Carbon Fiber Tubes Weight . We compare carbon fibre tubes to each other, and also benchmark them against stainless steel and aluminium to see how. Choosing the right carbon fiber tube size is crucial for the success of any project that requires strength, lightness, and durability. Virtually any wall thickness can be made by changing. I can get tensile strength from most carbon fiber tube manufacturers. They excel in applications where high. Estimating the weight of carbon fiber components is crucial for design and engineering purposes. On average, carbon fiber tubes can be 2 to 10 times stronger than steel of similar weight. 346 rows carbon fiber tubes are made with layers of prepreg, typically ~0.006” per layer. I believe i want to calculate maximum stress and more specifically sheer stress for a hollow tube. High strength roll wrapped carbon fibre tube with a glossy, woven carbon fibre finish making them a great choice for a huge range of both structural and cosmetic applications including drones,. 4.5/5 (8,291) 4.5/5 (8,291)

from dragonplate.com

High strength roll wrapped carbon fibre tube with a glossy, woven carbon fibre finish making them a great choice for a huge range of both structural and cosmetic applications including drones,. I can get tensile strength from most carbon fiber tube manufacturers. 4.5/5 (8,291) We compare carbon fibre tubes to each other, and also benchmark them against stainless steel and aluminium to see how. 4.5/5 (8,291) 346 rows carbon fiber tubes are made with layers of prepreg, typically ~0.006” per layer. Estimating the weight of carbon fiber components is crucial for design and engineering purposes. On average, carbon fiber tubes can be 2 to 10 times stronger than steel of similar weight. They excel in applications where high. Virtually any wall thickness can be made by changing.

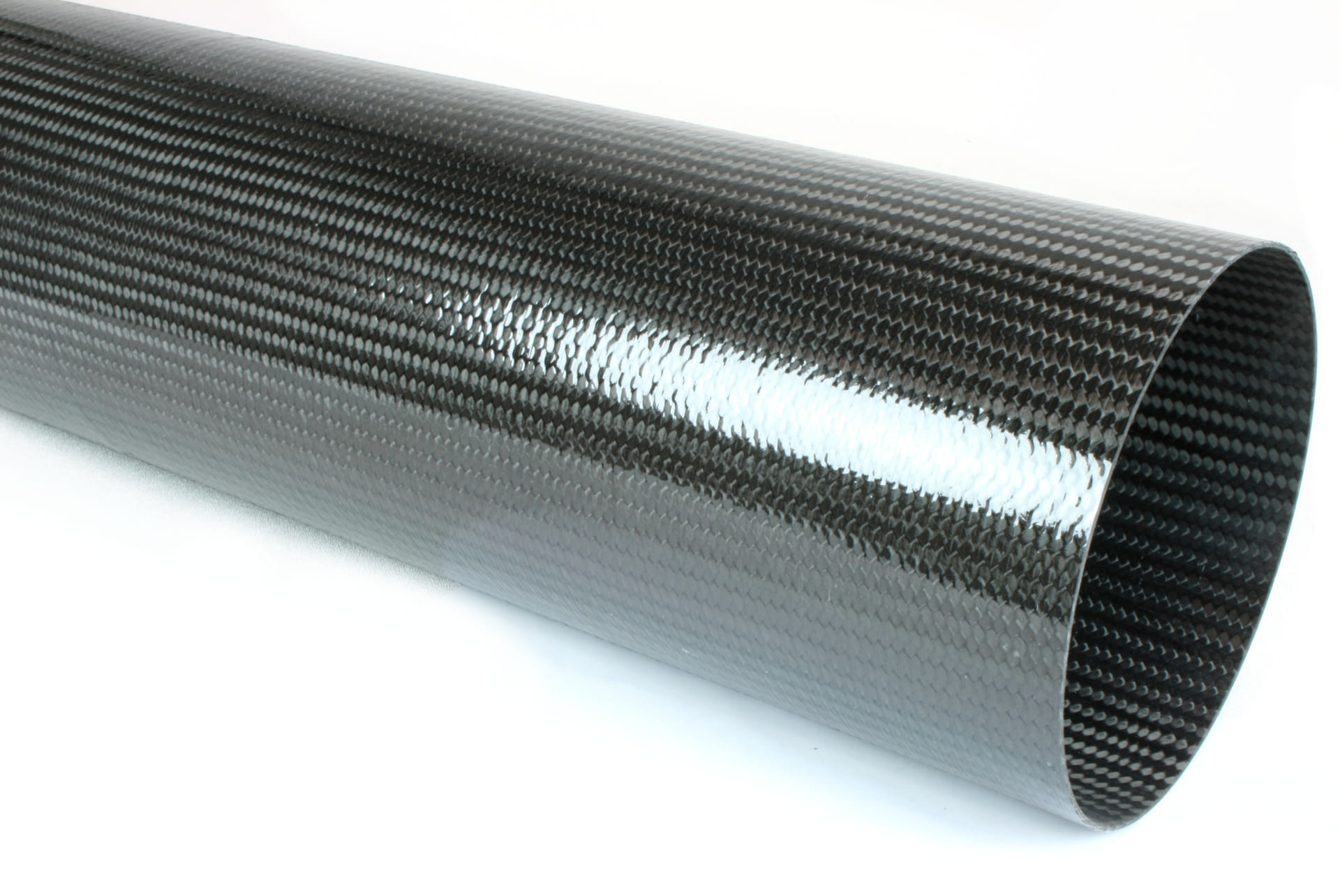

Braided Carbon Fiber Round Tubing 6" ID x 24" DragonPlate

Carbon Fiber Tubes Weight Virtually any wall thickness can be made by changing. We compare carbon fibre tubes to each other, and also benchmark them against stainless steel and aluminium to see how. Choosing the right carbon fiber tube size is crucial for the success of any project that requires strength, lightness, and durability. Virtually any wall thickness can be made by changing. On average, carbon fiber tubes can be 2 to 10 times stronger than steel of similar weight. Estimating the weight of carbon fiber components is crucial for design and engineering purposes. 346 rows carbon fiber tubes are made with layers of prepreg, typically ~0.006” per layer. 4.5/5 (8,291) 4.5/5 (8,291) High strength roll wrapped carbon fibre tube with a glossy, woven carbon fibre finish making them a great choice for a huge range of both structural and cosmetic applications including drones,. I believe i want to calculate maximum stress and more specifically sheer stress for a hollow tube. They excel in applications where high. I can get tensile strength from most carbon fiber tube manufacturers.

From carbonkevlarsupply.com

Carbon Fiber Tubing 20mm x 18mm x 500mm 3K Roll Wrapped 100 Carbo Carbon Fiber Tubes Weight I believe i want to calculate maximum stress and more specifically sheer stress for a hollow tube. 346 rows carbon fiber tubes are made with layers of prepreg, typically ~0.006” per layer. Choosing the right carbon fiber tube size is crucial for the success of any project that requires strength, lightness, and durability. I can get tensile strength from most. Carbon Fiber Tubes Weight.

From www.3kcarbontube.com

Light Weight Carbon Tube 40mm 50mm 60mm 70mm 80mm 2 Meters long Carbon Carbon Fiber Tubes Weight We compare carbon fibre tubes to each other, and also benchmark them against stainless steel and aluminium to see how. I believe i want to calculate maximum stress and more specifically sheer stress for a hollow tube. I can get tensile strength from most carbon fiber tube manufacturers. On average, carbon fiber tubes can be 2 to 10 times stronger. Carbon Fiber Tubes Weight.

From www.alibaba.com

3k Tapered Carbon Fiber Tubes 3k Twill Plain Glossy Matte High Strength Carbon Fiber Tubes Weight 4.5/5 (8,291) I can get tensile strength from most carbon fiber tube manufacturers. Estimating the weight of carbon fiber components is crucial for design and engineering purposes. They excel in applications where high. 4.5/5 (8,291) On average, carbon fiber tubes can be 2 to 10 times stronger than steel of similar weight. High strength roll wrapped carbon fibre. Carbon Fiber Tubes Weight.

From www.nitprocomposites.com

Carbon Fiber Tubes NitPro Composites Carbon Fiber Tubes Weight I can get tensile strength from most carbon fiber tube manufacturers. On average, carbon fiber tubes can be 2 to 10 times stronger than steel of similar weight. They excel in applications where high. Choosing the right carbon fiber tube size is crucial for the success of any project that requires strength, lightness, and durability. I believe i want to. Carbon Fiber Tubes Weight.

From www.carbonfiber-composites.com

Light weight High Strength Carbon Fiber Profiles , custom size Carbon Carbon Fiber Tubes Weight 4.5/5 (8,291) They excel in applications where high. 4.5/5 (8,291) 346 rows carbon fiber tubes are made with layers of prepreg, typically ~0.006” per layer. I can get tensile strength from most carbon fiber tube manufacturers. On average, carbon fiber tubes can be 2 to 10 times stronger than steel of similar weight. I believe i want to. Carbon Fiber Tubes Weight.

From www.jinjiuyi.net

100 3K Real Carbon Fiber Tubes T300 Carbon Tube Matte Plain carbon Carbon Fiber Tubes Weight High strength roll wrapped carbon fibre tube with a glossy, woven carbon fibre finish making them a great choice for a huge range of both structural and cosmetic applications including drones,. 4.5/5 (8,291) Virtually any wall thickness can be made by changing. 4.5/5 (8,291) Choosing the right carbon fiber tube size is crucial for the success of any. Carbon Fiber Tubes Weight.

From www.carbonfiberstar.com

High Standard Carbon Fiber Tube With Scale CFS1017 Carbon Fiber Star Carbon Fiber Tubes Weight I can get tensile strength from most carbon fiber tube manufacturers. I believe i want to calculate maximum stress and more specifically sheer stress for a hollow tube. Choosing the right carbon fiber tube size is crucial for the success of any project that requires strength, lightness, and durability. On average, carbon fiber tubes can be 2 to 10 times. Carbon Fiber Tubes Weight.

From dragonplate.com

Carbon Fiber Roll Wrapped Telescoping Twill Tube 1.125" ID x 48 Carbon Fiber Tubes Weight 346 rows carbon fiber tubes are made with layers of prepreg, typically ~0.006” per layer. High strength roll wrapped carbon fibre tube with a glossy, woven carbon fibre finish making them a great choice for a huge range of both structural and cosmetic applications including drones,. 4.5/5 (8,291) 4.5/5 (8,291) Virtually any wall thickness can be made by. Carbon Fiber Tubes Weight.

From www.alibaba.com

25mm,20mm,8mm,6mm,5mm,3mm,2mm Large Dimension 3k Carbon Fiber Tube Carbon Fiber Tubes Weight 346 rows carbon fiber tubes are made with layers of prepreg, typically ~0.006” per layer. I can get tensile strength from most carbon fiber tube manufacturers. 4.5/5 (8,291) Estimating the weight of carbon fiber components is crucial for design and engineering purposes. We compare carbon fibre tubes to each other, and also benchmark them against stainless steel and aluminium. Carbon Fiber Tubes Weight.

From www.tstarco.com

High strength light weight carbon fiber square tube tubing with 3K Carbon Fiber Tubes Weight On average, carbon fiber tubes can be 2 to 10 times stronger than steel of similar weight. 346 rows carbon fiber tubes are made with layers of prepreg, typically ~0.006” per layer. I believe i want to calculate maximum stress and more specifically sheer stress for a hollow tube. They excel in applications where high. I can get tensile strength. Carbon Fiber Tubes Weight.

From dragonplate.com

Braided Carbon Fiber Round Tubing 6" ID x 24" DragonPlate Carbon Fiber Tubes Weight 346 rows carbon fiber tubes are made with layers of prepreg, typically ~0.006” per layer. Virtually any wall thickness can be made by changing. Estimating the weight of carbon fiber components is crucial for design and engineering purposes. 4.5/5 (8,291) Choosing the right carbon fiber tube size is crucial for the success of any project that requires strength, lightness,. Carbon Fiber Tubes Weight.

From www.3kcarbontube.com

Factory wholesale light weight high strength carbon fiber tube Carbon Fiber Tubes Weight Virtually any wall thickness can be made by changing. 346 rows carbon fiber tubes are made with layers of prepreg, typically ~0.006” per layer. Estimating the weight of carbon fiber components is crucial for design and engineering purposes. We compare carbon fibre tubes to each other, and also benchmark them against stainless steel and aluminium to see how. 4.5/5 . Carbon Fiber Tubes Weight.

From www.alibaba.com

3k Tapered Carbon Fiber Tubes 3k Twill Plain Glossy Matte High Strength Carbon Fiber Tubes Weight They excel in applications where high. 4.5/5 (8,291) Virtually any wall thickness can be made by changing. Choosing the right carbon fiber tube size is crucial for the success of any project that requires strength, lightness, and durability. I believe i want to calculate maximum stress and more specifically sheer stress for a hollow tube. Estimating the weight of. Carbon Fiber Tubes Weight.

From www.alibaba.com

3k Tapered Carbon Fiber Tubes 3k Twill Plain Glossy Matte High Strength Carbon Fiber Tubes Weight 4.5/5 (8,291) 346 rows carbon fiber tubes are made with layers of prepreg, typically ~0.006” per layer. I can get tensile strength from most carbon fiber tube manufacturers. They excel in applications where high. On average, carbon fiber tubes can be 2 to 10 times stronger than steel of similar weight. Virtually any wall thickness can be made by. Carbon Fiber Tubes Weight.

From www.3kcarbontube.com

Light Weight Carbon Tube 40mm 50mm 60mm 70mm 80mm 2 Meters long Carbon Carbon Fiber Tubes Weight High strength roll wrapped carbon fibre tube with a glossy, woven carbon fibre finish making them a great choice for a huge range of both structural and cosmetic applications including drones,. Virtually any wall thickness can be made by changing. We compare carbon fibre tubes to each other, and also benchmark them against stainless steel and aluminium to see how.. Carbon Fiber Tubes Weight.

From carbonkevlarsupply.com

(2) Piece 14mm x 1000mm Carbon Fiber RODS Solid Pultruded Round Ro Carbon Fiber Tubes Weight 4.5/5 (8,291) They excel in applications where high. On average, carbon fiber tubes can be 2 to 10 times stronger than steel of similar weight. 346 rows carbon fiber tubes are made with layers of prepreg, typically ~0.006” per layer. 4.5/5 (8,291) I believe i want to calculate maximum stress and more specifically sheer stress for a hollow. Carbon Fiber Tubes Weight.

From www.3kcarbontube.com

Light Weight Carbon Tube 40mm 50mm 60mm 70mm 80mm 2 Meters long Carbon Carbon Fiber Tubes Weight We compare carbon fibre tubes to each other, and also benchmark them against stainless steel and aluminium to see how. I can get tensile strength from most carbon fiber tube manufacturers. Estimating the weight of carbon fiber components is crucial for design and engineering purposes. Choosing the right carbon fiber tube size is crucial for the success of any project. Carbon Fiber Tubes Weight.

From www.amazon.com

(4) Carbon Fiber Tubes 25mm x 23mm x 500mm 3K Roll Carbon Fiber Tubes Weight 346 rows carbon fiber tubes are made with layers of prepreg, typically ~0.006” per layer. High strength roll wrapped carbon fibre tube with a glossy, woven carbon fibre finish making them a great choice for a huge range of both structural and cosmetic applications including drones,. On average, carbon fiber tubes can be 2 to 10 times stronger than steel. Carbon Fiber Tubes Weight.

From www.3kcarbontube.com

Factory wholesale light weight high strength carbon fiber tube Carbon Fiber Tubes Weight Estimating the weight of carbon fiber components is crucial for design and engineering purposes. High strength roll wrapped carbon fibre tube with a glossy, woven carbon fibre finish making them a great choice for a huge range of both structural and cosmetic applications including drones,. I can get tensile strength from most carbon fiber tube manufacturers. 4.5/5 (8,291) Choosing. Carbon Fiber Tubes Weight.

From boulevardsupply.com

3K Carbon Fiber Tube, 1.5″OD Carbon Fiber Tubes Weight Virtually any wall thickness can be made by changing. Estimating the weight of carbon fiber components is crucial for design and engineering purposes. High strength roll wrapped carbon fibre tube with a glossy, woven carbon fibre finish making them a great choice for a huge range of both structural and cosmetic applications including drones,. 4.5/5 (8,291) Choosing the right. Carbon Fiber Tubes Weight.

From www.3kcarbontube.com

Light Weight Carbon Tube 40mm 50mm 60mm 70mm 80mm 2 Meters long Carbon Carbon Fiber Tubes Weight We compare carbon fibre tubes to each other, and also benchmark them against stainless steel and aluminium to see how. I believe i want to calculate maximum stress and more specifically sheer stress for a hollow tube. They excel in applications where high. Virtually any wall thickness can be made by changing. On average, carbon fiber tubes can be 2. Carbon Fiber Tubes Weight.

From www.3kcarbontube.com

Light Weight Carbon Tube 40mm 50mm 60mm 70mm 80mm 2 Meters long Carbon Carbon Fiber Tubes Weight Estimating the weight of carbon fiber components is crucial for design and engineering purposes. I believe i want to calculate maximum stress and more specifically sheer stress for a hollow tube. Virtually any wall thickness can be made by changing. We compare carbon fibre tubes to each other, and also benchmark them against stainless steel and aluminium to see how.. Carbon Fiber Tubes Weight.

From dragonplate.com

Carbon Fiber Roll Wrapped Twill Tube 4" ID x 96", Gloss Finish Carbon Fiber Tubes Weight 4.5/5 (8,291) 4.5/5 (8,291) High strength roll wrapped carbon fibre tube with a glossy, woven carbon fibre finish making them a great choice for a huge range of both structural and cosmetic applications including drones,. They excel in applications where high. I can get tensile strength from most carbon fiber tube manufacturers. Choosing the right carbon fiber tube. Carbon Fiber Tubes Weight.

From www.lowes.com

Carbon fiber Tubes at Carbon Fiber Tubes Weight We compare carbon fibre tubes to each other, and also benchmark them against stainless steel and aluminium to see how. I can get tensile strength from most carbon fiber tube manufacturers. Estimating the weight of carbon fiber components is crucial for design and engineering purposes. On average, carbon fiber tubes can be 2 to 10 times stronger than steel of. Carbon Fiber Tubes Weight.

From medium.com

4 different techniques to Manufacturer Carbon fiber tubes by NitPro Carbon Fiber Tubes Weight 4.5/5 (8,291) I can get tensile strength from most carbon fiber tube manufacturers. They excel in applications where high. 346 rows carbon fiber tubes are made with layers of prepreg, typically ~0.006” per layer. We compare carbon fibre tubes to each other, and also benchmark them against stainless steel and aluminium to see how. Choosing the right carbon fiber. Carbon Fiber Tubes Weight.

From www.bidfta.com

ARRIS 4PCS 12mm Carbon Fiber Tube, 12mm x 14mm x 500mm High Strength 3K Carbon Fiber Tubes Weight I believe i want to calculate maximum stress and more specifically sheer stress for a hollow tube. On average, carbon fiber tubes can be 2 to 10 times stronger than steel of similar weight. 4.5/5 (8,291) We compare carbon fibre tubes to each other, and also benchmark them against stainless steel and aluminium to see how. They excel in. Carbon Fiber Tubes Weight.

From www.easycomposites.eu

50mm (47mm) Roll Wrapped Carbon Fibre Tube; 1m, 2m Easy Composites Carbon Fiber Tubes Weight Choosing the right carbon fiber tube size is crucial for the success of any project that requires strength, lightness, and durability. Virtually any wall thickness can be made by changing. 4.5/5 (8,291) They excel in applications where high. We compare carbon fibre tubes to each other, and also benchmark them against stainless steel and aluminium to see how. Estimating. Carbon Fiber Tubes Weight.

From www.alibaba.com

Light Weight Carbon Fiber Tube 3k With Twill Plain Woven Fabric Buy Carbon Fiber Tubes Weight Choosing the right carbon fiber tube size is crucial for the success of any project that requires strength, lightness, and durability. 4.5/5 (8,291) Virtually any wall thickness can be made by changing. 346 rows carbon fiber tubes are made with layers of prepreg, typically ~0.006” per layer. They excel in applications where high. I believe i want to calculate. Carbon Fiber Tubes Weight.

From www.alibaba.com

Carbon Fiber Round Tube High Modulus Carbon Fiber Heater Tube Buy Low Carbon Fiber Tubes Weight 4.5/5 (8,291) 346 rows carbon fiber tubes are made with layers of prepreg, typically ~0.006” per layer. I can get tensile strength from most carbon fiber tube manufacturers. Estimating the weight of carbon fiber components is crucial for design and engineering purposes. High strength roll wrapped carbon fibre tube with a glossy, woven carbon fibre finish making them a. Carbon Fiber Tubes Weight.

From www.amazon.com

KARBXON Carbon Fiber Tube Black 10mm X 8mm X 1000mm Carbon Fiber Tubes Weight On average, carbon fiber tubes can be 2 to 10 times stronger than steel of similar weight. 346 rows carbon fiber tubes are made with layers of prepreg, typically ~0.006” per layer. I can get tensile strength from most carbon fiber tube manufacturers. High strength roll wrapped carbon fibre tube with a glossy, woven carbon fibre finish making them a. Carbon Fiber Tubes Weight.

From www.3kcarbontube.com

Factory wholesale light weight high strength carbon fiber tube Carbon Fiber Tubes Weight 4.5/5 (8,291) Choosing the right carbon fiber tube size is crucial for the success of any project that requires strength, lightness, and durability. 346 rows carbon fiber tubes are made with layers of prepreg, typically ~0.006” per layer. 4.5/5 (8,291) Virtually any wall thickness can be made by changing. I can get tensile strength from most carbon fiber. Carbon Fiber Tubes Weight.

From www.alibaba.com

3k Tapered Carbon Fiber Tubes 3k Twill Plain Glossy Matte High Strength Carbon Fiber Tubes Weight We compare carbon fibre tubes to each other, and also benchmark them against stainless steel and aluminium to see how. I can get tensile strength from most carbon fiber tube manufacturers. 4.5/5 (8,291) 346 rows carbon fiber tubes are made with layers of prepreg, typically ~0.006” per layer. High strength roll wrapped carbon fibre tube with a glossy, woven. Carbon Fiber Tubes Weight.

From www.easycomposites.co.uk

60mm (57mm) Woven Finish Carbon Fibre Tube; 1m, 2m Easy Composites Carbon Fiber Tubes Weight I can get tensile strength from most carbon fiber tube manufacturers. Choosing the right carbon fiber tube size is crucial for the success of any project that requires strength, lightness, and durability. High strength roll wrapped carbon fibre tube with a glossy, woven carbon fibre finish making them a great choice for a huge range of both structural and cosmetic. Carbon Fiber Tubes Weight.

From www.tstarco.com

3k carbon fiber tube Tstar Composites Co.,Ltd. Carbon Fiber Tubes Weight 346 rows carbon fiber tubes are made with layers of prepreg, typically ~0.006” per layer. We compare carbon fibre tubes to each other, and also benchmark them against stainless steel and aluminium to see how. I can get tensile strength from most carbon fiber tube manufacturers. 4.5/5 (8,291) Estimating the weight of carbon fiber components is crucial for design. Carbon Fiber Tubes Weight.

From www.tstarco.com

High strength light weight carbon fiber square tube tubing with 3K Carbon Fiber Tubes Weight 346 rows carbon fiber tubes are made with layers of prepreg, typically ~0.006” per layer. They excel in applications where high. Choosing the right carbon fiber tube size is crucial for the success of any project that requires strength, lightness, and durability. We compare carbon fibre tubes to each other, and also benchmark them against stainless steel and aluminium to. Carbon Fiber Tubes Weight.