What Is Corner Chamfer In Sheet Metal . Chamfer is an angled edge that also does the same function. A fillet is a rounded corner that connects two surfaces. Two commonly used and recommended sheet metal design features on the corners of a square or rectangular part are chamfers and radii. Line chamfering refers to the processing of a surface on the corner of a material that is invisible to the naked eye. To create a corner chamfer in cad with a specified distance and angle, you can follow these steps: A chamfer is an angle on the edge of a workpiece. They are created for mainly for protecting the chamfered. In metal fabrication and extrusion, fillets and chamfers are used to ease sharp edges and corners of. It is an antonym of the fillet. Select the “corner chamfer” command from the “modify” panel under the. A chamfer is the sloped or angled edges or corners of a part design. Line chamfering is generally considered to be about c0.2~0.3, but unlike c chamfering and r chamfering, there are no clear regulations on the shape and size of the chamfer. Instead of having a curved shape, a chamfer is straight and has a sharp angle.

from www.woodsmith.com

They are created for mainly for protecting the chamfered. A chamfer is an angle on the edge of a workpiece. Instead of having a curved shape, a chamfer is straight and has a sharp angle. Line chamfering refers to the processing of a surface on the corner of a material that is invisible to the naked eye. A chamfer is the sloped or angled edges or corners of a part design. Two commonly used and recommended sheet metal design features on the corners of a square or rectangular part are chamfers and radii. In metal fabrication and extrusion, fillets and chamfers are used to ease sharp edges and corners of. It is an antonym of the fillet. Select the “corner chamfer” command from the “modify” panel under the. Chamfer is an angled edge that also does the same function.

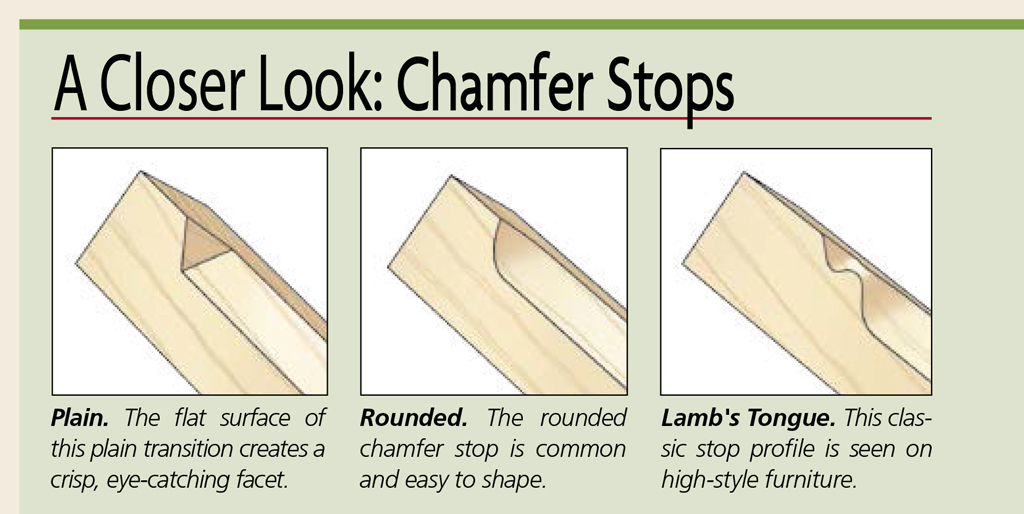

The Versatile Chamfer Woodsmith

What Is Corner Chamfer In Sheet Metal It is an antonym of the fillet. Chamfer is an angled edge that also does the same function. Two commonly used and recommended sheet metal design features on the corners of a square or rectangular part are chamfers and radii. Select the “corner chamfer” command from the “modify” panel under the. A chamfer is an angle on the edge of a workpiece. To create a corner chamfer in cad with a specified distance and angle, you can follow these steps: A fillet is a rounded corner that connects two surfaces. They are created for mainly for protecting the chamfered. Line chamfering is generally considered to be about c0.2~0.3, but unlike c chamfering and r chamfering, there are no clear regulations on the shape and size of the chamfer. It is an antonym of the fillet. A chamfer is the sloped or angled edges or corners of a part design. In metal fabrication and extrusion, fillets and chamfers are used to ease sharp edges and corners of. Instead of having a curved shape, a chamfer is straight and has a sharp angle. Line chamfering refers to the processing of a surface on the corner of a material that is invisible to the naked eye.

From ameritexllc.com

Sheet Metal Corner Treatments You Should Know About Ameritex What Is Corner Chamfer In Sheet Metal They are created for mainly for protecting the chamfered. A fillet is a rounded corner that connects two surfaces. Two commonly used and recommended sheet metal design features on the corners of a square or rectangular part are chamfers and radii. It is an antonym of the fillet. Line chamfering refers to the processing of a surface on the corner. What Is Corner Chamfer In Sheet Metal.

From www.gdandtbasics.com

Chamfer Dimensioning GD&T Basics What Is Corner Chamfer In Sheet Metal To create a corner chamfer in cad with a specified distance and angle, you can follow these steps: Line chamfering refers to the processing of a surface on the corner of a material that is invisible to the naked eye. A chamfer is the sloped or angled edges or corners of a part design. It is an antonym of the. What Is Corner Chamfer In Sheet Metal.

From forums.autodesk.com

Solved Inventor Sheet Metal Automatic Corner Chamfer On Surfaces With What Is Corner Chamfer In Sheet Metal They are created for mainly for protecting the chamfered. It is an antonym of the fillet. Chamfer is an angled edge that also does the same function. Line chamfering refers to the processing of a surface on the corner of a material that is invisible to the naked eye. A chamfer is an angle on the edge of a workpiece.. What Is Corner Chamfer In Sheet Metal.

From www.synergis.com

Sheet Metal Corner Relief Options Synergis® What Is Corner Chamfer In Sheet Metal A chamfer is an angle on the edge of a workpiece. A fillet is a rounded corner that connects two surfaces. They are created for mainly for protecting the chamfered. Line chamfering is generally considered to be about c0.2~0.3, but unlike c chamfering and r chamfering, there are no clear regulations on the shape and size of the chamfer. Instead. What Is Corner Chamfer In Sheet Metal.

From www.finepowertools.com

Bevel vs Chamfer Difference Between the Edges Demystified. What Is Corner Chamfer In Sheet Metal Chamfer is an angled edge that also does the same function. Line chamfering refers to the processing of a surface on the corner of a material that is invisible to the naked eye. Two commonly used and recommended sheet metal design features on the corners of a square or rectangular part are chamfers and radii. In metal fabrication and extrusion,. What Is Corner Chamfer In Sheet Metal.

From forums.autodesk.com

Solved Inventor Sheet Metal Automatic Corner Chamfer On Surfaces With What Is Corner Chamfer In Sheet Metal It is an antonym of the fillet. A fillet is a rounded corner that connects two surfaces. Select the “corner chamfer” command from the “modify” panel under the. Line chamfering is generally considered to be about c0.2~0.3, but unlike c chamfering and r chamfering, there are no clear regulations on the shape and size of the chamfer. To create a. What Is Corner Chamfer In Sheet Metal.

From www.clarkdietrich.com

Chamfered Corner Bead ClarkDietrich Building Systems What Is Corner Chamfer In Sheet Metal It is an antonym of the fillet. Line chamfering refers to the processing of a surface on the corner of a material that is invisible to the naked eye. A chamfer is the sloped or angled edges or corners of a part design. To create a corner chamfer in cad with a specified distance and angle, you can follow these. What Is Corner Chamfer In Sheet Metal.

From forums.autodesk.com

Corner Chamfer option within the Flange tool Sheet Metal Autodesk What Is Corner Chamfer In Sheet Metal To create a corner chamfer in cad with a specified distance and angle, you can follow these steps: Two commonly used and recommended sheet metal design features on the corners of a square or rectangular part are chamfers and radii. Instead of having a curved shape, a chamfer is straight and has a sharp angle. In metal fabrication and extrusion,. What Is Corner Chamfer In Sheet Metal.

From www.finepowertools.com

Bevel vs Chamfer Difference Between the Edges Demystified. What Is Corner Chamfer In Sheet Metal Line chamfering is generally considered to be about c0.2~0.3, but unlike c chamfering and r chamfering, there are no clear regulations on the shape and size of the chamfer. A fillet is a rounded corner that connects two surfaces. It is an antonym of the fillet. A chamfer is the sloped or angled edges or corners of a part design.. What Is Corner Chamfer In Sheet Metal.

From www.youtube.com

How to use Break Corner and Chamfer Feature Sheet Metal Design in NX What Is Corner Chamfer In Sheet Metal A fillet is a rounded corner that connects two surfaces. Instead of having a curved shape, a chamfer is straight and has a sharp angle. Select the “corner chamfer” command from the “modify” panel under the. A chamfer is an angle on the edge of a workpiece. Line chamfering refers to the processing of a surface on the corner of. What Is Corner Chamfer In Sheet Metal.

From www.madearia.com

Chamfer vs BevelExplained And Their Difference Aria What Is Corner Chamfer In Sheet Metal Instead of having a curved shape, a chamfer is straight and has a sharp angle. Line chamfering is generally considered to be about c0.2~0.3, but unlike c chamfering and r chamfering, there are no clear regulations on the shape and size of the chamfer. Two commonly used and recommended sheet metal design features on the corners of a square or. What Is Corner Chamfer In Sheet Metal.

From www.rapiddirect.com

Fillet vs Chamfers What a Fillet is and How It Differs from Chamfers What Is Corner Chamfer In Sheet Metal Instead of having a curved shape, a chamfer is straight and has a sharp angle. In metal fabrication and extrusion, fillets and chamfers are used to ease sharp edges and corners of. Line chamfering is generally considered to be about c0.2~0.3, but unlike c chamfering and r chamfering, there are no clear regulations on the shape and size of the. What Is Corner Chamfer In Sheet Metal.

From fiverrme.com

What is the difference between a bevel and chamfer? What Is Corner Chamfer In Sheet Metal Instead of having a curved shape, a chamfer is straight and has a sharp angle. They are created for mainly for protecting the chamfered. Select the “corner chamfer” command from the “modify” panel under the. A chamfer is an angle on the edge of a workpiece. Two commonly used and recommended sheet metal design features on the corners of a. What Is Corner Chamfer In Sheet Metal.

From www.slideserve.com

PPT Dimensioning Standards PowerPoint Presentation, free download What Is Corner Chamfer In Sheet Metal To create a corner chamfer in cad with a specified distance and angle, you can follow these steps: A chamfer is the sloped or angled edges or corners of a part design. It is an antonym of the fillet. They are created for mainly for protecting the chamfered. A fillet is a rounded corner that connects two surfaces. Line chamfering. What Is Corner Chamfer In Sheet Metal.

From www.madearia.com

Fillet vs Chamfer Basic Operations & Cad Design Features 2022 Aria What Is Corner Chamfer In Sheet Metal They are created for mainly for protecting the chamfered. Two commonly used and recommended sheet metal design features on the corners of a square or rectangular part are chamfers and radii. It is an antonym of the fillet. In metal fabrication and extrusion, fillets and chamfers are used to ease sharp edges and corners of. A fillet is a rounded. What Is Corner Chamfer In Sheet Metal.

From www.woodsmith.com

The Versatile Chamfer Woodsmith What Is Corner Chamfer In Sheet Metal A chamfer is the sloped or angled edges or corners of a part design. Two commonly used and recommended sheet metal design features on the corners of a square or rectangular part are chamfers and radii. In metal fabrication and extrusion, fillets and chamfers are used to ease sharp edges and corners of. It is an antonym of the fillet.. What Is Corner Chamfer In Sheet Metal.

From designandmotion.net

Inventor Sheet Metal Corner Round, Corner Chamfer, and Cut What Is Corner Chamfer In Sheet Metal They are created for mainly for protecting the chamfered. Chamfer is an angled edge that also does the same function. A chamfer is an angle on the edge of a workpiece. A fillet is a rounded corner that connects two surfaces. It is an antonym of the fillet. Instead of having a curved shape, a chamfer is straight and has. What Is Corner Chamfer In Sheet Metal.

From forums.sketchup.com

How to chamfer in 3d Corner Pro SketchUp Community What Is Corner Chamfer In Sheet Metal It is an antonym of the fillet. In metal fabrication and extrusion, fillets and chamfers are used to ease sharp edges and corners of. Line chamfering is generally considered to be about c0.2~0.3, but unlike c chamfering and r chamfering, there are no clear regulations on the shape and size of the chamfer. Select the “corner chamfer” command from the. What Is Corner Chamfer In Sheet Metal.

From forums.autodesk.com

Corner Chamfer option within the Flange tool Sheet Metal Autodesk What Is Corner Chamfer In Sheet Metal To create a corner chamfer in cad with a specified distance and angle, you can follow these steps: Line chamfering is generally considered to be about c0.2~0.3, but unlike c chamfering and r chamfering, there are no clear regulations on the shape and size of the chamfer. Instead of having a curved shape, a chamfer is straight and has a. What Is Corner Chamfer In Sheet Metal.

From www.youtube.com

Sheet Metal Fillet And Chamfer What's New in Onshape May 4, 2017 What Is Corner Chamfer In Sheet Metal A chamfer is the sloped or angled edges or corners of a part design. It is an antonym of the fillet. Select the “corner chamfer” command from the “modify” panel under the. Chamfer is an angled edge that also does the same function. Line chamfering refers to the processing of a surface on the corner of a material that is. What Is Corner Chamfer In Sheet Metal.

From waykenrm.com

Fillet vs Chamfer A Complete Guide for Applications WayKen What Is Corner Chamfer In Sheet Metal A chamfer is an angle on the edge of a workpiece. Line chamfering is generally considered to be about c0.2~0.3, but unlike c chamfering and r chamfering, there are no clear regulations on the shape and size of the chamfer. They are created for mainly for protecting the chamfered. Chamfer is an angled edge that also does the same function.. What Is Corner Chamfer In Sheet Metal.

From www.gdandtbasics.com

Chamfer Dimensioning GD&T Basics What Is Corner Chamfer In Sheet Metal To create a corner chamfer in cad with a specified distance and angle, you can follow these steps: A chamfer is an angle on the edge of a workpiece. They are created for mainly for protecting the chamfered. Chamfer is an angled edge that also does the same function. Line chamfering is generally considered to be about c0.2~0.3, but unlike. What Is Corner Chamfer In Sheet Metal.

From www.youtube.com

210 Autodesk Inventor Sheet Metal Corner Round & Corner Chamfer YouTube What Is Corner Chamfer In Sheet Metal A fillet is a rounded corner that connects two surfaces. Instead of having a curved shape, a chamfer is straight and has a sharp angle. A chamfer is an angle on the edge of a workpiece. It is an antonym of the fillet. They are created for mainly for protecting the chamfered. Line chamfering is generally considered to be about. What Is Corner Chamfer In Sheet Metal.

From forums.autodesk.com

Corner Chamfer option within the Flange tool Sheet Metal Autodesk What Is Corner Chamfer In Sheet Metal It is an antonym of the fillet. Line chamfering is generally considered to be about c0.2~0.3, but unlike c chamfering and r chamfering, there are no clear regulations on the shape and size of the chamfer. A chamfer is an angle on the edge of a workpiece. Instead of having a curved shape, a chamfer is straight and has a. What Is Corner Chamfer In Sheet Metal.

From solidworkstutorialsforbeginners.com

How to Use SolidWorks Chamfer Tool Features in SolidWorks CAD What Is Corner Chamfer In Sheet Metal They are created for mainly for protecting the chamfered. Select the “corner chamfer” command from the “modify” panel under the. A chamfer is an angle on the edge of a workpiece. To create a corner chamfer in cad with a specified distance and angle, you can follow these steps: Chamfer is an angled edge that also does the same function.. What Is Corner Chamfer In Sheet Metal.

From forums.autodesk.com

Solved Inventor Sheet Metal Automatic Corner Chamfer On Surfaces With What Is Corner Chamfer In Sheet Metal Line chamfering refers to the processing of a surface on the corner of a material that is invisible to the naked eye. Chamfer is an angled edge that also does the same function. Two commonly used and recommended sheet metal design features on the corners of a square or rectangular part are chamfers and radii. Instead of having a curved. What Is Corner Chamfer In Sheet Metal.

From www.3qmachining.com

Difference Between a Fillet and Chamfer, Everything You Need To Know What Is Corner Chamfer In Sheet Metal A chamfer is the sloped or angled edges or corners of a part design. To create a corner chamfer in cad with a specified distance and angle, you can follow these steps: In metal fabrication and extrusion, fillets and chamfers are used to ease sharp edges and corners of. A fillet is a rounded corner that connects two surfaces. Instead. What Is Corner Chamfer In Sheet Metal.

From www.practicalmachinist.com

Understanding Chamfer and Chamfer Mills Practical Machinist What Is Corner Chamfer In Sheet Metal In metal fabrication and extrusion, fillets and chamfers are used to ease sharp edges and corners of. It is an antonym of the fillet. They are created for mainly for protecting the chamfered. A chamfer is an angle on the edge of a workpiece. Line chamfering is generally considered to be about c0.2~0.3, but unlike c chamfering and r chamfering,. What Is Corner Chamfer In Sheet Metal.

From www.youtube.com

SolidWorks Sheet Metal Relief Type, Rectangle, Obround and Tear (Rip What Is Corner Chamfer In Sheet Metal A chamfer is an angle on the edge of a workpiece. A fillet is a rounded corner that connects two surfaces. In metal fabrication and extrusion, fillets and chamfers are used to ease sharp edges and corners of. To create a corner chamfer in cad with a specified distance and angle, you can follow these steps: A chamfer is the. What Is Corner Chamfer In Sheet Metal.

From www.thefabricator.com

Determining sharpness of sheet metal edges What Is Corner Chamfer In Sheet Metal They are created for mainly for protecting the chamfered. A chamfer is an angle on the edge of a workpiece. To create a corner chamfer in cad with a specified distance and angle, you can follow these steps: Instead of having a curved shape, a chamfer is straight and has a sharp angle. It is an antonym of the fillet.. What Is Corner Chamfer In Sheet Metal.

From bopha.co.za

construction formwork chamfers & corner fillets from Rebar, Mesh and What Is Corner Chamfer In Sheet Metal In metal fabrication and extrusion, fillets and chamfers are used to ease sharp edges and corners of. It is an antonym of the fillet. Select the “corner chamfer” command from the “modify” panel under the. A fillet is a rounded corner that connects two surfaces. A chamfer is an angle on the edge of a workpiece. To create a corner. What Is Corner Chamfer In Sheet Metal.

From www.cati.com

Sheetmetal Chamfer in SolidWorks Computer Aided Technology What Is Corner Chamfer In Sheet Metal In metal fabrication and extrusion, fillets and chamfers are used to ease sharp edges and corners of. Line chamfering is generally considered to be about c0.2~0.3, but unlike c chamfering and r chamfering, there are no clear regulations on the shape and size of the chamfer. Instead of having a curved shape, a chamfer is straight and has a sharp. What Is Corner Chamfer In Sheet Metal.

From designandmotion.net

Inventor Sheet Metal Corner Round, Corner Chamfer, and Cut What Is Corner Chamfer In Sheet Metal Two commonly used and recommended sheet metal design features on the corners of a square or rectangular part are chamfers and radii. A chamfer is an angle on the edge of a workpiece. To create a corner chamfer in cad with a specified distance and angle, you can follow these steps: Select the “corner chamfer” command from the “modify” panel. What Is Corner Chamfer In Sheet Metal.

From www.finepowertools.com

Bevel vs Chamfer Difference Between the Edges Demystified. What Is Corner Chamfer In Sheet Metal A chamfer is an angle on the edge of a workpiece. They are created for mainly for protecting the chamfered. Line chamfering refers to the processing of a surface on the corner of a material that is invisible to the naked eye. Chamfer is an angled edge that also does the same function. Two commonly used and recommended sheet metal. What Is Corner Chamfer In Sheet Metal.

From www.youtube.com

Chamfering metal chamfer metal YouTube What Is Corner Chamfer In Sheet Metal A chamfer is an angle on the edge of a workpiece. They are created for mainly for protecting the chamfered. A fillet is a rounded corner that connects two surfaces. It is an antonym of the fillet. In metal fabrication and extrusion, fillets and chamfers are used to ease sharp edges and corners of. Line chamfering refers to the processing. What Is Corner Chamfer In Sheet Metal.