Tool Deflection In Micro Milling . This paper investigates modeling of machining forces with shearing and plowing mechanisms and estimates instantaneous tool. The deflection of micro end mills has a detrimental effect on surface quality of the machined micro components and adversely. The main focus were on prediction of cutting forces during micro end milling and estimating the deflection amount of the micro end. Research in micromilling processes has found that tool deflection phenomenon affects the forces significantly, causing a smoothing. The cutting force model according.

from www.mdpi.com

The cutting force model according. The deflection of micro end mills has a detrimental effect on surface quality of the machined micro components and adversely. This paper investigates modeling of machining forces with shearing and plowing mechanisms and estimates instantaneous tool. The main focus were on prediction of cutting forces during micro end milling and estimating the deflection amount of the micro end. Research in micromilling processes has found that tool deflection phenomenon affects the forces significantly, causing a smoothing.

Micromachines Free FullText Modeling the Influence of Tool Deflection on Cutting Force and

Tool Deflection In Micro Milling The main focus were on prediction of cutting forces during micro end milling and estimating the deflection amount of the micro end. The main focus were on prediction of cutting forces during micro end milling and estimating the deflection amount of the micro end. The deflection of micro end mills has a detrimental effect on surface quality of the machined micro components and adversely. The cutting force model according. Research in micromilling processes has found that tool deflection phenomenon affects the forces significantly, causing a smoothing. This paper investigates modeling of machining forces with shearing and plowing mechanisms and estimates instantaneous tool.

From www.researchgate.net

Experimental setup for tool deflection measurements Download Scientific Diagram Tool Deflection In Micro Milling Research in micromilling processes has found that tool deflection phenomenon affects the forces significantly, causing a smoothing. The cutting force model according. This paper investigates modeling of machining forces with shearing and plowing mechanisms and estimates instantaneous tool. The main focus were on prediction of cutting forces during micro end milling and estimating the deflection amount of the micro end.. Tool Deflection In Micro Milling.

From www.researchgate.net

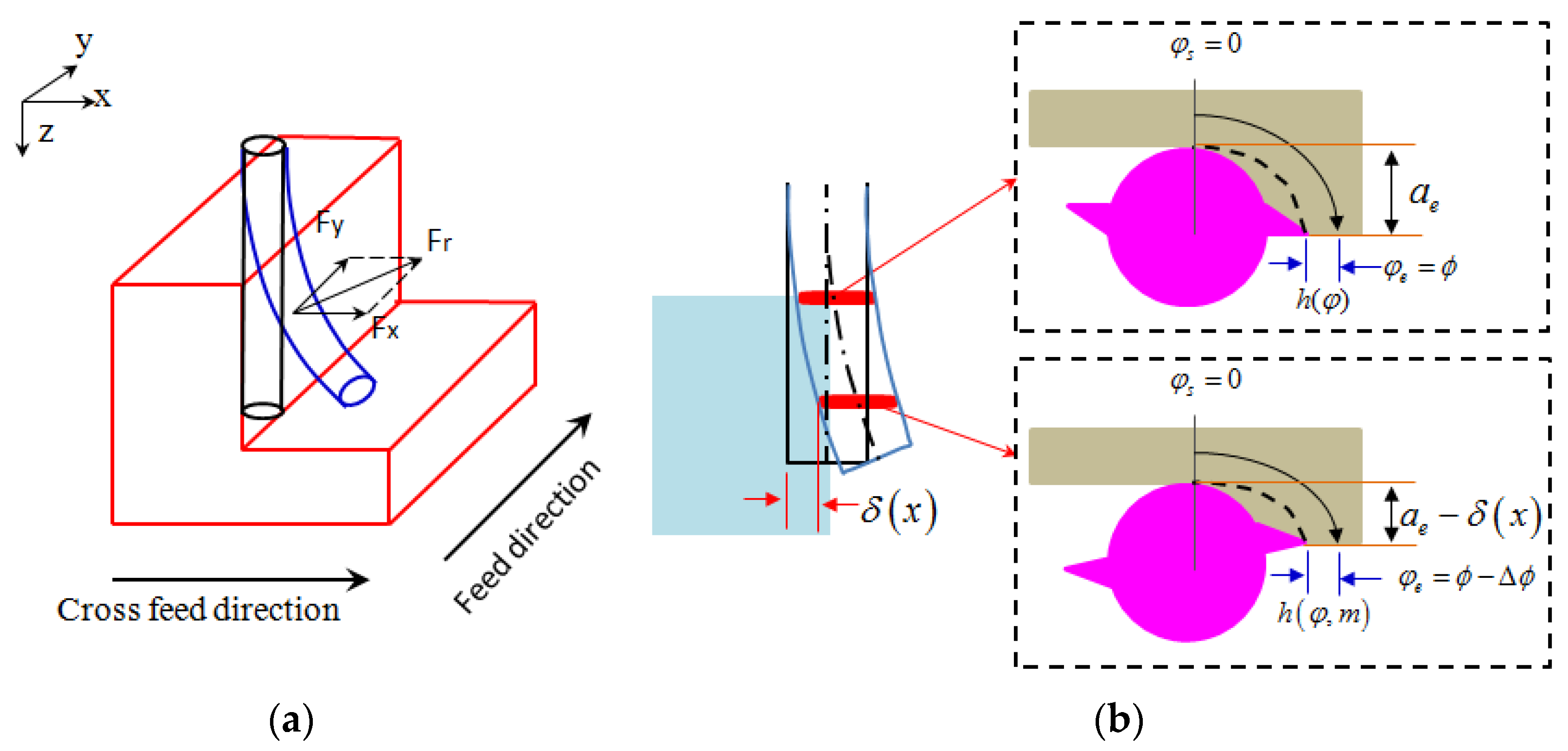

Deflection of milling tool at the bottom of the workpiece edge (Adapted... Download Scientific Tool Deflection In Micro Milling Research in micromilling processes has found that tool deflection phenomenon affects the forces significantly, causing a smoothing. The cutting force model according. The main focus were on prediction of cutting forces during micro end milling and estimating the deflection amount of the micro end. The deflection of micro end mills has a detrimental effect on surface quality of the machined. Tool Deflection In Micro Milling.

From www.mdpi.com

Micromachines Free FullText Modeling the Influence of Tool Deflection on Cutting Force and Tool Deflection In Micro Milling This paper investigates modeling of machining forces with shearing and plowing mechanisms and estimates instantaneous tool. The main focus were on prediction of cutting forces during micro end milling and estimating the deflection amount of the micro end. Research in micromilling processes has found that tool deflection phenomenon affects the forces significantly, causing a smoothing. The deflection of micro end. Tool Deflection In Micro Milling.

From www.mattech-journal.org

A model of micromilling cutting forces based on microcutting experiments including tool Tool Deflection In Micro Milling Research in micromilling processes has found that tool deflection phenomenon affects the forces significantly, causing a smoothing. The deflection of micro end mills has a detrimental effect on surface quality of the machined micro components and adversely. The cutting force model according. This paper investigates modeling of machining forces with shearing and plowing mechanisms and estimates instantaneous tool. The main. Tool Deflection In Micro Milling.

From www.researchgate.net

Deflection of milling tool at the bottom of the workpiece edge (Adapted... Download Scientific Tool Deflection In Micro Milling The main focus were on prediction of cutting forces during micro end milling and estimating the deflection amount of the micro end. This paper investigates modeling of machining forces with shearing and plowing mechanisms and estimates instantaneous tool. The deflection of micro end mills has a detrimental effect on surface quality of the machined micro components and adversely. The cutting. Tool Deflection In Micro Milling.

From www.semanticscholar.org

Table 2 from Simulation of threedimension cutting force and tool deflection in the end milling Tool Deflection In Micro Milling Research in micromilling processes has found that tool deflection phenomenon affects the forces significantly, causing a smoothing. The main focus were on prediction of cutting forces during micro end milling and estimating the deflection amount of the micro end. The deflection of micro end mills has a detrimental effect on surface quality of the machined micro components and adversely. This. Tool Deflection In Micro Milling.

From www.researchgate.net

Tool deflection of ball nose micro endmills with two different neck lengths Download Tool Deflection In Micro Milling The main focus were on prediction of cutting forces during micro end milling and estimating the deflection amount of the micro end. This paper investigates modeling of machining forces with shearing and plowing mechanisms and estimates instantaneous tool. The cutting force model according. The deflection of micro end mills has a detrimental effect on surface quality of the machined micro. Tool Deflection In Micro Milling.

From www.mattech-journal.org

A model of micromilling cutting forces based on microcutting experiments including tool Tool Deflection In Micro Milling This paper investigates modeling of machining forces with shearing and plowing mechanisms and estimates instantaneous tool. The cutting force model according. Research in micromilling processes has found that tool deflection phenomenon affects the forces significantly, causing a smoothing. The main focus were on prediction of cutting forces during micro end milling and estimating the deflection amount of the micro end.. Tool Deflection In Micro Milling.

From www.mattech-journal.org

A model of micromilling cutting forces based on microcutting experiments including tool Tool Deflection In Micro Milling The cutting force model according. The deflection of micro end mills has a detrimental effect on surface quality of the machined micro components and adversely. This paper investigates modeling of machining forces with shearing and plowing mechanisms and estimates instantaneous tool. Research in micromilling processes has found that tool deflection phenomenon affects the forces significantly, causing a smoothing. The main. Tool Deflection In Micro Milling.

From www.researchgate.net

Illustration of the influence of microendmill deflection on the chip... Download Scientific Tool Deflection In Micro Milling This paper investigates modeling of machining forces with shearing and plowing mechanisms and estimates instantaneous tool. The main focus were on prediction of cutting forces during micro end milling and estimating the deflection amount of the micro end. The cutting force model according. Research in micromilling processes has found that tool deflection phenomenon affects the forces significantly, causing a smoothing.. Tool Deflection In Micro Milling.

From www.researchgate.net

Effect of graphite type on the tool deflection for different radial... Download Scientific Diagram Tool Deflection In Micro Milling The main focus were on prediction of cutting forces during micro end milling and estimating the deflection amount of the micro end. The cutting force model according. Research in micromilling processes has found that tool deflection phenomenon affects the forces significantly, causing a smoothing. The deflection of micro end mills has a detrimental effect on surface quality of the machined. Tool Deflection In Micro Milling.

From www.researchgate.net

(PDF) A model of micromilling cutting forces based on microcutting experiments including tool Tool Deflection In Micro Milling Research in micromilling processes has found that tool deflection phenomenon affects the forces significantly, causing a smoothing. The cutting force model according. This paper investigates modeling of machining forces with shearing and plowing mechanisms and estimates instantaneous tool. The deflection of micro end mills has a detrimental effect on surface quality of the machined micro components and adversely. The main. Tool Deflection In Micro Milling.

From www.academia.edu

(PDF) Tool deflection model for micromilling processes Pablo N. Cortés Rodríguez Academia.edu Tool Deflection In Micro Milling The cutting force model according. The deflection of micro end mills has a detrimental effect on surface quality of the machined micro components and adversely. The main focus were on prediction of cutting forces during micro end milling and estimating the deflection amount of the micro end. Research in micromilling processes has found that tool deflection phenomenon affects the forces. Tool Deflection In Micro Milling.

From www.researchgate.net

Tool deflection model of micro mill. bthe cutting depth (mm). L, Lr,... Download Scientific Tool Deflection In Micro Milling The cutting force model according. This paper investigates modeling of machining forces with shearing and plowing mechanisms and estimates instantaneous tool. The main focus were on prediction of cutting forces during micro end milling and estimating the deflection amount of the micro end. Research in micromilling processes has found that tool deflection phenomenon affects the forces significantly, causing a smoothing.. Tool Deflection In Micro Milling.

From www.mdpi.com

Micromachines Free FullText Modeling the Influence of Tool Deflection on Cutting Force and Tool Deflection In Micro Milling This paper investigates modeling of machining forces with shearing and plowing mechanisms and estimates instantaneous tool. The main focus were on prediction of cutting forces during micro end milling and estimating the deflection amount of the micro end. The cutting force model according. The deflection of micro end mills has a detrimental effect on surface quality of the machined micro. Tool Deflection In Micro Milling.

From www.mdpi.com

Micromachines Free FullText Modeling the Influence of Tool Deflection on Cutting Force and Tool Deflection In Micro Milling The cutting force model according. This paper investigates modeling of machining forces with shearing and plowing mechanisms and estimates instantaneous tool. The deflection of micro end mills has a detrimental effect on surface quality of the machined micro components and adversely. The main focus were on prediction of cutting forces during micro end milling and estimating the deflection amount of. Tool Deflection In Micro Milling.

From www.semanticscholar.org

Figure 1 from Tool deflection compensation with an adaptronic milling spindle Semantic Scholar Tool Deflection In Micro Milling The main focus were on prediction of cutting forces during micro end milling and estimating the deflection amount of the micro end. This paper investigates modeling of machining forces with shearing and plowing mechanisms and estimates instantaneous tool. The deflection of micro end mills has a detrimental effect on surface quality of the machined micro components and adversely. The cutting. Tool Deflection In Micro Milling.

From www.semanticscholar.org

Figure 1 from Prediction of Cutting Force and Tool Deflection in Micro Flat End Milling Tool Deflection In Micro Milling The deflection of micro end mills has a detrimental effect on surface quality of the machined micro components and adversely. The cutting force model according. The main focus were on prediction of cutting forces during micro end milling and estimating the deflection amount of the micro end. This paper investigates modeling of machining forces with shearing and plowing mechanisms and. Tool Deflection In Micro Milling.

From www.mattech-journal.org

A model of micromilling cutting forces based on microcutting experiments including tool Tool Deflection In Micro Milling This paper investigates modeling of machining forces with shearing and plowing mechanisms and estimates instantaneous tool. The main focus were on prediction of cutting forces during micro end milling and estimating the deflection amount of the micro end. The cutting force model according. Research in micromilling processes has found that tool deflection phenomenon affects the forces significantly, causing a smoothing.. Tool Deflection In Micro Milling.

From www.mdpi.com

Micromachines Free FullText Modeling the Influence of Tool Deflection on Cutting Force and Tool Deflection In Micro Milling The cutting force model according. The deflection of micro end mills has a detrimental effect on surface quality of the machined micro components and adversely. Research in micromilling processes has found that tool deflection phenomenon affects the forces significantly, causing a smoothing. This paper investigates modeling of machining forces with shearing and plowing mechanisms and estimates instantaneous tool. The main. Tool Deflection In Micro Milling.

From www.mdpi.com

Micromachines Free FullText Modeling the Influence of Tool Deflection on Cutting Force and Tool Deflection In Micro Milling This paper investigates modeling of machining forces with shearing and plowing mechanisms and estimates instantaneous tool. The main focus were on prediction of cutting forces during micro end milling and estimating the deflection amount of the micro end. The cutting force model according. The deflection of micro end mills has a detrimental effect on surface quality of the machined micro. Tool Deflection In Micro Milling.

From www.academia.edu

(PDF) Modeling of cutting force, tool deflection, and surface error in micromilling operation Tool Deflection In Micro Milling The cutting force model according. The main focus were on prediction of cutting forces during micro end milling and estimating the deflection amount of the micro end. This paper investigates modeling of machining forces with shearing and plowing mechanisms and estimates instantaneous tool. Research in micromilling processes has found that tool deflection phenomenon affects the forces significantly, causing a smoothing.. Tool Deflection In Micro Milling.

From journals.sagepub.com

Prediction of tool deflection using image processing in ballend milling Burak Özdemir, Erkan Tool Deflection In Micro Milling The deflection of micro end mills has a detrimental effect on surface quality of the machined micro components and adversely. Research in micromilling processes has found that tool deflection phenomenon affects the forces significantly, causing a smoothing. The main focus were on prediction of cutting forces during micro end milling and estimating the deflection amount of the micro end. The. Tool Deflection In Micro Milling.

From www.researchgate.net

Comparison between measured analytical ratio of tool deflection for... Download Scientific Diagram Tool Deflection In Micro Milling Research in micromilling processes has found that tool deflection phenomenon affects the forces significantly, causing a smoothing. This paper investigates modeling of machining forces with shearing and plowing mechanisms and estimates instantaneous tool. The deflection of micro end mills has a detrimental effect on surface quality of the machined micro components and adversely. The main focus were on prediction of. Tool Deflection In Micro Milling.

From www.researchgate.net

(PDF) Analysis of tool deflection in micro milling of graphite electrodes Tool Deflection In Micro Milling The main focus were on prediction of cutting forces during micro end milling and estimating the deflection amount of the micro end. The cutting force model according. The deflection of micro end mills has a detrimental effect on surface quality of the machined micro components and adversely. This paper investigates modeling of machining forces with shearing and plowing mechanisms and. Tool Deflection In Micro Milling.

From www.researchgate.net

Effect of different peripheral milling strategies on the tool deflection Download Scientific Tool Deflection In Micro Milling The main focus were on prediction of cutting forces during micro end milling and estimating the deflection amount of the micro end. The deflection of micro end mills has a detrimental effect on surface quality of the machined micro components and adversely. Research in micromilling processes has found that tool deflection phenomenon affects the forces significantly, causing a smoothing. This. Tool Deflection In Micro Milling.

From www.researchgate.net

Effect of axial depth of cut on the tool deflection for different... Download Scientific Diagram Tool Deflection In Micro Milling Research in micromilling processes has found that tool deflection phenomenon affects the forces significantly, causing a smoothing. The cutting force model according. The main focus were on prediction of cutting forces during micro end milling and estimating the deflection amount of the micro end. The deflection of micro end mills has a detrimental effect on surface quality of the machined. Tool Deflection In Micro Milling.

From www.mdpi.com

Micromachines Free FullText Modeling the Influence of Tool Deflection on Cutting Force and Tool Deflection In Micro Milling This paper investigates modeling of machining forces with shearing and plowing mechanisms and estimates instantaneous tool. Research in micromilling processes has found that tool deflection phenomenon affects the forces significantly, causing a smoothing. The deflection of micro end mills has a detrimental effect on surface quality of the machined micro components and adversely. The main focus were on prediction of. Tool Deflection In Micro Milling.

From www.researchgate.net

Sketch of microtool deflection. Download Scientific Diagram Tool Deflection In Micro Milling Research in micromilling processes has found that tool deflection phenomenon affects the forces significantly, causing a smoothing. The deflection of micro end mills has a detrimental effect on surface quality of the machined micro components and adversely. The main focus were on prediction of cutting forces during micro end milling and estimating the deflection amount of the micro end. The. Tool Deflection In Micro Milling.

From www.semanticscholar.org

Figure 1 from Prediction of Cutting Force and Tool Deflection in Micro Flat End Milling Tool Deflection In Micro Milling The main focus were on prediction of cutting forces during micro end milling and estimating the deflection amount of the micro end. This paper investigates modeling of machining forces with shearing and plowing mechanisms and estimates instantaneous tool. Research in micromilling processes has found that tool deflection phenomenon affects the forces significantly, causing a smoothing. The deflection of micro end. Tool Deflection In Micro Milling.

From www.researchgate.net

Schematic illustration of tool deflection model Download Scientific Diagram Tool Deflection In Micro Milling The cutting force model according. The main focus were on prediction of cutting forces during micro end milling and estimating the deflection amount of the micro end. The deflection of micro end mills has a detrimental effect on surface quality of the machined micro components and adversely. This paper investigates modeling of machining forces with shearing and plowing mechanisms and. Tool Deflection In Micro Milling.

From www.researchgate.net

(PDF) Analysis of tool deflection in micro milling of graphite electrodes Tool Deflection In Micro Milling Research in micromilling processes has found that tool deflection phenomenon affects the forces significantly, causing a smoothing. The deflection of micro end mills has a detrimental effect on surface quality of the machined micro components and adversely. The main focus were on prediction of cutting forces during micro end milling and estimating the deflection amount of the micro end. The. Tool Deflection In Micro Milling.

From www.researchgate.net

Phenomena associated with micromilling (a) runout, (b) deflection,... Download Scientific Tool Deflection In Micro Milling The main focus were on prediction of cutting forces during micro end milling and estimating the deflection amount of the micro end. The deflection of micro end mills has a detrimental effect on surface quality of the machined micro components and adversely. Research in micromilling processes has found that tool deflection phenomenon affects the forces significantly, causing a smoothing. This. Tool Deflection In Micro Milling.

From www.researchgate.net

Tool deflection of ball nose micro endmills with two different neck lengths Download Tool Deflection In Micro Milling The cutting force model according. The deflection of micro end mills has a detrimental effect on surface quality of the machined micro components and adversely. Research in micromilling processes has found that tool deflection phenomenon affects the forces significantly, causing a smoothing. This paper investigates modeling of machining forces with shearing and plowing mechanisms and estimates instantaneous tool. The main. Tool Deflection In Micro Milling.

From www.mdpi.com

Micromachines Free FullText Modeling the Influence of Tool Deflection on Cutting Force and Tool Deflection In Micro Milling Research in micromilling processes has found that tool deflection phenomenon affects the forces significantly, causing a smoothing. The deflection of micro end mills has a detrimental effect on surface quality of the machined micro components and adversely. This paper investigates modeling of machining forces with shearing and plowing mechanisms and estimates instantaneous tool. The main focus were on prediction of. Tool Deflection In Micro Milling.