Cadmium Plating On Steel . Cadmium plating is typically used to coat steel, copper, or iron components. This process occurs in cyanide baths that contain a mixture of cadmium oxide and sodium cyanide. Cadmium plating is a technique used to coat metal surfaces with a layer of cadmium. This technique provides excellent corrosion. Cadmium plating involves depositing a thin layer of cadmium onto a base metal, typically steel, copper, iron, brass, or aluminum. Cadmium plating of stainless steel, particularly fasteners, is a long used and. Cadmium has been used widely for coating steel structural components and threaded assemblies principally to provide protection from corrosion. The most common method for applying this coating is through electroplating. A cadmium galvanic coating on steel has many advantages such as good lubricity, solderability, and low galvanic corrosion with aluminum [41]. Cadmium plating is a metallic silver, soft coating that can be deposited on various base materials such as steel, copper, iron, brass and aluminum. Galvanic compatibility between aluminium and stainless steel. It is prized for its corrosion. It offers excellent protection from corrosion, and provides a wide range of other benefits that help extend the lifespan of the metal substrate.

from elcoats.com

Galvanic compatibility between aluminium and stainless steel. This technique provides excellent corrosion. Cadmium plating is a technique used to coat metal surfaces with a layer of cadmium. This process occurs in cyanide baths that contain a mixture of cadmium oxide and sodium cyanide. It is prized for its corrosion. Cadmium plating of stainless steel, particularly fasteners, is a long used and. A cadmium galvanic coating on steel has many advantages such as good lubricity, solderability, and low galvanic corrosion with aluminum [41]. It offers excellent protection from corrosion, and provides a wide range of other benefits that help extend the lifespan of the metal substrate. Cadmium has been used widely for coating steel structural components and threaded assemblies principally to provide protection from corrosion. Cadmium plating involves depositing a thin layer of cadmium onto a base metal, typically steel, copper, iron, brass, or aluminum.

Types of Metal Plating Elcoats Allied Industries

Cadmium Plating On Steel It offers excellent protection from corrosion, and provides a wide range of other benefits that help extend the lifespan of the metal substrate. Cadmium plating is a metallic silver, soft coating that can be deposited on various base materials such as steel, copper, iron, brass and aluminum. Cadmium has been used widely for coating steel structural components and threaded assemblies principally to provide protection from corrosion. Cadmium plating of stainless steel, particularly fasteners, is a long used and. Galvanic compatibility between aluminium and stainless steel. This technique provides excellent corrosion. Cadmium plating is typically used to coat steel, copper, or iron components. The most common method for applying this coating is through electroplating. This process occurs in cyanide baths that contain a mixture of cadmium oxide and sodium cyanide. A cadmium galvanic coating on steel has many advantages such as good lubricity, solderability, and low galvanic corrosion with aluminum [41]. Cadmium plating is a technique used to coat metal surfaces with a layer of cadmium. Cadmium plating involves depositing a thin layer of cadmium onto a base metal, typically steel, copper, iron, brass, or aluminum. It is prized for its corrosion. It offers excellent protection from corrosion, and provides a wide range of other benefits that help extend the lifespan of the metal substrate.

From techmetals.com

Cadmium Plating Cad Plating AMSQQP416 Techmetals, Inc. Cadmium Plating On Steel Cadmium has been used widely for coating steel structural components and threaded assemblies principally to provide protection from corrosion. This technique provides excellent corrosion. The most common method for applying this coating is through electroplating. Cadmium plating is a metallic silver, soft coating that can be deposited on various base materials such as steel, copper, iron, brass and aluminum. Galvanic. Cadmium Plating On Steel.

From www.directindustry.com

Stainless steel cadmium plating Cadmiage inox BONNANS for aeronautics Cadmium Plating On Steel Cadmium plating involves depositing a thin layer of cadmium onto a base metal, typically steel, copper, iron, brass, or aluminum. This process occurs in cyanide baths that contain a mixture of cadmium oxide and sodium cyanide. A cadmium galvanic coating on steel has many advantages such as good lubricity, solderability, and low galvanic corrosion with aluminum [41]. Cadmium plating is. Cadmium Plating On Steel.

From www.youtube.com

SIFCO ASC Cadmium Plating Application YouTube Cadmium Plating On Steel This process occurs in cyanide baths that contain a mixture of cadmium oxide and sodium cyanide. A cadmium galvanic coating on steel has many advantages such as good lubricity, solderability, and low galvanic corrosion with aluminum [41]. Cadmium plating is typically used to coat steel, copper, or iron components. Galvanic compatibility between aluminium and stainless steel. Cadmium plating is a. Cadmium Plating On Steel.

From sheffieldplaters.com

Cadmium Plating My CMSMy CMS Cadmium Plating On Steel The most common method for applying this coating is through electroplating. Cadmium has been used widely for coating steel structural components and threaded assemblies principally to provide protection from corrosion. Cadmium plating involves depositing a thin layer of cadmium onto a base metal, typically steel, copper, iron, brass, or aluminum. Cadmium plating is a technique used to coat metal surfaces. Cadmium Plating On Steel.

From aerospacemetalsllc.com

The Power of Cadmium Plating A Closer Look into Its Applications and Cadmium Plating On Steel Cadmium has been used widely for coating steel structural components and threaded assemblies principally to provide protection from corrosion. The most common method for applying this coating is through electroplating. A cadmium galvanic coating on steel has many advantages such as good lubricity, solderability, and low galvanic corrosion with aluminum [41]. This process occurs in cyanide baths that contain a. Cadmium Plating On Steel.

From www.youtube.com

Why Choose Cadmium Plating YouTube Cadmium Plating On Steel Cadmium plating of stainless steel, particularly fasteners, is a long used and. Cadmium plating is a technique used to coat metal surfaces with a layer of cadmium. Cadmium plating involves depositing a thin layer of cadmium onto a base metal, typically steel, copper, iron, brass, or aluminum. This technique provides excellent corrosion. The most common method for applying this coating. Cadmium Plating On Steel.

From erieplating.com

Nadcap Cadmium Plating Services Erie Plating Company Cadmium Plating On Steel The most common method for applying this coating is through electroplating. Cadmium plating is a technique used to coat metal surfaces with a layer of cadmium. Cadmium plating is typically used to coat steel, copper, or iron components. A cadmium galvanic coating on steel has many advantages such as good lubricity, solderability, and low galvanic corrosion with aluminum [41]. It. Cadmium Plating On Steel.

From wolff-tech.com

An Introduction to Cadmium Plating Cadmium Plating On Steel Cadmium plating of stainless steel, particularly fasteners, is a long used and. It offers excellent protection from corrosion, and provides a wide range of other benefits that help extend the lifespan of the metal substrate. Cadmium plating is a metallic silver, soft coating that can be deposited on various base materials such as steel, copper, iron, brass and aluminum. Cadmium. Cadmium Plating On Steel.

From blog.thepipingmart.com

Zinc Nickel Plating vs Cadmium Plating What's the Difference Cadmium Plating On Steel It offers excellent protection from corrosion, and provides a wide range of other benefits that help extend the lifespan of the metal substrate. Galvanic compatibility between aluminium and stainless steel. Cadmium has been used widely for coating steel structural components and threaded assemblies principally to provide protection from corrosion. The most common method for applying this coating is through electroplating.. Cadmium Plating On Steel.

From chemresearchco.com

Cadmium Plating Company in Phoenix, AZ ChemResearch Co Cadmium Plating On Steel Galvanic compatibility between aluminium and stainless steel. Cadmium plating is typically used to coat steel, copper, or iron components. It is prized for its corrosion. Cadmium plating involves depositing a thin layer of cadmium onto a base metal, typically steel, copper, iron, brass, or aluminum. A cadmium galvanic coating on steel has many advantages such as good lubricity, solderability, and. Cadmium Plating On Steel.

From blog.thepipingmart.com

Zinc Plating vs Cadmium Plating What's the Difference Cadmium Plating On Steel The most common method for applying this coating is through electroplating. Cadmium plating is typically used to coat steel, copper, or iron components. This technique provides excellent corrosion. Cadmium has been used widely for coating steel structural components and threaded assemblies principally to provide protection from corrosion. Cadmium plating of stainless steel, particularly fasteners, is a long used and. Cadmium. Cadmium Plating On Steel.

From www.mftech.com

MILSTD 865 & ASTM B766 Cadmium Plating Services Metal Finishing Tech Cadmium Plating On Steel A cadmium galvanic coating on steel has many advantages such as good lubricity, solderability, and low galvanic corrosion with aluminum [41]. The most common method for applying this coating is through electroplating. This process occurs in cyanide baths that contain a mixture of cadmium oxide and sodium cyanide. This technique provides excellent corrosion. Cadmium plating involves depositing a thin layer. Cadmium Plating On Steel.

From techmetals.com

Cadmium Plating Cad Plating AMSQQP416 Techmetals, Inc. Cadmium Plating On Steel Cadmium plating is typically used to coat steel, copper, or iron components. This technique provides excellent corrosion. This process occurs in cyanide baths that contain a mixture of cadmium oxide and sodium cyanide. It offers excellent protection from corrosion, and provides a wide range of other benefits that help extend the lifespan of the metal substrate. Cadmium plating involves depositing. Cadmium Plating On Steel.

From rmfusa.com

Cadmium Plating Reid Metal Finishing Cadmium Plating On Steel Cadmium plating is a metallic silver, soft coating that can be deposited on various base materials such as steel, copper, iron, brass and aluminum. A cadmium galvanic coating on steel has many advantages such as good lubricity, solderability, and low galvanic corrosion with aluminum [41]. Cadmium plating is a technique used to coat metal surfaces with a layer of cadmium.. Cadmium Plating On Steel.

From techmetals.com

Cadmium Plating Cad Plating AMSQQP416 Techmetals, Inc. Cadmium Plating On Steel Cadmium plating is a technique used to coat metal surfaces with a layer of cadmium. Cadmium has been used widely for coating steel structural components and threaded assemblies principally to provide protection from corrosion. Galvanic compatibility between aluminium and stainless steel. The most common method for applying this coating is through electroplating. Cadmium plating is typically used to coat steel,. Cadmium Plating On Steel.

From techmetals.com

Cadmium Plating Cad Plating AMSQQP416 Techmetals, Inc. Cadmium Plating On Steel Cadmium plating involves depositing a thin layer of cadmium onto a base metal, typically steel, copper, iron, brass, or aluminum. A cadmium galvanic coating on steel has many advantages such as good lubricity, solderability, and low galvanic corrosion with aluminum [41]. Cadmium plating of stainless steel, particularly fasteners, is a long used and. Galvanic compatibility between aluminium and stainless steel.. Cadmium Plating On Steel.

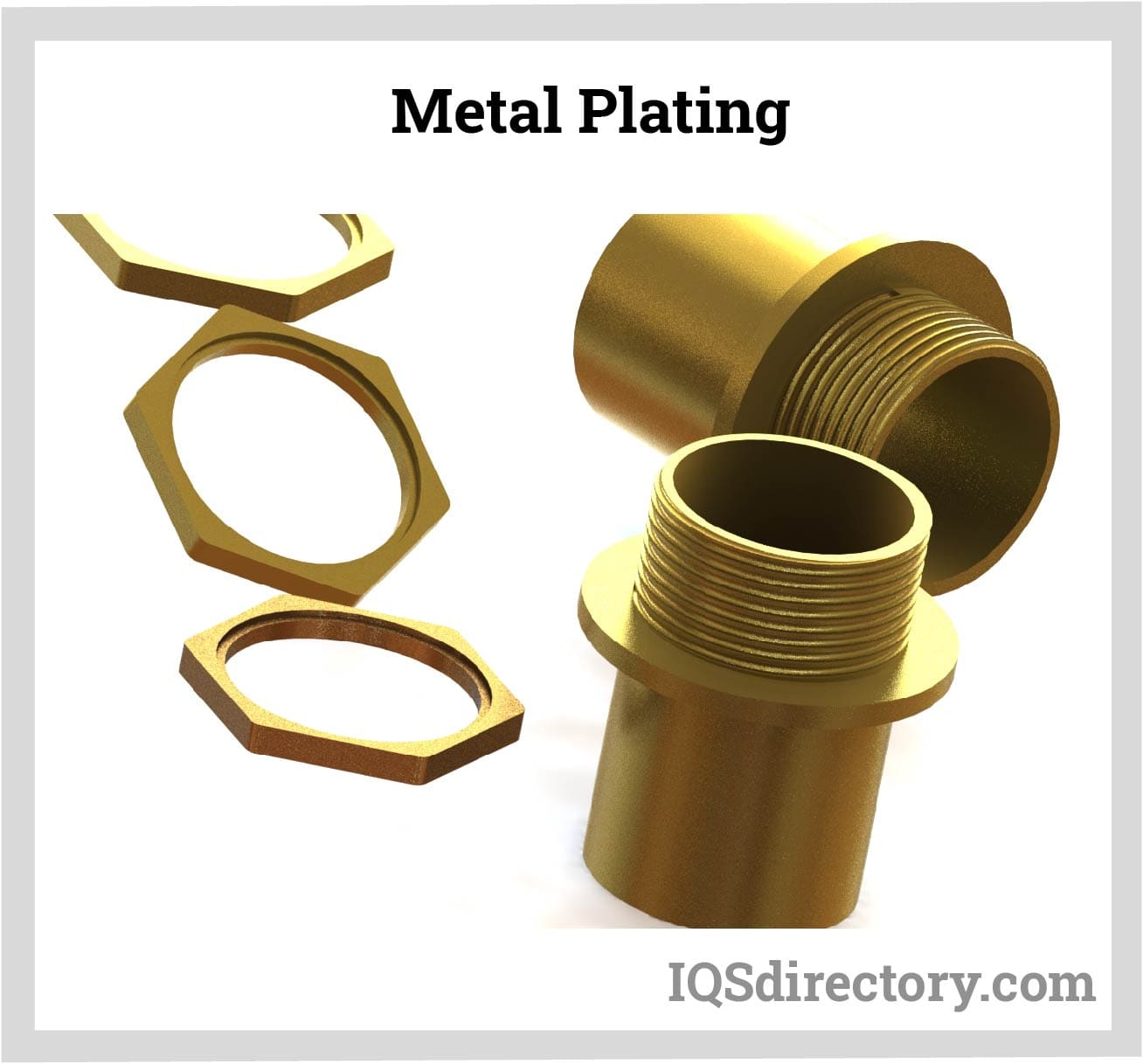

From www.iqsdirectory.com

Types of Metal Plating Metal, Types, Applications, and Benefits Cadmium Plating On Steel It is prized for its corrosion. Cadmium plating involves depositing a thin layer of cadmium onto a base metal, typically steel, copper, iron, brass, or aluminum. Cadmium plating is a technique used to coat metal surfaces with a layer of cadmium. It offers excellent protection from corrosion, and provides a wide range of other benefits that help extend the lifespan. Cadmium Plating On Steel.

From www.alamy.com

Cadmium on periodic table of the elements. Metal and chemical element Cadmium Plating On Steel It is prized for its corrosion. The most common method for applying this coating is through electroplating. This process occurs in cyanide baths that contain a mixture of cadmium oxide and sodium cyanide. A cadmium galvanic coating on steel has many advantages such as good lubricity, solderability, and low galvanic corrosion with aluminum [41]. Cadmium plating of stainless steel, particularly. Cadmium Plating On Steel.

From www.directindustry.com

Steel cadmium plating Industrial Metal Finishing military Cadmium Plating On Steel A cadmium galvanic coating on steel has many advantages such as good lubricity, solderability, and low galvanic corrosion with aluminum [41]. This process occurs in cyanide baths that contain a mixture of cadmium oxide and sodium cyanide. The most common method for applying this coating is through electroplating. It is prized for its corrosion. This technique provides excellent corrosion. Cadmium. Cadmium Plating On Steel.

From www.valencesurfacetech.com

The Shining Benefits Of Cadmium Plating In The Aerospace Industry Cadmium Plating On Steel This technique provides excellent corrosion. It is prized for its corrosion. The most common method for applying this coating is through electroplating. It offers excellent protection from corrosion, and provides a wide range of other benefits that help extend the lifespan of the metal substrate. A cadmium galvanic coating on steel has many advantages such as good lubricity, solderability, and. Cadmium Plating On Steel.

From aerospacemetalsllc.com

Cadmium Plating What Is It and What Are Its Benefits? Aerospace Metals Cadmium Plating On Steel Cadmium plating is typically used to coat steel, copper, or iron components. Galvanic compatibility between aluminium and stainless steel. It is prized for its corrosion. Cadmium plating of stainless steel, particularly fasteners, is a long used and. Cadmium plating involves depositing a thin layer of cadmium onto a base metal, typically steel, copper, iron, brass, or aluminum. Cadmium has been. Cadmium Plating On Steel.

From techmetals.com

Cadmium Plating Cad Plating AMSQQP416 Techmetals, Inc. Cadmium Plating On Steel It is prized for its corrosion. The most common method for applying this coating is through electroplating. Cadmium plating is a technique used to coat metal surfaces with a layer of cadmium. This technique provides excellent corrosion. Cadmium plating of stainless steel, particularly fasteners, is a long used and. Galvanic compatibility between aluminium and stainless steel. It offers excellent protection. Cadmium Plating On Steel.

From www.rfparts.com

TL53, H.H. Smith, Cadmium, Plated, Steel Lug Cadmium Plating On Steel Cadmium plating is a technique used to coat metal surfaces with a layer of cadmium. Cadmium plating of stainless steel, particularly fasteners, is a long used and. Cadmium plating is a metallic silver, soft coating that can be deposited on various base materials such as steel, copper, iron, brass and aluminum. The most common method for applying this coating is. Cadmium Plating On Steel.

From incertec.com

AMSQQP416 Cadmium Plating & Coating Services INCERTEC Cadmium Plating On Steel It offers excellent protection from corrosion, and provides a wide range of other benefits that help extend the lifespan of the metal substrate. Galvanic compatibility between aluminium and stainless steel. Cadmium has been used widely for coating steel structural components and threaded assemblies principally to provide protection from corrosion. A cadmium galvanic coating on steel has many advantages such as. Cadmium Plating On Steel.

From elcoats.com

Types of Metal Plating Elcoats Allied Industries Cadmium Plating On Steel Cadmium plating of stainless steel, particularly fasteners, is a long used and. Galvanic compatibility between aluminium and stainless steel. Cadmium plating is a metallic silver, soft coating that can be deposited on various base materials such as steel, copper, iron, brass and aluminum. It offers excellent protection from corrosion, and provides a wide range of other benefits that help extend. Cadmium Plating On Steel.

From www.nemetalworks.com

Cadmium Plating Services Cadmium Plating On Steel Cadmium plating is typically used to coat steel, copper, or iron components. It offers excellent protection from corrosion, and provides a wide range of other benefits that help extend the lifespan of the metal substrate. Cadmium plating involves depositing a thin layer of cadmium onto a base metal, typically steel, copper, iron, brass, or aluminum. Galvanic compatibility between aluminium and. Cadmium Plating On Steel.

From techmetals.com

Cadmium Plating Cad Plating AMSQQP416 Techmetals, Inc. Cadmium Plating On Steel Cadmium plating of stainless steel, particularly fasteners, is a long used and. This process occurs in cyanide baths that contain a mixture of cadmium oxide and sodium cyanide. The most common method for applying this coating is through electroplating. A cadmium galvanic coating on steel has many advantages such as good lubricity, solderability, and low galvanic corrosion with aluminum [41].. Cadmium Plating On Steel.

From www.mftech.com

MILSTD 865 & ASTM B766 Cadmium Plating Services Metal Finishing Tech Cadmium Plating On Steel This technique provides excellent corrosion. Cadmium plating is a metallic silver, soft coating that can be deposited on various base materials such as steel, copper, iron, brass and aluminum. The most common method for applying this coating is through electroplating. It offers excellent protection from corrosion, and provides a wide range of other benefits that help extend the lifespan of. Cadmium Plating On Steel.

From www.directindustry.com

Steel cadmium plating DALIC stainless steel / aluminum / for Cadmium Plating On Steel Cadmium plating is a technique used to coat metal surfaces with a layer of cadmium. The most common method for applying this coating is through electroplating. It offers excellent protection from corrosion, and provides a wide range of other benefits that help extend the lifespan of the metal substrate. It is prized for its corrosion. Cadmium plating is typically used. Cadmium Plating On Steel.

From weldingpros.net

Metal plating Processes Explained With Examples Cadmium Plating On Steel This technique provides excellent corrosion. Cadmium has been used widely for coating steel structural components and threaded assemblies principally to provide protection from corrosion. The most common method for applying this coating is through electroplating. Cadmium plating involves depositing a thin layer of cadmium onto a base metal, typically steel, copper, iron, brass, or aluminum. Galvanic compatibility between aluminium and. Cadmium Plating On Steel.

From techmetals.com

Cadmium Plating Cad Plating AMSQQP416 Techmetals, Inc. Cadmium Plating On Steel A cadmium galvanic coating on steel has many advantages such as good lubricity, solderability, and low galvanic corrosion with aluminum [41]. Cadmium plating involves depositing a thin layer of cadmium onto a base metal, typically steel, copper, iron, brass, or aluminum. Galvanic compatibility between aluminium and stainless steel. It offers excellent protection from corrosion, and provides a wide range of. Cadmium Plating On Steel.

From www.pinterest.com

Cadmium plating in Toronto, Toronto's electroplating company rebuild Cadmium Plating On Steel It is prized for its corrosion. This technique provides excellent corrosion. Cadmium plating is a metallic silver, soft coating that can be deposited on various base materials such as steel, copper, iron, brass and aluminum. Galvanic compatibility between aluminium and stainless steel. Cadmium plating involves depositing a thin layer of cadmium onto a base metal, typically steel, copper, iron, brass,. Cadmium Plating On Steel.

From www.pinterest.com

What is Cadmium Plating Cadmium Plating Plating, Service Cadmium Plating On Steel Cadmium plating is a technique used to coat metal surfaces with a layer of cadmium. Cadmium plating involves depositing a thin layer of cadmium onto a base metal, typically steel, copper, iron, brass, or aluminum. Cadmium has been used widely for coating steel structural components and threaded assemblies principally to provide protection from corrosion. Cadmium plating is a metallic silver,. Cadmium Plating On Steel.

From ar.inspiredpencil.com

Cadmium Plating Cadmium Plating On Steel This process occurs in cyanide baths that contain a mixture of cadmium oxide and sodium cyanide. This technique provides excellent corrosion. A cadmium galvanic coating on steel has many advantages such as good lubricity, solderability, and low galvanic corrosion with aluminum [41]. Galvanic compatibility between aluminium and stainless steel. It offers excellent protection from corrosion, and provides a wide range. Cadmium Plating On Steel.

From techmetals.com

Cadmium Plating Cad Plating AMSQQP416 Techmetals, Inc. Cadmium Plating On Steel A cadmium galvanic coating on steel has many advantages such as good lubricity, solderability, and low galvanic corrosion with aluminum [41]. Cadmium plating of stainless steel, particularly fasteners, is a long used and. The most common method for applying this coating is through electroplating. This technique provides excellent corrosion. It is prized for its corrosion. Cadmium plating is typically used. Cadmium Plating On Steel.