What Is Convection Reflow Oven . A common type of reflow oven is the infrared convection oven. These ovens can be further. This type of oven accomplishes heat transfer to the components and solder by radiation of heat from heating elements. Reflow soldering uses convection air stream to create. Fans provide circulation to improve heat transfer efficiency. Reflow ovens provide controlled heat exposure but require loading/unloading each board. Convection reflow soldering relies on forced hot air circulation within the reflow oven to heat the pcb and. Convection ovens use heated air to transfer heat to the pcb assembly. Learn how reflow soldering works, what types of machines are available, and what benefits it offers for pcb assembly. Convection reflow, a popular soldering technique in electronics manufacturing, is all about seamlessly connecting components onto printed. Convection ovens offer a continuous conveyor belt for high.

from core-emt.com

Convection ovens offer a continuous conveyor belt for high. Fans provide circulation to improve heat transfer efficiency. These ovens can be further. This type of oven accomplishes heat transfer to the components and solder by radiation of heat from heating elements. Reflow ovens provide controlled heat exposure but require loading/unloading each board. A common type of reflow oven is the infrared convection oven. Convection reflow soldering relies on forced hot air circulation within the reflow oven to heat the pcb and. Convection ovens use heated air to transfer heat to the pcb assembly. Convection reflow, a popular soldering technique in electronics manufacturing, is all about seamlessly connecting components onto printed. Learn how reflow soldering works, what types of machines are available, and what benefits it offers for pcb assembly.

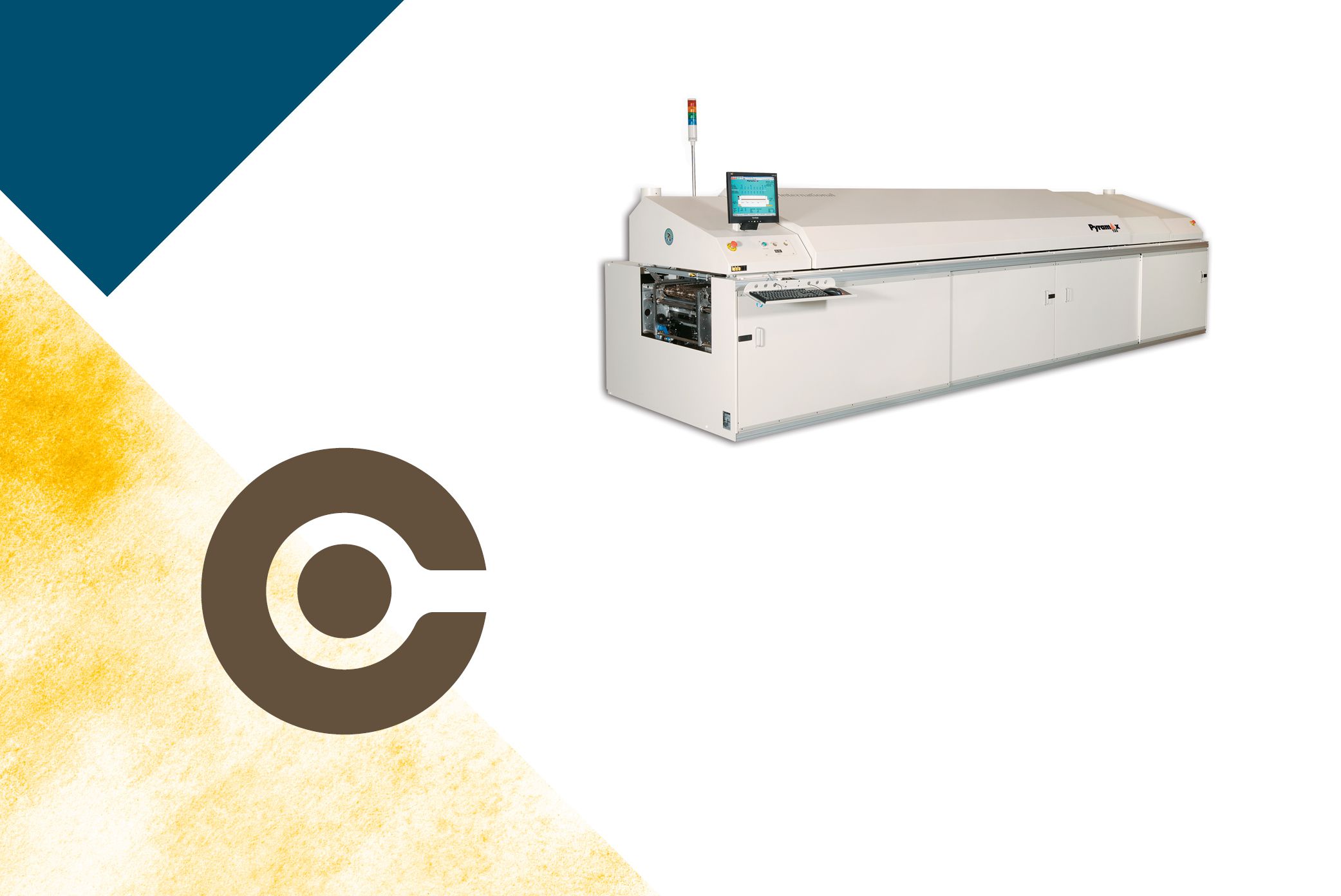

Pyramax 125N, reflow oven Nitrogen reflow convection oven BTU oven

What Is Convection Reflow Oven Convection ovens use heated air to transfer heat to the pcb assembly. Convection ovens use heated air to transfer heat to the pcb assembly. Convection ovens offer a continuous conveyor belt for high. Reflow soldering uses convection air stream to create. Learn how reflow soldering works, what types of machines are available, and what benefits it offers for pcb assembly. Fans provide circulation to improve heat transfer efficiency. These ovens can be further. Convection reflow, a popular soldering technique in electronics manufacturing, is all about seamlessly connecting components onto printed. A common type of reflow oven is the infrared convection oven. This type of oven accomplishes heat transfer to the components and solder by radiation of heat from heating elements. Reflow ovens provide controlled heat exposure but require loading/unloading each board. Convection reflow soldering relies on forced hot air circulation within the reflow oven to heat the pcb and.

From www.douyee.com

Products > SMT Force Convection Nitrogen Reflow Oven Dou Yee Enterprises What Is Convection Reflow Oven Convection reflow soldering relies on forced hot air circulation within the reflow oven to heat the pcb and. Convection reflow, a popular soldering technique in electronics manufacturing, is all about seamlessly connecting components onto printed. Learn how reflow soldering works, what types of machines are available, and what benefits it offers for pcb assembly. Reflow ovens provide controlled heat exposure. What Is Convection Reflow Oven.

From widaco.net

Convection Reflow Oven Reflow Oven Full Convection Widaco What Is Convection Reflow Oven Reflow soldering uses convection air stream to create. This type of oven accomplishes heat transfer to the components and solder by radiation of heat from heating elements. Learn how reflow soldering works, what types of machines are available, and what benefits it offers for pcb assembly. Convection reflow, a popular soldering technique in electronics manufacturing, is all about seamlessly connecting. What Is Convection Reflow Oven.

From www.bysipe.com

Tronstol D5 Reflow Oven 5 Heating Zones Convection Reflow For LED and What Is Convection Reflow Oven Convection reflow, a popular soldering technique in electronics manufacturing, is all about seamlessly connecting components onto printed. These ovens can be further. Reflow ovens provide controlled heat exposure but require loading/unloading each board. Learn how reflow soldering works, what types of machines are available, and what benefits it offers for pcb assembly. Convection reflow soldering relies on forced hot air. What Is Convection Reflow Oven.

From www.smtnet.com

Pyramax Convection Reflow Oven What Is Convection Reflow Oven A common type of reflow oven is the infrared convection oven. This type of oven accomplishes heat transfer to the components and solder by radiation of heat from heating elements. Reflow ovens provide controlled heat exposure but require loading/unloading each board. Convection ovens offer a continuous conveyor belt for high. Reflow soldering uses convection air stream to create. Learn how. What Is Convection Reflow Oven.

From microboard.com

Convection Reflow Ovens MicroboardMicroboard What Is Convection Reflow Oven A common type of reflow oven is the infrared convection oven. Convection ovens use heated air to transfer heat to the pcb assembly. Fans provide circulation to improve heat transfer efficiency. Reflow soldering uses convection air stream to create. Convection ovens offer a continuous conveyor belt for high. Reflow ovens provide controlled heat exposure but require loading/unloading each board. These. What Is Convection Reflow Oven.

From www.mechatronic-systems.com

smt reflow oven,reflow oven,reflow ovens,convection ovens,forced air What Is Convection Reflow Oven Convection ovens use heated air to transfer heat to the pcb assembly. Convection reflow, a popular soldering technique in electronics manufacturing, is all about seamlessly connecting components onto printed. These ovens can be further. Reflow ovens provide controlled heat exposure but require loading/unloading each board. Reflow soldering uses convection air stream to create. This type of oven accomplishes heat transfer. What Is Convection Reflow Oven.

From www.smtreflowsoldering.com

7 Zones Lead Free Reflow Oven 3P AC380V Convection Reflow Oven What Is Convection Reflow Oven This type of oven accomplishes heat transfer to the components and solder by radiation of heat from heating elements. Reflow soldering uses convection air stream to create. Fans provide circulation to improve heat transfer efficiency. Convection ovens use heated air to transfer heat to the pcb assembly. Convection reflow soldering relies on forced hot air circulation within the reflow oven. What Is Convection Reflow Oven.

From widaco.net

Convection Reflow Oven Reflow Oven Full Convection Widaco What Is Convection Reflow Oven Reflow ovens provide controlled heat exposure but require loading/unloading each board. Convection ovens offer a continuous conveyor belt for high. This type of oven accomplishes heat transfer to the components and solder by radiation of heat from heating elements. Convection reflow soldering relies on forced hot air circulation within the reflow oven to heat the pcb and. A common type. What Is Convection Reflow Oven.

From maverickindustrialsales.com

Essemtec RO300FC Full Convection 4Zone Reflow Oven, 300mm, 400V, 25A What Is Convection Reflow Oven This type of oven accomplishes heat transfer to the components and solder by radiation of heat from heating elements. Reflow soldering uses convection air stream to create. A common type of reflow oven is the infrared convection oven. Convection reflow soldering relies on forced hot air circulation within the reflow oven to heat the pcb and. These ovens can be. What Is Convection Reflow Oven.

From accelonix.co.uk

Flexible Convection System What Is Convection Reflow Oven Convection ovens offer a continuous conveyor belt for high. These ovens can be further. Reflow soldering uses convection air stream to create. A common type of reflow oven is the infrared convection oven. Reflow ovens provide controlled heat exposure but require loading/unloading each board. Convection reflow, a popular soldering technique in electronics manufacturing, is all about seamlessly connecting components onto. What Is Convection Reflow Oven.

From www.lpkfusa.com

LPKF Edition SMT ProtoFlow S4 Reflow Oven What Is Convection Reflow Oven Reflow ovens provide controlled heat exposure but require loading/unloading each board. Convection reflow soldering relies on forced hot air circulation within the reflow oven to heat the pcb and. Reflow soldering uses convection air stream to create. This type of oven accomplishes heat transfer to the components and solder by radiation of heat from heating elements. Fans provide circulation to. What Is Convection Reflow Oven.

From core-emt.com

BTU Pyramax 150A soldering air convection reflow oven BTU What Is Convection Reflow Oven Reflow soldering uses convection air stream to create. Fans provide circulation to improve heat transfer efficiency. This type of oven accomplishes heat transfer to the components and solder by radiation of heat from heating elements. Convection reflow soldering relies on forced hot air circulation within the reflow oven to heat the pcb and. Convection ovens offer a continuous conveyor belt. What Is Convection Reflow Oven.

From www.smtnet.com

RO400FC Full Convection Reflow Oven What Is Convection Reflow Oven Fans provide circulation to improve heat transfer efficiency. Convection reflow, a popular soldering technique in electronics manufacturing, is all about seamlessly connecting components onto printed. A common type of reflow oven is the infrared convection oven. Convection ovens offer a continuous conveyor belt for high. Convection ovens use heated air to transfer heat to the pcb assembly. Convection reflow soldering. What Is Convection Reflow Oven.

From www.pmtech.co.uk

Convection, conveyor reflow oven R260 PMTech What Is Convection Reflow Oven Convection ovens use heated air to transfer heat to the pcb assembly. Reflow ovens provide controlled heat exposure but require loading/unloading each board. Reflow soldering uses convection air stream to create. Convection reflow soldering relies on forced hot air circulation within the reflow oven to heat the pcb and. This type of oven accomplishes heat transfer to the components and. What Is Convection Reflow Oven.

From www.pmtech.co.uk

HB Convection Reflow Oven, CR16000, 6 Zone PMTech What Is Convection Reflow Oven Fans provide circulation to improve heat transfer efficiency. Learn how reflow soldering works, what types of machines are available, and what benefits it offers for pcb assembly. These ovens can be further. Convection ovens offer a continuous conveyor belt for high. Convection reflow soldering relies on forced hot air circulation within the reflow oven to heat the pcb and. This. What Is Convection Reflow Oven.

From www.pmtech.co.uk

Faroad Convection Reflow Oven, LY6600II, 6 Zone PMTech What Is Convection Reflow Oven Convection reflow, a popular soldering technique in electronics manufacturing, is all about seamlessly connecting components onto printed. A common type of reflow oven is the infrared convection oven. Reflow soldering uses convection air stream to create. These ovens can be further. This type of oven accomplishes heat transfer to the components and solder by radiation of heat from heating elements.. What Is Convection Reflow Oven.

From www.smtnet.com

Benchtop Convection SMT Reflow Oven T200C What Is Convection Reflow Oven Convection ovens offer a continuous conveyor belt for high. Convection reflow, a popular soldering technique in electronics manufacturing, is all about seamlessly connecting components onto printed. Convection ovens use heated air to transfer heat to the pcb assembly. A common type of reflow oven is the infrared convection oven. Reflow soldering uses convection air stream to create. Convection reflow soldering. What Is Convection Reflow Oven.

From widaco.net

Reliable Convection Reflow Ovens Reflow Oven Widaco What Is Convection Reflow Oven Reflow soldering uses convection air stream to create. Reflow ovens provide controlled heat exposure but require loading/unloading each board. A common type of reflow oven is the infrared convection oven. Convection reflow, a popular soldering technique in electronics manufacturing, is all about seamlessly connecting components onto printed. Learn how reflow soldering works, what types of machines are available, and what. What Is Convection Reflow Oven.

From www.pmtech.co.uk

Faroad Convection Reflow Oven, LY8800II, 8 Zone PMTech What Is Convection Reflow Oven A common type of reflow oven is the infrared convection oven. Reflow soldering uses convection air stream to create. These ovens can be further. Learn how reflow soldering works, what types of machines are available, and what benefits it offers for pcb assembly. Fans provide circulation to improve heat transfer efficiency. Convection ovens offer a continuous conveyor belt for high.. What Is Convection Reflow Oven.

From www.douyee.com

Products > SMT Force Convection Nitrogen Reflow Oven Dou Yee Enterprises What Is Convection Reflow Oven Fans provide circulation to improve heat transfer efficiency. Convection reflow, a popular soldering technique in electronics manufacturing, is all about seamlessly connecting components onto printed. Learn how reflow soldering works, what types of machines are available, and what benefits it offers for pcb assembly. Convection reflow soldering relies on forced hot air circulation within the reflow oven to heat the. What Is Convection Reflow Oven.

From www.youtube.com

Hotflow Convection reflow ovens YouTube What Is Convection Reflow Oven Convection reflow soldering relies on forced hot air circulation within the reflow oven to heat the pcb and. A common type of reflow oven is the infrared convection oven. Learn how reflow soldering works, what types of machines are available, and what benefits it offers for pcb assembly. This type of oven accomplishes heat transfer to the components and solder. What Is Convection Reflow Oven.

From www.tradeindia.com

Table Top Full Hot Air Convection Reflow Oven Dimension(l*w*h) 1810mm What Is Convection Reflow Oven Convection ovens offer a continuous conveyor belt for high. Fans provide circulation to improve heat transfer efficiency. Convection reflow soldering relies on forced hot air circulation within the reflow oven to heat the pcb and. Convection ovens use heated air to transfer heat to the pcb assembly. Convection reflow, a popular soldering technique in electronics manufacturing, is all about seamlessly. What Is Convection Reflow Oven.

From www.ams-electronics.co.uk

Mistral 360 Forced Air Convection Reflow oven AMS Ltd What Is Convection Reflow Oven This type of oven accomplishes heat transfer to the components and solder by radiation of heat from heating elements. Fans provide circulation to improve heat transfer efficiency. Convection ovens offer a continuous conveyor belt for high. Learn how reflow soldering works, what types of machines are available, and what benefits it offers for pcb assembly. A common type of reflow. What Is Convection Reflow Oven.

From www.tradeindia.com

Seven Zone Fully Hot Air Convection Reflow Oven at Best Price in Pune What Is Convection Reflow Oven This type of oven accomplishes heat transfer to the components and solder by radiation of heat from heating elements. Convection reflow, a popular soldering technique in electronics manufacturing, is all about seamlessly connecting components onto printed. These ovens can be further. Reflow ovens provide controlled heat exposure but require loading/unloading each board. Convection ovens offer a continuous conveyor belt for. What Is Convection Reflow Oven.

From www.bomir.com

XReflow306 LF Full Convection, Bench Top, Batch oven with Nitrogen What Is Convection Reflow Oven This type of oven accomplishes heat transfer to the components and solder by radiation of heat from heating elements. Reflow soldering uses convection air stream to create. Learn how reflow soldering works, what types of machines are available, and what benefits it offers for pcb assembly. A common type of reflow oven is the infrared convection oven. Fans provide circulation. What Is Convection Reflow Oven.

From smtnet.com

RO300FC Full Convection Reflow Oven What Is Convection Reflow Oven Convection reflow, a popular soldering technique in electronics manufacturing, is all about seamlessly connecting components onto printed. A common type of reflow oven is the infrared convection oven. Fans provide circulation to improve heat transfer efficiency. Convection ovens use heated air to transfer heat to the pcb assembly. Convection reflow soldering relies on forced hot air circulation within the reflow. What Is Convection Reflow Oven.

From www.pmtech.co.uk

HB Convection Reflow Oven, CR10802, 8 Zone PMTech What Is Convection Reflow Oven Reflow ovens provide controlled heat exposure but require loading/unloading each board. Convection reflow, a popular soldering technique in electronics manufacturing, is all about seamlessly connecting components onto printed. Reflow soldering uses convection air stream to create. Convection ovens use heated air to transfer heat to the pcb assembly. Convection reflow soldering relies on forced hot air circulation within the reflow. What Is Convection Reflow Oven.

From core-emt.com

Pyramax 125N, reflow oven Nitrogen reflow convection oven BTU oven What Is Convection Reflow Oven Fans provide circulation to improve heat transfer efficiency. Convection ovens use heated air to transfer heat to the pcb assembly. Reflow ovens provide controlled heat exposure but require loading/unloading each board. A common type of reflow oven is the infrared convection oven. Convection reflow, a popular soldering technique in electronics manufacturing, is all about seamlessly connecting components onto printed. This. What Is Convection Reflow Oven.

From widaco.net

Convection Reflow Oven Reflow Oven Full Convection Widaco What Is Convection Reflow Oven Convection ovens use heated air to transfer heat to the pcb assembly. These ovens can be further. Convection reflow soldering relies on forced hot air circulation within the reflow oven to heat the pcb and. Fans provide circulation to improve heat transfer efficiency. Learn how reflow soldering works, what types of machines are available, and what benefits it offers for. What Is Convection Reflow Oven.

From www.7pcb.com

Reflow Soldering Bittele What Is Convection Reflow Oven Reflow soldering uses convection air stream to create. A common type of reflow oven is the infrared convection oven. This type of oven accomplishes heat transfer to the components and solder by radiation of heat from heating elements. Reflow ovens provide controlled heat exposure but require loading/unloading each board. Learn how reflow soldering works, what types of machines are available,. What Is Convection Reflow Oven.

From www.electronics-lab.com

New Convection Reflow Oven for Soldering with 6 Heating Zones What Is Convection Reflow Oven Convection ovens offer a continuous conveyor belt for high. This type of oven accomplishes heat transfer to the components and solder by radiation of heat from heating elements. A common type of reflow oven is the infrared convection oven. Learn how reflow soldering works, what types of machines are available, and what benefits it offers for pcb assembly. Reflow soldering. What Is Convection Reflow Oven.

From www.itechsmt.com

iTECH RFB1230T 12 Zones Convection Reflow Oven For SMT Line What Is Convection Reflow Oven Reflow ovens provide controlled heat exposure but require loading/unloading each board. Reflow soldering uses convection air stream to create. Convection ovens use heated air to transfer heat to the pcb assembly. Convection ovens offer a continuous conveyor belt for high. Fans provide circulation to improve heat transfer efficiency. These ovens can be further. Learn how reflow soldering works, what types. What Is Convection Reflow Oven.

From www.ams-electronics.co.uk

Mistral 260 Forced Air Convection Reflow oven AMS Ltd What Is Convection Reflow Oven This type of oven accomplishes heat transfer to the components and solder by radiation of heat from heating elements. Reflow soldering uses convection air stream to create. Reflow ovens provide controlled heat exposure but require loading/unloading each board. Fans provide circulation to improve heat transfer efficiency. Convection ovens use heated air to transfer heat to the pcb assembly. Convection ovens. What Is Convection Reflow Oven.

From cpc.farnell.com

Convection Reflow Oven, 2.4kW Fortex CPC What Is Convection Reflow Oven This type of oven accomplishes heat transfer to the components and solder by radiation of heat from heating elements. Convection ovens offer a continuous conveyor belt for high. Learn how reflow soldering works, what types of machines are available, and what benefits it offers for pcb assembly. These ovens can be further. Convection ovens use heated air to transfer heat. What Is Convection Reflow Oven.

From hawkerrichardson.com.au

Heller Industries 1826 MK5 Series Convection Reflow Soldering Oven What Is Convection Reflow Oven Reflow soldering uses convection air stream to create. Convection reflow, a popular soldering technique in electronics manufacturing, is all about seamlessly connecting components onto printed. Reflow ovens provide controlled heat exposure but require loading/unloading each board. Fans provide circulation to improve heat transfer efficiency. A common type of reflow oven is the infrared convection oven. These ovens can be further.. What Is Convection Reflow Oven.