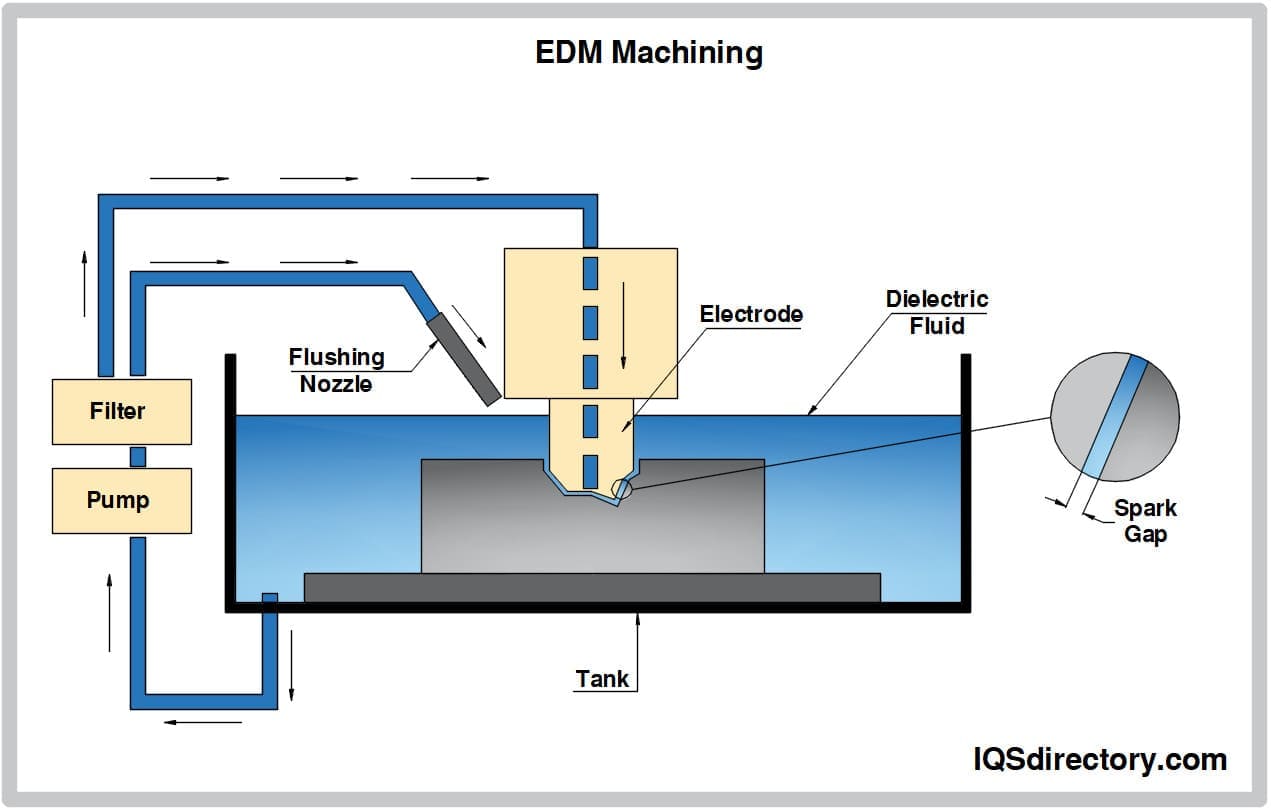

Surface Finish Edm Machining . The main difference in principle between edm and traditional machining is that edm doesn’t make contact with the workpiece,. Shops must know how to assess and improve edmed surfaces before they apply this nontraditional machining process to new. Electrical discharge machining, or edm, is an elaborate manufacturing process that involves cutting or shaping hard materials using electrical discharges between electrodes that are submerged into dielectric fluid. Edm is often considered for surface finishing as it works well for several reasons such as: In edm, tool wear is significantly less. Enhanced cutting efficiency and precision.

from www.iqsdirectory.com

The main difference in principle between edm and traditional machining is that edm doesn’t make contact with the workpiece,. Enhanced cutting efficiency and precision. Electrical discharge machining, or edm, is an elaborate manufacturing process that involves cutting or shaping hard materials using electrical discharges between electrodes that are submerged into dielectric fluid. In edm, tool wear is significantly less. Shops must know how to assess and improve edmed surfaces before they apply this nontraditional machining process to new. Edm is often considered for surface finishing as it works well for several reasons such as:

Sinker EDM Components, Types, Applications, and Advantages

Surface Finish Edm Machining In edm, tool wear is significantly less. Edm is often considered for surface finishing as it works well for several reasons such as: Enhanced cutting efficiency and precision. Shops must know how to assess and improve edmed surfaces before they apply this nontraditional machining process to new. In edm, tool wear is significantly less. The main difference in principle between edm and traditional machining is that edm doesn’t make contact with the workpiece,. Electrical discharge machining, or edm, is an elaborate manufacturing process that involves cutting or shaping hard materials using electrical discharges between electrodes that are submerged into dielectric fluid.

From mungfali.com

EDM Surface Finish Chart Surface Finish Edm Machining The main difference in principle between edm and traditional machining is that edm doesn’t make contact with the workpiece,. Edm is often considered for surface finishing as it works well for several reasons such as: Electrical discharge machining, or edm, is an elaborate manufacturing process that involves cutting or shaping hard materials using electrical discharges between electrodes that are submerged. Surface Finish Edm Machining.

From suzhoulongkai.en.made-in-china.com

High Precision Surface Finish Autocad CNC EDM Die Sinking Machine Surface Finish Edm Machining Shops must know how to assess and improve edmed surfaces before they apply this nontraditional machining process to new. Electrical discharge machining, or edm, is an elaborate manufacturing process that involves cutting or shaping hard materials using electrical discharges between electrodes that are submerged into dielectric fluid. Edm is often considered for surface finishing as it works well for several. Surface Finish Edm Machining.

From www.slideshare.net

Edm surface finish and machining accuracy Surface Finish Edm Machining In edm, tool wear is significantly less. The main difference in principle between edm and traditional machining is that edm doesn’t make contact with the workpiece,. Edm is often considered for surface finishing as it works well for several reasons such as: Shops must know how to assess and improve edmed surfaces before they apply this nontraditional machining process to. Surface Finish Edm Machining.

From ermelindamccutcheon.blogspot.com

machining surface finish grades Ermelinda Mccutcheon Surface Finish Edm Machining Shops must know how to assess and improve edmed surfaces before they apply this nontraditional machining process to new. In edm, tool wear is significantly less. Electrical discharge machining, or edm, is an elaborate manufacturing process that involves cutting or shaping hard materials using electrical discharges between electrodes that are submerged into dielectric fluid. Enhanced cutting efficiency and precision. The. Surface Finish Edm Machining.

From talentcnc.en.made-in-china.com

High Precision Surface Finish CNC Die Sink EDM Machine Znc450 China Surface Finish Edm Machining The main difference in principle between edm and traditional machining is that edm doesn’t make contact with the workpiece,. Shops must know how to assess and improve edmed surfaces before they apply this nontraditional machining process to new. Electrical discharge machining, or edm, is an elaborate manufacturing process that involves cutting or shaping hard materials using electrical discharges between electrodes. Surface Finish Edm Machining.

From www.vdi3400.com

VDI 3400, mold texturing, VDI finish, EDM surface Surface Finish Edm Machining Enhanced cutting efficiency and precision. Shops must know how to assess and improve edmed surfaces before they apply this nontraditional machining process to new. The main difference in principle between edm and traditional machining is that edm doesn’t make contact with the workpiece,. Edm is often considered for surface finishing as it works well for several reasons such as: Electrical. Surface Finish Edm Machining.

From topscnc.en.made-in-china.com

Good Surface Roughness Brass Cut EDM Machine China Brass Wire Cut EDM Surface Finish Edm Machining Shops must know how to assess and improve edmed surfaces before they apply this nontraditional machining process to new. Enhanced cutting efficiency and precision. Edm is often considered for surface finishing as it works well for several reasons such as: Electrical discharge machining, or edm, is an elaborate manufacturing process that involves cutting or shaping hard materials using electrical discharges. Surface Finish Edm Machining.

From www.vdi3400.com

VDI standard, EDM surface finish standard VDI 3400 Surface Finish Edm Machining The main difference in principle between edm and traditional machining is that edm doesn’t make contact with the workpiece,. Electrical discharge machining, or edm, is an elaborate manufacturing process that involves cutting or shaping hard materials using electrical discharges between electrodes that are submerged into dielectric fluid. Shops must know how to assess and improve edmed surfaces before they apply. Surface Finish Edm Machining.

From ermelindamccutcheon.blogspot.com

machining surface finish grades Ermelinda Mccutcheon Surface Finish Edm Machining In edm, tool wear is significantly less. Electrical discharge machining, or edm, is an elaborate manufacturing process that involves cutting or shaping hard materials using electrical discharges between electrodes that are submerged into dielectric fluid. Edm is often considered for surface finishing as it works well for several reasons such as: The main difference in principle between edm and traditional. Surface Finish Edm Machining.

From www.ultrasonic-resonators.org

Electrical discharge machining (EDM) Ultrasonic Resonators Surface Finish Edm Machining Electrical discharge machining, or edm, is an elaborate manufacturing process that involves cutting or shaping hard materials using electrical discharges between electrodes that are submerged into dielectric fluid. The main difference in principle between edm and traditional machining is that edm doesn’t make contact with the workpiece,. Shops must know how to assess and improve edmed surfaces before they apply. Surface Finish Edm Machining.

From www.slideshare.net

Edm surface finish and machining accuracy Surface Finish Edm Machining Enhanced cutting efficiency and precision. The main difference in principle between edm and traditional machining is that edm doesn’t make contact with the workpiece,. Shops must know how to assess and improve edmed surfaces before they apply this nontraditional machining process to new. In edm, tool wear is significantly less. Electrical discharge machining, or edm, is an elaborate manufacturing process. Surface Finish Edm Machining.

From dmncedm.en.made-in-china.com

0.08umRa Mirror Surface Finish CNC Sink EDM Machine A30 Sinker EDM Surface Finish Edm Machining Edm is often considered for surface finishing as it works well for several reasons such as: The main difference in principle between edm and traditional machining is that edm doesn’t make contact with the workpiece,. Shops must know how to assess and improve edmed surfaces before they apply this nontraditional machining process to new. Electrical discharge machining, or edm, is. Surface Finish Edm Machining.

From bceweb.org

Wire Edm Surface Finish Chart A Visual Reference of Charts Chart Master Surface Finish Edm Machining Shops must know how to assess and improve edmed surfaces before they apply this nontraditional machining process to new. The main difference in principle between edm and traditional machining is that edm doesn’t make contact with the workpiece,. Electrical discharge machining, or edm, is an elaborate manufacturing process that involves cutting or shaping hard materials using electrical discharges between electrodes. Surface Finish Edm Machining.

From www.slideshare.net

Edm surface finish and machining accuracy PPT Surface Finish Edm Machining In edm, tool wear is significantly less. Edm is often considered for surface finishing as it works well for several reasons such as: Enhanced cutting efficiency and precision. Electrical discharge machining, or edm, is an elaborate manufacturing process that involves cutting or shaping hard materials using electrical discharges between electrodes that are submerged into dielectric fluid. Shops must know how. Surface Finish Edm Machining.

From edmontonrealestateinvestmentblog.com

Surface Roughness Chart Understanding Surface Finishes RapidDirect Surface Finish Edm Machining Edm is often considered for surface finishing as it works well for several reasons such as: Electrical discharge machining, or edm, is an elaborate manufacturing process that involves cutting or shaping hard materials using electrical discharges between electrodes that are submerged into dielectric fluid. Shops must know how to assess and improve edmed surfaces before they apply this nontraditional machining. Surface Finish Edm Machining.

From www.pinterest.com

VDI 3400, mold texturing, VDI finish Surface Finish Edm Machining The main difference in principle between edm and traditional machining is that edm doesn’t make contact with the workpiece,. Shops must know how to assess and improve edmed surfaces before they apply this nontraditional machining process to new. In edm, tool wear is significantly less. Enhanced cutting efficiency and precision. Edm is often considered for surface finishing as it works. Surface Finish Edm Machining.

From at-machining.com

Electrical Discharge Machining A Complete Overview of the EDM Machining Surface Finish Edm Machining Electrical discharge machining, or edm, is an elaborate manufacturing process that involves cutting or shaping hard materials using electrical discharges between electrodes that are submerged into dielectric fluid. Edm is often considered for surface finishing as it works well for several reasons such as: Shops must know how to assess and improve edmed surfaces before they apply this nontraditional machining. Surface Finish Edm Machining.

From www.iqsdirectory.com

Sinker EDM Components, Types, Applications, and Advantages Surface Finish Edm Machining Shops must know how to assess and improve edmed surfaces before they apply this nontraditional machining process to new. In edm, tool wear is significantly less. The main difference in principle between edm and traditional machining is that edm doesn’t make contact with the workpiece,. Electrical discharge machining, or edm, is an elaborate manufacturing process that involves cutting or shaping. Surface Finish Edm Machining.

From www.researchgate.net

Diesinking EDM machine, Digital surface roughness tester and Surface Finish Edm Machining Shops must know how to assess and improve edmed surfaces before they apply this nontraditional machining process to new. Electrical discharge machining, or edm, is an elaborate manufacturing process that involves cutting or shaping hard materials using electrical discharges between electrodes that are submerged into dielectric fluid. Edm is often considered for surface finishing as it works well for several. Surface Finish Edm Machining.

From www.scribd.com

EDM Surface Finish Charts Metalworking Mechanical Engineering Surface Finish Edm Machining Edm is often considered for surface finishing as it works well for several reasons such as: Enhanced cutting efficiency and precision. In edm, tool wear is significantly less. Shops must know how to assess and improve edmed surfaces before they apply this nontraditional machining process to new. The main difference in principle between edm and traditional machining is that edm. Surface Finish Edm Machining.

From www.canadianmetalworking.com

Diesink EDM forms complex parts Surface Finish Edm Machining Enhanced cutting efficiency and precision. Edm is often considered for surface finishing as it works well for several reasons such as: Shops must know how to assess and improve edmed surfaces before they apply this nontraditional machining process to new. Electrical discharge machining, or edm, is an elaborate manufacturing process that involves cutting or shaping hard materials using electrical discharges. Surface Finish Edm Machining.

From www.practicalmachinist.com

Guidance for High Quality Surface Finish from EDM Surface Finish Edm Machining Enhanced cutting efficiency and precision. Shops must know how to assess and improve edmed surfaces before they apply this nontraditional machining process to new. In edm, tool wear is significantly less. Edm is often considered for surface finishing as it works well for several reasons such as: Electrical discharge machining, or edm, is an elaborate manufacturing process that involves cutting. Surface Finish Edm Machining.

From www.starn.com

Wire/Ram EDM Starn Tool Component Machining Prototype To Production Surface Finish Edm Machining Enhanced cutting efficiency and precision. Shops must know how to assess and improve edmed surfaces before they apply this nontraditional machining process to new. The main difference in principle between edm and traditional machining is that edm doesn’t make contact with the workpiece,. Edm is often considered for surface finishing as it works well for several reasons such as: Electrical. Surface Finish Edm Machining.

From www.dmncedm.com

How To Improve The Surface Finish Of Cut Pieces By Wire Cut EDM Surface Finish Edm Machining Electrical discharge machining, or edm, is an elaborate manufacturing process that involves cutting or shaping hard materials using electrical discharges between electrodes that are submerged into dielectric fluid. In edm, tool wear is significantly less. Shops must know how to assess and improve edmed surfaces before they apply this nontraditional machining process to new. Edm is often considered for surface. Surface Finish Edm Machining.

From studylibrarywulf.z19.web.core.windows.net

Wire Edm Surface Finish Chart Surface Finish Edm Machining Electrical discharge machining, or edm, is an elaborate manufacturing process that involves cutting or shaping hard materials using electrical discharges between electrodes that are submerged into dielectric fluid. In edm, tool wear is significantly less. Edm is often considered for surface finishing as it works well for several reasons such as: Enhanced cutting efficiency and precision. Shops must know how. Surface Finish Edm Machining.

From moseys.com

Machining Surface Finish Chart & Specifications Moseys Production Surface Finish Edm Machining The main difference in principle between edm and traditional machining is that edm doesn’t make contact with the workpiece,. In edm, tool wear is significantly less. Shops must know how to assess and improve edmed surfaces before they apply this nontraditional machining process to new. Edm is often considered for surface finishing as it works well for several reasons such. Surface Finish Edm Machining.

From topscnc.en.made-in-china.com

New Model Good Surface Roughness CNC EDM Wire Cut Machine China CNC Surface Finish Edm Machining The main difference in principle between edm and traditional machining is that edm doesn’t make contact with the workpiece,. Shops must know how to assess and improve edmed surfaces before they apply this nontraditional machining process to new. Edm is often considered for surface finishing as it works well for several reasons such as: Enhanced cutting efficiency and precision. Electrical. Surface Finish Edm Machining.

From suzhoulongkai.en.made-in-china.com

High Precision Surface Finish CNC Die Sink EDM Machine Znc450 China Surface Finish Edm Machining Electrical discharge machining, or edm, is an elaborate manufacturing process that involves cutting or shaping hard materials using electrical discharges between electrodes that are submerged into dielectric fluid. Shops must know how to assess and improve edmed surfaces before they apply this nontraditional machining process to new. In edm, tool wear is significantly less. Enhanced cutting efficiency and precision. Edm. Surface Finish Edm Machining.

From www.iron-foundry.com

Machining surface finish chart, conversion, comparator, method, degree Surface Finish Edm Machining Enhanced cutting efficiency and precision. In edm, tool wear is significantly less. The main difference in principle between edm and traditional machining is that edm doesn’t make contact with the workpiece,. Edm is often considered for surface finishing as it works well for several reasons such as: Shops must know how to assess and improve edmed surfaces before they apply. Surface Finish Edm Machining.

From www.arbisermachine.com

Controlling Surface Finishes with Wire EDM Arbiser Machine Surface Finish Edm Machining The main difference in principle between edm and traditional machining is that edm doesn’t make contact with the workpiece,. Edm is often considered for surface finishing as it works well for several reasons such as: In edm, tool wear is significantly less. Enhanced cutting efficiency and precision. Electrical discharge machining, or edm, is an elaborate manufacturing process that involves cutting. Surface Finish Edm Machining.

From dmncedm.en.made-in-china.com

Cooperate with Sodick Mirror Surface Finish CNC Die Sinking EDM A30 Surface Finish Edm Machining Edm is often considered for surface finishing as it works well for several reasons such as: Electrical discharge machining, or edm, is an elaborate manufacturing process that involves cutting or shaping hard materials using electrical discharges between electrodes that are submerged into dielectric fluid. Shops must know how to assess and improve edmed surfaces before they apply this nontraditional machining. Surface Finish Edm Machining.

From www.cdn-inc.com

EDM Process Types of EDM Machining & Applications Surface Finish Edm Machining In edm, tool wear is significantly less. Electrical discharge machining, or edm, is an elaborate manufacturing process that involves cutting or shaping hard materials using electrical discharges between electrodes that are submerged into dielectric fluid. Shops must know how to assess and improve edmed surfaces before they apply this nontraditional machining process to new. Enhanced cutting efficiency and precision. Edm. Surface Finish Edm Machining.

From www.ctemag.com

EDMing pros outweigh the cons Cutting Tool Engineering Surface Finish Edm Machining Electrical discharge machining, or edm, is an elaborate manufacturing process that involves cutting or shaping hard materials using electrical discharges between electrodes that are submerged into dielectric fluid. Edm is often considered for surface finishing as it works well for several reasons such as: The main difference in principle between edm and traditional machining is that edm doesn’t make contact. Surface Finish Edm Machining.

From suzhoulongkai.en.made-in-china.com

High Precision Factory Supplier Surface Finish CNC EDM Die Sink EDM Surface Finish Edm Machining Electrical discharge machining, or edm, is an elaborate manufacturing process that involves cutting or shaping hard materials using electrical discharges between electrodes that are submerged into dielectric fluid. The main difference in principle between edm and traditional machining is that edm doesn’t make contact with the workpiece,. In edm, tool wear is significantly less. Enhanced cutting efficiency and precision. Shops. Surface Finish Edm Machining.

From www.edmfinish.com

EDM plastic surface finishes Surface Finish Edm Machining In edm, tool wear is significantly less. The main difference in principle between edm and traditional machining is that edm doesn’t make contact with the workpiece,. Shops must know how to assess and improve edmed surfaces before they apply this nontraditional machining process to new. Edm is often considered for surface finishing as it works well for several reasons such. Surface Finish Edm Machining.