Hydraulic And Pneumatic Systems Used . Maintenance and safety concerns differ, with hydraulics needing more careful handling due to potential leaks and pneumatics being generally safer and easier to maintain. Pros, cons, and key differences. Pneumatics, on the other hand, is used for mechanisms that rely. By definition, hydraulics refers to the use liquids (mostly oil) to transfer power within a system or device. They move relatively slowly but can handle higher loads. The installation is complex and the maintenance cost is high. Pneumatic systems are used for relatively lower forces, faster motion, and where stiffness isn’t required. Air is compressible, which means pneumatic systems are generally less powerful than hydraulic systems but are faster and cleaner. Hydraulic systems are often used for heavier tasks, while pneumatics are preferred for lighter, quicker jobs. Comprehensive comparison of hydraulic vs pneumatic systems: Hydraulic systems are used for high force and where stiffness in position is necessary. Where hydraulic systems leverage the power of liquid under pressure, pneumatic systems use the force of compressed air or gas to do.

from engineeringlearn.com

Hydraulic systems are used for high force and where stiffness in position is necessary. The installation is complex and the maintenance cost is high. Pros, cons, and key differences. Hydraulic systems are often used for heavier tasks, while pneumatics are preferred for lighter, quicker jobs. Pneumatic systems are used for relatively lower forces, faster motion, and where stiffness isn’t required. Air is compressible, which means pneumatic systems are generally less powerful than hydraulic systems but are faster and cleaner. Comprehensive comparison of hydraulic vs pneumatic systems: Maintenance and safety concerns differ, with hydraulics needing more careful handling due to potential leaks and pneumatics being generally safer and easier to maintain. They move relatively slowly but can handle higher loads. Pneumatics, on the other hand, is used for mechanisms that rely.

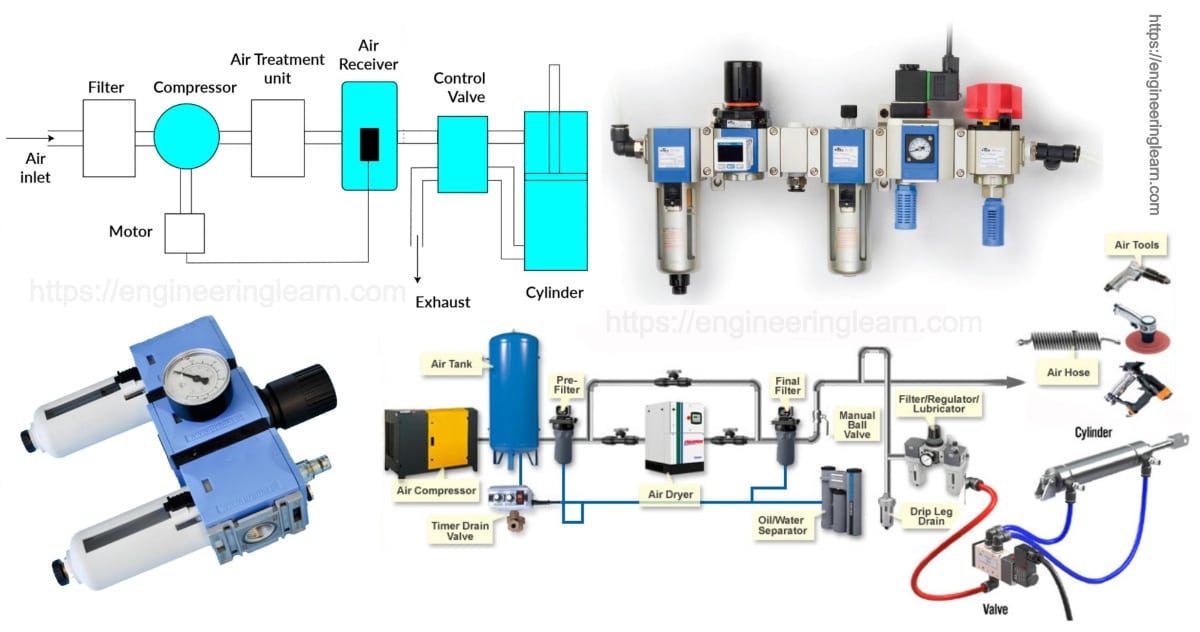

Pneumatic Control System Definition, Components, Working Principle

Hydraulic And Pneumatic Systems Used Where hydraulic systems leverage the power of liquid under pressure, pneumatic systems use the force of compressed air or gas to do. Pneumatics, on the other hand, is used for mechanisms that rely. By definition, hydraulics refers to the use liquids (mostly oil) to transfer power within a system or device. Hydraulic systems are often used for heavier tasks, while pneumatics are preferred for lighter, quicker jobs. Air is compressible, which means pneumatic systems are generally less powerful than hydraulic systems but are faster and cleaner. The installation is complex and the maintenance cost is high. Hydraulic systems are used for high force and where stiffness in position is necessary. Pneumatic systems are used for relatively lower forces, faster motion, and where stiffness isn’t required. Pros, cons, and key differences. They move relatively slowly but can handle higher loads. Where hydraulic systems leverage the power of liquid under pressure, pneumatic systems use the force of compressed air or gas to do. Maintenance and safety concerns differ, with hydraulics needing more careful handling due to potential leaks and pneumatics being generally safer and easier to maintain. Comprehensive comparison of hydraulic vs pneumatic systems:

From trimantec.com

Pneumatic Systems & Components An Industrial Guide Trimantec Hydraulic And Pneumatic Systems Used The installation is complex and the maintenance cost is high. Hydraulic systems are used for high force and where stiffness in position is necessary. Hydraulic systems are often used for heavier tasks, while pneumatics are preferred for lighter, quicker jobs. Pros, cons, and key differences. They move relatively slowly but can handle higher loads. Maintenance and safety concerns differ, with. Hydraulic And Pneumatic Systems Used.

From www.slideshare.net

Introduction to hydraulics and pneumatics Hydraulic And Pneumatic Systems Used Maintenance and safety concerns differ, with hydraulics needing more careful handling due to potential leaks and pneumatics being generally safer and easier to maintain. Hydraulic systems are often used for heavier tasks, while pneumatics are preferred for lighter, quicker jobs. Air is compressible, which means pneumatic systems are generally less powerful than hydraulic systems but are faster and cleaner. Pros,. Hydraulic And Pneumatic Systems Used.

From www.youtube.com

L 01 Introduction of Oil Hydraulics and Pneumatics SystemOil Hydraulic And Pneumatic Systems Used Pros, cons, and key differences. Hydraulic systems are often used for heavier tasks, while pneumatics are preferred for lighter, quicker jobs. Maintenance and safety concerns differ, with hydraulics needing more careful handling due to potential leaks and pneumatics being generally safer and easier to maintain. Where hydraulic systems leverage the power of liquid under pressure, pneumatic systems use the force. Hydraulic And Pneumatic Systems Used.

From www.artofit.org

Introduction to hydraulic and pneumatic system application advantages Hydraulic And Pneumatic Systems Used By definition, hydraulics refers to the use liquids (mostly oil) to transfer power within a system or device. Comprehensive comparison of hydraulic vs pneumatic systems: Pros, cons, and key differences. They move relatively slowly but can handle higher loads. Maintenance and safety concerns differ, with hydraulics needing more careful handling due to potential leaks and pneumatics being generally safer and. Hydraulic And Pneumatic Systems Used.

From www.industrialhydraulicsmachines.ca

Stratford Ontario Industrial Hydraulics & Pneumatics Hydraulic And Pneumatic Systems Used Air is compressible, which means pneumatic systems are generally less powerful than hydraulic systems but are faster and cleaner. Hydraulic systems are used for high force and where stiffness in position is necessary. They move relatively slowly but can handle higher loads. Where hydraulic systems leverage the power of liquid under pressure, pneumatic systems use the force of compressed air. Hydraulic And Pneumatic Systems Used.

From instrumentationtools.com

Hydraulic versus Pneumatic Systems Inst Tools Hydraulic And Pneumatic Systems Used Pneumatics, on the other hand, is used for mechanisms that rely. The installation is complex and the maintenance cost is high. Comprehensive comparison of hydraulic vs pneumatic systems: Hydraulic systems are used for high force and where stiffness in position is necessary. Where hydraulic systems leverage the power of liquid under pressure, pneumatic systems use the force of compressed air. Hydraulic And Pneumatic Systems Used.

From gesrepair.com

What is a Pneumatic System and How Do They Work? GES Hydraulic And Pneumatic Systems Used Where hydraulic systems leverage the power of liquid under pressure, pneumatic systems use the force of compressed air or gas to do. By definition, hydraulics refers to the use liquids (mostly oil) to transfer power within a system or device. Pneumatics, on the other hand, is used for mechanisms that rely. They move relatively slowly but can handle higher loads.. Hydraulic And Pneumatic Systems Used.

From theeargazm.com

Fluid Power Unleashed The Magic of Pneumatic and Hydraulic Systems Hydraulic And Pneumatic Systems Used Pneumatics, on the other hand, is used for mechanisms that rely. Comprehensive comparison of hydraulic vs pneumatic systems: Hydraulic systems are used for high force and where stiffness in position is necessary. Pneumatic systems are used for relatively lower forces, faster motion, and where stiffness isn’t required. Hydraulic systems are often used for heavier tasks, while pneumatics are preferred for. Hydraulic And Pneumatic Systems Used.

From www.netech.edu

Pneumatics Industrial Maintenance Northeast Tech Hydraulic And Pneumatic Systems Used Maintenance and safety concerns differ, with hydraulics needing more careful handling due to potential leaks and pneumatics being generally safer and easier to maintain. By definition, hydraulics refers to the use liquids (mostly oil) to transfer power within a system or device. Pros, cons, and key differences. Hydraulic systems are often used for heavier tasks, while pneumatics are preferred for. Hydraulic And Pneumatic Systems Used.

From www.slideserve.com

PPT Hydraulic & pneumatic systems PowerPoint Presentation, free Hydraulic And Pneumatic Systems Used Comprehensive comparison of hydraulic vs pneumatic systems: Where hydraulic systems leverage the power of liquid under pressure, pneumatic systems use the force of compressed air or gas to do. They move relatively slowly but can handle higher loads. Pros, cons, and key differences. Pneumatic systems are used for relatively lower forces, faster motion, and where stiffness isn’t required. Hydraulic systems. Hydraulic And Pneumatic Systems Used.

From www.circuitdiagram.co

Hydraulic And Pneumatic Circuits Circuit Diagram Hydraulic And Pneumatic Systems Used Comprehensive comparison of hydraulic vs pneumatic systems: By definition, hydraulics refers to the use liquids (mostly oil) to transfer power within a system or device. Air is compressible, which means pneumatic systems are generally less powerful than hydraulic systems but are faster and cleaner. Hydraulic systems are used for high force and where stiffness in position is necessary. Maintenance and. Hydraulic And Pneumatic Systems Used.

From www.powermotiontech.com

CHAPTER 5 Pneumatic and Hydraulic Systems Power & Motion Hydraulic And Pneumatic Systems Used Where hydraulic systems leverage the power of liquid under pressure, pneumatic systems use the force of compressed air or gas to do. Comprehensive comparison of hydraulic vs pneumatic systems: Hydraulic systems are often used for heavier tasks, while pneumatics are preferred for lighter, quicker jobs. By definition, hydraulics refers to the use liquids (mostly oil) to transfer power within a. Hydraulic And Pneumatic Systems Used.

From www.iqsdirectory.com

Hydraulics and Pneumatics Advantages, Types Of, Uses Hydraulic And Pneumatic Systems Used Comprehensive comparison of hydraulic vs pneumatic systems: Air is compressible, which means pneumatic systems are generally less powerful than hydraulic systems but are faster and cleaner. Where hydraulic systems leverage the power of liquid under pressure, pneumatic systems use the force of compressed air or gas to do. Hydraulic systems are used for high force and where stiffness in position. Hydraulic And Pneumatic Systems Used.

From blog.slsbearings.com

Pneumatic vs Hydraulic Systems What's the Difference? Hydraulic And Pneumatic Systems Used Comprehensive comparison of hydraulic vs pneumatic systems: Pneumatics, on the other hand, is used for mechanisms that rely. Hydraulic systems are used for high force and where stiffness in position is necessary. By definition, hydraulics refers to the use liquids (mostly oil) to transfer power within a system or device. Hydraulic systems are often used for heavier tasks, while pneumatics. Hydraulic And Pneumatic Systems Used.

From amatrol.com

Hydraulic and Pneumatic Systems HandsOn Fluid Power Training Amatrol Hydraulic And Pneumatic Systems Used Hydraulic systems are used for high force and where stiffness in position is necessary. The installation is complex and the maintenance cost is high. Pneumatics, on the other hand, is used for mechanisms that rely. Comprehensive comparison of hydraulic vs pneumatic systems: Pros, cons, and key differences. Air is compressible, which means pneumatic systems are generally less powerful than hydraulic. Hydraulic And Pneumatic Systems Used.

From www.iqsdirectory.com

Hydraulics and Pneumatics Advantages, Types Of, Uses Hydraulic And Pneumatic Systems Used Pneumatics, on the other hand, is used for mechanisms that rely. Pros, cons, and key differences. Hydraulic systems are often used for heavier tasks, while pneumatics are preferred for lighter, quicker jobs. Pneumatic systems are used for relatively lower forces, faster motion, and where stiffness isn’t required. Hydraulic systems are used for high force and where stiffness in position is. Hydraulic And Pneumatic Systems Used.

From www.youtube.com

Difference Between Hydraulic And Pneumatic System YouTube Hydraulic And Pneumatic Systems Used Pros, cons, and key differences. The installation is complex and the maintenance cost is high. Hydraulic systems are often used for heavier tasks, while pneumatics are preferred for lighter, quicker jobs. Maintenance and safety concerns differ, with hydraulics needing more careful handling due to potential leaks and pneumatics being generally safer and easier to maintain. Air is compressible, which means. Hydraulic And Pneumatic Systems Used.

From engineeringlearn.com

Hydraulic and Pneumatic What is Hydraulics? What is Pneumatics Hydraulic And Pneumatic Systems Used The installation is complex and the maintenance cost is high. Maintenance and safety concerns differ, with hydraulics needing more careful handling due to potential leaks and pneumatics being generally safer and easier to maintain. Comprehensive comparison of hydraulic vs pneumatic systems: Hydraulic systems are often used for heavier tasks, while pneumatics are preferred for lighter, quicker jobs. Hydraulic systems are. Hydraulic And Pneumatic Systems Used.

From www.youtube.com

Lecture No.1Unit1INTRODUCTION TO HYDRAULICS & PNEUMATICSTopic1 Hydraulic And Pneumatic Systems Used Pros, cons, and key differences. Pneumatic systems are used for relatively lower forces, faster motion, and where stiffness isn’t required. They move relatively slowly but can handle higher loads. Maintenance and safety concerns differ, with hydraulics needing more careful handling due to potential leaks and pneumatics being generally safer and easier to maintain. Air is compressible, which means pneumatic systems. Hydraulic And Pneumatic Systems Used.

From www.youtube.com

Pneumatic and Hydraulic Systems An Introduction YouTube Hydraulic And Pneumatic Systems Used Pros, cons, and key differences. Maintenance and safety concerns differ, with hydraulics needing more careful handling due to potential leaks and pneumatics being generally safer and easier to maintain. Pneumatic systems are used for relatively lower forces, faster motion, and where stiffness isn’t required. Pneumatics, on the other hand, is used for mechanisms that rely. Where hydraulic systems leverage the. Hydraulic And Pneumatic Systems Used.

From spunkysprout.com

What are The Basic Equipment Parts of a Pneumatic System? Spunky Sprout Hydraulic And Pneumatic Systems Used They move relatively slowly but can handle higher loads. Hydraulic systems are used for high force and where stiffness in position is necessary. Pros, cons, and key differences. Pneumatics, on the other hand, is used for mechanisms that rely. Maintenance and safety concerns differ, with hydraulics needing more careful handling due to potential leaks and pneumatics being generally safer and. Hydraulic And Pneumatic Systems Used.

From www.youtube.com

Hydraulic and Pneumatic Systems Lec 7 YouTube Hydraulic And Pneumatic Systems Used Comprehensive comparison of hydraulic vs pneumatic systems: Pneumatics, on the other hand, is used for mechanisms that rely. Pneumatic systems are used for relatively lower forces, faster motion, and where stiffness isn’t required. Where hydraulic systems leverage the power of liquid under pressure, pneumatic systems use the force of compressed air or gas to do. Maintenance and safety concerns differ,. Hydraulic And Pneumatic Systems Used.

From library.automationdirect.com

Pneumatics for Mechanical Motion Library.AutomationDirect Hydraulic And Pneumatic Systems Used Air is compressible, which means pneumatic systems are generally less powerful than hydraulic systems but are faster and cleaner. Pneumatic systems are used for relatively lower forces, faster motion, and where stiffness isn’t required. Comprehensive comparison of hydraulic vs pneumatic systems: Hydraulic systems are often used for heavier tasks, while pneumatics are preferred for lighter, quicker jobs. Pneumatics, on the. Hydraulic And Pneumatic Systems Used.

From easy-learning-academy.blogspot.com

Comparison of hydraulic and pneumatic systems Hydraulic And Pneumatic Systems Used The installation is complex and the maintenance cost is high. Comprehensive comparison of hydraulic vs pneumatic systems: Air is compressible, which means pneumatic systems are generally less powerful than hydraulic systems but are faster and cleaner. By definition, hydraulics refers to the use liquids (mostly oil) to transfer power within a system or device. Pneumatics, on the other hand, is. Hydraulic And Pneumatic Systems Used.

From www.vrogue.co

Common Symbols Used In Pneumatic Systems And Instrume vrogue.co Hydraulic And Pneumatic Systems Used Hydraulic systems are used for high force and where stiffness in position is necessary. Where hydraulic systems leverage the power of liquid under pressure, pneumatic systems use the force of compressed air or gas to do. Comprehensive comparison of hydraulic vs pneumatic systems: Maintenance and safety concerns differ, with hydraulics needing more careful handling due to potential leaks and pneumatics. Hydraulic And Pneumatic Systems Used.

From www.researchgate.net

Comparison between hydraulic and pneumatic systems Download Hydraulic And Pneumatic Systems Used Maintenance and safety concerns differ, with hydraulics needing more careful handling due to potential leaks and pneumatics being generally safer and easier to maintain. They move relatively slowly but can handle higher loads. Comprehensive comparison of hydraulic vs pneumatic systems: The installation is complex and the maintenance cost is high. Where hydraulic systems leverage the power of liquid under pressure,. Hydraulic And Pneumatic Systems Used.

From www.iqsdirectory.com

Hydraulics and Pneumatics Advantages, Types Of, Uses Hydraulic And Pneumatic Systems Used Air is compressible, which means pneumatic systems are generally less powerful than hydraulic systems but are faster and cleaner. Where hydraulic systems leverage the power of liquid under pressure, pneumatic systems use the force of compressed air or gas to do. Comprehensive comparison of hydraulic vs pneumatic systems: Maintenance and safety concerns differ, with hydraulics needing more careful handling due. Hydraulic And Pneumatic Systems Used.

From trdsf.com

Hydraulic vs. Pneumatic Systems TRADESAFE Hydraulic And Pneumatic Systems Used By definition, hydraulics refers to the use liquids (mostly oil) to transfer power within a system or device. Where hydraulic systems leverage the power of liquid under pressure, pneumatic systems use the force of compressed air or gas to do. Hydraulic systems are used for high force and where stiffness in position is necessary. Comprehensive comparison of hydraulic vs pneumatic. Hydraulic And Pneumatic Systems Used.

From www.youtube.com

Grade 9 TechnologyPneumatic and Hydraulic systems (Syringe system Hydraulic And Pneumatic Systems Used Maintenance and safety concerns differ, with hydraulics needing more careful handling due to potential leaks and pneumatics being generally safer and easier to maintain. Hydraulic systems are often used for heavier tasks, while pneumatics are preferred for lighter, quicker jobs. Hydraulic systems are used for high force and where stiffness in position is necessary. Air is compressible, which means pneumatic. Hydraulic And Pneumatic Systems Used.

From capraengineering.com

Products & Services Capra Engineering Hydraulic And Pneumatic Systems Used They move relatively slowly but can handle higher loads. By definition, hydraulics refers to the use liquids (mostly oil) to transfer power within a system or device. Maintenance and safety concerns differ, with hydraulics needing more careful handling due to potential leaks and pneumatics being generally safer and easier to maintain. The installation is complex and the maintenance cost is. Hydraulic And Pneumatic Systems Used.

From amw-welding.com

Hydraulic and Pneumatic Systems Welding Equipment & Accessories Hydraulic And Pneumatic Systems Used Pros, cons, and key differences. Comprehensive comparison of hydraulic vs pneumatic systems: Pneumatic systems are used for relatively lower forces, faster motion, and where stiffness isn’t required. The installation is complex and the maintenance cost is high. They move relatively slowly but can handle higher loads. Where hydraulic systems leverage the power of liquid under pressure, pneumatic systems use the. Hydraulic And Pneumatic Systems Used.

From engineeringlearn.com

Pneumatic Control System Definition, Components, Working Principle Hydraulic And Pneumatic Systems Used Hydraulic systems are used for high force and where stiffness in position is necessary. Air is compressible, which means pneumatic systems are generally less powerful than hydraulic systems but are faster and cleaner. They move relatively slowly but can handle higher loads. Maintenance and safety concerns differ, with hydraulics needing more careful handling due to potential leaks and pneumatics being. Hydraulic And Pneumatic Systems Used.

From www.youtube.com

Basic Electrical Device Used In Hydraulic And Pneumatic System Part 2 Hydraulic And Pneumatic Systems Used Pneumatics, on the other hand, is used for mechanisms that rely. Where hydraulic systems leverage the power of liquid under pressure, pneumatic systems use the force of compressed air or gas to do. By definition, hydraulics refers to the use liquids (mostly oil) to transfer power within a system or device. Comprehensive comparison of hydraulic vs pneumatic systems: Hydraulic systems. Hydraulic And Pneumatic Systems Used.

From www.youtube.com

Difference between pneumatic and hydraulic system YouTube Hydraulic And Pneumatic Systems Used Hydraulic systems are used for high force and where stiffness in position is necessary. Pros, cons, and key differences. By definition, hydraulics refers to the use liquids (mostly oil) to transfer power within a system or device. The installation is complex and the maintenance cost is high. Air is compressible, which means pneumatic systems are generally less powerful than hydraulic. Hydraulic And Pneumatic Systems Used.