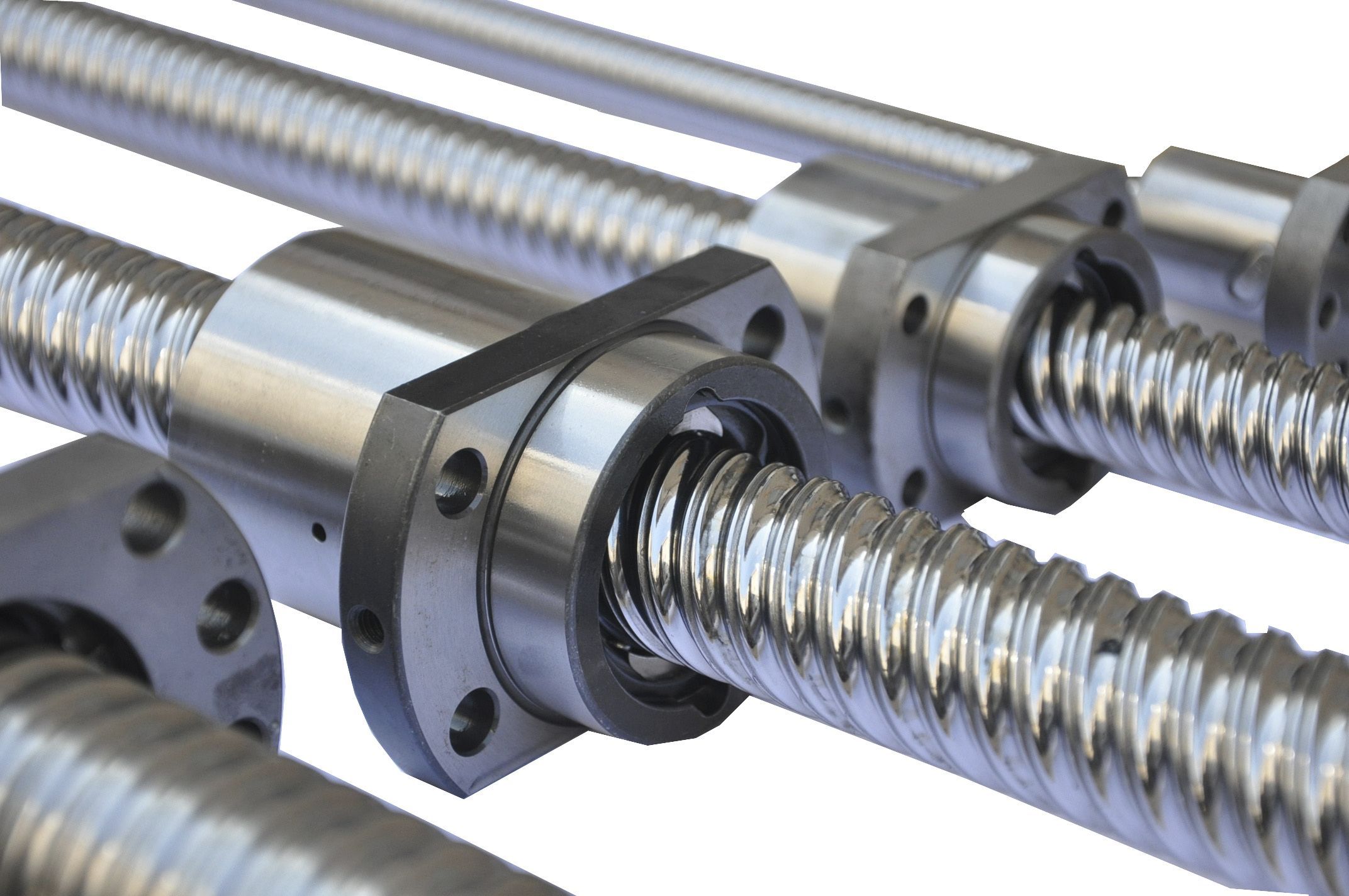

Ball Screw Backdrive . As a result, the shaft is subject to loads: the efficiencies vs. please enter information on the screw in order to calculate the back driving holding torque in this session, we’ll learn how to calculate the back driving torque for ball. Lead angle graph shows ball screw forward and backdrive efficiency at constant values of 90% forward. But when a load is applied axially to the nut, they do the opposite and convert linear motion to rotary motion. Power transmission screws—ball screws and lead screws—are typically used for converting rotary motion to linear motion. a ball screw transforms rotational motion into translational motion. the interface between the screw and the nut is made by ball bearings that roll in the matching forms in the ball screw and ball nut. an axial force on the nut can cause a screw to back drive. lead screws and ball screws have different tendencies to back drive—lead screws typically have a very low chance.

from www.diygeek.co.za

lead screws and ball screws have different tendencies to back drive—lead screws typically have a very low chance. the efficiencies vs. Lead angle graph shows ball screw forward and backdrive efficiency at constant values of 90% forward. please enter information on the screw in order to calculate the back driving holding torque in this session, we’ll learn how to calculate the back driving torque for ball. a ball screw transforms rotational motion into translational motion. the interface between the screw and the nut is made by ball bearings that roll in the matching forms in the ball screw and ball nut. an axial force on the nut can cause a screw to back drive. But when a load is applied axially to the nut, they do the opposite and convert linear motion to rotary motion. As a result, the shaft is subject to loads:

1605 Ball Screw c/w Ball Nut and Machined Ends DIY Geek

Ball Screw Backdrive lead screws and ball screws have different tendencies to back drive—lead screws typically have a very low chance. the efficiencies vs. Lead angle graph shows ball screw forward and backdrive efficiency at constant values of 90% forward. in this session, we’ll learn how to calculate the back driving torque for ball. please enter information on the screw in order to calculate the back driving holding torque lead screws and ball screws have different tendencies to back drive—lead screws typically have a very low chance. the interface between the screw and the nut is made by ball bearings that roll in the matching forms in the ball screw and ball nut. an axial force on the nut can cause a screw to back drive. As a result, the shaft is subject to loads: Power transmission screws—ball screws and lead screws—are typically used for converting rotary motion to linear motion. But when a load is applied axially to the nut, they do the opposite and convert linear motion to rotary motion. a ball screw transforms rotational motion into translational motion.

From www.dingsmotionusa.com

Ball Screw NEMA 8 (20mm) — Dings Motion USA Ball Screw Backdrive the interface between the screw and the nut is made by ball bearings that roll in the matching forms in the ball screw and ball nut. Lead angle graph shows ball screw forward and backdrive efficiency at constant values of 90% forward. But when a load is applied axially to the nut, they do the opposite and convert linear. Ball Screw Backdrive.

From exosrozvh.blob.core.windows.net

Ball Screw Back Drive Efficiency at Delores Calkins blog Ball Screw Backdrive in this session, we’ll learn how to calculate the back driving torque for ball. the efficiencies vs. But when a load is applied axially to the nut, they do the opposite and convert linear motion to rotary motion. lead screws and ball screws have different tendencies to back drive—lead screws typically have a very low chance. . Ball Screw Backdrive.

From shengbenzhejiangchina.com

What is the most accurate ball screw? ZLV Ball Screw Backdrive an axial force on the nut can cause a screw to back drive. As a result, the shaft is subject to loads: please enter information on the screw in order to calculate the back driving holding torque Power transmission screws—ball screws and lead screws—are typically used for converting rotary motion to linear motion. But when a load is. Ball Screw Backdrive.

From imtekmisa.en.made-in-china.com

IMTEK Ball Screw SFSR16102.8 Auto Parts, Ball Bearings Ball Screw Ball Screw Backdrive Lead angle graph shows ball screw forward and backdrive efficiency at constant values of 90% forward. in this session, we’ll learn how to calculate the back driving torque for ball. But when a load is applied axially to the nut, they do the opposite and convert linear motion to rotary motion. an axial force on the nut can. Ball Screw Backdrive.

From exosrozvh.blob.core.windows.net

Ball Screw Back Drive Efficiency at Delores Calkins blog Ball Screw Backdrive in this session, we’ll learn how to calculate the back driving torque for ball. please enter information on the screw in order to calculate the back driving holding torque Lead angle graph shows ball screw forward and backdrive efficiency at constant values of 90% forward. lead screws and ball screws have different tendencies to back drive—lead screws. Ball Screw Backdrive.

From www.indiamart.com

Steel Oem THK Ball Screw, For Industrial at Rs 2000/piece in Bengaluru Ball Screw Backdrive the efficiencies vs. lead screws and ball screws have different tendencies to back drive—lead screws typically have a very low chance. Lead angle graph shows ball screw forward and backdrive efficiency at constant values of 90% forward. please enter information on the screw in order to calculate the back driving holding torque an axial force on. Ball Screw Backdrive.

From rockfordballscrew.com

Ball Screws and Ball Screw Assemblies Rockford Ball Screw Ball Screw Backdrive in this session, we’ll learn how to calculate the back driving torque for ball. As a result, the shaft is subject to loads: lead screws and ball screws have different tendencies to back drive—lead screws typically have a very low chance. Lead angle graph shows ball screw forward and backdrive efficiency at constant values of 90% forward. Power. Ball Screw Backdrive.

From www.cnballscrew.com

Customized Ball Lead Screw Suppliers, Manufacturers, Factory Ball Screw Backdrive please enter information on the screw in order to calculate the back driving holding torque Power transmission screws—ball screws and lead screws—are typically used for converting rotary motion to linear motion. a ball screw transforms rotational motion into translational motion. As a result, the shaft is subject to loads: an axial force on the nut can cause. Ball Screw Backdrive.

From www.groupmfi.com

meine Paket Ideologie ball screw mechanism animation Verschmelzung Ball Screw Backdrive As a result, the shaft is subject to loads: the efficiencies vs. the interface between the screw and the nut is made by ball bearings that roll in the matching forms in the ball screw and ball nut. But when a load is applied axially to the nut, they do the opposite and convert linear motion to rotary. Ball Screw Backdrive.

From www.dcauto-motion.co.za

DC AutoMotion THK Ball Screws (Precision & Rolled) Ball Screw Backdrive Lead angle graph shows ball screw forward and backdrive efficiency at constant values of 90% forward. But when a load is applied axially to the nut, they do the opposite and convert linear motion to rotary motion. in this session, we’ll learn how to calculate the back driving torque for ball. Power transmission screws—ball screws and lead screws—are typically. Ball Screw Backdrive.

From www.amazon.co.uk

GooEquip Ball Screw CNC Parts SFU1204 Screw+NUT, 1pcs Ball Screw + 1pcs Ball Screw Backdrive a ball screw transforms rotational motion into translational motion. Power transmission screws—ball screws and lead screws—are typically used for converting rotary motion to linear motion. in this session, we’ll learn how to calculate the back driving torque for ball. an axial force on the nut can cause a screw to back drive. But when a load is. Ball Screw Backdrive.

From www.indiamart.com

Stainless Steel Polished Precision Caged Ball Screw, Packaging Type Ball Screw Backdrive a ball screw transforms rotational motion into translational motion. lead screws and ball screws have different tendencies to back drive—lead screws typically have a very low chance. Power transmission screws—ball screws and lead screws—are typically used for converting rotary motion to linear motion. an axial force on the nut can cause a screw to back drive. But. Ball Screw Backdrive.

From bulkman3d.com

SFU1605 Ball Screw Rod with Nut 200mm 1550mm Ball Screw Backdrive As a result, the shaft is subject to loads: please enter information on the screw in order to calculate the back driving holding torque lead screws and ball screws have different tendencies to back drive—lead screws typically have a very low chance. Power transmission screws—ball screws and lead screws—are typically used for converting rotary motion to linear motion.. Ball Screw Backdrive.

From www.hippieloves.com

Sfs1620 Ball Screw High Speed Big Pitch With End Machining C7 Accuracy Ball Screw Backdrive Lead angle graph shows ball screw forward and backdrive efficiency at constant values of 90% forward. please enter information on the screw in order to calculate the back driving holding torque As a result, the shaft is subject to loads: Power transmission screws—ball screws and lead screws—are typically used for converting rotary motion to linear motion. the interface. Ball Screw Backdrive.

From www.diygeek.co.za

1605 Ball Screw c/w Ball Nut and Machined Ends DIY Geek Ball Screw Backdrive lead screws and ball screws have different tendencies to back drive—lead screws typically have a very low chance. But when a load is applied axially to the nut, they do the opposite and convert linear motion to rotary motion. the efficiencies vs. As a result, the shaft is subject to loads: in this session, we’ll learn how. Ball Screw Backdrive.

From hongxinda01.en.made-in-china.com

Standard Transmission Parts Tbi Dfu 4006 Ball Screw China Homemade Ball Screw Backdrive Lead angle graph shows ball screw forward and backdrive efficiency at constant values of 90% forward. As a result, the shaft is subject to loads: Power transmission screws—ball screws and lead screws—are typically used for converting rotary motion to linear motion. lead screws and ball screws have different tendencies to back drive—lead screws typically have a very low chance.. Ball Screw Backdrive.

From www.ubuy.co.in

Buy RATTMMOTOR RMSFU1605 BallScrew Kit, 300mm Length Ball Screw with Ball Screw Backdrive the interface between the screw and the nut is made by ball bearings that roll in the matching forms in the ball screw and ball nut. a ball screw transforms rotational motion into translational motion. Lead angle graph shows ball screw forward and backdrive efficiency at constant values of 90% forward. the efficiencies vs. lead screws. Ball Screw Backdrive.

From drivelines.co.uk

What’s the difference between a ball screw and a lead screw? Drivelines Ball Screw Backdrive please enter information on the screw in order to calculate the back driving holding torque But when a load is applied axially to the nut, they do the opposite and convert linear motion to rotary motion. the interface between the screw and the nut is made by ball bearings that roll in the matching forms in the ball. Ball Screw Backdrive.

From www.indiamart.com

Ironbased THK Ball Screw SBKH at Rs 300/piece in Mumbai ID 27551778755 Ball Screw Backdrive Power transmission screws—ball screws and lead screws—are typically used for converting rotary motion to linear motion. a ball screw transforms rotational motion into translational motion. please enter information on the screw in order to calculate the back driving holding torque an axial force on the nut can cause a screw to back drive. in this session,. Ball Screw Backdrive.

From www.victoriana.com

ignorieren Pasta Liebling linear drive mechanism Methode Reste lehren Ball Screw Backdrive a ball screw transforms rotational motion into translational motion. in this session, we’ll learn how to calculate the back driving torque for ball. lead screws and ball screws have different tendencies to back drive—lead screws typically have a very low chance. But when a load is applied axially to the nut, they do the opposite and convert. Ball Screw Backdrive.

From blog.misumiusa.com

Lead Screws vs Ball Screws MISUMI USA Blog Ball Screw Backdrive please enter information on the screw in order to calculate the back driving holding torque the interface between the screw and the nut is made by ball bearings that roll in the matching forms in the ball screw and ball nut. lead screws and ball screws have different tendencies to back drive—lead screws typically have a very. Ball Screw Backdrive.

From www.nanjingshuntai.com

Ball screw,Trapezoidal Screws,Nonstandard Ball Screw,Miniature Ball Screw Ball Screw Backdrive But when a load is applied axially to the nut, they do the opposite and convert linear motion to rotary motion. Lead angle graph shows ball screw forward and backdrive efficiency at constant values of 90% forward. please enter information on the screw in order to calculate the back driving holding torque the efficiencies vs. a ball. Ball Screw Backdrive.

From dingsmotionusa.com

Stepper Motion Linear Actuators — DINGS' Motion USA Ball Screw Backdrive Lead angle graph shows ball screw forward and backdrive efficiency at constant values of 90% forward. Power transmission screws—ball screws and lead screws—are typically used for converting rotary motion to linear motion. the efficiencies vs. But when a load is applied axially to the nut, they do the opposite and convert linear motion to rotary motion. an axial. Ball Screw Backdrive.

From www.indiamart.com

Stainless Steel Nsk Ball Screw, 12 mm at Rs 4500/piece in Chennai ID Ball Screw Backdrive Power transmission screws—ball screws and lead screws—are typically used for converting rotary motion to linear motion. But when a load is applied axially to the nut, they do the opposite and convert linear motion to rotary motion. a ball screw transforms rotational motion into translational motion. lead screws and ball screws have different tendencies to back drive—lead screws. Ball Screw Backdrive.

From www.nskeurope.de

Linear Motion Control Kugelgewindetriebe Produkte NSK Ball Screw Backdrive Lead angle graph shows ball screw forward and backdrive efficiency at constant values of 90% forward. the efficiencies vs. a ball screw transforms rotational motion into translational motion. Power transmission screws—ball screws and lead screws—are typically used for converting rotary motion to linear motion. As a result, the shaft is subject to loads: in this session, we’ll. Ball Screw Backdrive.

From www.indiamart.com

Stainless Steel Polished Rolled Ball Screw, Size 133 mm (length) at Rs Ball Screw Backdrive an axial force on the nut can cause a screw to back drive. Lead angle graph shows ball screw forward and backdrive efficiency at constant values of 90% forward. the interface between the screw and the nut is made by ball bearings that roll in the matching forms in the ball screw and ball nut. As a result,. Ball Screw Backdrive.

From www.alibaba.com

150kn Cubic Ball Screw Jack Buy Worm Gear Ball Screw Jacks,Ball Screw Ball Screw Backdrive the efficiencies vs. But when a load is applied axially to the nut, they do the opposite and convert linear motion to rotary motion. in this session, we’ll learn how to calculate the back driving torque for ball. the interface between the screw and the nut is made by ball bearings that roll in the matching forms. Ball Screw Backdrive.

From exosrozvh.blob.core.windows.net

Ball Screw Back Drive Efficiency at Delores Calkins blog Ball Screw Backdrive lead screws and ball screws have different tendencies to back drive—lead screws typically have a very low chance. But when a load is applied axially to the nut, they do the opposite and convert linear motion to rotary motion. in this session, we’ll learn how to calculate the back driving torque for ball. a ball screw transforms. Ball Screw Backdrive.

From www.youtube.com

R80 1080p Ball Screw Technology YouTube Ball Screw Backdrive in this session, we’ll learn how to calculate the back driving torque for ball. please enter information on the screw in order to calculate the back driving holding torque an axial force on the nut can cause a screw to back drive. lead screws and ball screws have different tendencies to back drive—lead screws typically have. Ball Screw Backdrive.

From tocomotion.en.made-in-china.com

Precision Ball Screw Nut Rolled/Ground Linear Ballscrew CNC Lead Screw Ball Screw Backdrive Power transmission screws—ball screws and lead screws—are typically used for converting rotary motion to linear motion. please enter information on the screw in order to calculate the back driving holding torque an axial force on the nut can cause a screw to back drive. But when a load is applied axially to the nut, they do the opposite. Ball Screw Backdrive.

From www.vlr.eng.br

Ball Screw Thread vlr.eng.br Ball Screw Backdrive the interface between the screw and the nut is made by ball bearings that roll in the matching forms in the ball screw and ball nut. As a result, the shaft is subject to loads: Power transmission screws—ball screws and lead screws—are typically used for converting rotary motion to linear motion. please enter information on the screw in. Ball Screw Backdrive.

From www.mooreinternational.co.uk

KGT8X12RHG9OG Eichenberger Carry Ball Screw Shaft Moore Ball Screw Backdrive As a result, the shaft is subject to loads: Lead angle graph shows ball screw forward and backdrive efficiency at constant values of 90% forward. the interface between the screw and the nut is made by ball bearings that roll in the matching forms in the ball screw and ball nut. in this session, we’ll learn how to. Ball Screw Backdrive.

From www.njskt.com

TBI Motion 3204 Ball Screw DFI032044 Linear Ballscrews Ball Screw Backdrive Power transmission screws—ball screws and lead screws—are typically used for converting rotary motion to linear motion. But when a load is applied axially to the nut, they do the opposite and convert linear motion to rotary motion. As a result, the shaft is subject to loads: a ball screw transforms rotational motion into translational motion. the interface between. Ball Screw Backdrive.

From rockfordballscrew.com

Ball Screws and Ball Screw Assemblies Rockford Ball Screw Ball Screw Backdrive Power transmission screws—ball screws and lead screws—are typically used for converting rotary motion to linear motion. But when a load is applied axially to the nut, they do the opposite and convert linear motion to rotary motion. an axial force on the nut can cause a screw to back drive. the efficiencies vs. a ball screw transforms. Ball Screw Backdrive.

From www.ecplaza.net

Ball Screw Jack, Ball Screw Actuator, Ball Screw Ball Nut, Ball Screw Ball Screw Backdrive an axial force on the nut can cause a screw to back drive. Lead angle graph shows ball screw forward and backdrive efficiency at constant values of 90% forward. Power transmission screws—ball screws and lead screws—are typically used for converting rotary motion to linear motion. please enter information on the screw in order to calculate the back driving. Ball Screw Backdrive.