Sketch Flush Joint . This is the simplest but potentially least durable. The mortar is flush with the edge of the brickwork. In this type, mortar is pressed hard in the raked joints and by finishing off flush with the edge of masonry units. Jointing refers to finishing joints as brickwork proceeds, while pointing finishes raked joints after completion. Flush joints are used in brick wall construction, when the surface requires plastering and final finishing. The construction of flush joint takes more time and work to make it watertight and water resistant. These joints are mainly used when the surface is to be. Thus the flush joints will be hidden. As this joint has not been compressed by a finishing tool it should not be. There is no curve, dent or indentation in the mortar like you.

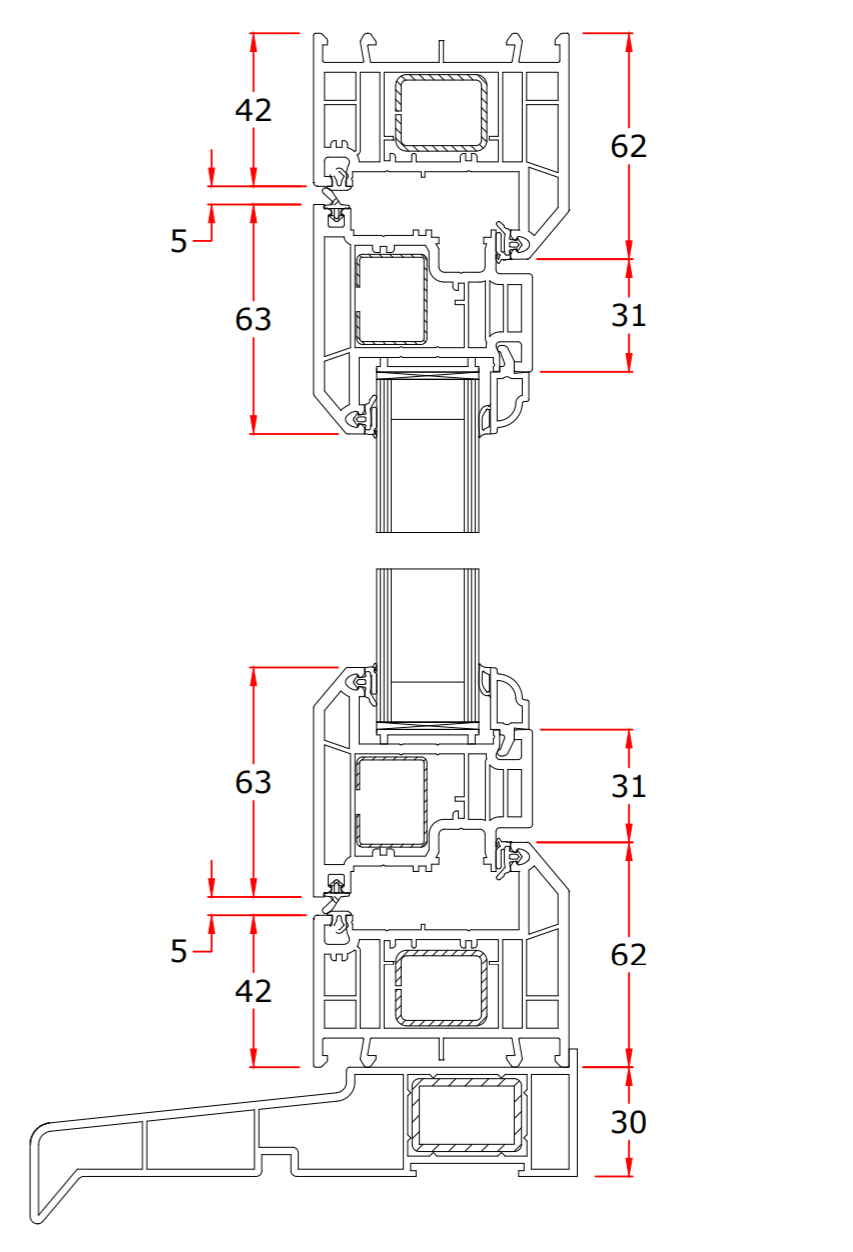

from www.solarwindows.co.uk

Thus the flush joints will be hidden. The construction of flush joint takes more time and work to make it watertight and water resistant. As this joint has not been compressed by a finishing tool it should not be. Flush joints are used in brick wall construction, when the surface requires plastering and final finishing. This is the simplest but potentially least durable. In this type, mortar is pressed hard in the raked joints and by finishing off flush with the edge of masonry units. The mortar is flush with the edge of the brickwork. These joints are mainly used when the surface is to be. Jointing refers to finishing joints as brickwork proceeds, while pointing finishes raked joints after completion. There is no curve, dent or indentation in the mortar like you.

70mm Flush Casement Window Solar Windows

Sketch Flush Joint Flush joints are used in brick wall construction, when the surface requires plastering and final finishing. The mortar is flush with the edge of the brickwork. Jointing refers to finishing joints as brickwork proceeds, while pointing finishes raked joints after completion. The construction of flush joint takes more time and work to make it watertight and water resistant. These joints are mainly used when the surface is to be. Flush joints are used in brick wall construction, when the surface requires plastering and final finishing. There is no curve, dent or indentation in the mortar like you. This is the simplest but potentially least durable. As this joint has not been compressed by a finishing tool it should not be. In this type, mortar is pressed hard in the raked joints and by finishing off flush with the edge of masonry units. Thus the flush joints will be hidden.

From www.9wood.com

2600 Flush Joint Linear 9Wood Sketch Flush Joint Thus the flush joints will be hidden. The mortar is flush with the edge of the brickwork. In this type, mortar is pressed hard in the raked joints and by finishing off flush with the edge of masonry units. As this joint has not been compressed by a finishing tool it should not be. This is the simplest but potentially. Sketch Flush Joint.

From www.pinterest.at

Pin on Drainage Sketch Flush Joint Flush joints are used in brick wall construction, when the surface requires plastering and final finishing. These joints are mainly used when the surface is to be. The construction of flush joint takes more time and work to make it watertight and water resistant. Jointing refers to finishing joints as brickwork proceeds, while pointing finishes raked joints after completion. As. Sketch Flush Joint.

From alugutter.co.uk

Flush Joint Square Aluminium Downpipes 72x72mm Sketch Flush Joint These joints are mainly used when the surface is to be. There is no curve, dent or indentation in the mortar like you. As this joint has not been compressed by a finishing tool it should not be. This is the simplest but potentially least durable. Flush joints are used in brick wall construction, when the surface requires plastering and. Sketch Flush Joint.

From guttercentre.co.uk

Aluminium Flush Joint Rectangular 92.5 Degree Branch Sketch Flush Joint Jointing refers to finishing joints as brickwork proceeds, while pointing finishes raked joints after completion. As this joint has not been compressed by a finishing tool it should not be. In this type, mortar is pressed hard in the raked joints and by finishing off flush with the edge of masonry units. The construction of flush joint takes more time. Sketch Flush Joint.

From www.youtube.com

HOW TO DO RECESSED POINTING [Bricklaying for beginners e.p.11] YouTube Sketch Flush Joint The mortar is flush with the edge of the brickwork. These joints are mainly used when the surface is to be. Thus the flush joints will be hidden. The construction of flush joint takes more time and work to make it watertight and water resistant. In this type, mortar is pressed hard in the raked joints and by finishing off. Sketch Flush Joint.

From cadbull.com

Interior and exterior door joints and structure cad drawing details dwg Sketch Flush Joint Thus the flush joints will be hidden. The construction of flush joint takes more time and work to make it watertight and water resistant. As this joint has not been compressed by a finishing tool it should not be. In this type, mortar is pressed hard in the raked joints and by finishing off flush with the edge of masonry. Sketch Flush Joint.

From flex-craft.com

Flush Joint 50083010 FlexCraft Sketch Flush Joint This is the simplest but potentially least durable. These joints are mainly used when the surface is to be. As this joint has not been compressed by a finishing tool it should not be. In this type, mortar is pressed hard in the raked joints and by finishing off flush with the edge of masonry units. The mortar is flush. Sketch Flush Joint.

From guttercentre.co.uk

Aluminium Flush Joint Rectangular Adjustable Standoff Pipe Clip (30mm Sketch Flush Joint Thus the flush joints will be hidden. In this type, mortar is pressed hard in the raked joints and by finishing off flush with the edge of masonry units. The mortar is flush with the edge of the brickwork. Flush joints are used in brick wall construction, when the surface requires plastering and final finishing. The construction of flush joint. Sketch Flush Joint.

From www.shriramcementindustries.com

Flush Joint RCC HUME Pipes Manufacturer in Shahjapur,Flush Joint RCC Sketch Flush Joint The construction of flush joint takes more time and work to make it watertight and water resistant. The mortar is flush with the edge of the brickwork. There is no curve, dent or indentation in the mortar like you. Flush joints are used in brick wall construction, when the surface requires plastering and final finishing. In this type, mortar is. Sketch Flush Joint.

From www.pinterest.com

Weatherstruck joint sheds water Trowelstruck joint is an invitation Sketch Flush Joint In this type, mortar is pressed hard in the raked joints and by finishing off flush with the edge of masonry units. The construction of flush joint takes more time and work to make it watertight and water resistant. Jointing refers to finishing joints as brickwork proceeds, while pointing finishes raked joints after completion. As this joint has not been. Sketch Flush Joint.

From galenafarms.com

How Do I Assemble My Beehive? Galena Farms Sketch Flush Joint In this type, mortar is pressed hard in the raked joints and by finishing off flush with the edge of masonry units. Jointing refers to finishing joints as brickwork proceeds, while pointing finishes raked joints after completion. There is no curve, dent or indentation in the mortar like you. The mortar is flush with the edge of the brickwork. This. Sketch Flush Joint.

From flex-craft.com

Flush Joint 50083010 FlexCraft Sketch Flush Joint Flush joints are used in brick wall construction, when the surface requires plastering and final finishing. Jointing refers to finishing joints as brickwork proceeds, while pointing finishes raked joints after completion. Thus the flush joints will be hidden. These joints are mainly used when the surface is to be. The mortar is flush with the edge of the brickwork. There. Sketch Flush Joint.

From www.cnexpansionjoint.com

Flush Rubber Wall Expansion Joint Cover(WW,WC) Sketch Flush Joint The mortar is flush with the edge of the brickwork. These joints are mainly used when the surface is to be. Thus the flush joints will be hidden. This is the simplest but potentially least durable. Flush joints are used in brick wall construction, when the surface requires plastering and final finishing. In this type, mortar is pressed hard in. Sketch Flush Joint.

From www.cruxweld.com

Understanding the Welding Symbols [Explained with Diagrams] cruxweld Sketch Flush Joint In this type, mortar is pressed hard in the raked joints and by finishing off flush with the edge of masonry units. The mortar is flush with the edge of the brickwork. Jointing refers to finishing joints as brickwork proceeds, while pointing finishes raked joints after completion. There is no curve, dent or indentation in the mortar like you. This. Sketch Flush Joint.

From www.fgg.uni-lj.si

ESDEP LECTURE NOTE [WG15] Sketch Flush Joint In this type, mortar is pressed hard in the raked joints and by finishing off flush with the edge of masonry units. Thus the flush joints will be hidden. There is no curve, dent or indentation in the mortar like you. These joints are mainly used when the surface is to be. This is the simplest but potentially least durable.. Sketch Flush Joint.

From alugutter.co.uk

Flush Joint Aluminium Downpipe Branches 76mmØ Sketch Flush Joint As this joint has not been compressed by a finishing tool it should not be. Thus the flush joints will be hidden. There is no curve, dent or indentation in the mortar like you. Flush joints are used in brick wall construction, when the surface requires plastering and final finishing. Jointing refers to finishing joints as brickwork proceeds, while pointing. Sketch Flush Joint.

From www.roof2floordrains.co.uk

Aluminium Flush Joint Round 135 Degree Branch Sketch Flush Joint The construction of flush joint takes more time and work to make it watertight and water resistant. The mortar is flush with the edge of the brickwork. These joints are mainly used when the surface is to be. Thus the flush joints will be hidden. Jointing refers to finishing joints as brickwork proceeds, while pointing finishes raked joints after completion.. Sketch Flush Joint.

From www.pinterest.com

Pin on Welding Related Sketch Flush Joint These joints are mainly used when the surface is to be. Thus the flush joints will be hidden. The mortar is flush with the edge of the brickwork. The construction of flush joint takes more time and work to make it watertight and water resistant. As this joint has not been compressed by a finishing tool it should not be.. Sketch Flush Joint.

From gioztyvyw.blob.core.windows.net

Internal Flush Joint at Diane Hayes blog Sketch Flush Joint The construction of flush joint takes more time and work to make it watertight and water resistant. This is the simplest but potentially least durable. Jointing refers to finishing joints as brickwork proceeds, while pointing finishes raked joints after completion. There is no curve, dent or indentation in the mortar like you. Thus the flush joints will be hidden. In. Sketch Flush Joint.

From www.jlconline.com

Joints in Concrete Slabs JLC Online Sketch Flush Joint There is no curve, dent or indentation in the mortar like you. As this joint has not been compressed by a finishing tool it should not be. Thus the flush joints will be hidden. Flush joints are used in brick wall construction, when the surface requires plastering and final finishing. Jointing refers to finishing joints as brickwork proceeds, while pointing. Sketch Flush Joint.

From www.cnexpansionjoint.com

Flush Seismic Floor Expansion Joint With Rubber Strip SFFS Sketch Flush Joint Jointing refers to finishing joints as brickwork proceeds, while pointing finishes raked joints after completion. The construction of flush joint takes more time and work to make it watertight and water resistant. As this joint has not been compressed by a finishing tool it should not be. Flush joints are used in brick wall construction, when the surface requires plastering. Sketch Flush Joint.

From webframes.org

Framing Joints Examples Sketch Flush Joint These joints are mainly used when the surface is to be. The construction of flush joint takes more time and work to make it watertight and water resistant. This is the simplest but potentially least durable. Jointing refers to finishing joints as brickwork proceeds, while pointing finishes raked joints after completion. As this joint has not been compressed by a. Sketch Flush Joint.

From bleckarchitects.com

Exploring Masonry Mortar Joints Bleck & Bleck Architects Sketch Flush Joint This is the simplest but potentially least durable. Thus the flush joints will be hidden. Flush joints are used in brick wall construction, when the surface requires plastering and final finishing. The mortar is flush with the edge of the brickwork. The construction of flush joint takes more time and work to make it watertight and water resistant. As this. Sketch Flush Joint.

From www.indiamart.com

Exterior and Interior Plywood Brown Flush Door, For Home,Office and Sketch Flush Joint This is the simplest but potentially least durable. The mortar is flush with the edge of the brickwork. Thus the flush joints will be hidden. Jointing refers to finishing joints as brickwork proceeds, while pointing finishes raked joints after completion. There is no curve, dent or indentation in the mortar like you. As this joint has not been compressed by. Sketch Flush Joint.

From www.pinterest.com

What is Pointing & Types of Pointing Brick masonry, Stone masonry Sketch Flush Joint This is the simplest but potentially least durable. Thus the flush joints will be hidden. Flush joints are used in brick wall construction, when the surface requires plastering and final finishing. The mortar is flush with the edge of the brickwork. There is no curve, dent or indentation in the mortar like you. These joints are mainly used when the. Sketch Flush Joint.

From www.linkedin.com

How Do You Make a Woodworking Joint? Sketch Flush Joint There is no curve, dent or indentation in the mortar like you. Flush joints are used in brick wall construction, when the surface requires plastering and final finishing. This is the simplest but potentially least durable. The mortar is flush with the edge of the brickwork. Jointing refers to finishing joints as brickwork proceeds, while pointing finishes raked joints after. Sketch Flush Joint.

From civilmart.com.au

Flush Joint (FJ/IJ) Concrete Pipes Civilmart Sketch Flush Joint Flush joints are used in brick wall construction, when the surface requires plastering and final finishing. There is no curve, dent or indentation in the mortar like you. These joints are mainly used when the surface is to be. The mortar is flush with the edge of the brickwork. The construction of flush joint takes more time and work to. Sketch Flush Joint.

From www.9wood.com

2600 Flush Joint Linear 9Wood Sketch Flush Joint In this type, mortar is pressed hard in the raked joints and by finishing off flush with the edge of masonry units. The mortar is flush with the edge of the brickwork. Flush joints are used in brick wall construction, when the surface requires plastering and final finishing. This is the simplest but potentially least durable. Thus the flush joints. Sketch Flush Joint.

From www.pinterest.com.au

Brick Joints Weather struck is good for resist water Flush Sketch Flush Joint The mortar is flush with the edge of the brickwork. Jointing refers to finishing joints as brickwork proceeds, while pointing finishes raked joints after completion. There is no curve, dent or indentation in the mortar like you. In this type, mortar is pressed hard in the raked joints and by finishing off flush with the edge of masonry units. This. Sketch Flush Joint.

From www.solarwindows.co.uk

70mm Flush Casement Window Solar Windows Sketch Flush Joint These joints are mainly used when the surface is to be. There is no curve, dent or indentation in the mortar like you. Thus the flush joints will be hidden. The construction of flush joint takes more time and work to make it watertight and water resistant. The mortar is flush with the edge of the brickwork. As this joint. Sketch Flush Joint.

From alugutter.co.uk

Flush Joint Aluminium Downpipe Jointer 76mmØ Sketch Flush Joint The mortar is flush with the edge of the brickwork. The construction of flush joint takes more time and work to make it watertight and water resistant. In this type, mortar is pressed hard in the raked joints and by finishing off flush with the edge of masonry units. Thus the flush joints will be hidden. This is the simplest. Sketch Flush Joint.

From icpi.org

Permeable Interlocking Concrete Pavement Drawings ICPI Sketch Flush Joint As this joint has not been compressed by a finishing tool it should not be. These joints are mainly used when the surface is to be. Jointing refers to finishing joints as brickwork proceeds, while pointing finishes raked joints after completion. The construction of flush joint takes more time and work to make it watertight and water resistant. This is. Sketch Flush Joint.

From cadbull.com

Flush joint Extruded Aluminum Circular Rainwater Diverters design in Sketch Flush Joint Thus the flush joints will be hidden. These joints are mainly used when the surface is to be. The construction of flush joint takes more time and work to make it watertight and water resistant. This is the simplest but potentially least durable. There is no curve, dent or indentation in the mortar like you. Jointing refers to finishing joints. Sketch Flush Joint.

From learningexpiamc.z21.web.core.windows.net

Welding Symbols Worksheets Sketch Flush Joint As this joint has not been compressed by a finishing tool it should not be. There is no curve, dent or indentation in the mortar like you. The mortar is flush with the edge of the brickwork. In this type, mortar is pressed hard in the raked joints and by finishing off flush with the edge of masonry units. Jointing. Sketch Flush Joint.

From www.tradeindia.com

Flush Joint Cement Pipes Length 2.5 Meter (m) at Best Price in Sketch Flush Joint The mortar is flush with the edge of the brickwork. Jointing refers to finishing joints as brickwork proceeds, while pointing finishes raked joints after completion. In this type, mortar is pressed hard in the raked joints and by finishing off flush with the edge of masonry units. These joints are mainly used when the surface is to be. Thus the. Sketch Flush Joint.