Thread Forming Titanium . Forming or rolling threads is a chipless method of thread production. Discover the advantages and disadvantages of hot forming, superplastic forming, and cold forming for titanium parts. This means that in this process, the thread isn't cut from the material. Form taps are typically less than 3⁄4 , or an m20, in diameter. Heating titanium increases its formability, reduces spring back, and permits maximum deformation with minimum annealing between forming. When form tapping titanium, a lot of that heat penetrates the tool and causes premature failure. Heating titanium increases its formability, reduces springback, and permits maximum deformation with minimum annealing between forming operations. These fluteless tools, which create threads by moving material rather than cutting action, are often used for titanium tapping because they offer a strong cross section.

from www.iqsdirectory.com

Form taps are typically less than 3⁄4 , or an m20, in diameter. When form tapping titanium, a lot of that heat penetrates the tool and causes premature failure. These fluteless tools, which create threads by moving material rather than cutting action, are often used for titanium tapping because they offer a strong cross section. Forming or rolling threads is a chipless method of thread production. Discover the advantages and disadvantages of hot forming, superplastic forming, and cold forming for titanium parts. This means that in this process, the thread isn't cut from the material. Heating titanium increases its formability, reduces springback, and permits maximum deformation with minimum annealing between forming operations. Heating titanium increases its formability, reduces spring back, and permits maximum deformation with minimum annealing between forming.

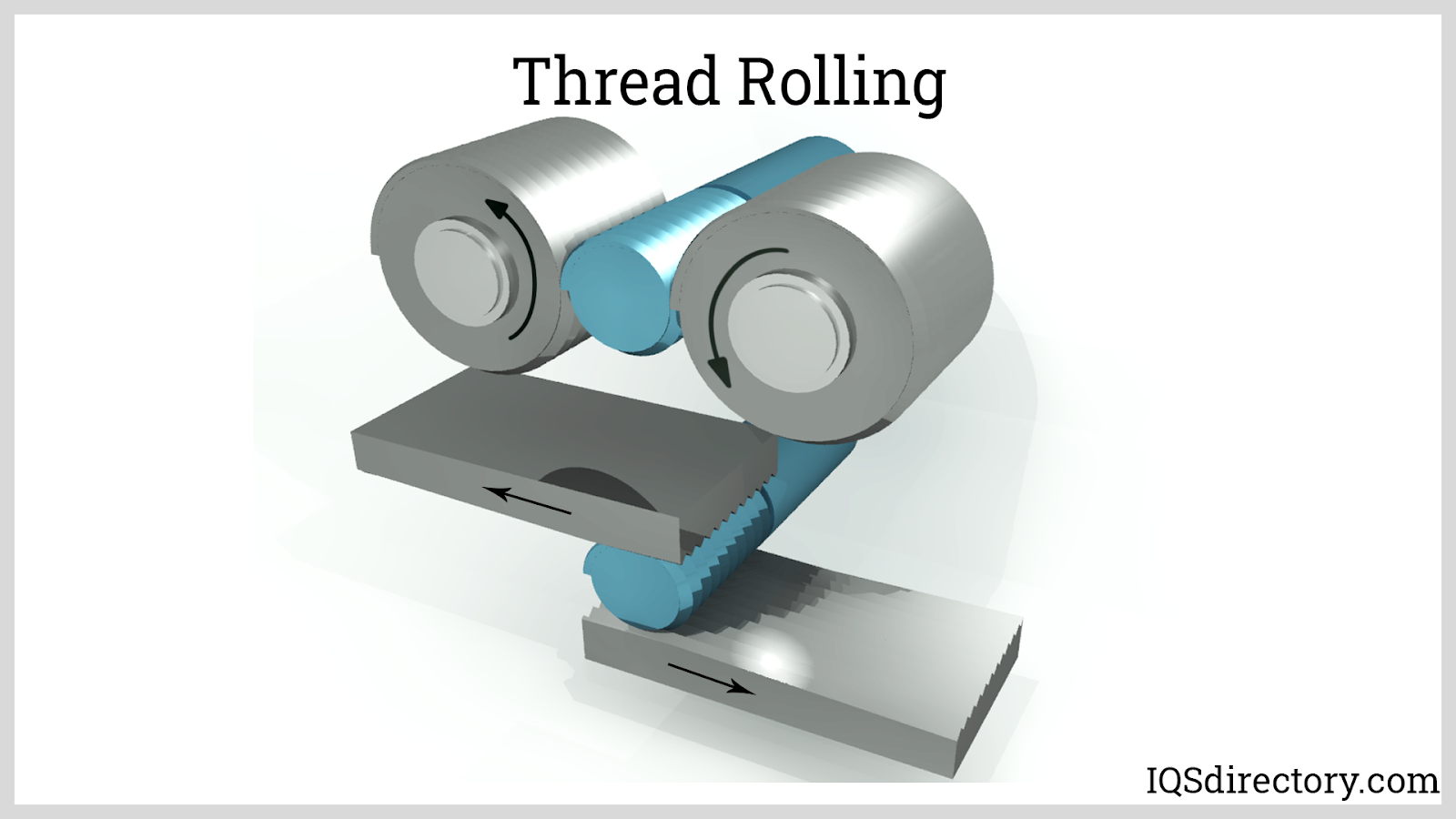

Thread Rolling What Is It? How Does It Work? Process, Types

Thread Forming Titanium Discover the advantages and disadvantages of hot forming, superplastic forming, and cold forming for titanium parts. Heating titanium increases its formability, reduces springback, and permits maximum deformation with minimum annealing between forming operations. When form tapping titanium, a lot of that heat penetrates the tool and causes premature failure. These fluteless tools, which create threads by moving material rather than cutting action, are often used for titanium tapping because they offer a strong cross section. Forming or rolling threads is a chipless method of thread production. This means that in this process, the thread isn't cut from the material. Heating titanium increases its formability, reduces spring back, and permits maximum deformation with minimum annealing between forming. Form taps are typically less than 3⁄4 , or an m20, in diameter. Discover the advantages and disadvantages of hot forming, superplastic forming, and cold forming for titanium parts.

From www.mscdirect.com

Hertel Thread Forming Tap Metric, Plug, HighSpeed Steel, Titanium Thread Forming Titanium This means that in this process, the thread isn't cut from the material. When form tapping titanium, a lot of that heat penetrates the tool and causes premature failure. Form taps are typically less than 3⁄4 , or an m20, in diameter. Heating titanium increases its formability, reduces spring back, and permits maximum deformation with minimum annealing between forming. Discover. Thread Forming Titanium.

From www.mscdirect.com

Hertel Thread Forming Tap 1/428 UNF, 2B Class of Fit, Bottoming Thread Forming Titanium Discover the advantages and disadvantages of hot forming, superplastic forming, and cold forming for titanium parts. This means that in this process, the thread isn't cut from the material. These fluteless tools, which create threads by moving material rather than cutting action, are often used for titanium tapping because they offer a strong cross section. Heating titanium increases its formability,. Thread Forming Titanium.

From www.aliexpress.com

Spiral Pointed Taps Tapping Thread Forming Tap Titanium Coated Hss 5pc Thread Forming Titanium Forming or rolling threads is a chipless method of thread production. Discover the advantages and disadvantages of hot forming, superplastic forming, and cold forming for titanium parts. Heating titanium increases its formability, reduces springback, and permits maximum deformation with minimum annealing between forming operations. Form taps are typically less than 3⁄4 , or an m20, in diameter. When form tapping. Thread Forming Titanium.

From www.mscdirect.com

Hertel Thread Forming Tap 256 UNC, 2B Class of Fit, Bottoming Thread Forming Titanium Heating titanium increases its formability, reduces springback, and permits maximum deformation with minimum annealing between forming operations. Forming or rolling threads is a chipless method of thread production. Heating titanium increases its formability, reduces spring back, and permits maximum deformation with minimum annealing between forming. Discover the advantages and disadvantages of hot forming, superplastic forming, and cold forming for titanium. Thread Forming Titanium.

From www.aliexpress.com

Spiral Pointed Taps Tapping Thread Forming Tap Titanium Coated Hss 5pc Thread Forming Titanium Heating titanium increases its formability, reduces spring back, and permits maximum deformation with minimum annealing between forming. Forming or rolling threads is a chipless method of thread production. This means that in this process, the thread isn't cut from the material. Heating titanium increases its formability, reduces springback, and permits maximum deformation with minimum annealing between forming operations. Form taps. Thread Forming Titanium.

From www.mscdirect.com

Hertel Thread Forming Tap 440 UNC, 2B & 3B Class of Fit, Plug Thread Forming Titanium Discover the advantages and disadvantages of hot forming, superplastic forming, and cold forming for titanium parts. Heating titanium increases its formability, reduces springback, and permits maximum deformation with minimum annealing between forming operations. When form tapping titanium, a lot of that heat penetrates the tool and causes premature failure. These fluteless tools, which create threads by moving material rather than. Thread Forming Titanium.

From www.mscdirect.com

Hertel Thread Forming Tap 632 UNC, 2B Class of Fit, Plug, High Thread Forming Titanium Form taps are typically less than 3⁄4 , or an m20, in diameter. Discover the advantages and disadvantages of hot forming, superplastic forming, and cold forming for titanium parts. Forming or rolling threads is a chipless method of thread production. Heating titanium increases its formability, reduces springback, and permits maximum deformation with minimum annealing between forming operations. This means that. Thread Forming Titanium.

From www.mscdirect.com

Hertel Thread Forming Tap 1/420 UNC, Bottoming, HighSpeed Steel Thread Forming Titanium This means that in this process, the thread isn't cut from the material. Forming or rolling threads is a chipless method of thread production. When form tapping titanium, a lot of that heat penetrates the tool and causes premature failure. Heating titanium increases its formability, reduces spring back, and permits maximum deformation with minimum annealing between forming. These fluteless tools,. Thread Forming Titanium.

From www.mscdirect.com

Hertel Thread Forming Tap 1032 UNF, Bottoming, HighSpeed Steel Thread Forming Titanium When form tapping titanium, a lot of that heat penetrates the tool and causes premature failure. Discover the advantages and disadvantages of hot forming, superplastic forming, and cold forming for titanium parts. Heating titanium increases its formability, reduces spring back, and permits maximum deformation with minimum annealing between forming. This means that in this process, the thread isn't cut from. Thread Forming Titanium.

From www.aliexpress.com

Buy Spiral Pointed Taps Tapping Thread Forming Tap Thread Forming Titanium Forming or rolling threads is a chipless method of thread production. Form taps are typically less than 3⁄4 , or an m20, in diameter. This means that in this process, the thread isn't cut from the material. Heating titanium increases its formability, reduces spring back, and permits maximum deformation with minimum annealing between forming. These fluteless tools, which create threads. Thread Forming Titanium.

From www.mscdirect.com

Hertel Thread Forming Tap 832 UNC, 2B Class of Fit, Bottoming Thread Forming Titanium These fluteless tools, which create threads by moving material rather than cutting action, are often used for titanium tapping because they offer a strong cross section. Heating titanium increases its formability, reduces spring back, and permits maximum deformation with minimum annealing between forming. Heating titanium increases its formability, reduces springback, and permits maximum deformation with minimum annealing between forming operations.. Thread Forming Titanium.

From www.mscdirect.com

Hertel Thread Forming Tap Metric, Bottoming, HighSpeed Steel Thread Forming Titanium Form taps are typically less than 3⁄4 , or an m20, in diameter. This means that in this process, the thread isn't cut from the material. When form tapping titanium, a lot of that heat penetrates the tool and causes premature failure. Heating titanium increases its formability, reduces spring back, and permits maximum deformation with minimum annealing between forming. Forming. Thread Forming Titanium.

From www.mscdirect.com

Hertel Thread Forming Tap 3/816 UNC, 2B Class of Fit, Bottoming Thread Forming Titanium These fluteless tools, which create threads by moving material rather than cutting action, are often used for titanium tapping because they offer a strong cross section. Heating titanium increases its formability, reduces springback, and permits maximum deformation with minimum annealing between forming operations. This means that in this process, the thread isn't cut from the material. Form taps are typically. Thread Forming Titanium.

From www.mscdirect.com

Hertel Thread Forming Tap 1024 UNC, Plug, HighSpeed Steel Thread Forming Titanium When form tapping titanium, a lot of that heat penetrates the tool and causes premature failure. Heating titanium increases its formability, reduces springback, and permits maximum deformation with minimum annealing between forming operations. Heating titanium increases its formability, reduces spring back, and permits maximum deformation with minimum annealing between forming. Discover the advantages and disadvantages of hot forming, superplastic forming,. Thread Forming Titanium.

From www.mscdirect.com

Emuge Thread Forming Tap 1224 UNC, 3BX Class of Fit, Bottoming Thread Forming Titanium This means that in this process, the thread isn't cut from the material. Heating titanium increases its formability, reduces spring back, and permits maximum deformation with minimum annealing between forming. Forming or rolling threads is a chipless method of thread production. Discover the advantages and disadvantages of hot forming, superplastic forming, and cold forming for titanium parts. Form taps are. Thread Forming Titanium.

From blog.thepipingmart.com

SelfTapping vs Thread Forming Screws What's the Difference Thread Forming Titanium Form taps are typically less than 3⁄4 , or an m20, in diameter. Forming or rolling threads is a chipless method of thread production. These fluteless tools, which create threads by moving material rather than cutting action, are often used for titanium tapping because they offer a strong cross section. This means that in this process, the thread isn't cut. Thread Forming Titanium.

From tengri.en.made-in-china.com

Titanium Ta2 Hexalobular / Six Lobe / Torx Drive Oval Head Machine Thread Forming Titanium When form tapping titanium, a lot of that heat penetrates the tool and causes premature failure. Form taps are typically less than 3⁄4 , or an m20, in diameter. These fluteless tools, which create threads by moving material rather than cutting action, are often used for titanium tapping because they offer a strong cross section. Discover the advantages and disadvantages. Thread Forming Titanium.

From www.mscdirect.com

Hertel Thread Forming Tap Metric, Bottoming, HighSpeed Steel Thread Forming Titanium Heating titanium increases its formability, reduces spring back, and permits maximum deformation with minimum annealing between forming. When form tapping titanium, a lot of that heat penetrates the tool and causes premature failure. Forming or rolling threads is a chipless method of thread production. Form taps are typically less than 3⁄4 , or an m20, in diameter. Discover the advantages. Thread Forming Titanium.

From www.mscdirect.com

Balax Thread Forming Tap 164 UNC, 3B Class of Fit, Bottoming, High Thread Forming Titanium Heating titanium increases its formability, reduces spring back, and permits maximum deformation with minimum annealing between forming. Forming or rolling threads is a chipless method of thread production. Heating titanium increases its formability, reduces springback, and permits maximum deformation with minimum annealing between forming operations. When form tapping titanium, a lot of that heat penetrates the tool and causes premature. Thread Forming Titanium.

From www.aliexpress.com

7pc Hss Spiral Point Tap Straight Flute Metric Titanium Machine Screw Thread Forming Titanium Heating titanium increases its formability, reduces springback, and permits maximum deformation with minimum annealing between forming operations. When form tapping titanium, a lot of that heat penetrates the tool and causes premature failure. These fluteless tools, which create threads by moving material rather than cutting action, are often used for titanium tapping because they offer a strong cross section. This. Thread Forming Titanium.

From www.mscdirect.com

Hertel Thread Forming Tap Metric, Plug, HighSpeed Steel, Titanium Thread Forming Titanium These fluteless tools, which create threads by moving material rather than cutting action, are often used for titanium tapping because they offer a strong cross section. Forming or rolling threads is a chipless method of thread production. When form tapping titanium, a lot of that heat penetrates the tool and causes premature failure. Heating titanium increases its formability, reduces spring. Thread Forming Titanium.

From www.aliexpress.com

5pcs/set Pointed Tapping Thread Forming Tap Titanium Coated Hss Metric Thread Forming Titanium Forming or rolling threads is a chipless method of thread production. This means that in this process, the thread isn't cut from the material. Heating titanium increases its formability, reduces springback, and permits maximum deformation with minimum annealing between forming operations. These fluteless tools, which create threads by moving material rather than cutting action, are often used for titanium tapping. Thread Forming Titanium.

From www.aliexpress.com

Spiral Pointed Taps Tapping Thread Forming Tap Titanium Coated Hss 5pc Thread Forming Titanium Heating titanium increases its formability, reduces spring back, and permits maximum deformation with minimum annealing between forming. Forming or rolling threads is a chipless method of thread production. Form taps are typically less than 3⁄4 , or an m20, in diameter. Discover the advantages and disadvantages of hot forming, superplastic forming, and cold forming for titanium parts. When form tapping. Thread Forming Titanium.

From www.mscdirect.com

Hertel Thread Forming Tap Metric, Bottoming, HighSpeed Steel Thread Forming Titanium Discover the advantages and disadvantages of hot forming, superplastic forming, and cold forming for titanium parts. Forming or rolling threads is a chipless method of thread production. This means that in this process, the thread isn't cut from the material. These fluteless tools, which create threads by moving material rather than cutting action, are often used for titanium tapping because. Thread Forming Titanium.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types Thread Forming Titanium Discover the advantages and disadvantages of hot forming, superplastic forming, and cold forming for titanium parts. When form tapping titanium, a lot of that heat penetrates the tool and causes premature failure. These fluteless tools, which create threads by moving material rather than cutting action, are often used for titanium tapping because they offer a strong cross section. Heating titanium. Thread Forming Titanium.

From www.msm-aero.com

Titanium Forming MSM aerospace fabricators Thread Forming Titanium When form tapping titanium, a lot of that heat penetrates the tool and causes premature failure. Heating titanium increases its formability, reduces spring back, and permits maximum deformation with minimum annealing between forming. These fluteless tools, which create threads by moving material rather than cutting action, are often used for titanium tapping because they offer a strong cross section. Heating. Thread Forming Titanium.

From www.mscdirect.com

Hertel Thread Forming Tap Metric, Bottoming, HighSpeed Steel Thread Forming Titanium This means that in this process, the thread isn't cut from the material. Heating titanium increases its formability, reduces springback, and permits maximum deformation with minimum annealing between forming operations. Form taps are typically less than 3⁄4 , or an m20, in diameter. Discover the advantages and disadvantages of hot forming, superplastic forming, and cold forming for titanium parts. These. Thread Forming Titanium.

From www.mscdirect.com

Hertel Thread Forming Tap Metric, Plug, HighSpeed Steel, Titanium Thread Forming Titanium This means that in this process, the thread isn't cut from the material. Form taps are typically less than 3⁄4 , or an m20, in diameter. These fluteless tools, which create threads by moving material rather than cutting action, are often used for titanium tapping because they offer a strong cross section. When form tapping titanium, a lot of that. Thread Forming Titanium.

From www.thefabricator.com

Tools designed for threading titanium alloys Thread Forming Titanium Heating titanium increases its formability, reduces springback, and permits maximum deformation with minimum annealing between forming operations. Heating titanium increases its formability, reduces spring back, and permits maximum deformation with minimum annealing between forming. These fluteless tools, which create threads by moving material rather than cutting action, are often used for titanium tapping because they offer a strong cross section.. Thread Forming Titanium.

From www.mscdirect.com

Hertel Thread Forming Tap 3/816 UNC, 2B Class of Fit, Plug, High Thread Forming Titanium Discover the advantages and disadvantages of hot forming, superplastic forming, and cold forming for titanium parts. Forming or rolling threads is a chipless method of thread production. These fluteless tools, which create threads by moving material rather than cutting action, are often used for titanium tapping because they offer a strong cross section. When form tapping titanium, a lot of. Thread Forming Titanium.

From www.mscdirect.com

Hertel Thread Forming Tap Metric, Bottoming, HighSpeed Steel Thread Forming Titanium Discover the advantages and disadvantages of hot forming, superplastic forming, and cold forming for titanium parts. These fluteless tools, which create threads by moving material rather than cutting action, are often used for titanium tapping because they offer a strong cross section. Heating titanium increases its formability, reduces spring back, and permits maximum deformation with minimum annealing between forming. Form. Thread Forming Titanium.

From www.mscdirect.com

Greenfield Threading Thread Forming Tap Metric, Bottoming, High Thread Forming Titanium Heating titanium increases its formability, reduces spring back, and permits maximum deformation with minimum annealing between forming. These fluteless tools, which create threads by moving material rather than cutting action, are often used for titanium tapping because they offer a strong cross section. When form tapping titanium, a lot of that heat penetrates the tool and causes premature failure. Form. Thread Forming Titanium.

From www.mscdirect.com

Hertel Thread Forming Tap 348 UNC, Bottoming, HighSpeed Steel Thread Forming Titanium Discover the advantages and disadvantages of hot forming, superplastic forming, and cold forming for titanium parts. Heating titanium increases its formability, reduces spring back, and permits maximum deformation with minimum annealing between forming. This means that in this process, the thread isn't cut from the material. These fluteless tools, which create threads by moving material rather than cutting action, are. Thread Forming Titanium.

From www.mscdirect.com

Emuge Thread Forming Tap Metric, 6HX Class of Fit, Bottoming, High Thread Forming Titanium Heating titanium increases its formability, reduces springback, and permits maximum deformation with minimum annealing between forming operations. Heating titanium increases its formability, reduces spring back, and permits maximum deformation with minimum annealing between forming. This means that in this process, the thread isn't cut from the material. Form taps are typically less than 3⁄4 , or an m20, in diameter.. Thread Forming Titanium.

From tengri.en.made-in-china.com

Titanium Torx Oval Head Machine Screw PT Thread Screw Thread Forming Thread Forming Titanium Forming or rolling threads is a chipless method of thread production. Form taps are typically less than 3⁄4 , or an m20, in diameter. When form tapping titanium, a lot of that heat penetrates the tool and causes premature failure. Heating titanium increases its formability, reduces spring back, and permits maximum deformation with minimum annealing between forming. Heating titanium increases. Thread Forming Titanium.