Aluminum Vs Zinc Strength . If you need a strong yet lightweight metal alloy that won’t corrode easily in harsh environments, then aluminium could be an ideal choice for you. While zinc may not be as strong as. Other alloying elements include magnesium. One key consideration when choosing between zinc and aluminum alloys is their strength and durability. However, if you need something that’s easy to shape or weld into intricate designs, then zinc may be your best bet. While zinc alloy excels in corrosion resistance and longevity outdoors, aluminum's strength and resilience make it a reliable choice for demanding environments such as. Zinc offers advantages such as high density, corrosion resistance, and low melting point, while aluminum provides lightweight, high strength, and superior thermal. Aluminium alloys are based on aluminium, in which the main alloying elements.

from batesvilleproducts.com

One key consideration when choosing between zinc and aluminum alloys is their strength and durability. Other alloying elements include magnesium. Zinc offers advantages such as high density, corrosion resistance, and low melting point, while aluminum provides lightweight, high strength, and superior thermal. If you need a strong yet lightweight metal alloy that won’t corrode easily in harsh environments, then aluminium could be an ideal choice for you. However, if you need something that’s easy to shape or weld into intricate designs, then zinc may be your best bet. While zinc may not be as strong as. Aluminium alloys are based on aluminium, in which the main alloying elements. While zinc alloy excels in corrosion resistance and longevity outdoors, aluminum's strength and resilience make it a reliable choice for demanding environments such as.

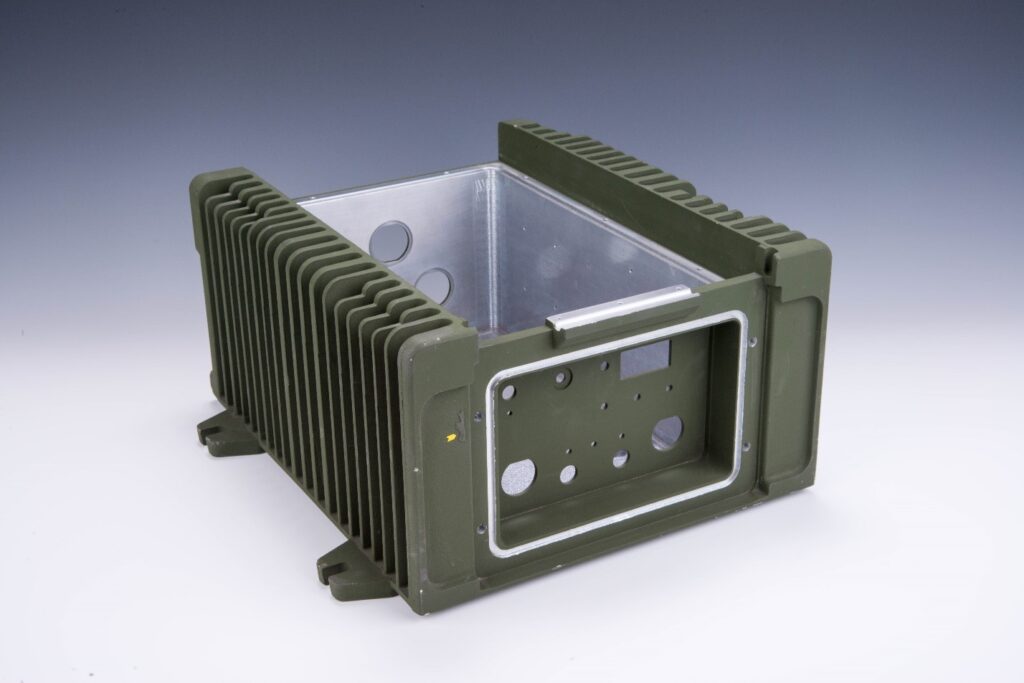

Aluminum vs. Zinc Casting Batesville products, inc.

Aluminum Vs Zinc Strength One key consideration when choosing between zinc and aluminum alloys is their strength and durability. While zinc may not be as strong as. One key consideration when choosing between zinc and aluminum alloys is their strength and durability. Zinc offers advantages such as high density, corrosion resistance, and low melting point, while aluminum provides lightweight, high strength, and superior thermal. However, if you need something that’s easy to shape or weld into intricate designs, then zinc may be your best bet. If you need a strong yet lightweight metal alloy that won’t corrode easily in harsh environments, then aluminium could be an ideal choice for you. While zinc alloy excels in corrosion resistance and longevity outdoors, aluminum's strength and resilience make it a reliable choice for demanding environments such as. Other alloying elements include magnesium. Aluminium alloys are based on aluminium, in which the main alloying elements.

From www.tfgusa.com

Aluminum Die Casting vs. Zinc Die Casting The Federal Group USA Aluminum Vs Zinc Strength However, if you need something that’s easy to shape or weld into intricate designs, then zinc may be your best bet. Aluminium alloys are based on aluminium, in which the main alloying elements. If you need a strong yet lightweight metal alloy that won’t corrode easily in harsh environments, then aluminium could be an ideal choice for you. Other alloying. Aluminum Vs Zinc Strength.

From www.pioneermetal.com

Zinc Plating vs. Zinc Flake Coating Processes Explained Aluminum Vs Zinc Strength If you need a strong yet lightweight metal alloy that won’t corrode easily in harsh environments, then aluminium could be an ideal choice for you. Aluminium alloys are based on aluminium, in which the main alloying elements. While zinc alloy excels in corrosion resistance and longevity outdoors, aluminum's strength and resilience make it a reliable choice for demanding environments such. Aluminum Vs Zinc Strength.

From www.thefabricator.com

Getting to know more about the metal you are forming Aluminum Vs Zinc Strength While zinc alloy excels in corrosion resistance and longevity outdoors, aluminum's strength and resilience make it a reliable choice for demanding environments such as. One key consideration when choosing between zinc and aluminum alloys is their strength and durability. While zinc may not be as strong as. If you need a strong yet lightweight metal alloy that won’t corrode easily. Aluminum Vs Zinc Strength.

From www.anodeoutlet.co.uk

Anode Help Guide Anode Outlet Aluminum Vs Zinc Strength One key consideration when choosing between zinc and aluminum alloys is their strength and durability. Zinc offers advantages such as high density, corrosion resistance, and low melting point, while aluminum provides lightweight, high strength, and superior thermal. Other alloying elements include magnesium. While zinc may not be as strong as. Aluminium alloys are based on aluminium, in which the main. Aluminum Vs Zinc Strength.

From paceind.com

ZincAluminum Alloy Pace Industries Aluminum Vs Zinc Strength One key consideration when choosing between zinc and aluminum alloys is their strength and durability. If you need a strong yet lightweight metal alloy that won’t corrode easily in harsh environments, then aluminium could be an ideal choice for you. Other alloying elements include magnesium. Zinc offers advantages such as high density, corrosion resistance, and low melting point, while aluminum. Aluminum Vs Zinc Strength.

From learninglibzeberhardt.z13.web.core.windows.net

Yield Strength Of Aluminium Alloy Aluminum Vs Zinc Strength While zinc alloy excels in corrosion resistance and longevity outdoors, aluminum's strength and resilience make it a reliable choice for demanding environments such as. If you need a strong yet lightweight metal alloy that won’t corrode easily in harsh environments, then aluminium could be an ideal choice for you. One key consideration when choosing between zinc and aluminum alloys is. Aluminum Vs Zinc Strength.

From leadrp.net

Metal Strength Chart A Basic Guide To Metal Strength You Must Know LEADRP Rapid Prototyping Aluminum Vs Zinc Strength If you need a strong yet lightweight metal alloy that won’t corrode easily in harsh environments, then aluminium could be an ideal choice for you. Zinc offers advantages such as high density, corrosion resistance, and low melting point, while aluminum provides lightweight, high strength, and superior thermal. While zinc alloy excels in corrosion resistance and longevity outdoors, aluminum's strength and. Aluminum Vs Zinc Strength.

From aj-racks.com

Aluminum Vs. Steel An Infographic A & J Manufacturing Co. Aluminum Vs Zinc Strength If you need a strong yet lightweight metal alloy that won’t corrode easily in harsh environments, then aluminium could be an ideal choice for you. However, if you need something that’s easy to shape or weld into intricate designs, then zinc may be your best bet. Other alloying elements include magnesium. One key consideration when choosing between zinc and aluminum. Aluminum Vs Zinc Strength.

From oldmymages.blogspot.com

Sheet Metal Tensile Strength Chart Oldmymages Aluminum Vs Zinc Strength While zinc may not be as strong as. While zinc alloy excels in corrosion resistance and longevity outdoors, aluminum's strength and resilience make it a reliable choice for demanding environments such as. Aluminium alloys are based on aluminium, in which the main alloying elements. Other alloying elements include magnesium. One key consideration when choosing between zinc and aluminum alloys is. Aluminum Vs Zinc Strength.

From www.aludiecasting.com

Zinc vs. Aluminum Die Casting A Comprehensive Comparison (2024) China Die Casting Aluminum Aluminum Vs Zinc Strength While zinc may not be as strong as. However, if you need something that’s easy to shape or weld into intricate designs, then zinc may be your best bet. Aluminium alloys are based on aluminium, in which the main alloying elements. One key consideration when choosing between zinc and aluminum alloys is their strength and durability. If you need a. Aluminum Vs Zinc Strength.

From www.anodeoutlet.co.uk

Aluminium Versus Zinc Anodes Anode Outlet Aluminum Vs Zinc Strength Other alloying elements include magnesium. Aluminium alloys are based on aluminium, in which the main alloying elements. While zinc alloy excels in corrosion resistance and longevity outdoors, aluminum's strength and resilience make it a reliable choice for demanding environments such as. One key consideration when choosing between zinc and aluminum alloys is their strength and durability. While zinc may not. Aluminum Vs Zinc Strength.

From zincroofs.co.uk

Zinc vs Aluminium vs Steel Roofing Systems ELC Hard Metals Aluminum Vs Zinc Strength However, if you need something that’s easy to shape or weld into intricate designs, then zinc may be your best bet. While zinc alloy excels in corrosion resistance and longevity outdoors, aluminum's strength and resilience make it a reliable choice for demanding environments such as. Other alloying elements include magnesium. One key consideration when choosing between zinc and aluminum alloys. Aluminum Vs Zinc Strength.

From www.ibcmetalgroup.com

The difference between galvanized steel and ZAM ZincAluminiumMagnesium coated steel Aluminum Vs Zinc Strength Other alloying elements include magnesium. Aluminium alloys are based on aluminium, in which the main alloying elements. However, if you need something that’s easy to shape or weld into intricate designs, then zinc may be your best bet. If you need a strong yet lightweight metal alloy that won’t corrode easily in harsh environments, then aluminium could be an ideal. Aluminum Vs Zinc Strength.

From blog.thepipingmart.com

Aluminium 2007 vs 7075 What's the Difference Aluminum Vs Zinc Strength If you need a strong yet lightweight metal alloy that won’t corrode easily in harsh environments, then aluminium could be an ideal choice for you. Other alloying elements include magnesium. While zinc alloy excels in corrosion resistance and longevity outdoors, aluminum's strength and resilience make it a reliable choice for demanding environments such as. However, if you need something that’s. Aluminum Vs Zinc Strength.

From www.researchgate.net

(PDF) Corrosion Resistance of Zinc/4Aluminum and Zinc/7Aluminum Alloy Coatings Compared to Aluminum Vs Zinc Strength If you need a strong yet lightweight metal alloy that won’t corrode easily in harsh environments, then aluminium could be an ideal choice for you. While zinc may not be as strong as. Other alloying elements include magnesium. While zinc alloy excels in corrosion resistance and longevity outdoors, aluminum's strength and resilience make it a reliable choice for demanding environments. Aluminum Vs Zinc Strength.

From www.scribd.com

55 AluminumZinc Alloy Coated Steel Grade Data Sheets Manganese Steel Aluminum Vs Zinc Strength While zinc alloy excels in corrosion resistance and longevity outdoors, aluminum's strength and resilience make it a reliable choice for demanding environments such as. However, if you need something that’s easy to shape or weld into intricate designs, then zinc may be your best bet. One key consideration when choosing between zinc and aluminum alloys is their strength and durability.. Aluminum Vs Zinc Strength.

From www.researchgate.net

The phase diagram of zinc aluminum alloys Download Scientific Diagram Aluminum Vs Zinc Strength However, if you need something that’s easy to shape or weld into intricate designs, then zinc may be your best bet. If you need a strong yet lightweight metal alloy that won’t corrode easily in harsh environments, then aluminium could be an ideal choice for you. While zinc alloy excels in corrosion resistance and longevity outdoors, aluminum's strength and resilience. Aluminum Vs Zinc Strength.

From blog.thepipingmart.com

Zinc vs. Aluminium What's the Difference Aluminum Vs Zinc Strength One key consideration when choosing between zinc and aluminum alloys is their strength and durability. While zinc may not be as strong as. Aluminium alloys are based on aluminium, in which the main alloying elements. Other alloying elements include magnesium. However, if you need something that’s easy to shape or weld into intricate designs, then zinc may be your best. Aluminum Vs Zinc Strength.

From www.smetals.co.uk

Steel vs. Aluminium Decoding the StrengthtoWeight Ratio for Optimal Material Selection Aluminum Vs Zinc Strength If you need a strong yet lightweight metal alloy that won’t corrode easily in harsh environments, then aluminium could be an ideal choice for you. Other alloying elements include magnesium. While zinc may not be as strong as. One key consideration when choosing between zinc and aluminum alloys is their strength and durability. While zinc alloy excels in corrosion resistance. Aluminum Vs Zinc Strength.

From www.youtube.com

Die Cast Identifying Zinc VS Aluminum For Casting or Scrapping YouTube Aluminum Vs Zinc Strength However, if you need something that’s easy to shape or weld into intricate designs, then zinc may be your best bet. Other alloying elements include magnesium. Aluminium alloys are based on aluminium, in which the main alloying elements. If you need a strong yet lightweight metal alloy that won’t corrode easily in harsh environments, then aluminium could be an ideal. Aluminum Vs Zinc Strength.

From blog.thepipingmart.com

Stainless Steel vs. Aluminum Strength Aluminum Vs Zinc Strength While zinc may not be as strong as. While zinc alloy excels in corrosion resistance and longevity outdoors, aluminum's strength and resilience make it a reliable choice for demanding environments such as. However, if you need something that’s easy to shape or weld into intricate designs, then zinc may be your best bet. Aluminium alloys are based on aluminium, in. Aluminum Vs Zinc Strength.

From flyingprecision.com

Aluminum vs Mild Steel A Comparative Analysis of Mechanical Properties and Uses Flying Precision Aluminum Vs Zinc Strength One key consideration when choosing between zinc and aluminum alloys is their strength and durability. Zinc offers advantages such as high density, corrosion resistance, and low melting point, while aluminum provides lightweight, high strength, and superior thermal. Aluminium alloys are based on aluminium, in which the main alloying elements. However, if you need something that’s easy to shape or weld. Aluminum Vs Zinc Strength.

From batesvilleproducts.com

Aluminum vs. Zinc Casting Batesville products, inc. Aluminum Vs Zinc Strength Other alloying elements include magnesium. While zinc may not be as strong as. Zinc offers advantages such as high density, corrosion resistance, and low melting point, while aluminum provides lightweight, high strength, and superior thermal. If you need a strong yet lightweight metal alloy that won’t corrode easily in harsh environments, then aluminium could be an ideal choice for you.. Aluminum Vs Zinc Strength.

From www.iqsdirectory.com

Types of Aluminum Types, Uses, Features and Benefits Aluminum Vs Zinc Strength Aluminium alloys are based on aluminium, in which the main alloying elements. While zinc alloy excels in corrosion resistance and longevity outdoors, aluminum's strength and resilience make it a reliable choice for demanding environments such as. Zinc offers advantages such as high density, corrosion resistance, and low melting point, while aluminum provides lightweight, high strength, and superior thermal. While zinc. Aluminum Vs Zinc Strength.

From blog.thepipingmart.com

Comparing the Strength of Aluminium vs Steel Aluminum Vs Zinc Strength If you need a strong yet lightweight metal alloy that won’t corrode easily in harsh environments, then aluminium could be an ideal choice for you. One key consideration when choosing between zinc and aluminum alloys is their strength and durability. Other alloying elements include magnesium. While zinc alloy excels in corrosion resistance and longevity outdoors, aluminum's strength and resilience make. Aluminum Vs Zinc Strength.

From www.researchgate.net

Ultimate strength and strain of aluminum and Alalloy Download Table Aluminum Vs Zinc Strength However, if you need something that’s easy to shape or weld into intricate designs, then zinc may be your best bet. While zinc alloy excels in corrosion resistance and longevity outdoors, aluminum's strength and resilience make it a reliable choice for demanding environments such as. One key consideration when choosing between zinc and aluminum alloys is their strength and durability.. Aluminum Vs Zinc Strength.

From batesvilleproducts.com

Aluminum vs. Zinc Casting Batesville products, inc. Aluminum Vs Zinc Strength Zinc offers advantages such as high density, corrosion resistance, and low melting point, while aluminum provides lightweight, high strength, and superior thermal. If you need a strong yet lightweight metal alloy that won’t corrode easily in harsh environments, then aluminium could be an ideal choice for you. Other alloying elements include magnesium. Aluminium alloys are based on aluminium, in which. Aluminum Vs Zinc Strength.

From sendcutsend.com

How to Identify the Difference in Aluminum Alloys Aluminum Vs Zinc Strength Aluminium alloys are based on aluminium, in which the main alloying elements. While zinc may not be as strong as. If you need a strong yet lightweight metal alloy that won’t corrode easily in harsh environments, then aluminium could be an ideal choice for you. Zinc offers advantages such as high density, corrosion resistance, and low melting point, while aluminum. Aluminum Vs Zinc Strength.

From www.gabrian.com

What is Ductility in Metals? Is it an Advantage for Alumium? Aluminum Vs Zinc Strength While zinc alloy excels in corrosion resistance and longevity outdoors, aluminum's strength and resilience make it a reliable choice for demanding environments such as. If you need a strong yet lightweight metal alloy that won’t corrode easily in harsh environments, then aluminium could be an ideal choice for you. However, if you need something that’s easy to shape or weld. Aluminum Vs Zinc Strength.

From www.researchgate.net

Comparison of yield strength of magnesium, aluminum, zinc, and titanium... Download Scientific Aluminum Vs Zinc Strength Other alloying elements include magnesium. While zinc alloy excels in corrosion resistance and longevity outdoors, aluminum's strength and resilience make it a reliable choice for demanding environments such as. Zinc offers advantages such as high density, corrosion resistance, and low melting point, while aluminum provides lightweight, high strength, and superior thermal. If you need a strong yet lightweight metal alloy. Aluminum Vs Zinc Strength.

From blog.thepipingmart.com

What makes Aluminium and Zinc SelfProtective Metals? Aluminum Vs Zinc Strength While zinc alloy excels in corrosion resistance and longevity outdoors, aluminum's strength and resilience make it a reliable choice for demanding environments such as. If you need a strong yet lightweight metal alloy that won’t corrode easily in harsh environments, then aluminium could be an ideal choice for you. One key consideration when choosing between zinc and aluminum alloys is. Aluminum Vs Zinc Strength.

From www.researchgate.net

Stressstrain relationships for typical steel and aluminium alloys. Download Scientific Diagram Aluminum Vs Zinc Strength Other alloying elements include magnesium. However, if you need something that’s easy to shape or weld into intricate designs, then zinc may be your best bet. If you need a strong yet lightweight metal alloy that won’t corrode easily in harsh environments, then aluminium could be an ideal choice for you. One key consideration when choosing between zinc and aluminum. Aluminum Vs Zinc Strength.

From www.seicastings.com

What Is The Difference Between Zinc And Aluminum Alloys? SEI CASTINGS Aluminum Vs Zinc Strength Aluminium alloys are based on aluminium, in which the main alloying elements. While zinc may not be as strong as. While zinc alloy excels in corrosion resistance and longevity outdoors, aluminum's strength and resilience make it a reliable choice for demanding environments such as. Other alloying elements include magnesium. If you need a strong yet lightweight metal alloy that won’t. Aluminum Vs Zinc Strength.

From www.mdpi.com

Materials Free FullText Thermal Stability of Aluminum Alloys Aluminum Vs Zinc Strength Aluminium alloys are based on aluminium, in which the main alloying elements. If you need a strong yet lightweight metal alloy that won’t corrode easily in harsh environments, then aluminium could be an ideal choice for you. Other alloying elements include magnesium. Zinc offers advantages such as high density, corrosion resistance, and low melting point, while aluminum provides lightweight, high. Aluminum Vs Zinc Strength.

From www.extreme-bolt.com

Fastener Ultimate Tensile Strength vs. Yield Strength Which is More Important? Extreme bolt Aluminum Vs Zinc Strength While zinc may not be as strong as. Zinc offers advantages such as high density, corrosion resistance, and low melting point, while aluminum provides lightweight, high strength, and superior thermal. Aluminium alloys are based on aluminium, in which the main alloying elements. However, if you need something that’s easy to shape or weld into intricate designs, then zinc may be. Aluminum Vs Zinc Strength.