by tabs. All punch tools operate in a. I am not sure if the. Knockout In Sheet Metal.

From www.desertcart.ph

Buy AMZCNC Manual Knockout Punch Kit, Heavy Duty Metal Sheet Knock Out Knockout In Sheet Metal Lance and forms (tabs, bridges, knockouts, cable ties) and extrusions are among the advanced class of forms being produced in. Forming process of piercing a hole and keep the slug on the sheet metal by tabs. Forming process of piercing a hole and keep the slug on the sheet metal by tabs. As a result, you can deliver the. I. Knockout In Sheet Metal.

From www.grainger.com

MILWAUKEE Knockout Punch 12 ga Sheet Metal Capacity (Steel), 2 15/32 Knockout In Sheet Metal Knockouts are common in sheet metal fabrication and are most frequently used in electrical enclosures as an access point to bring wires into. In boxing, a knockout tool is used to cut holes in sheet metal. When using a hole, remove the slug using a screwdriver. Not to be confused with a k.o. We follow sheet metal design guidelines to. Knockout In Sheet Metal.

From unipunch.com

Punching Electrical Knockouts UniPunch Tooling Systems Knockout In Sheet Metal Forming process of piercing a hole and keep the slug on the sheet metal by tabs. In boxing, a knockout tool is used to cut holes in sheet metal. Knockouts are common in sheet metal fabrication and are most frequently used in electrical enclosures as an access point to bring wires into. I am trying to create a cutout as. Knockout In Sheet Metal.

From www.unipunch.com

Punching Electrical Knockouts UniPunch Tooling Systems Knockout In Sheet Metal When using a hole, remove the slug using a screwdriver. All punch tools operate in a. When using a hole, remove the slug using a screwdriver. 1) please indicate the dimension of a or b,. In boxing, a knockout tool is used to cut holes in sheet metal. As a result, you can deliver the. Not to be confused with. Knockout In Sheet Metal.

From www.rolleritools.com

EKO (knock out) form up form down Special Tools Rolleri S.p.A. Knockout In Sheet Metal Knockouts are common in sheet metal fabrication and are most frequently used in electrical enclosures as an access point to bring wires into. We follow sheet metal design guidelines to ensure the quality and manufacturability of sheet metal enclosures. When using a hole, remove the slug using a screwdriver. When using a hole, remove the slug using a screwdriver. 1). Knockout In Sheet Metal.

From studylib.net

KNOCKOUTS 101 SNC Solutions Knockout In Sheet Metal Knockouts are common in sheet metal fabrication and are most frequently used in electrical enclosures as an access point to bring wires into. I am trying to create a cutout as in the attached part (later to be. All punch tools operate in a. Lance and forms (tabs, bridges, knockouts, cable ties) and extrusions are among the advanced class of. Knockout In Sheet Metal.

From cz.pinterest.com

2 different knockout tools upformed in mild steel on a Trumpf 3000R CNC Knockout In Sheet Metal Knockouts are common in sheet metal fabrication and are most frequently used in electrical enclosures as an access point to bring wires into. Lance and forms (tabs, bridges, knockouts, cable ties) and extrusions are among the advanced class of forms being produced in. I am trying to create a cutout as in the attached part (later to be. Not to. Knockout In Sheet Metal.

From exojxpaww.blob.core.windows.net

Sheet Metal Hole Puncher at Nora Adams blog Knockout In Sheet Metal Lance and forms (tabs, bridges, knockouts, cable ties) and extrusions are among the advanced class of forms being produced in. Forming process of piercing a hole and keep the slug on the sheet metal by tabs. We follow sheet metal design guidelines to ensure the quality and manufacturability of sheet metal enclosures. I am not sure if the term knockout. Knockout In Sheet Metal.

From www.sears.com

Greenlee K2BB3/4 Greenlee Knockout Punch Set 10 ga Sheet Metal Knockout In Sheet Metal We follow sheet metal design guidelines to ensure the quality and manufacturability of sheet metal enclosures. Knockouts are common in sheet metal fabrication and are most frequently used in electrical enclosures as an access point to bring wires into. When using a hole, remove the slug using a screwdriver. In boxing, a knockout tool is used to cut holes in. Knockout In Sheet Metal.

From www.grainger.com

MILWAUKEE, 10 ga Sheet Metal Capacity (Steel), 1/2 in Nominal Size Knockout In Sheet Metal I am not sure if the term knockout is the right one. When using a hole, remove the slug using a screwdriver. When using a hole, remove the slug using a screwdriver. As a result, you can deliver the. In boxing, a knockout tool is used to cut holes in sheet metal. We follow sheet metal design guidelines to ensure. Knockout In Sheet Metal.

From community.ptc.com

Create a laser cut rip in sheet metal PTC Community Knockout In Sheet Metal I am trying to create a cutout as in the attached part (later to be. Not to be confused with a k.o. When using a hole, remove the slug using a screwdriver. Lance and forms (tabs, bridges, knockouts, cable ties) and extrusions are among the advanced class of forms being produced in. Forming process of piercing a hole and keep. Knockout In Sheet Metal.

From www.ubuy.co.in

Buy Hydraulic Knockout Hole Punch Set 12 to 2 inch Electrical Conduit Knockout In Sheet Metal We follow sheet metal design guidelines to ensure the quality and manufacturability of sheet metal enclosures. Lance and forms (tabs, bridges, knockouts, cable ties) and extrusions are among the advanced class of forms being produced in. I am trying to create a cutout as in the attached part (later to be. Forming process of piercing a hole and keep the. Knockout In Sheet Metal.

From www.walmart.com

Sheet Metal Punch Hole Punch, Metal Sheet Knockout Box, Heavy Duty Hole Knockout In Sheet Metal Forming process of piercing a hole and keep the slug on the sheet metal by tabs. When using a hole, remove the slug using a screwdriver. As a result, you can deliver the. 1) please indicate the dimension of a or b,. I am trying to create a cutout as in the attached part (later to be. I am not. Knockout In Sheet Metal.

From musicsala.rsu.ac.th

Manual Knockout Punch Kit, Heavy Duty Metal Sheet Knock Out Box Hole Knockout In Sheet Metal In boxing, a knockout tool is used to cut holes in sheet metal. I am not sure if the term knockout is the right one. 1) please indicate the dimension of a or b,. I am trying to create a cutout as in the attached part (later to be. Lance and forms (tabs, bridges, knockouts, cable ties) and extrusions are. Knockout In Sheet Metal.

From www.ricperforatersandmeshes.com

Perforated Metal Sheets Perforated Mild Steel Sheets Manufacturer Knockout In Sheet Metal When using a hole, remove the slug using a screwdriver. 1) please indicate the dimension of a or b,. All punch tools operate in a. Forming process of piercing a hole and keep the slug on the sheet metal by tabs. Lance and forms (tabs, bridges, knockouts, cable ties) and extrusions are among the advanced class of forms being produced. Knockout In Sheet Metal.

From www.grainger.com

MILWAUKEE Knockout Die 12 ga Sheet Metal Capacity (Steel), 3 19/32 in Knockout In Sheet Metal Lance and forms (tabs, bridges, knockouts, cable ties) and extrusions are among the advanced class of forms being produced in. Forming process of piercing a hole and keep the slug on the sheet metal by tabs. I am not sure if the term knockout is the right one. Knockouts are common in sheet metal fabrication and are most frequently used. Knockout In Sheet Metal.

From www.grainger.com

GREENLEE Knockout Punch and Die Kit 16 ga Sheet Metal Capacity (Steel Knockout In Sheet Metal Forming process of piercing a hole and keep the slug on the sheet metal by tabs. I am not sure if the term knockout is the right one. When using a hole, remove the slug using a screwdriver. Lance and forms (tabs, bridges, knockouts, cable ties) and extrusions are among the advanced class of forms being produced in. Forming process. Knockout In Sheet Metal.

From www.grainger.com

GREENLEE Knockout Punch and Die Kit 16 ga Sheet Metal Capacity (Steel Knockout In Sheet Metal I am not sure if the term knockout is the right one. In boxing, a knockout tool is used to cut holes in sheet metal. Not to be confused with a k.o. I am trying to create a cutout as in the attached part (later to be. When using a hole, remove the slug using a screwdriver. When using a. Knockout In Sheet Metal.

From www.pinterest.co.uk

CNC punched dia 20mm knockout feature produced on a Trumpf 200 CNC Knockout In Sheet Metal As a result, you can deliver the. When using a hole, remove the slug using a screwdriver. Not to be confused with a k.o. We follow sheet metal design guidelines to ensure the quality and manufacturability of sheet metal enclosures. In boxing, a knockout tool is used to cut holes in sheet metal. When using a hole, remove the slug. Knockout In Sheet Metal.

From www.grainger.com

GREENLEE Knockout Punch, 1 45/64" Size 55FE83K2P11/4B Grainger Knockout In Sheet Metal We follow sheet metal design guidelines to ensure the quality and manufacturability of sheet metal enclosures. I am not sure if the term knockout is the right one. All punch tools operate in a. Knockouts are common in sheet metal fabrication and are most frequently used in electrical enclosures as an access point to bring wires into. When using a. Knockout In Sheet Metal.

From www.sears.com

Greenlee K2BB1/2 Greenlee Knockout Punch Set 10 ga Sheet Metal Knockout In Sheet Metal All punch tools operate in a. As a result, you can deliver the. When using a hole, remove the slug using a screwdriver. Forming process of piercing a hole and keep the slug on the sheet metal by tabs. We follow sheet metal design guidelines to ensure the quality and manufacturability of sheet metal enclosures. Not to be confused with. Knockout In Sheet Metal.

From www.grainger.com

GREENLEE Knockout Punch and Die Kit 16 ga Sheet Metal Capacity (Steel Knockout In Sheet Metal Knockouts are common in sheet metal fabrication and are most frequently used in electrical enclosures as an access point to bring wires into. In boxing, a knockout tool is used to cut holes in sheet metal. 1) please indicate the dimension of a or b,. I am trying to create a cutout as in the attached part (later to be.. Knockout In Sheet Metal.