Arc Welding Defects And Causes . When a welder accidentally strikes the electrode or the electrode holder against the work, unwanted arcs are generated adjacent to the weld. What causes them, how to identify, and ways to prevent them. Arc strike is usually caused by improper workmanship. Common causes of welding defects come from incorrect welding patterns, material selection, skill, or machine settings, including welding speed, current, and voltage. These spots are known as “arc strikes” which can initiate failure during bending or cyclic loading. Essential knowledge for welders to ensure quality welding. When a welded metal has a welding defect present, there are multiple options for resolving the issue.

from welding.tpub.com

When a welded metal has a welding defect present, there are multiple options for resolving the issue. These spots are known as “arc strikes” which can initiate failure during bending or cyclic loading. Essential knowledge for welders to ensure quality welding. When a welder accidentally strikes the electrode or the electrode holder against the work, unwanted arcs are generated adjacent to the weld. What causes them, how to identify, and ways to prevent them. Common causes of welding defects come from incorrect welding patterns, material selection, skill, or machine settings, including welding speed, current, and voltage. Arc strike is usually caused by improper workmanship.

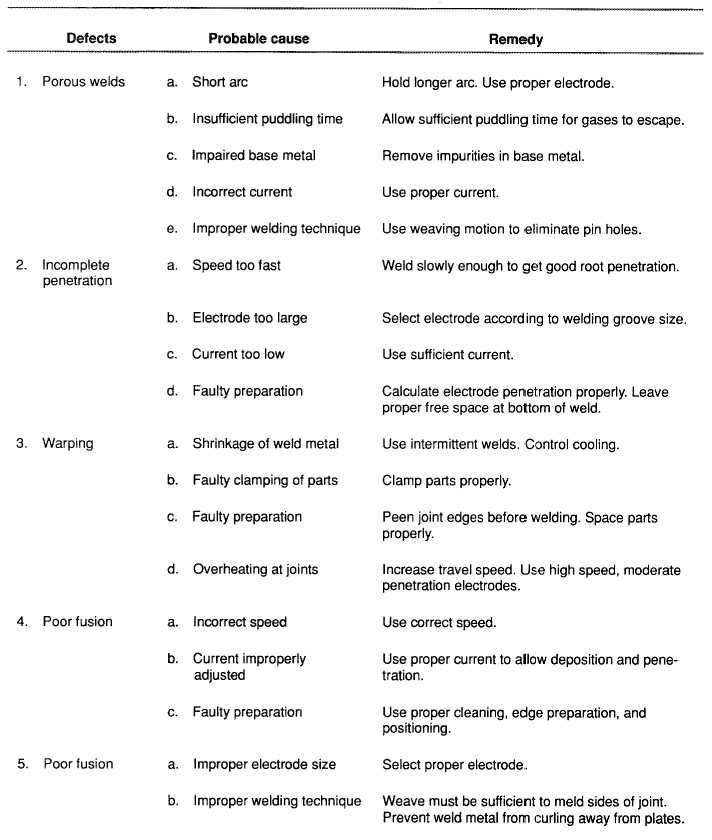

Table 33. Arc Welding Defects, Causes, and Remedies

Arc Welding Defects And Causes These spots are known as “arc strikes” which can initiate failure during bending or cyclic loading. When a welded metal has a welding defect present, there are multiple options for resolving the issue. What causes them, how to identify, and ways to prevent them. Arc strike is usually caused by improper workmanship. When a welder accidentally strikes the electrode or the electrode holder against the work, unwanted arcs are generated adjacent to the weld. Common causes of welding defects come from incorrect welding patterns, material selection, skill, or machine settings, including welding speed, current, and voltage. These spots are known as “arc strikes” which can initiate failure during bending or cyclic loading. Essential knowledge for welders to ensure quality welding.

From www.slideserve.com

PPT Module 3 Domestic Heating/MMA Welding Unit 5 Manual Arc Welding Arc Welding Defects And Causes Common causes of welding defects come from incorrect welding patterns, material selection, skill, or machine settings, including welding speed, current, and voltage. When a welded metal has a welding defect present, there are multiple options for resolving the issue. Essential knowledge for welders to ensure quality welding. When a welder accidentally strikes the electrode or the electrode holder against the. Arc Welding Defects And Causes.

From www.pinterest.com.au

Welding Defects Types of Welding Defects Causes of Welding Defects Arc Welding Defects And Causes Common causes of welding defects come from incorrect welding patterns, material selection, skill, or machine settings, including welding speed, current, and voltage. When a welder accidentally strikes the electrode or the electrode holder against the work, unwanted arcs are generated adjacent to the weld. These spots are known as “arc strikes” which can initiate failure during bending or cyclic loading.. Arc Welding Defects And Causes.

From www.weldingandndt.com

Welding Defects Classification, Causes and Remedies Welding and NDT Arc Welding Defects And Causes What causes them, how to identify, and ways to prevent them. When a welded metal has a welding defect present, there are multiple options for resolving the issue. When a welder accidentally strikes the electrode or the electrode holder against the work, unwanted arcs are generated adjacent to the weld. Essential knowledge for welders to ensure quality welding. Arc strike. Arc Welding Defects And Causes.

From www.riansclub.com

Welding Defects Causes, Types And Remedies ( With PDF ) Arc Welding Defects And Causes Common causes of welding defects come from incorrect welding patterns, material selection, skill, or machine settings, including welding speed, current, and voltage. Arc strike is usually caused by improper workmanship. These spots are known as “arc strikes” which can initiate failure during bending or cyclic loading. What causes them, how to identify, and ways to prevent them. When a welder. Arc Welding Defects And Causes.

From slidetodoc.com

WELD DEFECTS What causes them and how to Arc Welding Defects And Causes When a welder accidentally strikes the electrode or the electrode holder against the work, unwanted arcs are generated adjacent to the weld. What causes them, how to identify, and ways to prevent them. These spots are known as “arc strikes” which can initiate failure during bending or cyclic loading. Common causes of welding defects come from incorrect welding patterns, material. Arc Welding Defects And Causes.

From www.researchgate.net

Causes and Effect Diagram of Welding Defects. Download Scientific Diagram Arc Welding Defects And Causes When a welder accidentally strikes the electrode or the electrode holder against the work, unwanted arcs are generated adjacent to the weld. These spots are known as “arc strikes” which can initiate failure during bending or cyclic loading. Common causes of welding defects come from incorrect welding patterns, material selection, skill, or machine settings, including welding speed, current, and voltage.. Arc Welding Defects And Causes.

From arkman.com.tr

Welding Defects Causes And Remedies Arc Welding Defects And Causes When a welder accidentally strikes the electrode or the electrode holder against the work, unwanted arcs are generated adjacent to the weld. Arc strike is usually caused by improper workmanship. What causes them, how to identify, and ways to prevent them. Essential knowledge for welders to ensure quality welding. These spots are known as “arc strikes” which can initiate failure. Arc Welding Defects And Causes.

From www.theweldingmaster.com

What is Welding Defects Types, Causes and Remedies? The Welding Master Arc Welding Defects And Causes When a welder accidentally strikes the electrode or the electrode holder against the work, unwanted arcs are generated adjacent to the weld. These spots are known as “arc strikes” which can initiate failure during bending or cyclic loading. Arc strike is usually caused by improper workmanship. Common causes of welding defects come from incorrect welding patterns, material selection, skill, or. Arc Welding Defects And Causes.

From www.rapiddirect.com

16 Common Types of Welding Defects, Causes and Remedies Arc Welding Defects And Causes Arc strike is usually caused by improper workmanship. Essential knowledge for welders to ensure quality welding. These spots are known as “arc strikes” which can initiate failure during bending or cyclic loading. When a welded metal has a welding defect present, there are multiple options for resolving the issue. What causes them, how to identify, and ways to prevent them.. Arc Welding Defects And Causes.

From weldguru.com

13 Common Types of Welding Defects & How to Prevent Them Arc Welding Defects And Causes These spots are known as “arc strikes” which can initiate failure during bending or cyclic loading. Essential knowledge for welders to ensure quality welding. When a welder accidentally strikes the electrode or the electrode holder against the work, unwanted arcs are generated adjacent to the weld. When a welded metal has a welding defect present, there are multiple options for. Arc Welding Defects And Causes.

From welding.tpub.com

Table 33. Arc Welding Defects, Causes, and Remedies Arc Welding Defects And Causes When a welder accidentally strikes the electrode or the electrode holder against the work, unwanted arcs are generated adjacent to the weld. When a welded metal has a welding defect present, there are multiple options for resolving the issue. These spots are known as “arc strikes” which can initiate failure during bending or cyclic loading. What causes them, how to. Arc Welding Defects And Causes.

From www.slideshare.net

Welding defects causes & correction Arc Welding Defects And Causes These spots are known as “arc strikes” which can initiate failure during bending or cyclic loading. What causes them, how to identify, and ways to prevent them. Essential knowledge for welders to ensure quality welding. When a welded metal has a welding defect present, there are multiple options for resolving the issue. Arc strike is usually caused by improper workmanship.. Arc Welding Defects And Causes.

From technoweld.com.au

The Most Common Welding Defects Causes and Remedies Arc Welding Defects And Causes These spots are known as “arc strikes” which can initiate failure during bending or cyclic loading. When a welded metal has a welding defect present, there are multiple options for resolving the issue. Arc strike is usually caused by improper workmanship. Essential knowledge for welders to ensure quality welding. What causes them, how to identify, and ways to prevent them.. Arc Welding Defects And Causes.

From www.weldingandndt.com

Welding Defects Classification, Causes and Remedies Welding and NDT Arc Welding Defects And Causes These spots are known as “arc strikes” which can initiate failure during bending or cyclic loading. Common causes of welding defects come from incorrect welding patterns, material selection, skill, or machine settings, including welding speed, current, and voltage. When a welded metal has a welding defect present, there are multiple options for resolving the issue. When a welder accidentally strikes. Arc Welding Defects And Causes.

From www.researchgate.net

Typical defects in a Gas Metal Arc Welding process (Madhvacharyula et Arc Welding Defects And Causes Arc strike is usually caused by improper workmanship. What causes them, how to identify, and ways to prevent them. When a welded metal has a welding defect present, there are multiple options for resolving the issue. Common causes of welding defects come from incorrect welding patterns, material selection, skill, or machine settings, including welding speed, current, and voltage. These spots. Arc Welding Defects And Causes.

From www.mig-welding.co.uk

Arc Welding Faults Examples of Speed, Arc Length, and Current Problems Arc Welding Defects And Causes When a welder accidentally strikes the electrode or the electrode holder against the work, unwanted arcs are generated adjacent to the weld. Arc strike is usually caused by improper workmanship. Essential knowledge for welders to ensure quality welding. Common causes of welding defects come from incorrect welding patterns, material selection, skill, or machine settings, including welding speed, current, and voltage.. Arc Welding Defects And Causes.

From welding.org.au

The 7 Most Common Welding Defects, Causes & Remedies Australian Arc Welding Defects And Causes Arc strike is usually caused by improper workmanship. What causes them, how to identify, and ways to prevent them. When a welded metal has a welding defect present, there are multiple options for resolving the issue. When a welder accidentally strikes the electrode or the electrode holder against the work, unwanted arcs are generated adjacent to the weld. Essential knowledge. Arc Welding Defects And Causes.

From www.omsmeasure.com

Most common welding defects — OMS Optical Metrology Services Ltd Arc Welding Defects And Causes When a welder accidentally strikes the electrode or the electrode holder against the work, unwanted arcs are generated adjacent to the weld. Essential knowledge for welders to ensure quality welding. What causes them, how to identify, and ways to prevent them. Common causes of welding defects come from incorrect welding patterns, material selection, skill, or machine settings, including welding speed,. Arc Welding Defects And Causes.

From www.riansclub.com

Welding Defects Causes, Types And Remedies ( With PDF ) Arc Welding Defects And Causes Common causes of welding defects come from incorrect welding patterns, material selection, skill, or machine settings, including welding speed, current, and voltage. Arc strike is usually caused by improper workmanship. Essential knowledge for welders to ensure quality welding. When a welder accidentally strikes the electrode or the electrode holder against the work, unwanted arcs are generated adjacent to the weld.. Arc Welding Defects And Causes.

From welding.org.au

The 7 Most Common Welding Defects, Causes & Remedies Australian Arc Welding Defects And Causes Common causes of welding defects come from incorrect welding patterns, material selection, skill, or machine settings, including welding speed, current, and voltage. When a welder accidentally strikes the electrode or the electrode holder against the work, unwanted arcs are generated adjacent to the weld. Arc strike is usually caused by improper workmanship. When a welded metal has a welding defect. Arc Welding Defects And Causes.

From www.vrogue.co

What Is Welding Defects Types Causes And Remedies Too vrogue.co Arc Welding Defects And Causes These spots are known as “arc strikes” which can initiate failure during bending or cyclic loading. Arc strike is usually caused by improper workmanship. Essential knowledge for welders to ensure quality welding. Common causes of welding defects come from incorrect welding patterns, material selection, skill, or machine settings, including welding speed, current, and voltage. What causes them, how to identify,. Arc Welding Defects And Causes.

From welding.tpub.com

Arc Welding Defects, Causes, and Remedies CONT Arc Welding Defects And Causes When a welder accidentally strikes the electrode or the electrode holder against the work, unwanted arcs are generated adjacent to the weld. These spots are known as “arc strikes” which can initiate failure during bending or cyclic loading. What causes them, how to identify, and ways to prevent them. Common causes of welding defects come from incorrect welding patterns, material. Arc Welding Defects And Causes.

From www.slideserve.com

PPT Electric Arc Welding PowerPoint Presentation, free download ID Arc Welding Defects And Causes When a welded metal has a welding defect present, there are multiple options for resolving the issue. These spots are known as “arc strikes” which can initiate failure during bending or cyclic loading. Common causes of welding defects come from incorrect welding patterns, material selection, skill, or machine settings, including welding speed, current, and voltage. When a welder accidentally strikes. Arc Welding Defects And Causes.

From welding.org.au

The 7 Most Common Welding Defects, Causes & Remedies Australian Arc Welding Defects And Causes Essential knowledge for welders to ensure quality welding. When a welded metal has a welding defect present, there are multiple options for resolving the issue. Arc strike is usually caused by improper workmanship. When a welder accidentally strikes the electrode or the electrode holder against the work, unwanted arcs are generated adjacent to the weld. Common causes of welding defects. Arc Welding Defects And Causes.

From www.youtube.com

Defects in Arc Welding, Causes and Remedies.आर्क वेल्डिंगमधील दोष Arc Welding Defects And Causes Arc strike is usually caused by improper workmanship. What causes them, how to identify, and ways to prevent them. Common causes of welding defects come from incorrect welding patterns, material selection, skill, or machine settings, including welding speed, current, and voltage. When a welded metal has a welding defect present, there are multiple options for resolving the issue. When a. Arc Welding Defects And Causes.

From knoxfr.com

Welding Defects And What They Are? How To Avoid Them! Knox Incorporated Arc Welding Defects And Causes Arc strike is usually caused by improper workmanship. Essential knowledge for welders to ensure quality welding. Common causes of welding defects come from incorrect welding patterns, material selection, skill, or machine settings, including welding speed, current, and voltage. When a welder accidentally strikes the electrode or the electrode holder against the work, unwanted arcs are generated adjacent to the weld.. Arc Welding Defects And Causes.

From www.theengineerspost.com

16 Common Types of Welding Defects [Causes, Remedies] PDF Arc Welding Defects And Causes When a welded metal has a welding defect present, there are multiple options for resolving the issue. Common causes of welding defects come from incorrect welding patterns, material selection, skill, or machine settings, including welding speed, current, and voltage. Arc strike is usually caused by improper workmanship. Essential knowledge for welders to ensure quality welding. These spots are known as. Arc Welding Defects And Causes.

From technoweld.com.au

The Most Common Welding Defects Causes and Remedies Technoweld Arc Welding Defects And Causes What causes them, how to identify, and ways to prevent them. When a welder accidentally strikes the electrode or the electrode holder against the work, unwanted arcs are generated adjacent to the weld. Common causes of welding defects come from incorrect welding patterns, material selection, skill, or machine settings, including welding speed, current, and voltage. Essential knowledge for welders to. Arc Welding Defects And Causes.

From weldguru.com

13 Common Types of Welding Defects & How to Prevent Them Arc Welding Defects And Causes When a welded metal has a welding defect present, there are multiple options for resolving the issue. Essential knowledge for welders to ensure quality welding. Arc strike is usually caused by improper workmanship. What causes them, how to identify, and ways to prevent them. Common causes of welding defects come from incorrect welding patterns, material selection, skill, or machine settings,. Arc Welding Defects And Causes.

From whatispiping.com

15 Most Common Welding Defects, Causes and Remedies What Is Piping Arc Welding Defects And Causes Arc strike is usually caused by improper workmanship. These spots are known as “arc strikes” which can initiate failure during bending or cyclic loading. Essential knowledge for welders to ensure quality welding. What causes them, how to identify, and ways to prevent them. When a welded metal has a welding defect present, there are multiple options for resolving the issue.. Arc Welding Defects And Causes.

From www.mig-welding.co.uk

Arc Welding Faults Examples of Speed, Arc Length, and Current Problems Arc Welding Defects And Causes Common causes of welding defects come from incorrect welding patterns, material selection, skill, or machine settings, including welding speed, current, and voltage. These spots are known as “arc strikes” which can initiate failure during bending or cyclic loading. When a welder accidentally strikes the electrode or the electrode holder against the work, unwanted arcs are generated adjacent to the weld.. Arc Welding Defects And Causes.

From www.weldingandndt.com

Welding Defects Classification, Causes and Remedies Welding and NDT Arc Welding Defects And Causes Essential knowledge for welders to ensure quality welding. These spots are known as “arc strikes” which can initiate failure during bending or cyclic loading. Common causes of welding defects come from incorrect welding patterns, material selection, skill, or machine settings, including welding speed, current, and voltage. When a welded metal has a welding defect present, there are multiple options for. Arc Welding Defects And Causes.

From welding.org.au

The 7 Most Common Welding Defects, Causes & Remedies Australian Arc Welding Defects And Causes When a welder accidentally strikes the electrode or the electrode holder against the work, unwanted arcs are generated adjacent to the weld. These spots are known as “arc strikes” which can initiate failure during bending or cyclic loading. Common causes of welding defects come from incorrect welding patterns, material selection, skill, or machine settings, including welding speed, current, and voltage.. Arc Welding Defects And Causes.

From sentin.ai

The 10 Common Weld Defects You Should Know. sentin Arc Welding Defects And Causes Arc strike is usually caused by improper workmanship. When a welder accidentally strikes the electrode or the electrode holder against the work, unwanted arcs are generated adjacent to the weld. These spots are known as “arc strikes” which can initiate failure during bending or cyclic loading. Essential knowledge for welders to ensure quality welding. When a welded metal has a. Arc Welding Defects And Causes.

From enginemechanics.tpub.com

Table 104.Causes and Cures of Common Welding Problems Arc Welding Defects And Causes Essential knowledge for welders to ensure quality welding. Common causes of welding defects come from incorrect welding patterns, material selection, skill, or machine settings, including welding speed, current, and voltage. When a welder accidentally strikes the electrode or the electrode holder against the work, unwanted arcs are generated adjacent to the weld. When a welded metal has a welding defect. Arc Welding Defects And Causes.