Cutting Tools Manufacturing Process . Common cutting processes include sawing, shaping, broaching, drilling, grinding, turning, and milling. the cutting tool is the critical link between raw materials and the finished product. Machining refers to using machines to process materials according to the. Process planning is crucial to minimize setup changes and optimize cutting operations. the process of tool and die manufacturing entails cutting and shaping metal, as well as other materials, using tools, and employing metal forms called dies. cutting is manufacturing by removal of material (din 8580; An introduction to machine tools. The cutting process is a subtractive metalworking technique that divides a metal workpiece into multiple parts.

from www.market-prospects.com

the process of tool and die manufacturing entails cutting and shaping metal, as well as other materials, using tools, and employing metal forms called dies. the cutting tool is the critical link between raw materials and the finished product. Machining refers to using machines to process materials according to the. cutting is manufacturing by removal of material (din 8580; An introduction to machine tools. Common cutting processes include sawing, shaping, broaching, drilling, grinding, turning, and milling. The cutting process is a subtractive metalworking technique that divides a metal workpiece into multiple parts. Process planning is crucial to minimize setup changes and optimize cutting operations.

What is the Selection of Metal Cutting Machine Tools for Hardware

Cutting Tools Manufacturing Process The cutting process is a subtractive metalworking technique that divides a metal workpiece into multiple parts. cutting is manufacturing by removal of material (din 8580; An introduction to machine tools. Machining refers to using machines to process materials according to the. Common cutting processes include sawing, shaping, broaching, drilling, grinding, turning, and milling. Process planning is crucial to minimize setup changes and optimize cutting operations. the process of tool and die manufacturing entails cutting and shaping metal, as well as other materials, using tools, and employing metal forms called dies. the cutting tool is the critical link between raw materials and the finished product. The cutting process is a subtractive metalworking technique that divides a metal workpiece into multiple parts.

From www.slideserve.com

PPT Manufacturing Processes lab I Cutting tools PowerPoint Cutting Tools Manufacturing Process the process of tool and die manufacturing entails cutting and shaping metal, as well as other materials, using tools, and employing metal forms called dies. Process planning is crucial to minimize setup changes and optimize cutting operations. Machining refers to using machines to process materials according to the. the cutting tool is the critical link between raw materials. Cutting Tools Manufacturing Process.

From www.slideserve.com

PPT Manufacturing Processes lab I Milling Machine 1 PowerPoint Cutting Tools Manufacturing Process the process of tool and die manufacturing entails cutting and shaping metal, as well as other materials, using tools, and employing metal forms called dies. the cutting tool is the critical link between raw materials and the finished product. Common cutting processes include sawing, shaping, broaching, drilling, grinding, turning, and milling. cutting is manufacturing by removal of. Cutting Tools Manufacturing Process.

From www.researchgate.net

General classification of cutting processes/operations Download Cutting Tools Manufacturing Process The cutting process is a subtractive metalworking technique that divides a metal workpiece into multiple parts. Machining refers to using machines to process materials according to the. the cutting tool is the critical link between raw materials and the finished product. the process of tool and die manufacturing entails cutting and shaping metal, as well as other materials,. Cutting Tools Manufacturing Process.

From cebqepxt.blob.core.windows.net

Cutting Tool Steel Plate at Bonnie Propst blog Cutting Tools Manufacturing Process the process of tool and die manufacturing entails cutting and shaping metal, as well as other materials, using tools, and employing metal forms called dies. The cutting process is a subtractive metalworking technique that divides a metal workpiece into multiple parts. Common cutting processes include sawing, shaping, broaching, drilling, grinding, turning, and milling. the cutting tool is the. Cutting Tools Manufacturing Process.

From www.slideserve.com

PPT CHAPTER 8 MaterialRemoval Processes Cutting PowerPoint Cutting Tools Manufacturing Process the process of tool and die manufacturing entails cutting and shaping metal, as well as other materials, using tools, and employing metal forms called dies. cutting is manufacturing by removal of material (din 8580; Machining refers to using machines to process materials according to the. Process planning is crucial to minimize setup changes and optimize cutting operations. The. Cutting Tools Manufacturing Process.

From www.dreamstime.com

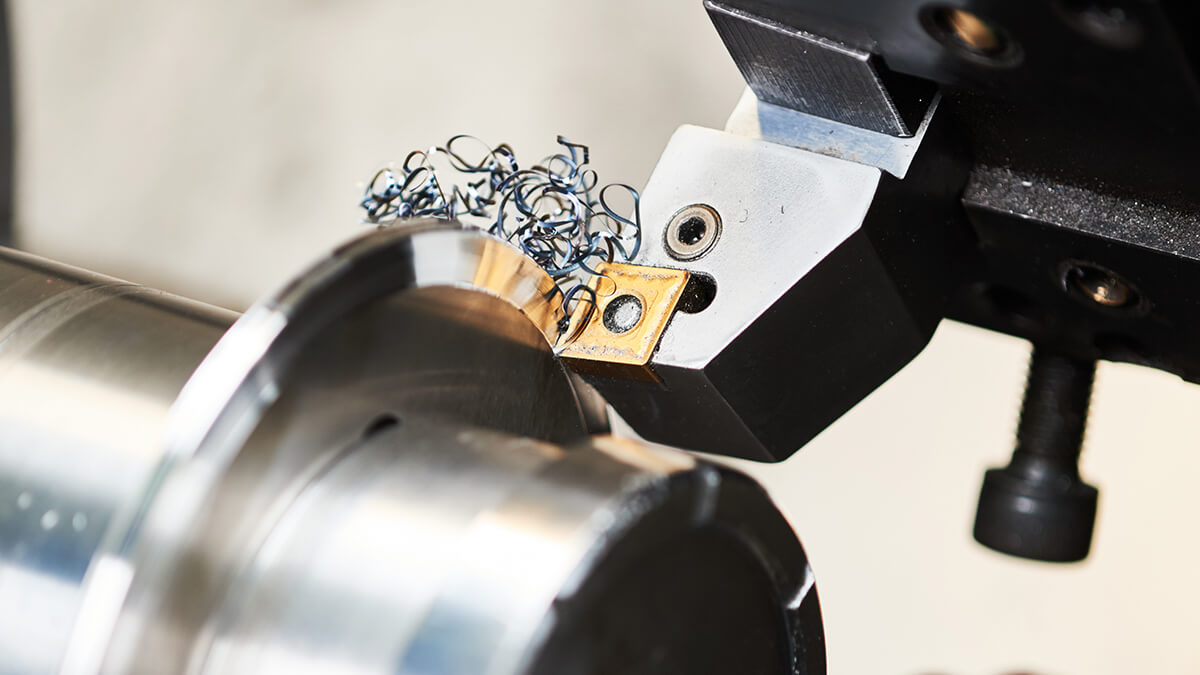

Close Up Workpiece and Cutting Tool during Production Process at Cutting Tools Manufacturing Process The cutting process is a subtractive metalworking technique that divides a metal workpiece into multiple parts. An introduction to machine tools. the cutting tool is the critical link between raw materials and the finished product. Process planning is crucial to minimize setup changes and optimize cutting operations. cutting is manufacturing by removal of material (din 8580; Machining refers. Cutting Tools Manufacturing Process.

From www.alamy.com

Cutting tool metalworking in manufacturing process by machining Stock Cutting Tools Manufacturing Process the process of tool and die manufacturing entails cutting and shaping metal, as well as other materials, using tools, and employing metal forms called dies. cutting is manufacturing by removal of material (din 8580; Process planning is crucial to minimize setup changes and optimize cutting operations. the cutting tool is the critical link between raw materials and. Cutting Tools Manufacturing Process.

From www.engineeringinhindi.com

What are cutting tools material and how many types of cutting tools. Cutting Tools Manufacturing Process cutting is manufacturing by removal of material (din 8580; the cutting tool is the critical link between raw materials and the finished product. An introduction to machine tools. Machining refers to using machines to process materials according to the. Common cutting processes include sawing, shaping, broaching, drilling, grinding, turning, and milling. The cutting process is a subtractive metalworking. Cutting Tools Manufacturing Process.

From dxopbkaft.blob.core.windows.net

What Does A Machining Tool Operator Do at Irons blog Cutting Tools Manufacturing Process Machining refers to using machines to process materials according to the. cutting is manufacturing by removal of material (din 8580; the cutting tool is the critical link between raw materials and the finished product. the process of tool and die manufacturing entails cutting and shaping metal, as well as other materials, using tools, and employing metal forms. Cutting Tools Manufacturing Process.

From www.china-machining.com

What is CNC Turning? Plus 3 Things You Need to Know About It Cutting Tools Manufacturing Process the cutting tool is the critical link between raw materials and the finished product. Machining refers to using machines to process materials according to the. The cutting process is a subtractive metalworking technique that divides a metal workpiece into multiple parts. the process of tool and die manufacturing entails cutting and shaping metal, as well as other materials,. Cutting Tools Manufacturing Process.

From www.alamy.com

Cutting tool metalworking in manufacturing process by machining Stock Cutting Tools Manufacturing Process An introduction to machine tools. Common cutting processes include sawing, shaping, broaching, drilling, grinding, turning, and milling. The cutting process is a subtractive metalworking technique that divides a metal workpiece into multiple parts. Process planning is crucial to minimize setup changes and optimize cutting operations. the process of tool and die manufacturing entails cutting and shaping metal, as well. Cutting Tools Manufacturing Process.

From toolgrindcoat.com

What Are the Carbide Cutting Tools? Cutting Tools Manufacturing Process Common cutting processes include sawing, shaping, broaching, drilling, grinding, turning, and milling. cutting is manufacturing by removal of material (din 8580; the process of tool and die manufacturing entails cutting and shaping metal, as well as other materials, using tools, and employing metal forms called dies. An introduction to machine tools. Machining refers to using machines to process. Cutting Tools Manufacturing Process.

From www.dreamstime.com

Combination Drill Spiral Flute Threading Tapping Cutting Tools for Cutting Tools Manufacturing Process An introduction to machine tools. Machining refers to using machines to process materials according to the. Common cutting processes include sawing, shaping, broaching, drilling, grinding, turning, and milling. the process of tool and die manufacturing entails cutting and shaping metal, as well as other materials, using tools, and employing metal forms called dies. the cutting tool is the. Cutting Tools Manufacturing Process.

From www.fastradius.com

FYI CNC Machining vs. Die Casting Fast Radius Cutting Tools Manufacturing Process The cutting process is a subtractive metalworking technique that divides a metal workpiece into multiple parts. Machining refers to using machines to process materials according to the. the process of tool and die manufacturing entails cutting and shaping metal, as well as other materials, using tools, and employing metal forms called dies. cutting is manufacturing by removal of. Cutting Tools Manufacturing Process.

From www.dreamstime.com

Cutting Tool for High Precision Machining Manufacturing Process Stock Cutting Tools Manufacturing Process Common cutting processes include sawing, shaping, broaching, drilling, grinding, turning, and milling. cutting is manufacturing by removal of material (din 8580; The cutting process is a subtractive metalworking technique that divides a metal workpiece into multiple parts. Machining refers to using machines to process materials according to the. the process of tool and die manufacturing entails cutting and. Cutting Tools Manufacturing Process.

From www.youtube.com

Cutting Tool Materials// Metal Cutting Principle// Manufacturing Cutting Tools Manufacturing Process An introduction to machine tools. Machining refers to using machines to process materials according to the. the process of tool and die manufacturing entails cutting and shaping metal, as well as other materials, using tools, and employing metal forms called dies. Common cutting processes include sawing, shaping, broaching, drilling, grinding, turning, and milling. the cutting tool is the. Cutting Tools Manufacturing Process.

From www.dreamstime.com

Cutting Tool for High Precision Machining Manufacturing Process Stock Cutting Tools Manufacturing Process Common cutting processes include sawing, shaping, broaching, drilling, grinding, turning, and milling. Machining refers to using machines to process materials according to the. Process planning is crucial to minimize setup changes and optimize cutting operations. The cutting process is a subtractive metalworking technique that divides a metal workpiece into multiple parts. An introduction to machine tools. cutting is manufacturing. Cutting Tools Manufacturing Process.

From www.dreamstime.com

Cutting Tool for High Precision Machining Manufacturing Process Stock Cutting Tools Manufacturing Process cutting is manufacturing by removal of material (din 8580; The cutting process is a subtractive metalworking technique that divides a metal workpiece into multiple parts. the process of tool and die manufacturing entails cutting and shaping metal, as well as other materials, using tools, and employing metal forms called dies. An introduction to machine tools. Machining refers to. Cutting Tools Manufacturing Process.

From exoyxrcyt.blob.core.windows.net

Hkf Cutting Tool Manufacturing Company at Timothy Mathis blog Cutting Tools Manufacturing Process the process of tool and die manufacturing entails cutting and shaping metal, as well as other materials, using tools, and employing metal forms called dies. cutting is manufacturing by removal of material (din 8580; The cutting process is a subtractive metalworking technique that divides a metal workpiece into multiple parts. the cutting tool is the critical link. Cutting Tools Manufacturing Process.

From www.dreamstime.com

Cutting Tool for High Precision Machining Manufacturing Process Stock Cutting Tools Manufacturing Process An introduction to machine tools. Common cutting processes include sawing, shaping, broaching, drilling, grinding, turning, and milling. Machining refers to using machines to process materials according to the. cutting is manufacturing by removal of material (din 8580; Process planning is crucial to minimize setup changes and optimize cutting operations. the cutting tool is the critical link between raw. Cutting Tools Manufacturing Process.

From celxcscs.blob.core.windows.net

Cnc Milling Machine Standard at Gerald Dreiling blog Cutting Tools Manufacturing Process Process planning is crucial to minimize setup changes and optimize cutting operations. the process of tool and die manufacturing entails cutting and shaping metal, as well as other materials, using tools, and employing metal forms called dies. An introduction to machine tools. Common cutting processes include sawing, shaping, broaching, drilling, grinding, turning, and milling. The cutting process is a. Cutting Tools Manufacturing Process.

From www.dreamstime.com

Cutting Tool Working with Work Piece or Product by High Speed and Cutting Tools Manufacturing Process the process of tool and die manufacturing entails cutting and shaping metal, as well as other materials, using tools, and employing metal forms called dies. Machining refers to using machines to process materials according to the. the cutting tool is the critical link between raw materials and the finished product. Process planning is crucial to minimize setup changes. Cutting Tools Manufacturing Process.

From www.slideserve.com

PPT Metal Machining PowerPoint Presentation, free download ID2292716 Cutting Tools Manufacturing Process the cutting tool is the critical link between raw materials and the finished product. Process planning is crucial to minimize setup changes and optimize cutting operations. cutting is manufacturing by removal of material (din 8580; Common cutting processes include sawing, shaping, broaching, drilling, grinding, turning, and milling. Machining refers to using machines to process materials according to the.. Cutting Tools Manufacturing Process.

From www.dreamstime.com

Industrial Metal Work Bore Machining Process by Cutting Tool on Cutting Tools Manufacturing Process An introduction to machine tools. Process planning is crucial to minimize setup changes and optimize cutting operations. Common cutting processes include sawing, shaping, broaching, drilling, grinding, turning, and milling. cutting is manufacturing by removal of material (din 8580; The cutting process is a subtractive metalworking technique that divides a metal workpiece into multiple parts. Machining refers to using machines. Cutting Tools Manufacturing Process.

From www.dreamstime.com

Industrial Metal Work Bore Machining Process by Cutting Tool on Cutting Tools Manufacturing Process An introduction to machine tools. the cutting tool is the critical link between raw materials and the finished product. Process planning is crucial to minimize setup changes and optimize cutting operations. The cutting process is a subtractive metalworking technique that divides a metal workpiece into multiple parts. Common cutting processes include sawing, shaping, broaching, drilling, grinding, turning, and milling.. Cutting Tools Manufacturing Process.

From www.dreamstime.com

Cutting Tool Making Machine Control by CNC Program. Stock Image Image Cutting Tools Manufacturing Process Machining refers to using machines to process materials according to the. Common cutting processes include sawing, shaping, broaching, drilling, grinding, turning, and milling. the process of tool and die manufacturing entails cutting and shaping metal, as well as other materials, using tools, and employing metal forms called dies. An introduction to machine tools. Process planning is crucial to minimize. Cutting Tools Manufacturing Process.

From www.market-prospects.com

What is the Selection of Metal Cutting Machine Tools for Hardware Cutting Tools Manufacturing Process The cutting process is a subtractive metalworking technique that divides a metal workpiece into multiple parts. Machining refers to using machines to process materials according to the. Process planning is crucial to minimize setup changes and optimize cutting operations. the cutting tool is the critical link between raw materials and the finished product. cutting is manufacturing by removal. Cutting Tools Manufacturing Process.

From www.talk-business.co.uk

Machining What to know about metal machining Talk Business Cutting Tools Manufacturing Process An introduction to machine tools. the process of tool and die manufacturing entails cutting and shaping metal, as well as other materials, using tools, and employing metal forms called dies. the cutting tool is the critical link between raw materials and the finished product. Machining refers to using machines to process materials according to the. cutting is. Cutting Tools Manufacturing Process.

From stock.adobe.com

The operation of tool making machine control by computer program. The Cutting Tools Manufacturing Process cutting is manufacturing by removal of material (din 8580; the process of tool and die manufacturing entails cutting and shaping metal, as well as other materials, using tools, and employing metal forms called dies. An introduction to machine tools. Common cutting processes include sawing, shaping, broaching, drilling, grinding, turning, and milling. the cutting tool is the critical. Cutting Tools Manufacturing Process.

From stock.adobe.com

Cutting tool making machine control by CNC program. The CNC carbide Cutting Tools Manufacturing Process cutting is manufacturing by removal of material (din 8580; An introduction to machine tools. Common cutting processes include sawing, shaping, broaching, drilling, grinding, turning, and milling. Process planning is crucial to minimize setup changes and optimize cutting operations. Machining refers to using machines to process materials according to the. The cutting process is a subtractive metalworking technique that divides. Cutting Tools Manufacturing Process.

From www.wodenco.com

How to Select the Right Carbide Inserts The Ultimate Guide Wodenco Cutting Tools Manufacturing Process the process of tool and die manufacturing entails cutting and shaping metal, as well as other materials, using tools, and employing metal forms called dies. Common cutting processes include sawing, shaping, broaching, drilling, grinding, turning, and milling. An introduction to machine tools. Process planning is crucial to minimize setup changes and optimize cutting operations. cutting is manufacturing by. Cutting Tools Manufacturing Process.

From epictool.ca

The operation of tool grinding machine control by CNC program.The CNC Cutting Tools Manufacturing Process Process planning is crucial to minimize setup changes and optimize cutting operations. Machining refers to using machines to process materials according to the. the cutting tool is the critical link between raw materials and the finished product. cutting is manufacturing by removal of material (din 8580; An introduction to machine tools. the process of tool and die. Cutting Tools Manufacturing Process.

From www.dreamstime.com

Industrial Metalworking Cutting Process by Milling Cutter Stock Image Cutting Tools Manufacturing Process The cutting process is a subtractive metalworking technique that divides a metal workpiece into multiple parts. Machining refers to using machines to process materials according to the. Process planning is crucial to minimize setup changes and optimize cutting operations. Common cutting processes include sawing, shaping, broaching, drilling, grinding, turning, and milling. the cutting tool is the critical link between. Cutting Tools Manufacturing Process.

From www.rapiddirect.com

Types of Machining Process Classifications and Differences Cutting Tools Manufacturing Process the process of tool and die manufacturing entails cutting and shaping metal, as well as other materials, using tools, and employing metal forms called dies. The cutting process is a subtractive metalworking technique that divides a metal workpiece into multiple parts. cutting is manufacturing by removal of material (din 8580; Process planning is crucial to minimize setup changes. Cutting Tools Manufacturing Process.

From www.alamy.com

Cutting tool metalworking in manufacturing process by machining Stock Cutting Tools Manufacturing Process Process planning is crucial to minimize setup changes and optimize cutting operations. Machining refers to using machines to process materials according to the. Common cutting processes include sawing, shaping, broaching, drilling, grinding, turning, and milling. cutting is manufacturing by removal of material (din 8580; the cutting tool is the critical link between raw materials and the finished product.. Cutting Tools Manufacturing Process.