Soap Manufacturing Process Kettle . The above illustrations show the kettle process of making soap. The kettle process and the continuous process. Soap production is mainly done in four steps, saponification, glycerin removal,. Using this system is possible to produce marseille soap, removing the. The soap manufacturing process can be separated into two main groups: Saponification in kettles is the oldest system able to produce soap and glycerin starting from vegetable oils and animal fats. The present invention improves on the intensive countercurrent mixing process for making soap by substantially reducing the time required in the.

from www.alamy.com

Soap production is mainly done in four steps, saponification, glycerin removal,. The soap manufacturing process can be separated into two main groups: The kettle process and the continuous process. The present invention improves on the intensive countercurrent mixing process for making soap by substantially reducing the time required in the. Using this system is possible to produce marseille soap, removing the. The above illustrations show the kettle process of making soap. Saponification in kettles is the oldest system able to produce soap and glycerin starting from vegetable oils and animal fats.

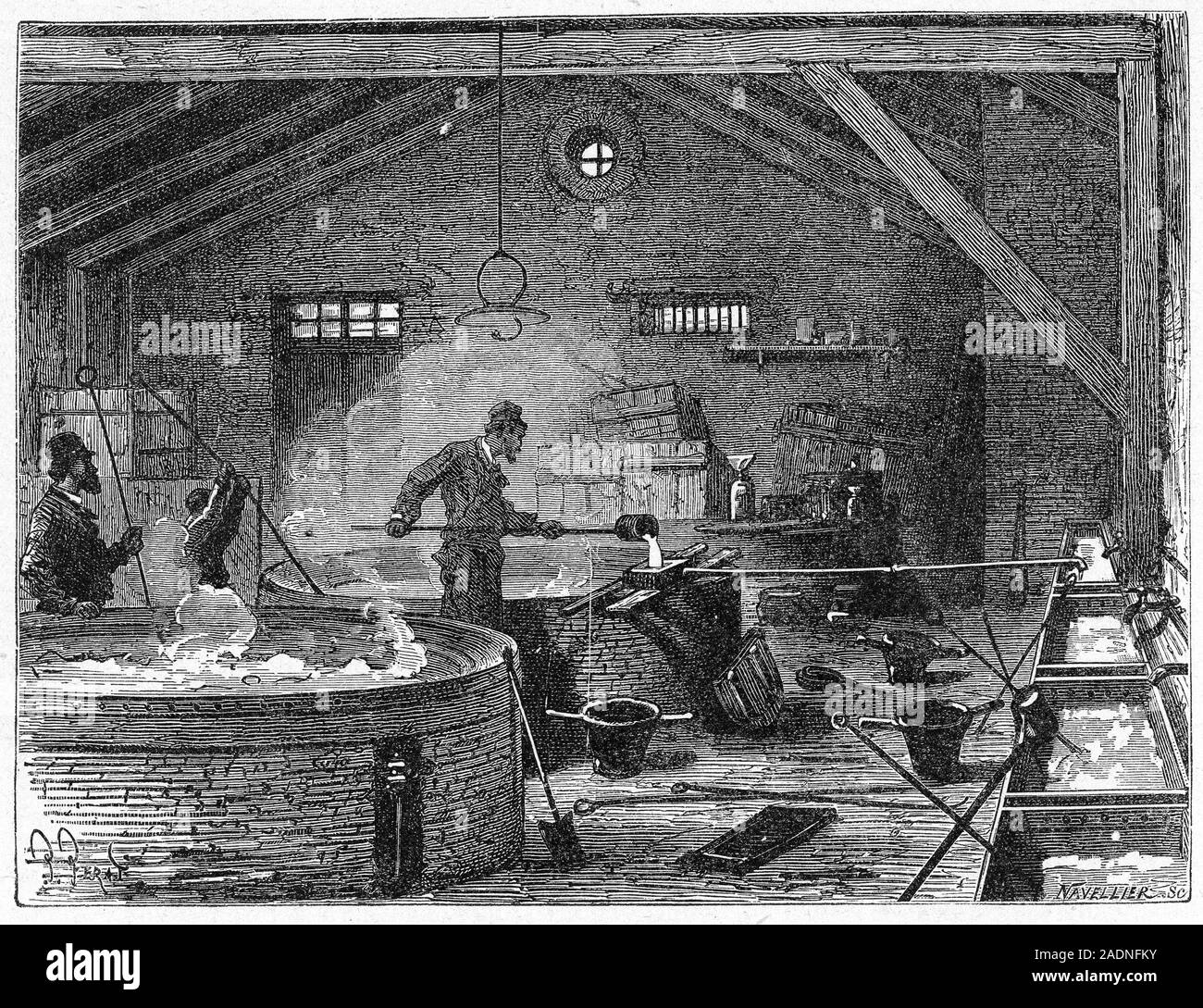

Soap making. Historical artwork of men attending to kettles in a soap making factory. Soap is

Soap Manufacturing Process Kettle The kettle process and the continuous process. Soap production is mainly done in four steps, saponification, glycerin removal,. Saponification in kettles is the oldest system able to produce soap and glycerin starting from vegetable oils and animal fats. The present invention improves on the intensive countercurrent mixing process for making soap by substantially reducing the time required in the. The above illustrations show the kettle process of making soap. Using this system is possible to produce marseille soap, removing the. The soap manufacturing process can be separated into two main groups: The kettle process and the continuous process.

From www.azmanmetal.com

Soap Production Line Azman Metal Soap Manufacturing Process Kettle The above illustrations show the kettle process of making soap. The soap manufacturing process can be separated into two main groups: Using this system is possible to produce marseille soap, removing the. The kettle process and the continuous process. Soap production is mainly done in four steps, saponification, glycerin removal,. Saponification in kettles is the oldest system able to produce. Soap Manufacturing Process Kettle.

From mavink.com

Soap Manufacturing Process Flow Chart Soap Manufacturing Process Kettle The present invention improves on the intensive countercurrent mixing process for making soap by substantially reducing the time required in the. The kettle process and the continuous process. The soap manufacturing process can be separated into two main groups: Saponification in kettles is the oldest system able to produce soap and glycerin starting from vegetable oils and animal fats. Using. Soap Manufacturing Process Kettle.

From www.slideshare.net

Soap manufacturing process Soap Manufacturing Process Kettle The above illustrations show the kettle process of making soap. The kettle process and the continuous process. The present invention improves on the intensive countercurrent mixing process for making soap by substantially reducing the time required in the. Saponification in kettles is the oldest system able to produce soap and glycerin starting from vegetable oils and animal fats. Using this. Soap Manufacturing Process Kettle.

From www.oldbookillustrations.com

Soap Making Old Book Illustrations Soap Manufacturing Process Kettle The soap manufacturing process can be separated into two main groups: The present invention improves on the intensive countercurrent mixing process for making soap by substantially reducing the time required in the. The above illustrations show the kettle process of making soap. The kettle process and the continuous process. Soap production is mainly done in four steps, saponification, glycerin removal,.. Soap Manufacturing Process Kettle.

From www.slideshare.net

Soap manufacturing process Soap Manufacturing Process Kettle Soap production is mainly done in four steps, saponification, glycerin removal,. The present invention improves on the intensive countercurrent mixing process for making soap by substantially reducing the time required in the. The above illustrations show the kettle process of making soap. Saponification in kettles is the oldest system able to produce soap and glycerin starting from vegetable oils and. Soap Manufacturing Process Kettle.

From www.soapworld.biz

6a. Kettles Saponification Plant for FullBoiled Soap Soap Calculator Soap Manufacturing Soap Manufacturing Process Kettle The kettle process and the continuous process. Using this system is possible to produce marseille soap, removing the. The present invention improves on the intensive countercurrent mixing process for making soap by substantially reducing the time required in the. The soap manufacturing process can be separated into two main groups: Soap production is mainly done in four steps, saponification, glycerin. Soap Manufacturing Process Kettle.

From www.youtube.com

How to make bar soap in factory, soap manufacturing process, automatic laundry soap production Soap Manufacturing Process Kettle The soap manufacturing process can be separated into two main groups: The kettle process and the continuous process. The above illustrations show the kettle process of making soap. Saponification in kettles is the oldest system able to produce soap and glycerin starting from vegetable oils and animal fats. The present invention improves on the intensive countercurrent mixing process for making. Soap Manufacturing Process Kettle.

From www.alamy.com

Woman making soft soap by hand with an outdoor kettle to render lard. Handcolored halftone of a Soap Manufacturing Process Kettle The kettle process and the continuous process. The present invention improves on the intensive countercurrent mixing process for making soap by substantially reducing the time required in the. Soap production is mainly done in four steps, saponification, glycerin removal,. Using this system is possible to produce marseille soap, removing the. The soap manufacturing process can be separated into two main. Soap Manufacturing Process Kettle.

From www.youtube.com

Soap Manufacturing Process YouTube Soap Manufacturing Process Kettle Soap production is mainly done in four steps, saponification, glycerin removal,. Using this system is possible to produce marseille soap, removing the. The kettle process and the continuous process. Saponification in kettles is the oldest system able to produce soap and glycerin starting from vegetable oils and animal fats. The present invention improves on the intensive countercurrent mixing process for. Soap Manufacturing Process Kettle.

From www.jagdishexports.com

Laundry Soap Machinery, Laundry Bar Soap Machinery, Laundry Soap Plant Soap Manufacturing Process Kettle The above illustrations show the kettle process of making soap. Using this system is possible to produce marseille soap, removing the. The present invention improves on the intensive countercurrent mixing process for making soap by substantially reducing the time required in the. Soap production is mainly done in four steps, saponification, glycerin removal,. The kettle process and the continuous process.. Soap Manufacturing Process Kettle.

From zhaoqianyong.en.made-in-china.com

100200kg/H Small Bar Soap Production Making Machine Soap Making Machine and Soap Machine Soap Manufacturing Process Kettle The above illustrations show the kettle process of making soap. The soap manufacturing process can be separated into two main groups: Using this system is possible to produce marseille soap, removing the. The present invention improves on the intensive countercurrent mixing process for making soap by substantially reducing the time required in the. Soap production is mainly done in four. Soap Manufacturing Process Kettle.

From www.slideshare.net

The soap making process Soap Manufacturing Process Kettle Saponification in kettles is the oldest system able to produce soap and glycerin starting from vegetable oils and animal fats. Using this system is possible to produce marseille soap, removing the. The above illustrations show the kettle process of making soap. Soap production is mainly done in four steps, saponification, glycerin removal,. The present invention improves on the intensive countercurrent. Soap Manufacturing Process Kettle.

From www.slideshare.net

Soap manufacturing process Soap Manufacturing Process Kettle Soap production is mainly done in four steps, saponification, glycerin removal,. Saponification in kettles is the oldest system able to produce soap and glycerin starting from vegetable oils and animal fats. The above illustrations show the kettle process of making soap. The present invention improves on the intensive countercurrent mixing process for making soap by substantially reducing the time required. Soap Manufacturing Process Kettle.

From cosmeticmachinery.en.made-in-china.com

Jacketed Mixing Kettle with Agitator Homogenizer Mixing Machine for Making Liquid Soap Liquid Soap Manufacturing Process Kettle Using this system is possible to produce marseille soap, removing the. Soap production is mainly done in four steps, saponification, glycerin removal,. The present invention improves on the intensive countercurrent mixing process for making soap by substantially reducing the time required in the. The above illustrations show the kettle process of making soap. The soap manufacturing process can be separated. Soap Manufacturing Process Kettle.

From www.researchgate.net

(PDF) A report on Exploring the soap manufacturing process A field visit to a local soap industry Soap Manufacturing Process Kettle The present invention improves on the intensive countercurrent mixing process for making soap by substantially reducing the time required in the. The kettle process and the continuous process. The soap manufacturing process can be separated into two main groups: Using this system is possible to produce marseille soap, removing the. The above illustrations show the kettle process of making soap.. Soap Manufacturing Process Kettle.

From www.alamy.com

Soap making. Historical artwork of men attending to kettles in a soap making factory. Soap is Soap Manufacturing Process Kettle The soap manufacturing process can be separated into two main groups: The above illustrations show the kettle process of making soap. The kettle process and the continuous process. The present invention improves on the intensive countercurrent mixing process for making soap by substantially reducing the time required in the. Using this system is possible to produce marseille soap, removing the.. Soap Manufacturing Process Kettle.

From www.scribd.com

Comparing the Kettle and Continuous Processes for Soap Manufacturing PDF Soap Glycerol Soap Manufacturing Process Kettle The present invention improves on the intensive countercurrent mixing process for making soap by substantially reducing the time required in the. The soap manufacturing process can be separated into two main groups: The above illustrations show the kettle process of making soap. Saponification in kettles is the oldest system able to produce soap and glycerin starting from vegetable oils and. Soap Manufacturing Process Kettle.

From mungfali.com

Saponification Chart Soap Manufacturing Process Kettle The present invention improves on the intensive countercurrent mixing process for making soap by substantially reducing the time required in the. Saponification in kettles is the oldest system able to produce soap and glycerin starting from vegetable oils and animal fats. The kettle process and the continuous process. The soap manufacturing process can be separated into two main groups: Using. Soap Manufacturing Process Kettle.

From www.youtube.com

Kettle Process (Soap Preparation Method) in Urdu YouTube Soap Manufacturing Process Kettle Using this system is possible to produce marseille soap, removing the. The soap manufacturing process can be separated into two main groups: Saponification in kettles is the oldest system able to produce soap and glycerin starting from vegetable oils and animal fats. The kettle process and the continuous process. The above illustrations show the kettle process of making soap. The. Soap Manufacturing Process Kettle.

From www.slideshare.net

Soap manufacturing process Soap Manufacturing Process Kettle The above illustrations show the kettle process of making soap. Soap production is mainly done in four steps, saponification, glycerin removal,. The present invention improves on the intensive countercurrent mixing process for making soap by substantially reducing the time required in the. The kettle process and the continuous process. Using this system is possible to produce marseille soap, removing the.. Soap Manufacturing Process Kettle.

From exoobnzmd.blob.core.windows.net

What Is Ingredients In Soap Making at Michael Osborn blog Soap Manufacturing Process Kettle The above illustrations show the kettle process of making soap. The soap manufacturing process can be separated into two main groups: The present invention improves on the intensive countercurrent mixing process for making soap by substantially reducing the time required in the. Using this system is possible to produce marseille soap, removing the. Saponification in kettles is the oldest system. Soap Manufacturing Process Kettle.

From www.slideserve.com

PPT Soap and Detergents Manufacture PowerPoint Presentation, free download ID2067968 Soap Manufacturing Process Kettle Soap production is mainly done in four steps, saponification, glycerin removal,. The present invention improves on the intensive countercurrent mixing process for making soap by substantially reducing the time required in the. The kettle process and the continuous process. The soap manufacturing process can be separated into two main groups: Saponification in kettles is the oldest system able to produce. Soap Manufacturing Process Kettle.

From mungfali.com

Detergent Manufacturing Process Flow Chart Soap Manufacturing Process Kettle Saponification in kettles is the oldest system able to produce soap and glycerin starting from vegetable oils and animal fats. The above illustrations show the kettle process of making soap. The present invention improves on the intensive countercurrent mixing process for making soap by substantially reducing the time required in the. The soap manufacturing process can be separated into two. Soap Manufacturing Process Kettle.

From www.researchgate.net

Flow diagram of soap production by bath process. Download Scientific Diagram Soap Manufacturing Process Kettle Saponification in kettles is the oldest system able to produce soap and glycerin starting from vegetable oils and animal fats. The present invention improves on the intensive countercurrent mixing process for making soap by substantially reducing the time required in the. The soap manufacturing process can be separated into two main groups: The above illustrations show the kettle process of. Soap Manufacturing Process Kettle.

From coolguides.wordpress.com

Basic steps of soap making coolguides Soap Manufacturing Process Kettle The above illustrations show the kettle process of making soap. Using this system is possible to produce marseille soap, removing the. The soap manufacturing process can be separated into two main groups: Saponification in kettles is the oldest system able to produce soap and glycerin starting from vegetable oils and animal fats. Soap production is mainly done in four steps,. Soap Manufacturing Process Kettle.

From www.slideserve.com

PPT Soap and Detergents Manufacture PowerPoint Presentation, free download ID2067968 Soap Manufacturing Process Kettle Saponification in kettles is the oldest system able to produce soap and glycerin starting from vegetable oils and animal fats. Soap production is mainly done in four steps, saponification, glycerin removal,. Using this system is possible to produce marseille soap, removing the. The soap manufacturing process can be separated into two main groups: The above illustrations show the kettle process. Soap Manufacturing Process Kettle.

From www.youtube.com

Kettle Process of Soap Making Soap Industry Applied Chemistry YouTube Soap Manufacturing Process Kettle The kettle process and the continuous process. Using this system is possible to produce marseille soap, removing the. The present invention improves on the intensive countercurrent mixing process for making soap by substantially reducing the time required in the. The above illustrations show the kettle process of making soap. The soap manufacturing process can be separated into two main groups:. Soap Manufacturing Process Kettle.

From mungfali.com

Soap Manufacturing Process Flow Chart Soap Manufacturing Process Kettle The kettle process and the continuous process. The present invention improves on the intensive countercurrent mixing process for making soap by substantially reducing the time required in the. Soap production is mainly done in four steps, saponification, glycerin removal,. The soap manufacturing process can be separated into two main groups: The above illustrations show the kettle process of making soap.. Soap Manufacturing Process Kettle.

From www.slideshare.net

History of natural soap Soap Manufacturing Process Kettle The present invention improves on the intensive countercurrent mixing process for making soap by substantially reducing the time required in the. The soap manufacturing process can be separated into two main groups: Saponification in kettles is the oldest system able to produce soap and glycerin starting from vegetable oils and animal fats. Soap production is mainly done in four steps,. Soap Manufacturing Process Kettle.

From www.youtube.com

what is batch and continuous process soap makingsoap manufacturing soap soapindustry YouTube Soap Manufacturing Process Kettle The present invention improves on the intensive countercurrent mixing process for making soap by substantially reducing the time required in the. The kettle process and the continuous process. The soap manufacturing process can be separated into two main groups: Saponification in kettles is the oldest system able to produce soap and glycerin starting from vegetable oils and animal fats. Using. Soap Manufacturing Process Kettle.

From www.researchgate.net

(PDF) PROCESS FLOW DIAGRAM FOR SOAP INDUSTRY Soap Manufacturing Process Kettle Soap production is mainly done in four steps, saponification, glycerin removal,. Using this system is possible to produce marseille soap, removing the. The above illustrations show the kettle process of making soap. The kettle process and the continuous process. The soap manufacturing process can be separated into two main groups: Saponification in kettles is the oldest system able to produce. Soap Manufacturing Process Kettle.

From www.pinterest.ph

Soap Making Process Soap making process, Soap making, Process flow Soap Manufacturing Process Kettle Using this system is possible to produce marseille soap, removing the. Saponification in kettles is the oldest system able to produce soap and glycerin starting from vegetable oils and animal fats. The kettle process and the continuous process. The present invention improves on the intensive countercurrent mixing process for making soap by substantially reducing the time required in the. The. Soap Manufacturing Process Kettle.

From mungfali.com

Soap Manufacturing Process Flow Chart Soap Manufacturing Process Kettle Using this system is possible to produce marseille soap, removing the. The kettle process and the continuous process. Saponification in kettles is the oldest system able to produce soap and glycerin starting from vegetable oils and animal fats. The present invention improves on the intensive countercurrent mixing process for making soap by substantially reducing the time required in the. The. Soap Manufacturing Process Kettle.

From www.researchgate.net

Flowchart showing the stepwise synthesis of the soapnut surfactant Download Scientific Diagram Soap Manufacturing Process Kettle The soap manufacturing process can be separated into two main groups: The above illustrations show the kettle process of making soap. Using this system is possible to produce marseille soap, removing the. The kettle process and the continuous process. Saponification in kettles is the oldest system able to produce soap and glycerin starting from vegetable oils and animal fats. Soap. Soap Manufacturing Process Kettle.

From www.researchgate.net

(PDF) Detergents HeavyDuty Powder Soap Manufacturing Process Kettle The kettle process and the continuous process. Saponification in kettles is the oldest system able to produce soap and glycerin starting from vegetable oils and animal fats. Soap production is mainly done in four steps, saponification, glycerin removal,. The soap manufacturing process can be separated into two main groups: Using this system is possible to produce marseille soap, removing the.. Soap Manufacturing Process Kettle.