Cutter Geometry . The five important angles involved in the making of the millcutter are: Every one of these tool shapes. Brief geometry of the milling cutter: Cutting tools for metalcutting have many shapes, each of which are described by their angles or geometries. Tool geometries are critical because they directly impact tool life, chip control, edge stability and micro cutting characteristics, all of which, in turn, affect overall machining costs. Lead angle, which influences cutting forces and chip thickness. Cutter geometry, which describes various radial and axial rake angles. When cutting metal, the tool angle plays a crucial role in determining the geometry of the cutting part of the tool as it penetrates the. Double negative, double positive, and positive/ negative. This dimension refers to the diameter of the theoretical circle formed by the cutting edges as the tool rotates. Cutting tools for metalcutting have many shapes, each of which are described by their angles or geometries. Each has certain advantages and disadvantages that must be considered when selecting the right milling cutter for the job. Milling cutter geometry there are three industry standard milling cutter geometries: Every one of these tool shapes have a specific purpose in metalcutting. The cutter diameter is often the first thing machinists look for when choosing a tool for their job.

from www.youtube.com

Tool geometries are critical because they directly impact tool life, chip control, edge stability and micro cutting characteristics, all of which, in turn, affect overall machining costs. Each has certain advantages and disadvantages that must be considered when selecting the right milling cutter for the job. Cutting tools for metalcutting have many shapes, each of which are described by their angles or geometries. This dimension refers to the diameter of the theoretical circle formed by the cutting edges as the tool rotates. Every one of these tool shapes have a specific purpose in metalcutting. Milling cutter geometry there are three industry standard milling cutter geometries: Lead angle, which influences cutting forces and chip thickness. When cutting metal, the tool angle plays a crucial role in determining the geometry of the cutting part of the tool as it penetrates the. Brief geometry of the milling cutter: The cutter diameter is often the first thing machinists look for when choosing a tool for their job.

Understanding Cutting Tool Geometry YouTube

Cutter Geometry Cutter geometry, which describes various radial and axial rake angles. When cutting metal, the tool angle plays a crucial role in determining the geometry of the cutting part of the tool as it penetrates the. Milling cutter geometry there are three industry standard milling cutter geometries: Brief geometry of the milling cutter: Double negative, double positive, and positive/ negative. Each has certain advantages and disadvantages that must be considered when selecting the right milling cutter for the job. Tool geometries are critical because they directly impact tool life, chip control, edge stability and micro cutting characteristics, all of which, in turn, affect overall machining costs. Lead angle, which influences cutting forces and chip thickness. The cutter diameter is often the first thing machinists look for when choosing a tool for their job. This dimension refers to the diameter of the theoretical circle formed by the cutting edges as the tool rotates. Every one of these tool shapes. Cutting tools for metalcutting have many shapes, each of which are described by their angles or geometries. Cutter geometry, which describes various radial and axial rake angles. Every one of these tool shapes have a specific purpose in metalcutting. The five important angles involved in the making of the millcutter are: Cutting tools for metalcutting have many shapes, each of which are described by their angles or geometries.

From learnmech.com

Milling Cutter Types Of Milling Cutter used For Machining Cutter Geometry Lead angle, which influences cutting forces and chip thickness. Each has certain advantages and disadvantages that must be considered when selecting the right milling cutter for the job. Double negative, double positive, and positive/ negative. When cutting metal, the tool angle plays a crucial role in determining the geometry of the cutting part of the tool as it penetrates the.. Cutter Geometry.

From cooper-yersblogbridges.blogspot.com

Describe the Different Types of Cutters Used in Milling Operations Cutter Geometry Double negative, double positive, and positive/ negative. This dimension refers to the diameter of the theoretical circle formed by the cutting edges as the tool rotates. Brief geometry of the milling cutter: Every one of these tool shapes have a specific purpose in metalcutting. Every one of these tool shapes. Each has certain advantages and disadvantages that must be considered. Cutter Geometry.

From learnmechanical.com

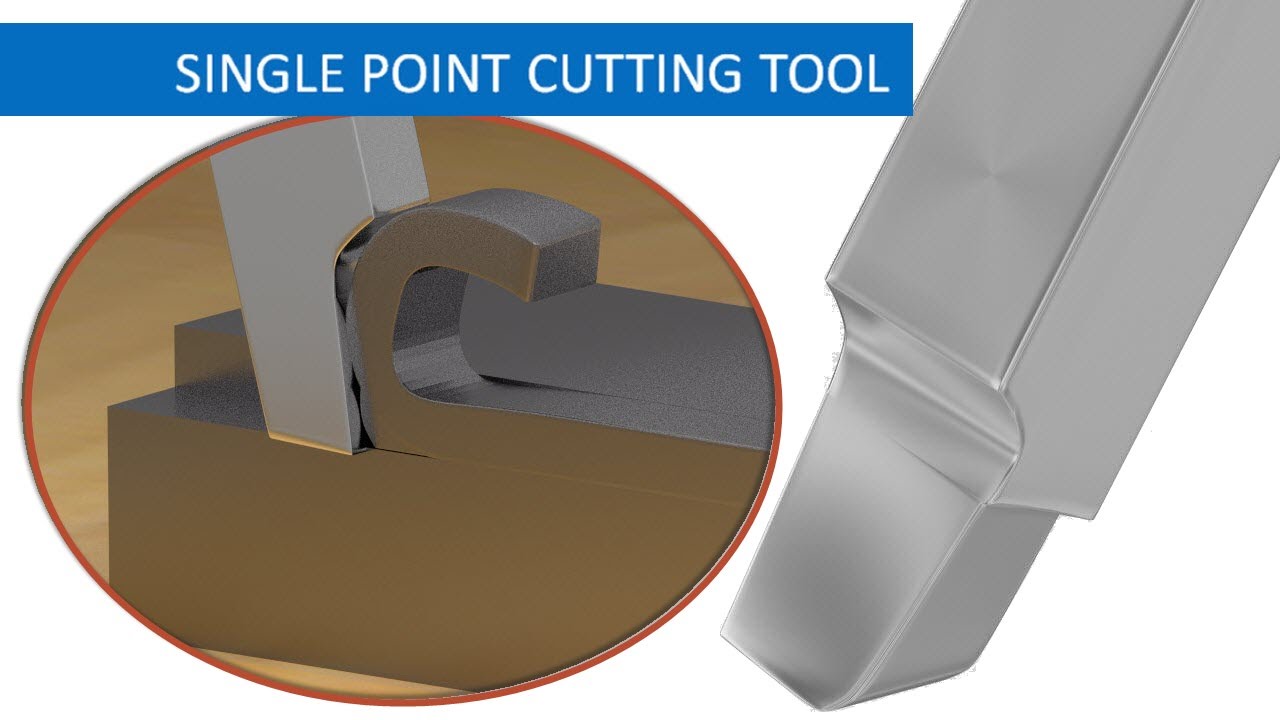

Single Point Cutting Tool Definition, Types, Geometry, Nomenclature, Angle, PDF Learn Mechanical Cutter Geometry Milling cutter geometry there are three industry standard milling cutter geometries: Every one of these tool shapes. Cutting tools for metalcutting have many shapes, each of which are described by their angles or geometries. The cutter diameter is often the first thing machinists look for when choosing a tool for their job. Lead angle, which influences cutting forces and chip. Cutter Geometry.

From www.researchgate.net

Geometry of the cutter. Download Scientific Diagram Cutter Geometry Cutter geometry, which describes various radial and axial rake angles. The five important angles involved in the making of the millcutter are: Lead angle, which influences cutting forces and chip thickness. When cutting metal, the tool angle plays a crucial role in determining the geometry of the cutting part of the tool as it penetrates the. The cutter diameter is. Cutter Geometry.

From www.researchgate.net

Schematic diagram of the VPBNC a cutter cutting process, b cutting... Download Scientific Diagram Cutter Geometry The five important angles involved in the making of the millcutter are: Each has certain advantages and disadvantages that must be considered when selecting the right milling cutter for the job. Brief geometry of the milling cutter: The cutter diameter is often the first thing machinists look for when choosing a tool for their job. This dimension refers to the. Cutter Geometry.

From www.youtube.com

Single Point Cutting Tool Nomenclature, Tool Signature, Side Rake Angle, Terminology Cutter Geometry The cutter diameter is often the first thing machinists look for when choosing a tool for their job. Every one of these tool shapes. When cutting metal, the tool angle plays a crucial role in determining the geometry of the cutting part of the tool as it penetrates the. Tool geometries are critical because they directly impact tool life, chip. Cutter Geometry.

From www.themachinedesign.com

Single Point Cutting Tool Nomenclature, Geometry The Machine Design Cutter Geometry This dimension refers to the diameter of the theoretical circle formed by the cutting edges as the tool rotates. Cutting tools for metalcutting have many shapes, each of which are described by their angles or geometries. Each has certain advantages and disadvantages that must be considered when selecting the right milling cutter for the job. Every one of these tool. Cutter Geometry.

From www.researchgate.net

Geometry location of the cutter on the freeform surface S. Download Scientific Diagram Cutter Geometry The five important angles involved in the making of the millcutter are: Tool geometries are critical because they directly impact tool life, chip control, edge stability and micro cutting characteristics, all of which, in turn, affect overall machining costs. Double negative, double positive, and positive/ negative. Cutting tools for metalcutting have many shapes, each of which are described by their. Cutter Geometry.

From toolnotes.com

Lathe Tools and Toolholders ToolNotes Cutter Geometry Every one of these tool shapes have a specific purpose in metalcutting. This dimension refers to the diameter of the theoretical circle formed by the cutting edges as the tool rotates. Lead angle, which influences cutting forces and chip thickness. Brief geometry of the milling cutter: Every one of these tool shapes. Each has certain advantages and disadvantages that must. Cutter Geometry.

From www.researchgate.net

Geometry model of ballend milling cutter. Download Scientific Diagram Cutter Geometry The five important angles involved in the making of the millcutter are: The cutter diameter is often the first thing machinists look for when choosing a tool for their job. Every one of these tool shapes have a specific purpose in metalcutting. Double negative, double positive, and positive/ negative. When cutting metal, the tool angle plays a crucial role in. Cutter Geometry.

From innovationdiscoveries.space

TECHNICAL TERMS OF TOOLS AND CUTTERS EXPLAINED Cutter Geometry Every one of these tool shapes have a specific purpose in metalcutting. Brief geometry of the milling cutter: When cutting metal, the tool angle plays a crucial role in determining the geometry of the cutting part of the tool as it penetrates the. This dimension refers to the diameter of the theoretical circle formed by the cutting edges as the. Cutter Geometry.

From www.youtube.com

Understanding Cutting Tool Geometry YouTube Cutter Geometry Each has certain advantages and disadvantages that must be considered when selecting the right milling cutter for the job. The five important angles involved in the making of the millcutter are: Brief geometry of the milling cutter: Cutting tools for metalcutting have many shapes, each of which are described by their angles or geometries. Double negative, double positive, and positive/. Cutter Geometry.

From www.researchgate.net

Endmilling cutter geometry and coordinate system a schematic of an... Download Scientific Cutter Geometry Tool geometries are critical because they directly impact tool life, chip control, edge stability and micro cutting characteristics, all of which, in turn, affect overall machining costs. Lead angle, which influences cutting forces and chip thickness. Cutting tools for metalcutting have many shapes, each of which are described by their angles or geometries. Brief geometry of the milling cutter: When. Cutter Geometry.

From www.researchgate.net

General definition of tool geometric parameters. a Cutter geometry. b... Download Scientific Cutter Geometry The five important angles involved in the making of the millcutter are: Brief geometry of the milling cutter: Tool geometries are critical because they directly impact tool life, chip control, edge stability and micro cutting characteristics, all of which, in turn, affect overall machining costs. Cutting tools for metalcutting have many shapes, each of which are described by their angles. Cutter Geometry.

From www.researchgate.net

Geometric definitions of the conical skiving cutter Download Scientific Diagram Cutter Geometry Each has certain advantages and disadvantages that must be considered when selecting the right milling cutter for the job. When cutting metal, the tool angle plays a crucial role in determining the geometry of the cutting part of the tool as it penetrates the. Cutting tools for metalcutting have many shapes, each of which are described by their angles or. Cutter Geometry.

From www.researchgate.net

Tool geometry and principal angles of a taper ballend mill cutter. Download Scientific Diagram Cutter Geometry Every one of these tool shapes. This dimension refers to the diameter of the theoretical circle formed by the cutting edges as the tool rotates. Brief geometry of the milling cutter: The five important angles involved in the making of the millcutter are: When cutting metal, the tool angle plays a crucial role in determining the geometry of the cutting. Cutter Geometry.

From www.redlinetools.com

Endmill Selection Guide RedLine Tools Redline Tools Cutter Geometry Cutting tools for metalcutting have many shapes, each of which are described by their angles or geometries. Every one of these tool shapes have a specific purpose in metalcutting. When cutting metal, the tool angle plays a crucial role in determining the geometry of the cutting part of the tool as it penetrates the. Each has certain advantages and disadvantages. Cutter Geometry.

From drilling-manual.blogspot.com

PDC Cutter Geometry Cutter Geometry Cutter geometry, which describes various radial and axial rake angles. Tool geometries are critical because they directly impact tool life, chip control, edge stability and micro cutting characteristics, all of which, in turn, affect overall machining costs. The five important angles involved in the making of the millcutter are: Milling cutter geometry there are three industry standard milling cutter geometries:. Cutter Geometry.

From www.researchgate.net

Effects on the cuttermark geometry for milling tools with different... Download Scientific Cutter Geometry Cutting tools for metalcutting have many shapes, each of which are described by their angles or geometries. Every one of these tool shapes. Milling cutter geometry there are three industry standard milling cutter geometries: When cutting metal, the tool angle plays a crucial role in determining the geometry of the cutting part of the tool as it penetrates the. This. Cutter Geometry.

From www.researchgate.net

Flute profile of the endmill cutter—example 1 Download Scientific Diagram Cutter Geometry Double negative, double positive, and positive/ negative. Every one of these tool shapes have a specific purpose in metalcutting. Cutting tools for metalcutting have many shapes, each of which are described by their angles or geometries. Cutter geometry, which describes various radial and axial rake angles. Brief geometry of the milling cutter: This dimension refers to the diameter of the. Cutter Geometry.

From www.mech4study.com

Single Point Cutting Tool Nomenclature, Angle,Geometry and Signature Mech4study Cutter Geometry The cutter diameter is often the first thing machinists look for when choosing a tool for their job. Double negative, double positive, and positive/ negative. Brief geometry of the milling cutter: Cutting tools for metalcutting have many shapes, each of which are described by their angles or geometries. Milling cutter geometry there are three industry standard milling cutter geometries: Each. Cutter Geometry.

From www.researchgate.net

3D cutter geometry, axial section profile (green) in axial section... Download Scientific Diagram Cutter Geometry When cutting metal, the tool angle plays a crucial role in determining the geometry of the cutting part of the tool as it penetrates the. Cutter geometry, which describes various radial and axial rake angles. Every one of these tool shapes. The five important angles involved in the making of the millcutter are: Cutting tools for metalcutting have many shapes,. Cutter Geometry.

From www.researchgate.net

Encoding of the cutter geometry. Download Scientific Diagram Cutter Geometry Each has certain advantages and disadvantages that must be considered when selecting the right milling cutter for the job. When cutting metal, the tool angle plays a crucial role in determining the geometry of the cutting part of the tool as it penetrates the. Brief geometry of the milling cutter: Every one of these tool shapes have a specific purpose. Cutter Geometry.

From www.robertsonprecision.com

Shear Geometry® Cutting Tools Cutter Geometry The five important angles involved in the making of the millcutter are: Every one of these tool shapes. Double negative, double positive, and positive/ negative. Milling cutter geometry there are three industry standard milling cutter geometries: Cutting tools for metalcutting have many shapes, each of which are described by their angles or geometries. This dimension refers to the diameter of. Cutter Geometry.

From www.youtube.com

Hougen Annular Cutter Stack Cut Geometry Explained GME Supply YouTube Cutter Geometry The cutter diameter is often the first thing machinists look for when choosing a tool for their job. Brief geometry of the milling cutter: Each has certain advantages and disadvantages that must be considered when selecting the right milling cutter for the job. Tool geometries are critical because they directly impact tool life, chip control, edge stability and micro cutting. Cutter Geometry.

From advanceseng.com

Generalized modelling of cutting tool geometries for unified process simulation Advances in Cutter Geometry The cutter diameter is often the first thing machinists look for when choosing a tool for their job. Every one of these tool shapes. The five important angles involved in the making of the millcutter are: Each has certain advantages and disadvantages that must be considered when selecting the right milling cutter for the job. This dimension refers to the. Cutter Geometry.

From www.researchgate.net

Ball end milling cutter geometry. 16 Download Scientific Diagram Cutter Geometry When cutting metal, the tool angle plays a crucial role in determining the geometry of the cutting part of the tool as it penetrates the. Cutting tools for metalcutting have many shapes, each of which are described by their angles or geometries. The five important angles involved in the making of the millcutter are: Tool geometries are critical because they. Cutter Geometry.

From www.researchgate.net

Tool geometry with cutter runout Download Scientific Diagram Cutter Geometry Brief geometry of the milling cutter: Cutter geometry, which describes various radial and axial rake angles. Lead angle, which influences cutting forces and chip thickness. Every one of these tool shapes. Tool geometries are critical because they directly impact tool life, chip control, edge stability and micro cutting characteristics, all of which, in turn, affect overall machining costs. Every one. Cutter Geometry.

From www.machinemfg.com

Lathe Cutting Tool Angles Selection Principle MachineMFG Cutter Geometry Each has certain advantages and disadvantages that must be considered when selecting the right milling cutter for the job. The cutter diameter is often the first thing machinists look for when choosing a tool for their job. The five important angles involved in the making of the millcutter are: Cutting tools for metalcutting have many shapes, each of which are. Cutter Geometry.

From drilling-manual.blogspot.com

PDC Cutter Geometry Cutter Geometry The cutter diameter is often the first thing machinists look for when choosing a tool for their job. Lead angle, which influences cutting forces and chip thickness. Cutting tools for metalcutting have many shapes, each of which are described by their angles or geometries. Milling cutter geometry there are three industry standard milling cutter geometries: This dimension refers to the. Cutter Geometry.

From slideplayer.com

Cutting Tool Technology ppt download Cutter Geometry When cutting metal, the tool angle plays a crucial role in determining the geometry of the cutting part of the tool as it penetrates the. Every one of these tool shapes have a specific purpose in metalcutting. Each has certain advantages and disadvantages that must be considered when selecting the right milling cutter for the job. Tool geometries are critical. Cutter Geometry.

From www.researchgate.net

Geometry model of cutter runout (a) schematic diagram of cutter runout... Download Scientific Cutter Geometry When cutting metal, the tool angle plays a crucial role in determining the geometry of the cutting part of the tool as it penetrates the. This dimension refers to the diameter of the theoretical circle formed by the cutting edges as the tool rotates. Every one of these tool shapes. The cutter diameter is often the first thing machinists look. Cutter Geometry.

From toolnotes.com

Lathe Tools and Toolholders ToolNotes Cutter Geometry The cutter diameter is often the first thing machinists look for when choosing a tool for their job. Lead angle, which influences cutting forces and chip thickness. Brief geometry of the milling cutter: Cutting tools for metalcutting have many shapes, each of which are described by their angles or geometries. Cutting tools for metalcutting have many shapes, each of which. Cutter Geometry.

From www.slideserve.com

PPT Chapter 23 CUTTING TOOL TECHNOLOGY PowerPoint Presentation, free download ID547580 Cutter Geometry Every one of these tool shapes. Each has certain advantages and disadvantages that must be considered when selecting the right milling cutter for the job. Tool geometries are critical because they directly impact tool life, chip control, edge stability and micro cutting characteristics, all of which, in turn, affect overall machining costs. Every one of these tool shapes have a. Cutter Geometry.

From themechanicalengineering.com

Milling Cutter Definition, Types in detail, Geometry Material [Notes & PDF] Cutter Geometry Brief geometry of the milling cutter: This dimension refers to the diameter of the theoretical circle formed by the cutting edges as the tool rotates. The cutter diameter is often the first thing machinists look for when choosing a tool for their job. Cutting tools for metalcutting have many shapes, each of which are described by their angles or geometries.. Cutter Geometry.