Sheet Metal Bend Limits . The v die is usually selected to be 5x to 8x the workpiece thickness. Sheet metal bending can be done using many methods. The basic bending design guidelines that a designer needs to consider when modelling a sheet metal component include wall thickness, bend radii, and bend allowance. During bending, the sheet metal must bridge fully across the v die (see figure 2). We discuss those along with springback, bend allowances, k factor, design tips etc. The minimum distance between hole/slot edge to bend edge avoid metal distortion, deformation, and fracturing. Sheet metal parts are usually fabricated from a single sheet of metal, so they should have a uniform wall thickness.

from giojrypcp.blob.core.windows.net

The minimum distance between hole/slot edge to bend edge avoid metal distortion, deformation, and fracturing. The basic bending design guidelines that a designer needs to consider when modelling a sheet metal component include wall thickness, bend radii, and bend allowance. During bending, the sheet metal must bridge fully across the v die (see figure 2). We discuss those along with springback, bend allowances, k factor, design tips etc. Sheet metal parts are usually fabricated from a single sheet of metal, so they should have a uniform wall thickness. The v die is usually selected to be 5x to 8x the workpiece thickness. Sheet metal bending can be done using many methods.

Sheet Metal Bend Tips at Gary Lindquist blog

Sheet Metal Bend Limits During bending, the sheet metal must bridge fully across the v die (see figure 2). The v die is usually selected to be 5x to 8x the workpiece thickness. Sheet metal parts are usually fabricated from a single sheet of metal, so they should have a uniform wall thickness. The basic bending design guidelines that a designer needs to consider when modelling a sheet metal component include wall thickness, bend radii, and bend allowance. During bending, the sheet metal must bridge fully across the v die (see figure 2). The minimum distance between hole/slot edge to bend edge avoid metal distortion, deformation, and fracturing. We discuss those along with springback, bend allowances, k factor, design tips etc. Sheet metal bending can be done using many methods.

From www.tiktok.com

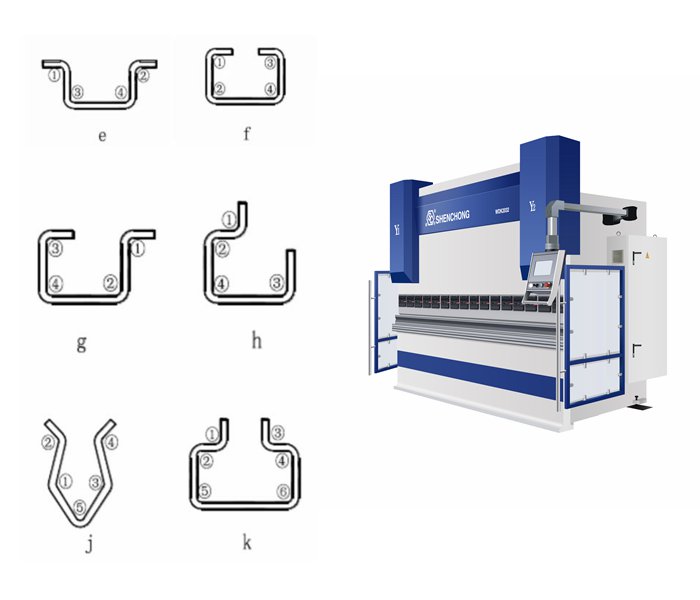

Essential Tools for Press Brake in Sheet Metal Fabrication TikTok Sheet Metal Bend Limits The basic bending design guidelines that a designer needs to consider when modelling a sheet metal component include wall thickness, bend radii, and bend allowance. Sheet metal parts are usually fabricated from a single sheet of metal, so they should have a uniform wall thickness. During bending, the sheet metal must bridge fully across the v die (see figure 2).. Sheet Metal Bend Limits.

From unitymanufacture.com

How To Bend Sheet Metal In Solidworks? Unity Manufacture Sheet Metal Bend Limits Sheet metal bending can be done using many methods. The basic bending design guidelines that a designer needs to consider when modelling a sheet metal component include wall thickness, bend radii, and bend allowance. The minimum distance between hole/slot edge to bend edge avoid metal distortion, deformation, and fracturing. The v die is usually selected to be 5x to 8x. Sheet Metal Bend Limits.

From giojrypcp.blob.core.windows.net

Sheet Metal Bend Tips at Gary Lindquist blog Sheet Metal Bend Limits The v die is usually selected to be 5x to 8x the workpiece thickness. We discuss those along with springback, bend allowances, k factor, design tips etc. The basic bending design guidelines that a designer needs to consider when modelling a sheet metal component include wall thickness, bend radii, and bend allowance. Sheet metal parts are usually fabricated from a. Sheet Metal Bend Limits.

From www.scentstrategy.com

Hand Bending Sheet Metal A Guide Sheet Metal Bend Limits The v die is usually selected to be 5x to 8x the workpiece thickness. The basic bending design guidelines that a designer needs to consider when modelling a sheet metal component include wall thickness, bend radii, and bend allowance. Sheet metal bending can be done using many methods. The minimum distance between hole/slot edge to bend edge avoid metal distortion,. Sheet Metal Bend Limits.

From aluminumsheetentafu.blogspot.com

Aluminum Sheet How To Bend Aluminum Sheet At Home Sheet Metal Bend Limits Sheet metal bending can be done using many methods. During bending, the sheet metal must bridge fully across the v die (see figure 2). The v die is usually selected to be 5x to 8x the workpiece thickness. Sheet metal parts are usually fabricated from a single sheet of metal, so they should have a uniform wall thickness. We discuss. Sheet Metal Bend Limits.

From www.slideserve.com

PPT MAE Course 3344 Lecture 8 Sheet Metal Shaping and Forming Sheet Metal Bend Limits Sheet metal parts are usually fabricated from a single sheet of metal, so they should have a uniform wall thickness. Sheet metal bending can be done using many methods. The basic bending design guidelines that a designer needs to consider when modelling a sheet metal component include wall thickness, bend radii, and bend allowance. During bending, the sheet metal must. Sheet Metal Bend Limits.

From www.cati.com

Common SOLIDWORKS sheet metal issues Computer Aided Technology Sheet Metal Bend Limits Sheet metal bending can be done using many methods. We discuss those along with springback, bend allowances, k factor, design tips etc. Sheet metal parts are usually fabricated from a single sheet of metal, so they should have a uniform wall thickness. The basic bending design guidelines that a designer needs to consider when modelling a sheet metal component include. Sheet Metal Bend Limits.

From www.vrogue.co

Rebar Bend Chart vrogue.co Sheet Metal Bend Limits Sheet metal parts are usually fabricated from a single sheet of metal, so they should have a uniform wall thickness. Sheet metal bending can be done using many methods. The v die is usually selected to be 5x to 8x the workpiece thickness. We discuss those along with springback, bend allowances, k factor, design tips etc. The minimum distance between. Sheet Metal Bend Limits.

From www.tiktok.com

Essential Tools for Press Brake in Sheet Metal Fabrication TikTok Sheet Metal Bend Limits The v die is usually selected to be 5x to 8x the workpiece thickness. The basic bending design guidelines that a designer needs to consider when modelling a sheet metal component include wall thickness, bend radii, and bend allowance. We discuss those along with springback, bend allowances, k factor, design tips etc. Sheet metal bending can be done using many. Sheet Metal Bend Limits.

From www.tiktok.com

Automatic bending. cncpressbrake bendingmachine pressbendingmachine Sheet Metal Bend Limits The v die is usually selected to be 5x to 8x the workpiece thickness. Sheet metal bending can be done using many methods. The basic bending design guidelines that a designer needs to consider when modelling a sheet metal component include wall thickness, bend radii, and bend allowance. We discuss those along with springback, bend allowances, k factor, design tips. Sheet Metal Bend Limits.

From web.solacesf.org

Rebar Bending Radius Chart Home Interior Design Sheet Metal Bend Limits During bending, the sheet metal must bridge fully across the v die (see figure 2). We discuss those along with springback, bend allowances, k factor, design tips etc. Sheet metal bending can be done using many methods. The v die is usually selected to be 5x to 8x the workpiece thickness. Sheet metal parts are usually fabricated from a single. Sheet Metal Bend Limits.

From www.thefabricator.com

Reasonable tolerancing for press brake bending Sheet Metal Bend Limits We discuss those along with springback, bend allowances, k factor, design tips etc. The v die is usually selected to be 5x to 8x the workpiece thickness. Sheet metal parts are usually fabricated from a single sheet of metal, so they should have a uniform wall thickness. During bending, the sheet metal must bridge fully across the v die (see. Sheet Metal Bend Limits.

From in.pinterest.com

Reinforcement Specifications "Rebars bending" Engineering Discoveries Sheet Metal Bend Limits During bending, the sheet metal must bridge fully across the v die (see figure 2). The minimum distance between hole/slot edge to bend edge avoid metal distortion, deformation, and fracturing. We discuss those along with springback, bend allowances, k factor, design tips etc. Sheet metal parts are usually fabricated from a single sheet of metal, so they should have a. Sheet Metal Bend Limits.

From www.smlease.com

Sheet Metal KFactor, Bend Allowance and Flat Length Calculations Sheet Metal Bend Limits Sheet metal parts are usually fabricated from a single sheet of metal, so they should have a uniform wall thickness. The basic bending design guidelines that a designer needs to consider when modelling a sheet metal component include wall thickness, bend radii, and bend allowance. During bending, the sheet metal must bridge fully across the v die (see figure 2).. Sheet Metal Bend Limits.

From www.smlease.com

Sheet Metal Bending Operation Types Methods and applications Sheet Metal Bend Limits Sheet metal parts are usually fabricated from a single sheet of metal, so they should have a uniform wall thickness. During bending, the sheet metal must bridge fully across the v die (see figure 2). The basic bending design guidelines that a designer needs to consider when modelling a sheet metal component include wall thickness, bend radii, and bend allowance.. Sheet Metal Bend Limits.

From giojrypcp.blob.core.windows.net

Sheet Metal Bend Tips at Gary Lindquist blog Sheet Metal Bend Limits Sheet metal parts are usually fabricated from a single sheet of metal, so they should have a uniform wall thickness. We discuss those along with springback, bend allowances, k factor, design tips etc. During bending, the sheet metal must bridge fully across the v die (see figure 2). The v die is usually selected to be 5x to 8x the. Sheet Metal Bend Limits.

From eziil.com

Sheet Metal Bend Radius Full Guide Chart Sheet Metal Bend Limits The basic bending design guidelines that a designer needs to consider when modelling a sheet metal component include wall thickness, bend radii, and bend allowance. Sheet metal bending can be done using many methods. The v die is usually selected to be 5x to 8x the workpiece thickness. The minimum distance between hole/slot edge to bend edge avoid metal distortion,. Sheet Metal Bend Limits.

From giojrypcp.blob.core.windows.net

Sheet Metal Bend Tips at Gary Lindquist blog Sheet Metal Bend Limits Sheet metal bending can be done using many methods. The minimum distance between hole/slot edge to bend edge avoid metal distortion, deformation, and fracturing. During bending, the sheet metal must bridge fully across the v die (see figure 2). The basic bending design guidelines that a designer needs to consider when modelling a sheet metal component include wall thickness, bend. Sheet Metal Bend Limits.

From www.huimfg.com

Free Air Bending Force Chart HUI Manufacturing Sheet Metal Bend Limits We discuss those along with springback, bend allowances, k factor, design tips etc. Sheet metal parts are usually fabricated from a single sheet of metal, so they should have a uniform wall thickness. The minimum distance between hole/slot edge to bend edge avoid metal distortion, deformation, and fracturing. Sheet metal bending can be done using many methods. The basic bending. Sheet Metal Bend Limits.

From eziil.com

Sheet Metal Bend Radius Full Guide Chart Sheet Metal Bend Limits Sheet metal parts are usually fabricated from a single sheet of metal, so they should have a uniform wall thickness. The v die is usually selected to be 5x to 8x the workpiece thickness. We discuss those along with springback, bend allowances, k factor, design tips etc. Sheet metal bending can be done using many methods. The minimum distance between. Sheet Metal Bend Limits.

From www.dmtcmanufacturing.com

The Guide For Sheet Metal Bending Service From DMTC Sheet Metal Bend Limits We discuss those along with springback, bend allowances, k factor, design tips etc. Sheet metal bending can be done using many methods. During bending, the sheet metal must bridge fully across the v die (see figure 2). The v die is usually selected to be 5x to 8x the workpiece thickness. The basic bending design guidelines that a designer needs. Sheet Metal Bend Limits.

From www.rapiddirect.com

Bending Stainless Steel Tubing Effective Processes and Considerations Sheet Metal Bend Limits The minimum distance between hole/slot edge to bend edge avoid metal distortion, deformation, and fracturing. The v die is usually selected to be 5x to 8x the workpiece thickness. We discuss those along with springback, bend allowances, k factor, design tips etc. Sheet metal bending can be done using many methods. Sheet metal parts are usually fabricated from a single. Sheet Metal Bend Limits.

From www.mech4study.com

Different Sheet Metal Bending Process mech4study Sheet Metal Bend Limits The v die is usually selected to be 5x to 8x the workpiece thickness. Sheet metal parts are usually fabricated from a single sheet of metal, so they should have a uniform wall thickness. We discuss those along with springback, bend allowances, k factor, design tips etc. The basic bending design guidelines that a designer needs to consider when modelling. Sheet Metal Bend Limits.

From www.youtube.com

Sheet metal Bend parameters and Bend allowance YouTube Sheet Metal Bend Limits The minimum distance between hole/slot edge to bend edge avoid metal distortion, deformation, and fracturing. Sheet metal bending can be done using many methods. We discuss those along with springback, bend allowances, k factor, design tips etc. During bending, the sheet metal must bridge fully across the v die (see figure 2). The v die is usually selected to be. Sheet Metal Bend Limits.

From www.vrogue.co

Sheet Metal Design Guidelines All You Need To Know H vrogue.co Sheet Metal Bend Limits Sheet metal bending can be done using many methods. Sheet metal parts are usually fabricated from a single sheet of metal, so they should have a uniform wall thickness. We discuss those along with springback, bend allowances, k factor, design tips etc. The basic bending design guidelines that a designer needs to consider when modelling a sheet metal component include. Sheet Metal Bend Limits.

From www.thefabricator.com

Precision sheet metal bending and the V groove Part II Sheet Metal Bend Limits Sheet metal parts are usually fabricated from a single sheet of metal, so they should have a uniform wall thickness. The basic bending design guidelines that a designer needs to consider when modelling a sheet metal component include wall thickness, bend radii, and bend allowance. The v die is usually selected to be 5x to 8x the workpiece thickness. During. Sheet Metal Bend Limits.

From pdfprof.com

factor calculator Sheet Metal Bend Limits Sheet metal parts are usually fabricated from a single sheet of metal, so they should have a uniform wall thickness. The v die is usually selected to be 5x to 8x the workpiece thickness. We discuss those along with springback, bend allowances, k factor, design tips etc. The basic bending design guidelines that a designer needs to consider when modelling. Sheet Metal Bend Limits.

From www.javelin-tech.com

How to flip the Bend Direction of a SOLIDWORKS Sheet Metal Part Sheet Metal Bend Limits The basic bending design guidelines that a designer needs to consider when modelling a sheet metal component include wall thickness, bend radii, and bend allowance. We discuss those along with springback, bend allowances, k factor, design tips etc. The minimum distance between hole/slot edge to bend edge avoid metal distortion, deformation, and fracturing. Sheet metal bending can be done using. Sheet Metal Bend Limits.

From thelibraryofmanufacturing.com

Sheet Metal Bending Sheet Metal Bend Limits Sheet metal parts are usually fabricated from a single sheet of metal, so they should have a uniform wall thickness. The v die is usually selected to be 5x to 8x the workpiece thickness. Sheet metal bending can be done using many methods. During bending, the sheet metal must bridge fully across the v die (see figure 2). The basic. Sheet Metal Bend Limits.

From www.kanakmetal.com

ASME B16.49 Pipe Bend and Schedule 40 Steel Elbow manufacturer India Sheet Metal Bend Limits Sheet metal parts are usually fabricated from a single sheet of metal, so they should have a uniform wall thickness. During bending, the sheet metal must bridge fully across the v die (see figure 2). The basic bending design guidelines that a designer needs to consider when modelling a sheet metal component include wall thickness, bend radii, and bend allowance.. Sheet Metal Bend Limits.

From www.slideserve.com

PPT ME 350 Lecture 18 Chapter 20 PowerPoint Presentation, free Sheet Metal Bend Limits Sheet metal parts are usually fabricated from a single sheet of metal, so they should have a uniform wall thickness. The basic bending design guidelines that a designer needs to consider when modelling a sheet metal component include wall thickness, bend radii, and bend allowance. The v die is usually selected to be 5x to 8x the workpiece thickness. Sheet. Sheet Metal Bend Limits.

From www.alubend.com

Bending Aluminium with a Tangent Alubend Sheet Metal Bend Limits The v die is usually selected to be 5x to 8x the workpiece thickness. The minimum distance between hole/slot edge to bend edge avoid metal distortion, deformation, and fracturing. The basic bending design guidelines that a designer needs to consider when modelling a sheet metal component include wall thickness, bend radii, and bend allowance. We discuss those along with springback,. Sheet Metal Bend Limits.

From toolnotes.com

Bend Allowance ToolNotes Sheet Metal Bend Limits The basic bending design guidelines that a designer needs to consider when modelling a sheet metal component include wall thickness, bend radii, and bend allowance. Sheet metal bending can be done using many methods. We discuss those along with springback, bend allowances, k factor, design tips etc. The minimum distance between hole/slot edge to bend edge avoid metal distortion, deformation,. Sheet Metal Bend Limits.

From www.minifaber.com

The sheet bending Sheet Metal Bend Limits We discuss those along with springback, bend allowances, k factor, design tips etc. The v die is usually selected to be 5x to 8x the workpiece thickness. The minimum distance between hole/slot edge to bend edge avoid metal distortion, deformation, and fracturing. During bending, the sheet metal must bridge fully across the v die (see figure 2). Sheet metal bending. Sheet Metal Bend Limits.

From www.tiktok.com

Automatic bending. cncpressbrake bendingmachine pressbendingmachine Sheet Metal Bend Limits The basic bending design guidelines that a designer needs to consider when modelling a sheet metal component include wall thickness, bend radii, and bend allowance. Sheet metal parts are usually fabricated from a single sheet of metal, so they should have a uniform wall thickness. During bending, the sheet metal must bridge fully across the v die (see figure 2).. Sheet Metal Bend Limits.