Punching Machine Process . Punching is a metalworking process that’s used extensively in the manufacturing industry. The working principle of a power press machine involves the following steps: The workpiece, usually a sheet of metal, is securely clamped between the. It’s called “punching” because it involves punching a. Sheet metal punching is a metalworking technique that involves using a punch and die set to create holes or shapes in sheet metal. The punching machine works by applying pressure to the material through a punch and a die. The punching operation's success starts with the features built. This process offers several advantages, including high productivity, repeatability, and the ability to work with a wide range of materials and thicknesses. How does a punching machine work? The machine consists of a punch and a die that are used to cut holes and shapes in the material. Punch, stripper, die, and toolholder system. Punching machines are commonly used in manufacturing, construction, and metalworking industries. Tool design comprises four essential components:

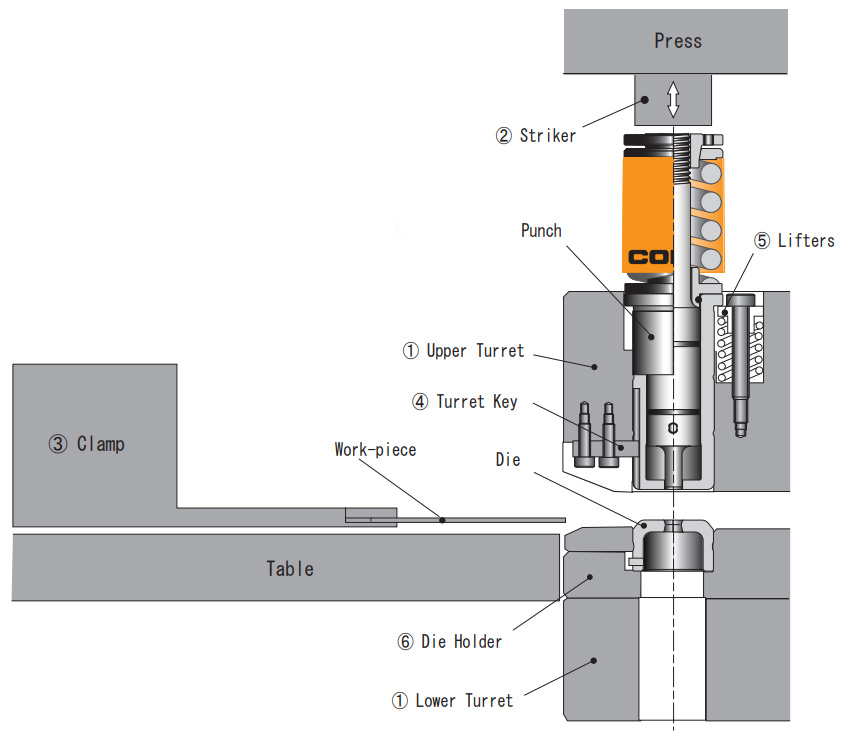

from www.conic.co.jp

Sheet metal punching is a metalworking technique that involves using a punch and die set to create holes or shapes in sheet metal. The punching machine works by applying pressure to the material through a punch and a die. Punching machines are commonly used in manufacturing, construction, and metalworking industries. Tool design comprises four essential components: Punching is a metalworking process that’s used extensively in the manufacturing industry. The punching operation's success starts with the features built. The working principle of a power press machine involves the following steps: The workpiece, usually a sheet of metal, is securely clamped between the. This process offers several advantages, including high productivity, repeatability, and the ability to work with a wide range of materials and thicknesses. How does a punching machine work?

Vol.7 ABOUT TURRET PUNCH PRESS MACHINE TECHNICAL GUIDE CONIC

Punching Machine Process Punching machines are commonly used in manufacturing, construction, and metalworking industries. Sheet metal punching is a metalworking technique that involves using a punch and die set to create holes or shapes in sheet metal. The working principle of a power press machine involves the following steps: The punching operation's success starts with the features built. This process offers several advantages, including high productivity, repeatability, and the ability to work with a wide range of materials and thicknesses. Punching machines are commonly used in manufacturing, construction, and metalworking industries. The workpiece, usually a sheet of metal, is securely clamped between the. It’s called “punching” because it involves punching a. The machine consists of a punch and a die that are used to cut holes and shapes in the material. How does a punching machine work? Tool design comprises four essential components: The punching machine works by applying pressure to the material through a punch and a die. Punch, stripper, die, and toolholder system. Punching is a metalworking process that’s used extensively in the manufacturing industry.

From www.dreamstime.com

Close Up Punch and Die of Hydraulic Punching and Shearing Machine for Punching Machine Process It’s called “punching” because it involves punching a. Punching is a metalworking process that’s used extensively in the manufacturing industry. The machine consists of a punch and a die that are used to cut holes and shapes in the material. The workpiece, usually a sheet of metal, is securely clamped between the. Punching machines are commonly used in manufacturing, construction,. Punching Machine Process.

From www.qs-wiremesh.com

Efficient And Accurate CNC Punching Process Punching Machine Process The punching machine works by applying pressure to the material through a punch and a die. Punch, stripper, die, and toolholder system. The workpiece, usually a sheet of metal, is securely clamped between the. The working principle of a power press machine involves the following steps: The machine consists of a punch and a die that are used to cut. Punching Machine Process.

From www.youtube.com

Punching Machine for rubber processing, punch press, press for sheet Punching Machine Process Tool design comprises four essential components: Punching machines are commonly used in manufacturing, construction, and metalworking industries. Sheet metal punching is a metalworking technique that involves using a punch and die set to create holes or shapes in sheet metal. This process offers several advantages, including high productivity, repeatability, and the ability to work with a wide range of materials. Punching Machine Process.

From rajeshpowerpress.ae

What is a Hydraulic Punching Machine? Punching Machine Process How does a punching machine work? The punching operation's success starts with the features built. Tool design comprises four essential components: The workpiece, usually a sheet of metal, is securely clamped between the. The punching machine works by applying pressure to the material through a punch and a die. Punching machines are commonly used in manufacturing, construction, and metalworking industries.. Punching Machine Process.

From www.mgsaws.com

8 Reasons To Opt for Aluminum Cutting MachinesTRONZADORAS MG Punching Machine Process Punching is a metalworking process that’s used extensively in the manufacturing industry. It’s called “punching” because it involves punching a. The working principle of a power press machine involves the following steps: Sheet metal punching is a metalworking technique that involves using a punch and die set to create holes or shapes in sheet metal. Punching machines are commonly used. Punching Machine Process.

From pharmacyscope.com

Tablet Compression Machine Pharmacy Scope Punching Machine Process Tool design comprises four essential components: Punching machines are commonly used in manufacturing, construction, and metalworking industries. This process offers several advantages, including high productivity, repeatability, and the ability to work with a wide range of materials and thicknesses. The working principle of a power press machine involves the following steps: Punching is a metalworking process that’s used extensively in. Punching Machine Process.

From qatar.desertcart.com

Buy Bonvoisin Electric Hydraulic Hole Puncher Φ1/4"4/5" 1200W Punching Punching Machine Process Punching machines are commonly used in manufacturing, construction, and metalworking industries. The working principle of a power press machine involves the following steps: How does a punching machine work? This process offers several advantages, including high productivity, repeatability, and the ability to work with a wide range of materials and thicknesses. The workpiece, usually a sheet of metal, is securely. Punching Machine Process.

From us.misumi-ec.com

Understanding Punch and Die Terminology MISUMI Mech Lab Blog Punching Machine Process Tool design comprises four essential components: It’s called “punching” because it involves punching a. The working principle of a power press machine involves the following steps: Punching machines are commonly used in manufacturing, construction, and metalworking industries. Punching is a metalworking process that’s used extensively in the manufacturing industry. Punch, stripper, die, and toolholder system. This process offers several advantages,. Punching Machine Process.

From www.suntayhvac.com

Punching machineChina duct machine supplierSuntay Punching Machine Process How does a punching machine work? Tool design comprises four essential components: Punch, stripper, die, and toolholder system. The punching operation's success starts with the features built. Punching is a metalworking process that’s used extensively in the manufacturing industry. It’s called “punching” because it involves punching a. The workpiece, usually a sheet of metal, is securely clamped between the. The. Punching Machine Process.

From www.alibaba.com

Mechanical Punch Press 40 Tons Stainless Steel Press Punching Machine Punching Machine Process This process offers several advantages, including high productivity, repeatability, and the ability to work with a wide range of materials and thicknesses. Punching is a metalworking process that’s used extensively in the manufacturing industry. The punching operation's success starts with the features built. Punching machines are commonly used in manufacturing, construction, and metalworking industries. The workpiece, usually a sheet of. Punching Machine Process.

From anthropology.iresearchnet.com

Small HandOperated Punch Presses Processing Pressure Punching Machine Punching Machine Process How does a punching machine work? Punch, stripper, die, and toolholder system. Punching is a metalworking process that’s used extensively in the manufacturing industry. The machine consists of a punch and a die that are used to cut holes and shapes in the material. The punching machine works by applying pressure to the material through a punch and a die.. Punching Machine Process.

From www.otalum.com

Aluminum Punching Otalum Punching Machine Process It’s called “punching” because it involves punching a. Punching machines are commonly used in manufacturing, construction, and metalworking industries. The punching operation's success starts with the features built. Tool design comprises four essential components: The workpiece, usually a sheet of metal, is securely clamped between the. The punching machine works by applying pressure to the material through a punch and. Punching Machine Process.

From www.rapiddirect.com

Sheet Metal Fabrication An Ultimate Guide on Manufacturing Processes Punching Machine Process Punching machines are commonly used in manufacturing, construction, and metalworking industries. Tool design comprises four essential components: The machine consists of a punch and a die that are used to cut holes and shapes in the material. How does a punching machine work? The workpiece, usually a sheet of metal, is securely clamped between the. The punching operation's success starts. Punching Machine Process.

From pass-systemsupply.com

Industrial VIA/ HOLE Punching Machine PASS Punching Machine Process The machine consists of a punch and a die that are used to cut holes and shapes in the material. How does a punching machine work? The workpiece, usually a sheet of metal, is securely clamped between the. The punching operation's success starts with the features built. Punching machines are commonly used in manufacturing, construction, and metalworking industries. Tool design. Punching Machine Process.

From www.ametals.com

What Is CNC Punching Punching Machine Process Punching is a metalworking process that’s used extensively in the manufacturing industry. The working principle of a power press machine involves the following steps: The punching machine works by applying pressure to the material through a punch and a die. It’s called “punching” because it involves punching a. The workpiece, usually a sheet of metal, is securely clamped between the.. Punching Machine Process.

From www.cncprocessingmachine.com

BNC100 Hydraulic Cnc Plate Processing Machine Punching And Marking High Punching Machine Process The machine consists of a punch and a die that are used to cut holes and shapes in the material. It’s called “punching” because it involves punching a. Punching is a metalworking process that’s used extensively in the manufacturing industry. The punching operation's success starts with the features built. This process offers several advantages, including high productivity, repeatability, and the. Punching Machine Process.

From www.youtube.com

FOAM PUNCHING PRESS MACHINE YouTube Punching Machine Process Tool design comprises four essential components: The punching machine works by applying pressure to the material through a punch and a die. The machine consists of a punch and a die that are used to cut holes and shapes in the material. Sheet metal punching is a metalworking technique that involves using a punch and die set to create holes. Punching Machine Process.

From www.jcmetalworks.co.uk

CNC Metal Punching Sheet Metal Punching JCMetalworks Punching Machine Process Punching machines are commonly used in manufacturing, construction, and metalworking industries. The punching machine works by applying pressure to the material through a punch and a die. The workpiece, usually a sheet of metal, is securely clamped between the. Sheet metal punching is a metalworking technique that involves using a punch and die set to create holes or shapes in. Punching Machine Process.

From www.youtube.com

Fully Automated Sheet Metal Punching YouTube Punching Machine Process Punch, stripper, die, and toolholder system. Punching is a metalworking process that’s used extensively in the manufacturing industry. The working principle of a power press machine involves the following steps: Punching machines are commonly used in manufacturing, construction, and metalworking industries. The machine consists of a punch and a die that are used to cut holes and shapes in the. Punching Machine Process.

From www.youtube.com

Hydraulic Sheet Metal Punching Forming Machine YouTube Punching Machine Process This process offers several advantages, including high productivity, repeatability, and the ability to work with a wide range of materials and thicknesses. How does a punching machine work? Punching machines are commonly used in manufacturing, construction, and metalworking industries. The punching machine works by applying pressure to the material through a punch and a die. It’s called “punching” because it. Punching Machine Process.

From kcg.com.my

Sheet metal punching KCG Punching Machine Process This process offers several advantages, including high productivity, repeatability, and the ability to work with a wide range of materials and thicknesses. Punching is a metalworking process that’s used extensively in the manufacturing industry. The punching machine works by applying pressure to the material through a punch and a die. Sheet metal punching is a metalworking technique that involves using. Punching Machine Process.

From www.minifaber.com

5 FAQ about sheet metal punching Punching Machine Process Punch, stripper, die, and toolholder system. How does a punching machine work? Punching machines are commonly used in manufacturing, construction, and metalworking industries. Punching is a metalworking process that’s used extensively in the manufacturing industry. The working principle of a power press machine involves the following steps: Sheet metal punching is a metalworking technique that involves using a punch and. Punching Machine Process.

From www.dreamstime.com

Close Up Punch and Die of Hydraulic Punching and Shearing Machine for Punching Machine Process The punching machine works by applying pressure to the material through a punch and a die. Punching is a metalworking process that’s used extensively in the manufacturing industry. The working principle of a power press machine involves the following steps: How does a punching machine work? Punching machines are commonly used in manufacturing, construction, and metalworking industries. The machine consists. Punching Machine Process.

From www.thefabricator.com

Discovering versatility on the punching machine Punching Machine Process The working principle of a power press machine involves the following steps: This process offers several advantages, including high productivity, repeatability, and the ability to work with a wide range of materials and thicknesses. The punching machine works by applying pressure to the material through a punch and a die. Punch, stripper, die, and toolholder system. The workpiece, usually a. Punching Machine Process.

From www.conic.co.jp

Vol.7 ABOUT TURRET PUNCH PRESS MACHINE TECHNICAL GUIDE CONIC Punching Machine Process This process offers several advantages, including high productivity, repeatability, and the ability to work with a wide range of materials and thicknesses. It’s called “punching” because it involves punching a. Punching machines are commonly used in manufacturing, construction, and metalworking industries. The working principle of a power press machine involves the following steps: Sheet metal punching is a metalworking technique. Punching Machine Process.

From learnmech.com

Turret punch Construction and Working Of Turret Punch presses Punching Machine Process Punching is a metalworking process that’s used extensively in the manufacturing industry. Punching machines are commonly used in manufacturing, construction, and metalworking industries. The machine consists of a punch and a die that are used to cut holes and shapes in the material. Sheet metal punching is a metalworking technique that involves using a punch and die set to create. Punching Machine Process.

From www.china-prima.com

Auto Cnc pipe punching line 6m , tube punching machine Ma'anshan Punching Machine Process It’s called “punching” because it involves punching a. How does a punching machine work? This process offers several advantages, including high productivity, repeatability, and the ability to work with a wide range of materials and thicknesses. Punching machines are commonly used in manufacturing, construction, and metalworking industries. The workpiece, usually a sheet of metal, is securely clamped between the. Punch,. Punching Machine Process.

From www.vandf.co.uk

What is CNC Punching? Punching Machine Process This process offers several advantages, including high productivity, repeatability, and the ability to work with a wide range of materials and thicknesses. Punching is a metalworking process that’s used extensively in the manufacturing industry. The workpiece, usually a sheet of metal, is securely clamped between the. The working principle of a power press machine involves the following steps: The punching. Punching Machine Process.

From www.zenithengineering.co.in

Punching Machine Aluminium Pneumatic Punching Machine Manufacturer Punching Machine Process Tool design comprises four essential components: How does a punching machine work? Punching is a metalworking process that’s used extensively in the manufacturing industry. The punching operation's success starts with the features built. This process offers several advantages, including high productivity, repeatability, and the ability to work with a wide range of materials and thicknesses. Punching machines are commonly used. Punching Machine Process.

From packhelp.com

Understanding the Die Cutting Process in Custom Packaging Packhelp Punching Machine Process Punch, stripper, die, and toolholder system. How does a punching machine work? Punching is a metalworking process that’s used extensively in the manufacturing industry. The punching machine works by applying pressure to the material through a punch and a die. Tool design comprises four essential components: It’s called “punching” because it involves punching a. The working principle of a power. Punching Machine Process.

From www.trumpf.com

Punching machines TRUMPF Punching Machine Process It’s called “punching” because it involves punching a. The machine consists of a punch and a die that are used to cut holes and shapes in the material. This process offers several advantages, including high productivity, repeatability, and the ability to work with a wide range of materials and thicknesses. The workpiece, usually a sheet of metal, is securely clamped. Punching Machine Process.

From www.saintytec.com

11 Critical Tablet Compression Machine Parts You Must Know to Optimize Punching Machine Process The machine consists of a punch and a die that are used to cut holes and shapes in the material. Punching is a metalworking process that’s used extensively in the manufacturing industry. Punch, stripper, die, and toolholder system. How does a punching machine work? It’s called “punching” because it involves punching a. Sheet metal punching is a metalworking technique that. Punching Machine Process.

From www.degruyter.com

Studies on mechanical properties of thermoplastic composites prepared Punching Machine Process The working principle of a power press machine involves the following steps: How does a punching machine work? The punching machine works by applying pressure to the material through a punch and a die. Punching is a metalworking process that’s used extensively in the manufacturing industry. Punching machines are commonly used in manufacturing, construction, and metalworking industries. Sheet metal punching. Punching Machine Process.

From www.trumpf.com

Advantages of punching machines TRUMPF Punching Machine Process Punch, stripper, die, and toolholder system. The workpiece, usually a sheet of metal, is securely clamped between the. The machine consists of a punch and a die that are used to cut holes and shapes in the material. This process offers several advantages, including high productivity, repeatability, and the ability to work with a wide range of materials and thicknesses.. Punching Machine Process.

From busbarmc.blogspot.com

How to punch busbars by busbar punching machine? Punching Machine Process How does a punching machine work? Punch, stripper, die, and toolholder system. Tool design comprises four essential components: The punching operation's success starts with the features built. This process offers several advantages, including high productivity, repeatability, and the ability to work with a wide range of materials and thicknesses. It’s called “punching” because it involves punching a. The working principle. Punching Machine Process.