What Is The Definition Of Soft Soldering . The most common soft solders are tin/lead or tin/silver/copper. This soldering process uses solder with lower melting points, typically below 840°f/450°c. Soldering is a joining process used to join different types of metals together by melting solder. The heat source is often an electric soldering iron but copper ‘irons’ heated with a gas torch may be needed for. Solder is a metal alloy usually. Soft soldering is a method of joining metals with a eutectic tin/lead alloy. Soft soldering involves the use of. Soldering is a process that joins metals using a filler metal, typically an alloy of tin and lead, which melts at lower temperatures. It is a process that has the lowest filler metal melting point compared to the other soldering types which are seen to be less than 400°c. Definition and differences from other soldering techniques:

from components101.com

Solder is a metal alloy usually. Soft soldering is a method of joining metals with a eutectic tin/lead alloy. This soldering process uses solder with lower melting points, typically below 840°f/450°c. Soldering is a joining process used to join different types of metals together by melting solder. The heat source is often an electric soldering iron but copper ‘irons’ heated with a gas torch may be needed for. The most common soft solders are tin/lead or tin/silver/copper. It is a process that has the lowest filler metal melting point compared to the other soldering types which are seen to be less than 400°c. Definition and differences from other soldering techniques: Soft soldering involves the use of. Soldering is a process that joins metals using a filler metal, typically an alloy of tin and lead, which melts at lower temperatures.

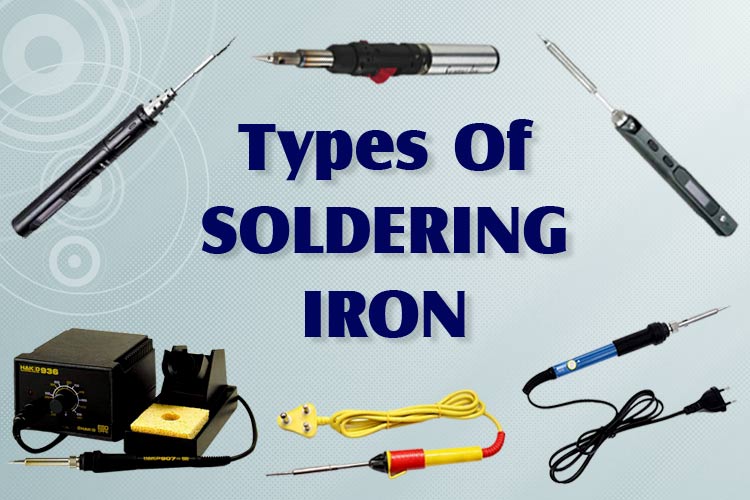

Types of Soldering Iron and How to Select the Right One

What Is The Definition Of Soft Soldering The heat source is often an electric soldering iron but copper ‘irons’ heated with a gas torch may be needed for. The heat source is often an electric soldering iron but copper ‘irons’ heated with a gas torch may be needed for. This soldering process uses solder with lower melting points, typically below 840°f/450°c. The most common soft solders are tin/lead or tin/silver/copper. Definition and differences from other soldering techniques: Solder is a metal alloy usually. Soft soldering is a method of joining metals with a eutectic tin/lead alloy. It is a process that has the lowest filler metal melting point compared to the other soldering types which are seen to be less than 400°c. Soldering is a process that joins metals using a filler metal, typically an alloy of tin and lead, which melts at lower temperatures. Soldering is a joining process used to join different types of metals together by melting solder. Soft soldering involves the use of.

From www.naa.edu

9 Essential Electronics Soldering Tips and Tricks for Beginners What Is The Definition Of Soft Soldering This soldering process uses solder with lower melting points, typically below 840°f/450°c. Soldering is a process that joins metals using a filler metal, typically an alloy of tin and lead, which melts at lower temperatures. Soft soldering is a method of joining metals with a eutectic tin/lead alloy. The heat source is often an electric soldering iron but copper ‘irons’. What Is The Definition Of Soft Soldering.

From www.theengineerspost.com

Different Types of Soldering Process and Their Uses [PDF] What Is The Definition Of Soft Soldering Soldering is a process that joins metals using a filler metal, typically an alloy of tin and lead, which melts at lower temperatures. Solder is a metal alloy usually. Definition and differences from other soldering techniques: The heat source is often an electric soldering iron but copper ‘irons’ heated with a gas torch may be needed for. Soft soldering involves. What Is The Definition Of Soft Soldering.

From exyxpqihl.blob.core.windows.net

Solder Paste Mixing Procedure at Forand blog What Is The Definition Of Soft Soldering Soft soldering involves the use of. Solder is a metal alloy usually. Soft soldering is a method of joining metals with a eutectic tin/lead alloy. Soldering is a joining process used to join different types of metals together by melting solder. It is a process that has the lowest filler metal melting point compared to the other soldering types which. What Is The Definition Of Soft Soldering.

From blog.thepipingmart.com

Brazing vs Silver Soldering What's the Difference What Is The Definition Of Soft Soldering The most common soft solders are tin/lead or tin/silver/copper. Soldering is a joining process used to join different types of metals together by melting solder. Soft soldering is a method of joining metals with a eutectic tin/lead alloy. Solder is a metal alloy usually. Definition and differences from other soldering techniques: This soldering process uses solder with lower melting points,. What Is The Definition Of Soft Soldering.

From www.versaceoutletinc.com

The Different Parts Of A Soldering Iron Versaceoutletinc What Is The Definition Of Soft Soldering Soldering is a process that joins metals using a filler metal, typically an alloy of tin and lead, which melts at lower temperatures. Soft soldering involves the use of. Solder is a metal alloy usually. This soldering process uses solder with lower melting points, typically below 840°f/450°c. The heat source is often an electric soldering iron but copper ‘irons’ heated. What Is The Definition Of Soft Soldering.

From www.youtube.com

What is Solder Flux and How to Use It YouTube What Is The Definition Of Soft Soldering Definition and differences from other soldering techniques: It is a process that has the lowest filler metal melting point compared to the other soldering types which are seen to be less than 400°c. This soldering process uses solder with lower melting points, typically below 840°f/450°c. The heat source is often an electric soldering iron but copper ‘irons’ heated with a. What Is The Definition Of Soft Soldering.

From www.makerspaces.com

How To Solder A Complete Beginners Guide What Is The Definition Of Soft Soldering Soft soldering is a method of joining metals with a eutectic tin/lead alloy. This soldering process uses solder with lower melting points, typically below 840°f/450°c. The most common soft solders are tin/lead or tin/silver/copper. Soldering is a process that joins metals using a filler metal, typically an alloy of tin and lead, which melts at lower temperatures. Soft soldering involves. What Is The Definition Of Soft Soldering.

From www.youtube.com

Basic Soldering YouTube What Is The Definition Of Soft Soldering This soldering process uses solder with lower melting points, typically below 840°f/450°c. Definition and differences from other soldering techniques: Soldering is a process that joins metals using a filler metal, typically an alloy of tin and lead, which melts at lower temperatures. Soft soldering involves the use of. It is a process that has the lowest filler metal melting point. What Is The Definition Of Soft Soldering.

From www.youtube.com

Differences between Soldering and Brazing. YouTube What Is The Definition Of Soft Soldering Soft soldering is a method of joining metals with a eutectic tin/lead alloy. Definition and differences from other soldering techniques: The most common soft solders are tin/lead or tin/silver/copper. Soldering is a process that joins metals using a filler metal, typically an alloy of tin and lead, which melts at lower temperatures. It is a process that has the lowest. What Is The Definition Of Soft Soldering.

From www.atetool.com

What is soft soldering? What Is The Definition Of Soft Soldering Solder is a metal alloy usually. Definition and differences from other soldering techniques: It is a process that has the lowest filler metal melting point compared to the other soldering types which are seen to be less than 400°c. The heat source is often an electric soldering iron but copper ‘irons’ heated with a gas torch may be needed for.. What Is The Definition Of Soft Soldering.

From dxosufskg.blob.core.windows.net

Soldering Definition Business at Julie Ogg blog What Is The Definition Of Soft Soldering Soft soldering involves the use of. The most common soft solders are tin/lead or tin/silver/copper. It is a process that has the lowest filler metal melting point compared to the other soldering types which are seen to be less than 400°c. Soldering is a joining process used to join different types of metals together by melting solder. Definition and differences. What Is The Definition Of Soft Soldering.

From klabphagc.blob.core.windows.net

How To Solder A Brass Radiator Tank at Kathryn Alvarez blog What Is The Definition Of Soft Soldering Solder is a metal alloy usually. This soldering process uses solder with lower melting points, typically below 840°f/450°c. Soft soldering involves the use of. Soft soldering is a method of joining metals with a eutectic tin/lead alloy. Soldering is a joining process used to join different types of metals together by melting solder. The most common soft solders are tin/lead. What Is The Definition Of Soft Soldering.

From itvevents.indiantelevision.com

Soldering Welding What Are The Differences?, 42 OFF What Is The Definition Of Soft Soldering Soldering is a process that joins metals using a filler metal, typically an alloy of tin and lead, which melts at lower temperatures. Soldering is a joining process used to join different types of metals together by melting solder. The heat source is often an electric soldering iron but copper ‘irons’ heated with a gas torch may be needed for.. What Is The Definition Of Soft Soldering.

From webstories.robocraze.com

What is Soldering Types & Applications What Is The Definition Of Soft Soldering Soft soldering involves the use of. The most common soft solders are tin/lead or tin/silver/copper. The heat source is often an electric soldering iron but copper ‘irons’ heated with a gas torch may be needed for. Soldering is a joining process used to join different types of metals together by melting solder. It is a process that has the lowest. What Is The Definition Of Soft Soldering.

From www.theengineerspost.com

Difference Between Brazing and Soldering [Guide with PDF] What Is The Definition Of Soft Soldering Soldering is a joining process used to join different types of metals together by melting solder. Soft soldering involves the use of. The most common soft solders are tin/lead or tin/silver/copper. This soldering process uses solder with lower melting points, typically below 840°f/450°c. Soft soldering is a method of joining metals with a eutectic tin/lead alloy. Definition and differences from. What Is The Definition Of Soft Soldering.

From blog.thepipingmart.com

Soft Soldering Brass A StepbyStep Guide What Is The Definition Of Soft Soldering Soldering is a joining process used to join different types of metals together by melting solder. It is a process that has the lowest filler metal melting point compared to the other soldering types which are seen to be less than 400°c. The heat source is often an electric soldering iron but copper ‘irons’ heated with a gas torch may. What Is The Definition Of Soft Soldering.

From dxosufskg.blob.core.windows.net

Soldering Definition Business at Julie Ogg blog What Is The Definition Of Soft Soldering The most common soft solders are tin/lead or tin/silver/copper. Soldering is a process that joins metals using a filler metal, typically an alloy of tin and lead, which melts at lower temperatures. Soft soldering involves the use of. The heat source is often an electric soldering iron but copper ‘irons’ heated with a gas torch may be needed for. Soft. What Is The Definition Of Soft Soldering.

From exootrukg.blob.core.windows.net

What Is Solder Retention at Rick Woolf blog What Is The Definition Of Soft Soldering Soldering is a process that joins metals using a filler metal, typically an alloy of tin and lead, which melts at lower temperatures. Soft soldering involves the use of. Solder is a metal alloy usually. Soft soldering is a method of joining metals with a eutectic tin/lead alloy. The most common soft solders are tin/lead or tin/silver/copper. This soldering process. What Is The Definition Of Soft Soldering.

From blog.thepipingmart.com

Welding vs Soldering What's the Difference What Is The Definition Of Soft Soldering It is a process that has the lowest filler metal melting point compared to the other soldering types which are seen to be less than 400°c. Soldering is a joining process used to join different types of metals together by melting solder. The most common soft solders are tin/lead or tin/silver/copper. Soft soldering involves the use of. Definition and differences. What Is The Definition Of Soft Soldering.

From mechathon.com

Soldering vs Brazing; Its Process, Advantages, Disadvantages What Is The Definition Of Soft Soldering Solder is a metal alloy usually. This soldering process uses solder with lower melting points, typically below 840°f/450°c. It is a process that has the lowest filler metal melting point compared to the other soldering types which are seen to be less than 400°c. The most common soft solders are tin/lead or tin/silver/copper. Soldering is a process that joins metals. What Is The Definition Of Soft Soldering.

From weldingtroop.com

What Is Soldering? An Indepth Guide [Definition, Types, and Meaning] What Is The Definition Of Soft Soldering Soldering is a process that joins metals using a filler metal, typically an alloy of tin and lead, which melts at lower temperatures. The heat source is often an electric soldering iron but copper ‘irons’ heated with a gas torch may be needed for. This soldering process uses solder with lower melting points, typically below 840°f/450°c. Soldering is a joining. What Is The Definition Of Soft Soldering.

From www.youtube.com

How to Choose a Soldering Iron. Main Types YouTube What Is The Definition Of Soft Soldering Solder is a metal alloy usually. Soldering is a joining process used to join different types of metals together by melting solder. The most common soft solders are tin/lead or tin/silver/copper. Definition and differences from other soldering techniques: This soldering process uses solder with lower melting points, typically below 840°f/450°c. Soldering is a process that joins metals using a filler. What Is The Definition Of Soft Soldering.

From www.weldingdirect.co.uk

Lead Free Soft Solder 97 Tin Flux Cored 2,00 mm Dia 500g Reel What Is The Definition Of Soft Soldering It is a process that has the lowest filler metal melting point compared to the other soldering types which are seen to be less than 400°c. Soft soldering involves the use of. Soldering is a joining process used to join different types of metals together by melting solder. Definition and differences from other soldering techniques: The heat source is often. What Is The Definition Of Soft Soldering.

From www.cruxweld.com

The Difference between Soldering and Brazing with Welding [The What Is The Definition Of Soft Soldering The most common soft solders are tin/lead or tin/silver/copper. Soft soldering is a method of joining metals with a eutectic tin/lead alloy. Soldering is a joining process used to join different types of metals together by melting solder. Definition and differences from other soldering techniques: Solder is a metal alloy usually. Soft soldering involves the use of. This soldering process. What Is The Definition Of Soft Soldering.

From joifesmwb.blob.core.windows.net

Manual Soldering Process at Sidney Becker blog What Is The Definition Of Soft Soldering Solder is a metal alloy usually. Soft soldering is a method of joining metals with a eutectic tin/lead alloy. Soft soldering involves the use of. The heat source is often an electric soldering iron but copper ‘irons’ heated with a gas torch may be needed for. Soldering is a process that joins metals using a filler metal, typically an alloy. What Is The Definition Of Soft Soldering.

From www.interweave.com

Soft Soldering 4 Tips for Glass + Pottery Jewelry Interweave What Is The Definition Of Soft Soldering It is a process that has the lowest filler metal melting point compared to the other soldering types which are seen to be less than 400°c. The most common soft solders are tin/lead or tin/silver/copper. Soft soldering is a method of joining metals with a eutectic tin/lead alloy. This soldering process uses solder with lower melting points, typically below 840°f/450°c.. What Is The Definition Of Soft Soldering.

From www.expondo.ie

Brazing and soft soldering practical examples expondo.co.uk What Is The Definition Of Soft Soldering Soldering is a process that joins metals using a filler metal, typically an alloy of tin and lead, which melts at lower temperatures. Soft soldering is a method of joining metals with a eutectic tin/lead alloy. The most common soft solders are tin/lead or tin/silver/copper. Soft soldering involves the use of. Solder is a metal alloy usually. It is a. What Is The Definition Of Soft Soldering.

From www.mechanicalbooster.com

What is Soldering and How it Works? Mechanical Booster What Is The Definition Of Soft Soldering The heat source is often an electric soldering iron but copper ‘irons’ heated with a gas torch may be needed for. Soldering is a joining process used to join different types of metals together by melting solder. Definition and differences from other soldering techniques: This soldering process uses solder with lower melting points, typically below 840°f/450°c. Soft soldering is a. What Is The Definition Of Soft Soldering.

From www.youtube.com

Soft Soldering Basics for Beginners YouTube What Is The Definition Of Soft Soldering The most common soft solders are tin/lead or tin/silver/copper. Soldering is a process that joins metals using a filler metal, typically an alloy of tin and lead, which melts at lower temperatures. Soft soldering involves the use of. Soldering is a joining process used to join different types of metals together by melting solder. It is a process that has. What Is The Definition Of Soft Soldering.

From www.tescaglobal.com

What Is Soldering? A Full Guide (Meaning, Definition And Types) What Is The Definition Of Soft Soldering Definition and differences from other soldering techniques: Solder is a metal alloy usually. Soldering is a process that joins metals using a filler metal, typically an alloy of tin and lead, which melts at lower temperatures. Soft soldering involves the use of. The most common soft solders are tin/lead or tin/silver/copper. It is a process that has the lowest filler. What Is The Definition Of Soft Soldering.

From dxorhpmvm.blob.core.windows.net

Car Soldering Near Me at Lillie Kimzey blog What Is The Definition Of Soft Soldering Solder is a metal alloy usually. Soft soldering is a method of joining metals with a eutectic tin/lead alloy. Soft soldering involves the use of. The heat source is often an electric soldering iron but copper ‘irons’ heated with a gas torch may be needed for. Definition and differences from other soldering techniques: It is a process that has the. What Is The Definition Of Soft Soldering.

From www.mechanicalbooster.com

What are Different Types of Soldering? Mechanical Booster What Is The Definition Of Soft Soldering The most common soft solders are tin/lead or tin/silver/copper. Definition and differences from other soldering techniques: It is a process that has the lowest filler metal melting point compared to the other soldering types which are seen to be less than 400°c. This soldering process uses solder with lower melting points, typically below 840°f/450°c. Soldering is a joining process used. What Is The Definition Of Soft Soldering.

From weldingstars.com

Welding, soldering, and brazing. Do you know the difference? Welding What Is The Definition Of Soft Soldering The heat source is often an electric soldering iron but copper ‘irons’ heated with a gas torch may be needed for. This soldering process uses solder with lower melting points, typically below 840°f/450°c. Solder is a metal alloy usually. Soft soldering is a method of joining metals with a eutectic tin/lead alloy. Soft soldering involves the use of. Soldering is. What Is The Definition Of Soft Soldering.

From components101.com

Types of Soldering Iron and How to Select the Right One What Is The Definition Of Soft Soldering The most common soft solders are tin/lead or tin/silver/copper. It is a process that has the lowest filler metal melting point compared to the other soldering types which are seen to be less than 400°c. Soldering is a process that joins metals using a filler metal, typically an alloy of tin and lead, which melts at lower temperatures. Soft soldering. What Is The Definition Of Soft Soldering.

From www.skillcatapp.com

The Soldering Process in 5 Simple Steps What Is The Definition Of Soft Soldering Definition and differences from other soldering techniques: Solder is a metal alloy usually. The most common soft solders are tin/lead or tin/silver/copper. Soldering is a process that joins metals using a filler metal, typically an alloy of tin and lead, which melts at lower temperatures. The heat source is often an electric soldering iron but copper ‘irons’ heated with a. What Is The Definition Of Soft Soldering.