Flue Gas Recirculation Boiler . When the process is used in internal combustion engines it is commonly referred to as exhaust gas recirculation (egr). In this paper the effectiveness of the flue gas recirculation (fgr) system that is applied to reduce nox emissions of the utility. Flue gas recirculation (fgr) can be a highly effective technique for lowering nox emissions from burners in certain applications, as well as being relatively inexpensive to apply. Internal flue gas recirculation (ifgr) is one of the most effective techniques for eliminating nitric oxides (no x) in boilers,. Flue gas recirculation (fgr) is the process of taking a portion of the flue gas from a combustion process and recirculating it back through a boiler or burner. One of the significant contributing factors is no x emissions from commercial natural gas boilers.

from www.cibsejournal.com

Flue gas recirculation (fgr) is the process of taking a portion of the flue gas from a combustion process and recirculating it back through a boiler or burner. Flue gas recirculation (fgr) can be a highly effective technique for lowering nox emissions from burners in certain applications, as well as being relatively inexpensive to apply. Internal flue gas recirculation (ifgr) is one of the most effective techniques for eliminating nitric oxides (no x) in boilers,. One of the significant contributing factors is no x emissions from commercial natural gas boilers. In this paper the effectiveness of the flue gas recirculation (fgr) system that is applied to reduce nox emissions of the utility. When the process is used in internal combustion engines it is commonly referred to as exhaust gas recirculation (egr).

Module 106 Natural gas boiler flue gas recirculation to reduce NOx

Flue Gas Recirculation Boiler One of the significant contributing factors is no x emissions from commercial natural gas boilers. Internal flue gas recirculation (ifgr) is one of the most effective techniques for eliminating nitric oxides (no x) in boilers,. Flue gas recirculation (fgr) is the process of taking a portion of the flue gas from a combustion process and recirculating it back through a boiler or burner. When the process is used in internal combustion engines it is commonly referred to as exhaust gas recirculation (egr). Flue gas recirculation (fgr) can be a highly effective technique for lowering nox emissions from burners in certain applications, as well as being relatively inexpensive to apply. In this paper the effectiveness of the flue gas recirculation (fgr) system that is applied to reduce nox emissions of the utility. One of the significant contributing factors is no x emissions from commercial natural gas boilers.

From www.dtaplumbingandheating.co.uk

DTA Plumbing and Heating Servicing the West Midlands Flue Gas Recirculation Boiler Flue gas recirculation (fgr) can be a highly effective technique for lowering nox emissions from burners in certain applications, as well as being relatively inexpensive to apply. Internal flue gas recirculation (ifgr) is one of the most effective techniques for eliminating nitric oxides (no x) in boilers,. When the process is used in internal combustion engines it is commonly referred. Flue Gas Recirculation Boiler.

From www.mdpi.com

Energies Free FullText Flue Gas Recirculation System for Biomass Flue Gas Recirculation Boiler When the process is used in internal combustion engines it is commonly referred to as exhaust gas recirculation (egr). In this paper the effectiveness of the flue gas recirculation (fgr) system that is applied to reduce nox emissions of the utility. Flue gas recirculation (fgr) is the process of taking a portion of the flue gas from a combustion process. Flue Gas Recirculation Boiler.

From www.mdpi.com

Energies Free FullText Flue Gas Recirculation System for Biomass Flue Gas Recirculation Boiler One of the significant contributing factors is no x emissions from commercial natural gas boilers. In this paper the effectiveness of the flue gas recirculation (fgr) system that is applied to reduce nox emissions of the utility. Flue gas recirculation (fgr) can be a highly effective technique for lowering nox emissions from burners in certain applications, as well as being. Flue Gas Recirculation Boiler.

From www.crazyengineers.com

Boiler AIR AND FLUE GAS SYSTEM CrazyEngineers Flue Gas Recirculation Boiler When the process is used in internal combustion engines it is commonly referred to as exhaust gas recirculation (egr). One of the significant contributing factors is no x emissions from commercial natural gas boilers. Internal flue gas recirculation (ifgr) is one of the most effective techniques for eliminating nitric oxides (no x) in boilers,. Flue gas recirculation (fgr) can be. Flue Gas Recirculation Boiler.

From www.mdpi.com

Energies Free FullText Analysis of Gas Recirculation Influencing Flue Gas Recirculation Boiler Flue gas recirculation (fgr) is the process of taking a portion of the flue gas from a combustion process and recirculating it back through a boiler or burner. Flue gas recirculation (fgr) can be a highly effective technique for lowering nox emissions from burners in certain applications, as well as being relatively inexpensive to apply. In this paper the effectiveness. Flue Gas Recirculation Boiler.

From emcombustion.es

Flue gas recirculation clean environment emissions reduction Flue Gas Recirculation Boiler Flue gas recirculation (fgr) is the process of taking a portion of the flue gas from a combustion process and recirculating it back through a boiler or burner. Flue gas recirculation (fgr) can be a highly effective technique for lowering nox emissions from burners in certain applications, as well as being relatively inexpensive to apply. When the process is used. Flue Gas Recirculation Boiler.

From www.researchgate.net

Scheme of a steam boiler gasair duct for burning fuel oil and natural Flue Gas Recirculation Boiler When the process is used in internal combustion engines it is commonly referred to as exhaust gas recirculation (egr). Internal flue gas recirculation (ifgr) is one of the most effective techniques for eliminating nitric oxides (no x) in boilers,. One of the significant contributing factors is no x emissions from commercial natural gas boilers. In this paper the effectiveness of. Flue Gas Recirculation Boiler.

From www.researchgate.net

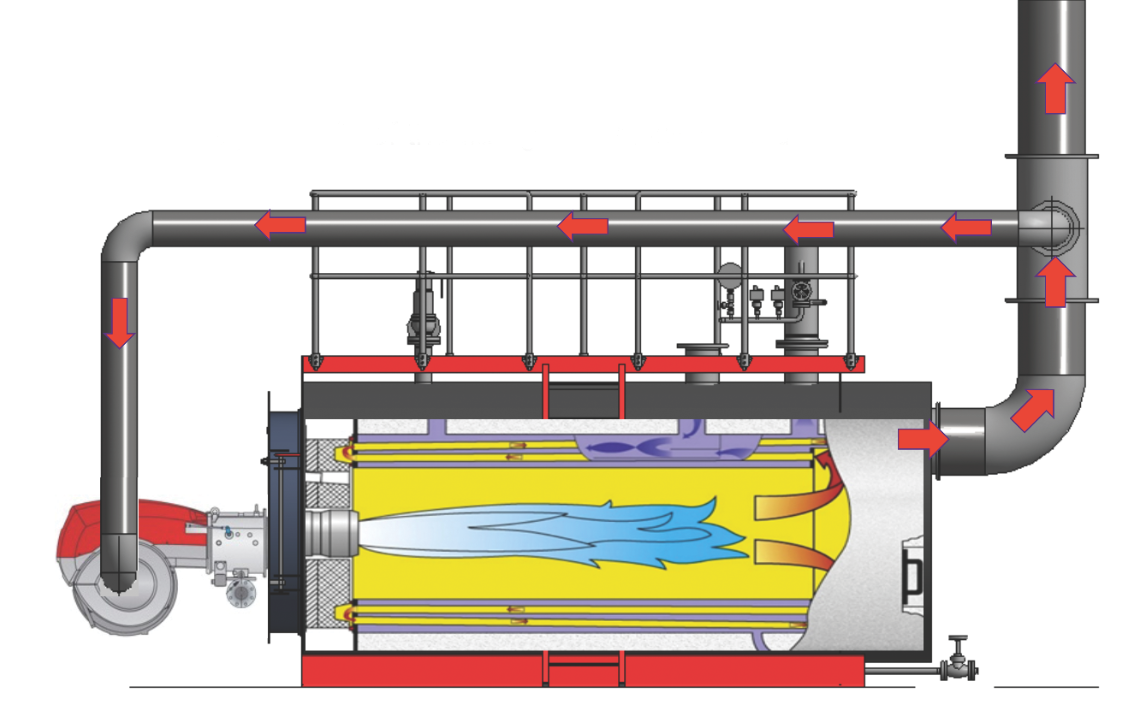

Scheme of an industrial gasandoil boiler with recirculating devices Flue Gas Recirculation Boiler In this paper the effectiveness of the flue gas recirculation (fgr) system that is applied to reduce nox emissions of the utility. Internal flue gas recirculation (ifgr) is one of the most effective techniques for eliminating nitric oxides (no x) in boilers,. Flue gas recirculation (fgr) can be a highly effective technique for lowering nox emissions from burners in certain. Flue Gas Recirculation Boiler.

From www.youtube.com

Reducing Boiler Emissions with Flue Gas Recirculation Boiling Point Flue Gas Recirculation Boiler Flue gas recirculation (fgr) can be a highly effective technique for lowering nox emissions from burners in certain applications, as well as being relatively inexpensive to apply. In this paper the effectiveness of the flue gas recirculation (fgr) system that is applied to reduce nox emissions of the utility. One of the significant contributing factors is no x emissions from. Flue Gas Recirculation Boiler.

From www.tcf-azen.com

Flue Gas Recirculation TCF Azen Flue Gas Recirculation Boiler Flue gas recirculation (fgr) can be a highly effective technique for lowering nox emissions from burners in certain applications, as well as being relatively inexpensive to apply. When the process is used in internal combustion engines it is commonly referred to as exhaust gas recirculation (egr). One of the significant contributing factors is no x emissions from commercial natural gas. Flue Gas Recirculation Boiler.

From www.semanticscholar.org

Figure 1 from Modeling and simulation of an oxyfuel combustion boiler Flue Gas Recirculation Boiler One of the significant contributing factors is no x emissions from commercial natural gas boilers. When the process is used in internal combustion engines it is commonly referred to as exhaust gas recirculation (egr). Flue gas recirculation (fgr) is the process of taking a portion of the flue gas from a combustion process and recirculating it back through a boiler. Flue Gas Recirculation Boiler.

From www.cpecn.com

Refinery boiler replacement project’s air and fuel gas measurement Flue Gas Recirculation Boiler When the process is used in internal combustion engines it is commonly referred to as exhaust gas recirculation (egr). Internal flue gas recirculation (ifgr) is one of the most effective techniques for eliminating nitric oxides (no x) in boilers,. One of the significant contributing factors is no x emissions from commercial natural gas boilers. In this paper the effectiveness of. Flue Gas Recirculation Boiler.

From www.pentol.net

Flue Gas Conditioning for Coal Boilers (FGC) Pentol Flue Gas Recirculation Boiler When the process is used in internal combustion engines it is commonly referred to as exhaust gas recirculation (egr). One of the significant contributing factors is no x emissions from commercial natural gas boilers. Flue gas recirculation (fgr) is the process of taking a portion of the flue gas from a combustion process and recirculating it back through a boiler. Flue Gas Recirculation Boiler.

From www.cibsejournal.com

Module 106 Natural gas boiler flue gas recirculation to reduce NOx Flue Gas Recirculation Boiler In this paper the effectiveness of the flue gas recirculation (fgr) system that is applied to reduce nox emissions of the utility. Flue gas recirculation (fgr) can be a highly effective technique for lowering nox emissions from burners in certain applications, as well as being relatively inexpensive to apply. One of the significant contributing factors is no x emissions from. Flue Gas Recirculation Boiler.

From eprenewable.com

Flue Gas Recirculation History and Uses EnviroPower Renewable Inc. Flue Gas Recirculation Boiler Flue gas recirculation (fgr) is the process of taking a portion of the flue gas from a combustion process and recirculating it back through a boiler or burner. Internal flue gas recirculation (ifgr) is one of the most effective techniques for eliminating nitric oxides (no x) in boilers,. When the process is used in internal combustion engines it is commonly. Flue Gas Recirculation Boiler.

From emcombustion.es

Flue gas recirculation clean environment emissions reduction Flue Gas Recirculation Boiler One of the significant contributing factors is no x emissions from commercial natural gas boilers. Flue gas recirculation (fgr) can be a highly effective technique for lowering nox emissions from burners in certain applications, as well as being relatively inexpensive to apply. Internal flue gas recirculation (ifgr) is one of the most effective techniques for eliminating nitric oxides (no x). Flue Gas Recirculation Boiler.

From www.youtube.com

How boiler flues are installed, CORRECT INSTALLATION OF BOILER FLUES Flue Gas Recirculation Boiler When the process is used in internal combustion engines it is commonly referred to as exhaust gas recirculation (egr). Flue gas recirculation (fgr) can be a highly effective technique for lowering nox emissions from burners in certain applications, as well as being relatively inexpensive to apply. One of the significant contributing factors is no x emissions from commercial natural gas. Flue Gas Recirculation Boiler.

From solucionesdecombustion.com

Flue gas recirculation helps to keep our environment clean Flue Gas Recirculation Boiler When the process is used in internal combustion engines it is commonly referred to as exhaust gas recirculation (egr). Flue gas recirculation (fgr) can be a highly effective technique for lowering nox emissions from burners in certain applications, as well as being relatively inexpensive to apply. One of the significant contributing factors is no x emissions from commercial natural gas. Flue Gas Recirculation Boiler.

From www.innovativeboiler.com

Autoflame Flue Gas Recirculation Control Valve Innovative Boiler, Inc. Flue Gas Recirculation Boiler Internal flue gas recirculation (ifgr) is one of the most effective techniques for eliminating nitric oxides (no x) in boilers,. Flue gas recirculation (fgr) is the process of taking a portion of the flue gas from a combustion process and recirculating it back through a boiler or burner. When the process is used in internal combustion engines it is commonly. Flue Gas Recirculation Boiler.

From www.scribd.com

Flue Gas Recirculation For Stoker Boilers Download Free PDF N Ox Flue Gas Recirculation Boiler In this paper the effectiveness of the flue gas recirculation (fgr) system that is applied to reduce nox emissions of the utility. Flue gas recirculation (fgr) can be a highly effective technique for lowering nox emissions from burners in certain applications, as well as being relatively inexpensive to apply. Flue gas recirculation (fgr) is the process of taking a portion. Flue Gas Recirculation Boiler.

From www.esapyronics.com

Flue Gas Recirculation ESA Pyronics Flue Gas Recirculation Boiler In this paper the effectiveness of the flue gas recirculation (fgr) system that is applied to reduce nox emissions of the utility. Flue gas recirculation (fgr) can be a highly effective technique for lowering nox emissions from burners in certain applications, as well as being relatively inexpensive to apply. Flue gas recirculation (fgr) is the process of taking a portion. Flue Gas Recirculation Boiler.

From www.researchgate.net

Scheme of a steam boiler with flushing water into the flue gases Flue Gas Recirculation Boiler Flue gas recirculation (fgr) is the process of taking a portion of the flue gas from a combustion process and recirculating it back through a boiler or burner. One of the significant contributing factors is no x emissions from commercial natural gas boilers. Internal flue gas recirculation (ifgr) is one of the most effective techniques for eliminating nitric oxides (no. Flue Gas Recirculation Boiler.

From www.mdpi.com

Energies Free FullText Numerical Studies of the Influence of Flue Flue Gas Recirculation Boiler When the process is used in internal combustion engines it is commonly referred to as exhaust gas recirculation (egr). One of the significant contributing factors is no x emissions from commercial natural gas boilers. Internal flue gas recirculation (ifgr) is one of the most effective techniques for eliminating nitric oxides (no x) in boilers,. In this paper the effectiveness of. Flue Gas Recirculation Boiler.

From clr-industries.com

FLUE GAS RECIRCULATING DUCT CLR Industries Flue Gas Recirculation Boiler Flue gas recirculation (fgr) is the process of taking a portion of the flue gas from a combustion process and recirculating it back through a boiler or burner. Internal flue gas recirculation (ifgr) is one of the most effective techniques for eliminating nitric oxides (no x) in boilers,. When the process is used in internal combustion engines it is commonly. Flue Gas Recirculation Boiler.

From www.lewaythermal.com

Brief Introduction Of Flue Gas Recirculation In Gas Boiler Flue Gas Recirculation Boiler In this paper the effectiveness of the flue gas recirculation (fgr) system that is applied to reduce nox emissions of the utility. Flue gas recirculation (fgr) can be a highly effective technique for lowering nox emissions from burners in certain applications, as well as being relatively inexpensive to apply. When the process is used in internal combustion engines it is. Flue Gas Recirculation Boiler.

From www.hpac.com

New Trends in Burner Technology HPAC Engineering Flue Gas Recirculation Boiler Flue gas recirculation (fgr) can be a highly effective technique for lowering nox emissions from burners in certain applications, as well as being relatively inexpensive to apply. Flue gas recirculation (fgr) is the process of taking a portion of the flue gas from a combustion process and recirculating it back through a boiler or burner. Internal flue gas recirculation (ifgr). Flue Gas Recirculation Boiler.

From www.esmagazine.com

LowEmission Burners Continue to Pace the Market Engineered Systems Flue Gas Recirculation Boiler Internal flue gas recirculation (ifgr) is one of the most effective techniques for eliminating nitric oxides (no x) in boilers,. Flue gas recirculation (fgr) is the process of taking a portion of the flue gas from a combustion process and recirculating it back through a boiler or burner. In this paper the effectiveness of the flue gas recirculation (fgr) system. Flue Gas Recirculation Boiler.

From www.semanticscholar.org

Figure 1 from Combustion Characteristics of 0.5 MW Class OxyFuel FGR Flue Gas Recirculation Boiler When the process is used in internal combustion engines it is commonly referred to as exhaust gas recirculation (egr). Internal flue gas recirculation (ifgr) is one of the most effective techniques for eliminating nitric oxides (no x) in boilers,. In this paper the effectiveness of the flue gas recirculation (fgr) system that is applied to reduce nox emissions of the. Flue Gas Recirculation Boiler.

From emcombustion.es

Flue gas recirculation clean environment emissions reduction Flue Gas Recirculation Boiler One of the significant contributing factors is no x emissions from commercial natural gas boilers. Flue gas recirculation (fgr) can be a highly effective technique for lowering nox emissions from burners in certain applications, as well as being relatively inexpensive to apply. Internal flue gas recirculation (ifgr) is one of the most effective techniques for eliminating nitric oxides (no x). Flue Gas Recirculation Boiler.

From www.elco-burners.com

Elco Burners FGR SYSTEM Flue Gas Recirculation Boiler In this paper the effectiveness of the flue gas recirculation (fgr) system that is applied to reduce nox emissions of the utility. Internal flue gas recirculation (ifgr) is one of the most effective techniques for eliminating nitric oxides (no x) in boilers,. One of the significant contributing factors is no x emissions from commercial natural gas boilers. Flue gas recirculation. Flue Gas Recirculation Boiler.

From www2.mdpi.com

Energies Free FullText Combustion Characteristics of 0.5 MW Class Flue Gas Recirculation Boiler One of the significant contributing factors is no x emissions from commercial natural gas boilers. Internal flue gas recirculation (ifgr) is one of the most effective techniques for eliminating nitric oxides (no x) in boilers,. In this paper the effectiveness of the flue gas recirculation (fgr) system that is applied to reduce nox emissions of the utility. When the process. Flue Gas Recirculation Boiler.

From eureka-patsnap-com.libproxy1.nus.edu.sg

Flue gas recirculation method and flue gas recirculation system capable Flue Gas Recirculation Boiler Internal flue gas recirculation (ifgr) is one of the most effective techniques for eliminating nitric oxides (no x) in boilers,. When the process is used in internal combustion engines it is commonly referred to as exhaust gas recirculation (egr). One of the significant contributing factors is no x emissions from commercial natural gas boilers. Flue gas recirculation (fgr) is the. Flue Gas Recirculation Boiler.

From gasheatdenkabo.blogspot.com

Gas Heat Flue Gas Heat Recovery System Flue Gas Recirculation Boiler Flue gas recirculation (fgr) is the process of taking a portion of the flue gas from a combustion process and recirculating it back through a boiler or burner. Internal flue gas recirculation (ifgr) is one of the most effective techniques for eliminating nitric oxides (no x) in boilers,. In this paper the effectiveness of the flue gas recirculation (fgr) system. Flue Gas Recirculation Boiler.

From www.mdpi.com

Atmosphere Free FullText Investigation and Evaluation of Flue Gas Flue Gas Recirculation Boiler Flue gas recirculation (fgr) is the process of taking a portion of the flue gas from a combustion process and recirculating it back through a boiler or burner. In this paper the effectiveness of the flue gas recirculation (fgr) system that is applied to reduce nox emissions of the utility. Flue gas recirculation (fgr) can be a highly effective technique. Flue Gas Recirculation Boiler.

From www.researchgate.net

Volumetric combustion concept with internal recirculation of flue gas Flue Gas Recirculation Boiler One of the significant contributing factors is no x emissions from commercial natural gas boilers. Flue gas recirculation (fgr) is the process of taking a portion of the flue gas from a combustion process and recirculating it back through a boiler or burner. In this paper the effectiveness of the flue gas recirculation (fgr) system that is applied to reduce. Flue Gas Recirculation Boiler.