Pipe Welding Requirements . to pipe weld, clean the surfaces, tightly fit the pipes, secure them with clamps or tacks, and weld them with. these general welding guidelines are intended to provide background information and supplementary instructions to contractors and their. select the appropriate welding process based on factors such as pipe thickness, material type, and application requirements. it is essential to protect work pieces from weather during welding. these practices include: 10 rows all welding work, equipments for welding, heat treatment, other auxiliary functions and the welding. Properly preparing the pipe for welding, including. Ensuring a clean working environment to minimize contaminants. Proper welding technique is usually specified in project welding specification. this chapter is to introduce you to the main general welding rules contained in api 570 and asme b31.3.

from sensibledigs.com

it is essential to protect work pieces from weather during welding. Proper welding technique is usually specified in project welding specification. 10 rows all welding work, equipments for welding, heat treatment, other auxiliary functions and the welding. Properly preparing the pipe for welding, including. this chapter is to introduce you to the main general welding rules contained in api 570 and asme b31.3. to pipe weld, clean the surfaces, tightly fit the pipes, secure them with clamps or tacks, and weld them with. Ensuring a clean working environment to minimize contaminants. select the appropriate welding process based on factors such as pipe thickness, material type, and application requirements. these practices include: these general welding guidelines are intended to provide background information and supplementary instructions to contractors and their.

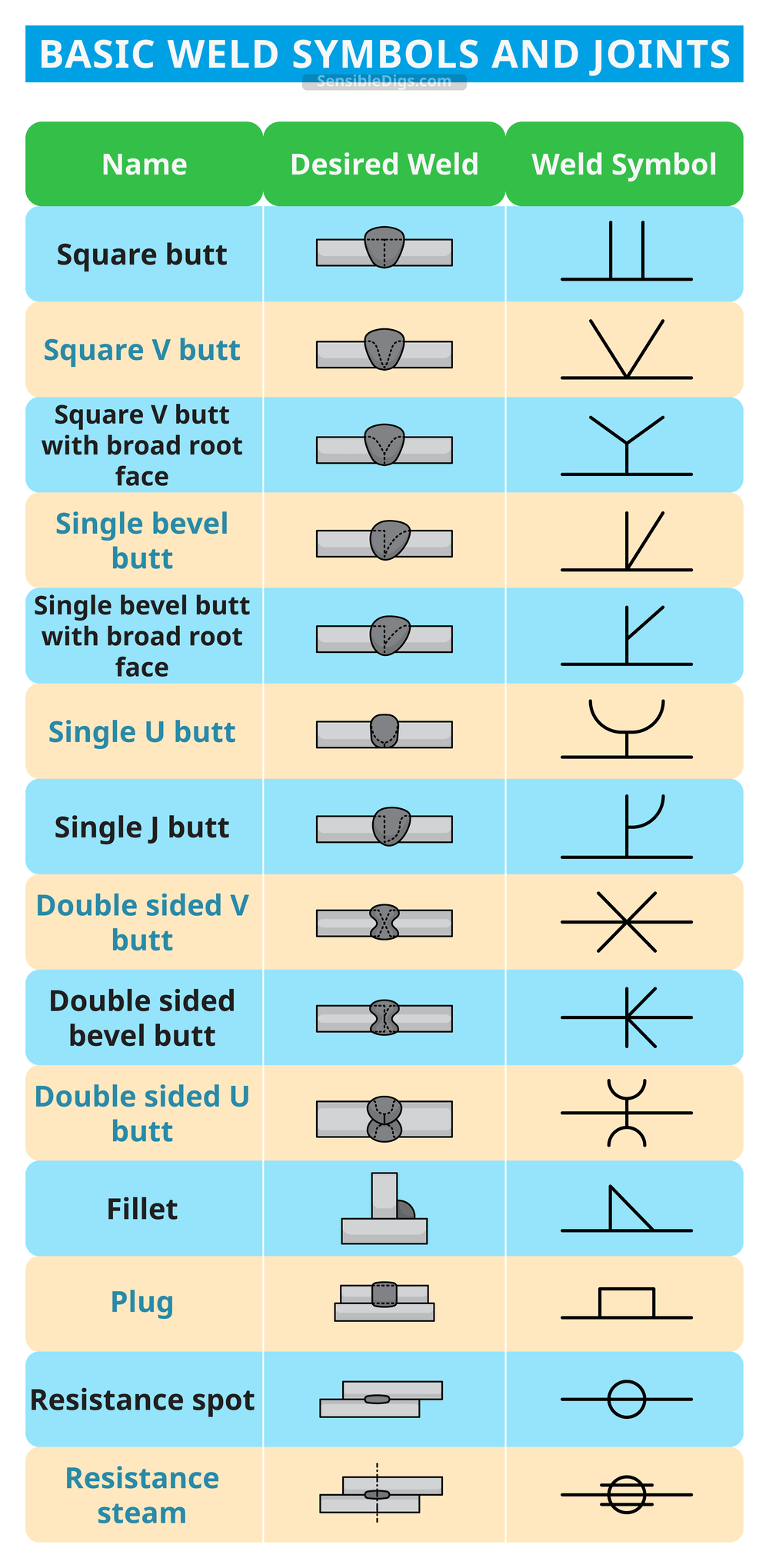

Welding Symbols Diagrams & Types (Fully Explained) Sensible Digs

Pipe Welding Requirements these general welding guidelines are intended to provide background information and supplementary instructions to contractors and their. it is essential to protect work pieces from weather during welding. Ensuring a clean working environment to minimize contaminants. Properly preparing the pipe for welding, including. this chapter is to introduce you to the main general welding rules contained in api 570 and asme b31.3. these practices include: these general welding guidelines are intended to provide background information and supplementary instructions to contractors and their. to pipe weld, clean the surfaces, tightly fit the pipes, secure them with clamps or tacks, and weld them with. Proper welding technique is usually specified in project welding specification. select the appropriate welding process based on factors such as pipe thickness, material type, and application requirements. 10 rows all welding work, equipments for welding, heat treatment, other auxiliary functions and the welding.

From aqcinspection.com

Welding StandardsPositions for Welding Pipe AQC Inspection Pipe Welding Requirements these general welding guidelines are intended to provide background information and supplementary instructions to contractors and their. to pipe weld, clean the surfaces, tightly fit the pipes, secure them with clamps or tacks, and weld them with. Properly preparing the pipe for welding, including. select the appropriate welding process based on factors such as pipe thickness, material. Pipe Welding Requirements.

From upweld.org

What are the 4 Basic Pipe Welding Positions? UpWeld Pipe Welding Requirements select the appropriate welding process based on factors such as pipe thickness, material type, and application requirements. 10 rows all welding work, equipments for welding, heat treatment, other auxiliary functions and the welding. these general welding guidelines are intended to provide background information and supplementary instructions to contractors and their. these practices include: it is. Pipe Welding Requirements.

From www.youtube.com

ms pipe welding ms pipe welding methods ms pipe welding joints ms Pipe Welding Requirements Properly preparing the pipe for welding, including. 10 rows all welding work, equipments for welding, heat treatment, other auxiliary functions and the welding. Ensuring a clean working environment to minimize contaminants. these general welding guidelines are intended to provide background information and supplementary instructions to contractors and their. Proper welding technique is usually specified in project welding specification.. Pipe Welding Requirements.

From eziil.com

5 Types of Welding Positions 1g, 2f, 3g, 4g... Pipe Welding Requirements select the appropriate welding process based on factors such as pipe thickness, material type, and application requirements. Properly preparing the pipe for welding, including. these practices include: to pipe weld, clean the surfaces, tightly fit the pipes, secure them with clamps or tacks, and weld them with. it is essential to protect work pieces from weather. Pipe Welding Requirements.

From bakerti.org

Introduction to Pipe Welding Baker Technical Institute Pipe Welding Requirements select the appropriate welding process based on factors such as pipe thickness, material type, and application requirements. these practices include: it is essential to protect work pieces from weather during welding. 10 rows all welding work, equipments for welding, heat treatment, other auxiliary functions and the welding. Proper welding technique is usually specified in project welding. Pipe Welding Requirements.

From animalia-life.club

Welder Welding Pipe Pipe Welding Requirements Proper welding technique is usually specified in project welding specification. it is essential to protect work pieces from weather during welding. these practices include: Ensuring a clean working environment to minimize contaminants. 10 rows all welding work, equipments for welding, heat treatment, other auxiliary functions and the welding. to pipe weld, clean the surfaces, tightly fit. Pipe Welding Requirements.

From www.scribd.com

Welding Procedure Specification for 24'' Pipe Pipe Welding Requirements it is essential to protect work pieces from weather during welding. these practices include: select the appropriate welding process based on factors such as pipe thickness, material type, and application requirements. this chapter is to introduce you to the main general welding rules contained in api 570 and asme b31.3. Properly preparing the pipe for welding,. Pipe Welding Requirements.

From blog.thepipingmart.com

An Overview Of Positions For Pipe Welding 1G, 2G, 5G And 6G Pipe Welding Requirements to pipe weld, clean the surfaces, tightly fit the pipes, secure them with clamps or tacks, and weld them with. these general welding guidelines are intended to provide background information and supplementary instructions to contractors and their. select the appropriate welding process based on factors such as pipe thickness, material type, and application requirements. it is. Pipe Welding Requirements.

From weldingtroop.com

Pipe Welding Guide Here's How to Pass a SMAW 6G Welding Certification Pipe Welding Requirements these general welding guidelines are intended to provide background information and supplementary instructions to contractors and their. to pipe weld, clean the surfaces, tightly fit the pipes, secure them with clamps or tacks, and weld them with. these practices include: Properly preparing the pipe for welding, including. 10 rows all welding work, equipments for welding, heat. Pipe Welding Requirements.

From www.twi-global.com

What is Pipe Welding? (Everything You Need To Know) TWI Pipe Welding Requirements select the appropriate welding process based on factors such as pipe thickness, material type, and application requirements. 10 rows all welding work, equipments for welding, heat treatment, other auxiliary functions and the welding. these general welding guidelines are intended to provide background information and supplementary instructions to contractors and their. it is essential to protect work. Pipe Welding Requirements.

From coremaintenance.com

PIPE WELDING & INSTALLATION Core Industrial Maintenance Pipe Welding Requirements these general welding guidelines are intended to provide background information and supplementary instructions to contractors and their. this chapter is to introduce you to the main general welding rules contained in api 570 and asme b31.3. Proper welding technique is usually specified in project welding specification. 10 rows all welding work, equipments for welding, heat treatment, other. Pipe Welding Requirements.

From www.dreamstime.com

View of the Weldolet Fitting Weld of the Pipe with Gas Tungsten Arc Pipe Welding Requirements Properly preparing the pipe for welding, including. to pipe weld, clean the surfaces, tightly fit the pipes, secure them with clamps or tacks, and weld them with. select the appropriate welding process based on factors such as pipe thickness, material type, and application requirements. these practices include: this chapter is to introduce you to the main. Pipe Welding Requirements.

From www.millerwelds.com

Meet the Demanding Requirements of Welding P91 Pipe With Advanced Wire Pipe Welding Requirements select the appropriate welding process based on factors such as pipe thickness, material type, and application requirements. 10 rows all welding work, equipments for welding, heat treatment, other auxiliary functions and the welding. these general welding guidelines are intended to provide background information and supplementary instructions to contractors and their. Ensuring a clean working environment to minimize. Pipe Welding Requirements.

From pt.scribd.com

WELDING CHART Stainless Steel Pipe (Fluid Conveyance) Pipe Welding Requirements this chapter is to introduce you to the main general welding rules contained in api 570 and asme b31.3. it is essential to protect work pieces from weather during welding. Proper welding technique is usually specified in project welding specification. select the appropriate welding process based on factors such as pipe thickness, material type, and application requirements.. Pipe Welding Requirements.

From www.canadianmetalworking.com

Pipe welding progress Pipe Welding Requirements to pipe weld, clean the surfaces, tightly fit the pipes, secure them with clamps or tacks, and weld them with. select the appropriate welding process based on factors such as pipe thickness, material type, and application requirements. Ensuring a clean working environment to minimize contaminants. these general welding guidelines are intended to provide background information and supplementary. Pipe Welding Requirements.

From unimig.com.au

Pipe Welding 101 UNIMIG Welding Guides & Tutorials Pipe Welding Requirements these practices include: Ensuring a clean working environment to minimize contaminants. it is essential to protect work pieces from weather during welding. Proper welding technique is usually specified in project welding specification. select the appropriate welding process based on factors such as pipe thickness, material type, and application requirements. to pipe weld, clean the surfaces, tightly. Pipe Welding Requirements.

From www.yumpu.com

METHOD STATEMENT FOR PIPE WELDING WORKS Kerala IT Pipe Welding Requirements Proper welding technique is usually specified in project welding specification. these practices include: Properly preparing the pipe for welding, including. 10 rows all welding work, equipments for welding, heat treatment, other auxiliary functions and the welding. it is essential to protect work pieces from weather during welding. to pipe weld, clean the surfaces, tightly fit the. Pipe Welding Requirements.

From www.wermac.org

Welding general Welding requirements of OLet Fittings like Weldolet Pipe Welding Requirements 10 rows all welding work, equipments for welding, heat treatment, other auxiliary functions and the welding. Ensuring a clean working environment to minimize contaminants. Properly preparing the pipe for welding, including. select the appropriate welding process based on factors such as pipe thickness, material type, and application requirements. this chapter is to introduce you to the main. Pipe Welding Requirements.

From www.hsedocuments.com

PIPE WELDING PROCEDURE FOR ERW, BLACK STEEL, SCHEDULE 40, GRADE ‘B Pipe Welding Requirements select the appropriate welding process based on factors such as pipe thickness, material type, and application requirements. Ensuring a clean working environment to minimize contaminants. Proper welding technique is usually specified in project welding specification. these practices include: to pipe weld, clean the surfaces, tightly fit the pipes, secure them with clamps or tacks, and weld them. Pipe Welding Requirements.

From www.weldingandndt.com

Welding Positions Welding & NDT Pipe Welding Requirements to pipe weld, clean the surfaces, tightly fit the pipes, secure them with clamps or tacks, and weld them with. Ensuring a clean working environment to minimize contaminants. Properly preparing the pipe for welding, including. this chapter is to introduce you to the main general welding rules contained in api 570 and asme b31.3. these general welding. Pipe Welding Requirements.

From www.vicswelding.com

What is Pipe Welding? Vic's Welding Pipe Welding Requirements to pipe weld, clean the surfaces, tightly fit the pipes, secure them with clamps or tacks, and weld them with. this chapter is to introduce you to the main general welding rules contained in api 570 and asme b31.3. 10 rows all welding work, equipments for welding, heat treatment, other auxiliary functions and the welding. it. Pipe Welding Requirements.

From pdfslide.net

(PDF) ARAMCO Welding Requirements for Pipe Lines.pdf Pipe Welding Requirements Proper welding technique is usually specified in project welding specification. to pipe weld, clean the surfaces, tightly fit the pipes, secure them with clamps or tacks, and weld them with. this chapter is to introduce you to the main general welding rules contained in api 570 and asme b31.3. select the appropriate welding process based on factors. Pipe Welding Requirements.

From weldgears.com

Pipe Welding Positions Chart Weld Gears Pipe Welding Requirements these general welding guidelines are intended to provide background information and supplementary instructions to contractors and their. Proper welding technique is usually specified in project welding specification. this chapter is to introduce you to the main general welding rules contained in api 570 and asme b31.3. these practices include: Properly preparing the pipe for welding, including. . Pipe Welding Requirements.

From stock.adobe.com

Welding branch pipes / Preparing the edges of pipes and structural of Pipe Welding Requirements Ensuring a clean working environment to minimize contaminants. this chapter is to introduce you to the main general welding rules contained in api 570 and asme b31.3. Proper welding technique is usually specified in project welding specification. to pipe weld, clean the surfaces, tightly fit the pipes, secure them with clamps or tacks, and weld them with. . Pipe Welding Requirements.

From sensibledigs.com

Welding Symbols Diagrams & Types (Fully Explained) Sensible Digs Pipe Welding Requirements this chapter is to introduce you to the main general welding rules contained in api 570 and asme b31.3. it is essential to protect work pieces from weather during welding. Proper welding technique is usually specified in project welding specification. these practices include: to pipe weld, clean the surfaces, tightly fit the pipes, secure them with. Pipe Welding Requirements.

From www.researchgate.net

(PDF) Welding Pipelines & Piping systems Procedures and Techniques Pipe Welding Requirements to pipe weld, clean the surfaces, tightly fit the pipes, secure them with clamps or tacks, and weld them with. Proper welding technique is usually specified in project welding specification. Properly preparing the pipe for welding, including. it is essential to protect work pieces from weather during welding. 10 rows all welding work, equipments for welding, heat. Pipe Welding Requirements.

From frontlinemanufacturing.com.au

What are the 5 different kinds of pipe welding positions? Pipe Welding Requirements these general welding guidelines are intended to provide background information and supplementary instructions to contractors and their. 10 rows all welding work, equipments for welding, heat treatment, other auxiliary functions and the welding. to pipe weld, clean the surfaces, tightly fit the pipes, secure them with clamps or tacks, and weld them with. Proper welding technique is. Pipe Welding Requirements.

From www.protemusa.com

Assembling Pipes by ButtWelding The Different Types of Bevels and How Pipe Welding Requirements select the appropriate welding process based on factors such as pipe thickness, material type, and application requirements. Proper welding technique is usually specified in project welding specification. these practices include: Ensuring a clean working environment to minimize contaminants. to pipe weld, clean the surfaces, tightly fit the pipes, secure them with clamps or tacks, and weld them. Pipe Welding Requirements.

From hlweldinginc.com

Pipeline welding operation requirements HL Welding Inc Pipe Welding Requirements Ensuring a clean working environment to minimize contaminants. 10 rows all welding work, equipments for welding, heat treatment, other auxiliary functions and the welding. select the appropriate welding process based on factors such as pipe thickness, material type, and application requirements. these practices include: to pipe weld, clean the surfaces, tightly fit the pipes, secure them. Pipe Welding Requirements.

From blog.thepipingmart.com

How to Weld Carbon Steel Pipe for Beginner Welders Pipe Welding Requirements Ensuring a clean working environment to minimize contaminants. Proper welding technique is usually specified in project welding specification. to pipe weld, clean the surfaces, tightly fit the pipes, secure them with clamps or tacks, and weld them with. these practices include: this chapter is to introduce you to the main general welding rules contained in api 570. Pipe Welding Requirements.

From blog.thepipingmart.com

Stainless Steel Pipe Welding Process A Complete Guide Pipe Welding Requirements Ensuring a clean working environment to minimize contaminants. select the appropriate welding process based on factors such as pipe thickness, material type, and application requirements. these general welding guidelines are intended to provide background information and supplementary instructions to contractors and their. these practices include: to pipe weld, clean the surfaces, tightly fit the pipes, secure. Pipe Welding Requirements.

From www.pipsisland.com

8 Simple Steps To Weld Pipe Pipe Welding Requirements select the appropriate welding process based on factors such as pipe thickness, material type, and application requirements. Ensuring a clean working environment to minimize contaminants. to pipe weld, clean the surfaces, tightly fit the pipes, secure them with clamps or tacks, and weld them with. Proper welding technique is usually specified in project welding specification. these general. Pipe Welding Requirements.

From template.mapadapalavra.ba.gov.br

Welding Procedure Specification Template Pipe Welding Requirements these practices include: 10 rows all welding work, equipments for welding, heat treatment, other auxiliary functions and the welding. select the appropriate welding process based on factors such as pipe thickness, material type, and application requirements. Properly preparing the pipe for welding, including. to pipe weld, clean the surfaces, tightly fit the pipes, secure them with. Pipe Welding Requirements.

From ahssinsights.org

High Frequency Tube/Pipe Welding AHSS Guidelines Pipe Welding Requirements these practices include: this chapter is to introduce you to the main general welding rules contained in api 570 and asme b31.3. Ensuring a clean working environment to minimize contaminants. select the appropriate welding process based on factors such as pipe thickness, material type, and application requirements. it is essential to protect work pieces from weather. Pipe Welding Requirements.

From www.youtube.com

Requirements for pipe welding YouTube Pipe Welding Requirements 10 rows all welding work, equipments for welding, heat treatment, other auxiliary functions and the welding. Proper welding technique is usually specified in project welding specification. select the appropriate welding process based on factors such as pipe thickness, material type, and application requirements. these general welding guidelines are intended to provide background information and supplementary instructions to. Pipe Welding Requirements.