Hot Rolled Vs Cold Rolled Aluminum . A general comparison of hot vs. Cold rolled aluminum can be seen in the table below: The primary differences between hot rolled and cold rolled aluminum sheets lie in their surface finish, grain structure, and thickness tolerance. Whereas an extrusion is typically performed at a high temperature when the aluminum is easier to form, cold finishing takes place at room temperature. The most common form of cold finishing is known as drawing. Cold rolling hardens and strengthens the aluminum by changing its microstructure, but it makes the metal more. Hot rolled sheets, while potentially having a rougher surface due to faster rolling speeds, can still be suitable for applications where surface aesthetics are less critical. The cold rolling aluminum sheet is with poor mechanical properties and high hardness, so the cold rolling aluminum sheet is commonly used for mould material, and hot rolled. When cold finishing occurs, it leads to extremely close outer diameter tolerances. Cold rolled sheets, with their smooth and uniform surfaces, are better suited for treatments like painting and coating.

from kianhuatmetal.com

The primary differences between hot rolled and cold rolled aluminum sheets lie in their surface finish, grain structure, and thickness tolerance. Hot rolled sheets, while potentially having a rougher surface due to faster rolling speeds, can still be suitable for applications where surface aesthetics are less critical. Cold rolling hardens and strengthens the aluminum by changing its microstructure, but it makes the metal more. Whereas an extrusion is typically performed at a high temperature when the aluminum is easier to form, cold finishing takes place at room temperature. The most common form of cold finishing is known as drawing. Cold rolled sheets, with their smooth and uniform surfaces, are better suited for treatments like painting and coating. When cold finishing occurs, it leads to extremely close outer diameter tolerances. Cold rolled aluminum can be seen in the table below: A general comparison of hot vs. The cold rolling aluminum sheet is with poor mechanical properties and high hardness, so the cold rolling aluminum sheet is commonly used for mould material, and hot rolled.

Exploring the Differences Hot Rolled vs. Cold Rolled vs. Cold Drawn Steel Kian Huat Metal Blog

Hot Rolled Vs Cold Rolled Aluminum Whereas an extrusion is typically performed at a high temperature when the aluminum is easier to form, cold finishing takes place at room temperature. The primary differences between hot rolled and cold rolled aluminum sheets lie in their surface finish, grain structure, and thickness tolerance. Cold rolling hardens and strengthens the aluminum by changing its microstructure, but it makes the metal more. The cold rolling aluminum sheet is with poor mechanical properties and high hardness, so the cold rolling aluminum sheet is commonly used for mould material, and hot rolled. Hot rolled sheets, while potentially having a rougher surface due to faster rolling speeds, can still be suitable for applications where surface aesthetics are less critical. Cold rolled aluminum can be seen in the table below: Cold rolled sheets, with their smooth and uniform surfaces, are better suited for treatments like painting and coating. A general comparison of hot vs. When cold finishing occurs, it leads to extremely close outer diameter tolerances. The most common form of cold finishing is known as drawing. Whereas an extrusion is typically performed at a high temperature when the aluminum is easier to form, cold finishing takes place at room temperature.

From www.youtube.com

Shop Tip 2 Hot Rolled vs Cold Rolled Steels YouTube Hot Rolled Vs Cold Rolled Aluminum Hot rolled sheets, while potentially having a rougher surface due to faster rolling speeds, can still be suitable for applications where surface aesthetics are less critical. A general comparison of hot vs. The most common form of cold finishing is known as drawing. Whereas an extrusion is typically performed at a high temperature when the aluminum is easier to form,. Hot Rolled Vs Cold Rolled Aluminum.

From www.slideserve.com

PPT Steel Correctly choosing between Hot Roll and Cold Roll PowerPoint Presentation ID3516645 Hot Rolled Vs Cold Rolled Aluminum Whereas an extrusion is typically performed at a high temperature when the aluminum is easier to form, cold finishing takes place at room temperature. Cold rolling hardens and strengthens the aluminum by changing its microstructure, but it makes the metal more. When cold finishing occurs, it leads to extremely close outer diameter tolerances. Hot rolled sheets, while potentially having a. Hot Rolled Vs Cold Rolled Aluminum.

From www.reliance-foundry.com

Hot Rolled vs Cold Rolled Steel Metal Casting Blog Hot Rolled Vs Cold Rolled Aluminum Hot rolled sheets, while potentially having a rougher surface due to faster rolling speeds, can still be suitable for applications where surface aesthetics are less critical. The most common form of cold finishing is known as drawing. When cold finishing occurs, it leads to extremely close outer diameter tolerances. The cold rolling aluminum sheet is with poor mechanical properties and. Hot Rolled Vs Cold Rolled Aluminum.

From hkfabrication.com

Hot Rolled vs. Cold Rolled Steel A Comparison Guide Hot Rolled Vs Cold Rolled Aluminum The most common form of cold finishing is known as drawing. Cold rolled aluminum can be seen in the table below: The cold rolling aluminum sheet is with poor mechanical properties and high hardness, so the cold rolling aluminum sheet is commonly used for mould material, and hot rolled. Hot rolled sheets, while potentially having a rougher surface due to. Hot Rolled Vs Cold Rolled Aluminum.

From www.ohareprecision.com

Hot Rolled VS Cold Rolled Steel Hot Rolled Vs Cold Rolled Aluminum A general comparison of hot vs. Cold rolled aluminum can be seen in the table below: The cold rolling aluminum sheet is with poor mechanical properties and high hardness, so the cold rolling aluminum sheet is commonly used for mould material, and hot rolled. The most common form of cold finishing is known as drawing. The primary differences between hot. Hot Rolled Vs Cold Rolled Aluminum.

From www.pasteel.com

Difference Between Hot & ColdRolled Steel PA Steel Hot Rolled Vs Cold Rolled Aluminum The cold rolling aluminum sheet is with poor mechanical properties and high hardness, so the cold rolling aluminum sheet is commonly used for mould material, and hot rolled. The primary differences between hot rolled and cold rolled aluminum sheets lie in their surface finish, grain structure, and thickness tolerance. Whereas an extrusion is typically performed at a high temperature when. Hot Rolled Vs Cold Rolled Aluminum.

From www.kemalmfg.com

Hot Rolled VS Cold Rolled Steel Overview and Differences Kemal Hot Rolled Vs Cold Rolled Aluminum Cold rolling hardens and strengthens the aluminum by changing its microstructure, but it makes the metal more. A general comparison of hot vs. Cold rolled aluminum can be seen in the table below: Hot rolled sheets, while potentially having a rougher surface due to faster rolling speeds, can still be suitable for applications where surface aesthetics are less critical. The. Hot Rolled Vs Cold Rolled Aluminum.

From eziil.com

What is the Difference Between Hot Rolled (HR) & Cold Rolled (CR) Steel? Hot Rolled Vs Cold Rolled Aluminum Cold rolled sheets, with their smooth and uniform surfaces, are better suited for treatments like painting and coating. The cold rolling aluminum sheet is with poor mechanical properties and high hardness, so the cold rolling aluminum sheet is commonly used for mould material, and hot rolled. The most common form of cold finishing is known as drawing. Whereas an extrusion. Hot Rolled Vs Cold Rolled Aluminum.

From china-maching.com

Hot Rolled vs Cold Rolled Steel Understanding the Differences ETCN Hot Rolled Vs Cold Rolled Aluminum Cold rolling hardens and strengthens the aluminum by changing its microstructure, but it makes the metal more. A general comparison of hot vs. Cold rolled aluminum can be seen in the table below: The most common form of cold finishing is known as drawing. The cold rolling aluminum sheet is with poor mechanical properties and high hardness, so the cold. Hot Rolled Vs Cold Rolled Aluminum.

From blog.thepipingmart.com

Hot Rolled vs Cold Rolled Steel What's the Difference Hot Rolled Vs Cold Rolled Aluminum Hot rolled sheets, while potentially having a rougher surface due to faster rolling speeds, can still be suitable for applications where surface aesthetics are less critical. When cold finishing occurs, it leads to extremely close outer diameter tolerances. A general comparison of hot vs. Whereas an extrusion is typically performed at a high temperature when the aluminum is easier to. Hot Rolled Vs Cold Rolled Aluminum.

From www.rmtus.com

Cold Rolled Vs. Hot Rolled Steel RMT Revolution Machine Tools™ Hot Rolled Vs Cold Rolled Aluminum Hot rolled sheets, while potentially having a rougher surface due to faster rolling speeds, can still be suitable for applications where surface aesthetics are less critical. Cold rolling hardens and strengthens the aluminum by changing its microstructure, but it makes the metal more. When cold finishing occurs, it leads to extremely close outer diameter tolerances. The cold rolling aluminum sheet. Hot Rolled Vs Cold Rolled Aluminum.

From joigieabg.blob.core.windows.net

Hot Rolled Vs Cold Rolled Tubing at Wayne Hewitt blog Hot Rolled Vs Cold Rolled Aluminum When cold finishing occurs, it leads to extremely close outer diameter tolerances. The most common form of cold finishing is known as drawing. Cold rolled aluminum can be seen in the table below: The cold rolling aluminum sheet is with poor mechanical properties and high hardness, so the cold rolling aluminum sheet is commonly used for mould material, and hot. Hot Rolled Vs Cold Rolled Aluminum.

From sciencing.com

Hot Rolled Steel Vs. Cold Rolled Steel Sciencing Hot Rolled Vs Cold Rolled Aluminum Whereas an extrusion is typically performed at a high temperature when the aluminum is easier to form, cold finishing takes place at room temperature. Cold rolling hardens and strengthens the aluminum by changing its microstructure, but it makes the metal more. Hot rolled sheets, while potentially having a rougher surface due to faster rolling speeds, can still be suitable for. Hot Rolled Vs Cold Rolled Aluminum.

From www.madearia.com

Hot rolled steel Vs cold rolled steel, what is difference? Hot Rolled Vs Cold Rolled Aluminum The most common form of cold finishing is known as drawing. Cold rolling hardens and strengthens the aluminum by changing its microstructure, but it makes the metal more. The cold rolling aluminum sheet is with poor mechanical properties and high hardness, so the cold rolling aluminum sheet is commonly used for mould material, and hot rolled. Whereas an extrusion is. Hot Rolled Vs Cold Rolled Aluminum.

From pediaa.com

Difference Between Hot Rolled and Cold Rolled Steel Definition, Production, and Benefits Hot Rolled Vs Cold Rolled Aluminum The cold rolling aluminum sheet is with poor mechanical properties and high hardness, so the cold rolling aluminum sheet is commonly used for mould material, and hot rolled. A general comparison of hot vs. The most common form of cold finishing is known as drawing. Whereas an extrusion is typically performed at a high temperature when the aluminum is easier. Hot Rolled Vs Cold Rolled Aluminum.

From quantumsteel.co.za

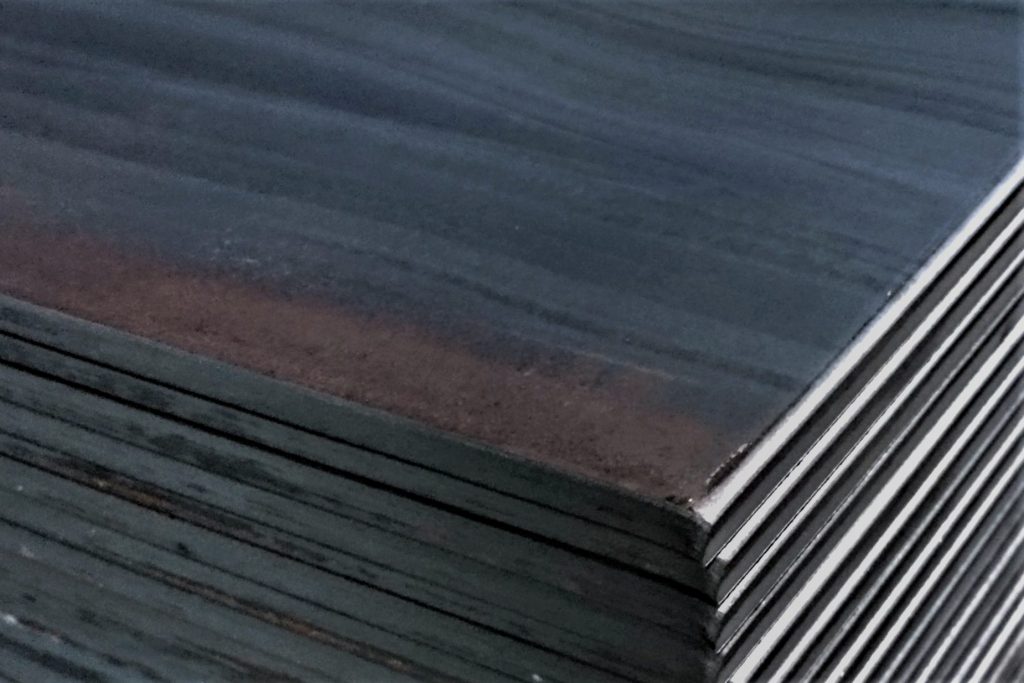

Rolled Sheet Metal Quantum Steel Hot Rolled Vs Cold Rolled Aluminum Whereas an extrusion is typically performed at a high temperature when the aluminum is easier to form, cold finishing takes place at room temperature. Cold rolling hardens and strengthens the aluminum by changing its microstructure, but it makes the metal more. The cold rolling aluminum sheet is with poor mechanical properties and high hardness, so the cold rolling aluminum sheet. Hot Rolled Vs Cold Rolled Aluminum.

From blog.thepipingmart.com

Hot Rolling vs Cold Rolling Aluminium What's the Difference Hot Rolled Vs Cold Rolled Aluminum The cold rolling aluminum sheet is with poor mechanical properties and high hardness, so the cold rolling aluminum sheet is commonly used for mould material, and hot rolled. Whereas an extrusion is typically performed at a high temperature when the aluminum is easier to form, cold finishing takes place at room temperature. A general comparison of hot vs. The primary. Hot Rolled Vs Cold Rolled Aluminum.

From www.groupnirmal.com

Hot Rolled vs Cold Rolled Steel Key Differences Between Them Hot Rolled Vs Cold Rolled Aluminum The most common form of cold finishing is known as drawing. Cold rolled sheets, with their smooth and uniform surfaces, are better suited for treatments like painting and coating. Cold rolling hardens and strengthens the aluminum by changing its microstructure, but it makes the metal more. The cold rolling aluminum sheet is with poor mechanical properties and high hardness, so. Hot Rolled Vs Cold Rolled Aluminum.

From www.kemalmfg.com

Hot Rolled VS Cold Rolled Steel Overview and Differences Kemal Hot Rolled Vs Cold Rolled Aluminum Cold rolling hardens and strengthens the aluminum by changing its microstructure, but it makes the metal more. When cold finishing occurs, it leads to extremely close outer diameter tolerances. The primary differences between hot rolled and cold rolled aluminum sheets lie in their surface finish, grain structure, and thickness tolerance. Cold rolled sheets, with their smooth and uniform surfaces, are. Hot Rolled Vs Cold Rolled Aluminum.

From www.whkassner.com

HOT ROLLED STEEL VS COLD ROLLED STEEL — W.H. Kassner, Inc. Hot Rolled Vs Cold Rolled Aluminum Cold rolled sheets, with their smooth and uniform surfaces, are better suited for treatments like painting and coating. Whereas an extrusion is typically performed at a high temperature when the aluminum is easier to form, cold finishing takes place at room temperature. Hot rolled sheets, while potentially having a rougher surface due to faster rolling speeds, can still be suitable. Hot Rolled Vs Cold Rolled Aluminum.

From infragreen.biz

Hot rolled Steel VS Cold Rolled Steel Steel Buildings Construction Hot Rolled Vs Cold Rolled Aluminum Cold rolling hardens and strengthens the aluminum by changing its microstructure, but it makes the metal more. Whereas an extrusion is typically performed at a high temperature when the aluminum is easier to form, cold finishing takes place at room temperature. Cold rolled sheets, with their smooth and uniform surfaces, are better suited for treatments like painting and coating. A. Hot Rolled Vs Cold Rolled Aluminum.

From kianhuatmetal.com

Exploring the Differences Hot Rolled vs. Cold Rolled vs. Cold Drawn Steel Kian Huat Metal Blog Hot Rolled Vs Cold Rolled Aluminum The cold rolling aluminum sheet is with poor mechanical properties and high hardness, so the cold rolling aluminum sheet is commonly used for mould material, and hot rolled. The most common form of cold finishing is known as drawing. Hot rolled sheets, while potentially having a rougher surface due to faster rolling speeds, can still be suitable for applications where. Hot Rolled Vs Cold Rolled Aluminum.

From blog.thepipingmart.com

Hot Rolling vs Cold Rolling What's the Difference? Hot Rolled Vs Cold Rolled Aluminum Cold rolling hardens and strengthens the aluminum by changing its microstructure, but it makes the metal more. A general comparison of hot vs. Hot rolled sheets, while potentially having a rougher surface due to faster rolling speeds, can still be suitable for applications where surface aesthetics are less critical. The primary differences between hot rolled and cold rolled aluminum sheets. Hot Rolled Vs Cold Rolled Aluminum.

From www.kemalmfg.com

Hot Rolled VS Cold Rolled Steel Overview and Differences Kemal Hot Rolled Vs Cold Rolled Aluminum Cold rolled aluminum can be seen in the table below: Cold rolled sheets, with their smooth and uniform surfaces, are better suited for treatments like painting and coating. Hot rolled sheets, while potentially having a rougher surface due to faster rolling speeds, can still be suitable for applications where surface aesthetics are less critical. The most common form of cold. Hot Rolled Vs Cold Rolled Aluminum.

From www.youtube.com

Cold Rolled Steel Cold Rolling vs Hot Rolling Hot Rolled Steel YouTube Hot Rolled Vs Cold Rolled Aluminum A general comparison of hot vs. The primary differences between hot rolled and cold rolled aluminum sheets lie in their surface finish, grain structure, and thickness tolerance. Hot rolled sheets, while potentially having a rougher surface due to faster rolling speeds, can still be suitable for applications where surface aesthetics are less critical. Cold rolled sheets, with their smooth and. Hot Rolled Vs Cold Rolled Aluminum.

From azironsupply.com

Hot Rolled versus Cold Rolled Metals Arizona Iron Supply Hot Rolled Vs Cold Rolled Aluminum A general comparison of hot vs. The most common form of cold finishing is known as drawing. Cold rolling hardens and strengthens the aluminum by changing its microstructure, but it makes the metal more. Cold rolled sheets, with their smooth and uniform surfaces, are better suited for treatments like painting and coating. When cold finishing occurs, it leads to extremely. Hot Rolled Vs Cold Rolled Aluminum.

From kianhuatmetal.com

Exploring the Differences Hot Rolled vs. Cold Rolled vs. Cold Drawn Steel Kian Huat Metal Blog Hot Rolled Vs Cold Rolled Aluminum Whereas an extrusion is typically performed at a high temperature when the aluminum is easier to form, cold finishing takes place at room temperature. Cold rolling hardens and strengthens the aluminum by changing its microstructure, but it makes the metal more. A general comparison of hot vs. Hot rolled sheets, while potentially having a rougher surface due to faster rolling. Hot Rolled Vs Cold Rolled Aluminum.

From www.smetals.co.uk

Cold Rolled vs Hot Rolled Steel Speciality Metals Hot Rolled Vs Cold Rolled Aluminum Cold rolled aluminum can be seen in the table below: The primary differences between hot rolled and cold rolled aluminum sheets lie in their surface finish, grain structure, and thickness tolerance. The most common form of cold finishing is known as drawing. When cold finishing occurs, it leads to extremely close outer diameter tolerances. Cold rolling hardens and strengthens the. Hot Rolled Vs Cold Rolled Aluminum.

From blog.thepipingmart.com

Welding Cold Rolled Vs Welding Hot Rolled What's the Difference Hot Rolled Vs Cold Rolled Aluminum Cold rolled aluminum can be seen in the table below: Whereas an extrusion is typically performed at a high temperature when the aluminum is easier to form, cold finishing takes place at room temperature. The cold rolling aluminum sheet is with poor mechanical properties and high hardness, so the cold rolling aluminum sheet is commonly used for mould material, and. Hot Rolled Vs Cold Rolled Aluminum.

From endura-steel.com

Hot Rolled vs. Cold Rolled Steel Hot Rolled Vs Cold Rolled Aluminum Whereas an extrusion is typically performed at a high temperature when the aluminum is easier to form, cold finishing takes place at room temperature. The most common form of cold finishing is known as drawing. Cold rolled sheets, with their smooth and uniform surfaces, are better suited for treatments like painting and coating. When cold finishing occurs, it leads to. Hot Rolled Vs Cold Rolled Aluminum.

From baoxinsteel.com

What Is the Difference Between Hot Rolled vs Cold Rolled Steel? Baoxin Steel Hot Rolled Vs Cold Rolled Aluminum Cold rolling hardens and strengthens the aluminum by changing its microstructure, but it makes the metal more. Hot rolled sheets, while potentially having a rougher surface due to faster rolling speeds, can still be suitable for applications where surface aesthetics are less critical. The cold rolling aluminum sheet is with poor mechanical properties and high hardness, so the cold rolling. Hot Rolled Vs Cold Rolled Aluminum.

From loekragde.blob.core.windows.net

What Is The Difference Between Hot Rolled And Cold Rolled Stainless Steel at Nancy Gibson blog Hot Rolled Vs Cold Rolled Aluminum When cold finishing occurs, it leads to extremely close outer diameter tolerances. The most common form of cold finishing is known as drawing. Cold rolling hardens and strengthens the aluminum by changing its microstructure, but it makes the metal more. The cold rolling aluminum sheet is with poor mechanical properties and high hardness, so the cold rolling aluminum sheet is. Hot Rolled Vs Cold Rolled Aluminum.

From weldingmaniac.com

Hot Rolled Vs Cold Rolled for Welding Welding Maniac Hot Rolled Vs Cold Rolled Aluminum The cold rolling aluminum sheet is with poor mechanical properties and high hardness, so the cold rolling aluminum sheet is commonly used for mould material, and hot rolled. The primary differences between hot rolled and cold rolled aluminum sheets lie in their surface finish, grain structure, and thickness tolerance. When cold finishing occurs, it leads to extremely close outer diameter. Hot Rolled Vs Cold Rolled Aluminum.

From www.anandseamless.com

Choosing Seamless Tubes Cold Drawn vs. Hot Rolled Hot Rolled Vs Cold Rolled Aluminum Whereas an extrusion is typically performed at a high temperature when the aluminum is easier to form, cold finishing takes place at room temperature. Cold rolled aluminum can be seen in the table below: Cold rolling hardens and strengthens the aluminum by changing its microstructure, but it makes the metal more. The primary differences between hot rolled and cold rolled. Hot Rolled Vs Cold Rolled Aluminum.

From www.mechstudies.com

Hot Rolled vs Cold Rolled Steel What are the differences? Hot Rolled Vs Cold Rolled Aluminum Cold rolling hardens and strengthens the aluminum by changing its microstructure, but it makes the metal more. Cold rolled aluminum can be seen in the table below: A general comparison of hot vs. The most common form of cold finishing is known as drawing. Hot rolled sheets, while potentially having a rougher surface due to faster rolling speeds, can still. Hot Rolled Vs Cold Rolled Aluminum.