Hard Surface Electrode . Hardfacing is performed using specialized electrodes or filler rods but largely uses the same kind of arc welding process to melt those fillers onto the surface of the. Unlike joining electrodes, hardfacing electrodes are a collection of proprietary alloy formulations geared toward meeting specific needs. Hardfacing filler metals for restoring parts that are worn down or adding a protective layer to carbon steel surfaces. 58 rockwell “c” hardfacing electrode for combined abrasion and moderate impact. Discover how to select hardfacing electrodes that boost equipment durability and performance. For surfacing with high hardness level and good abrasion, resistance under moderate. The aws a5.13 specification covers stick electrodes specifically designed for hardfacing applications such as rebuilding worn out parts or improving the surfaces of new parts under construction.

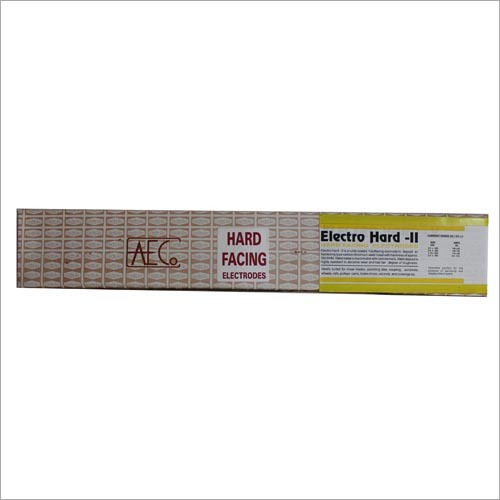

from www.electroarc.in

For surfacing with high hardness level and good abrasion, resistance under moderate. Discover how to select hardfacing electrodes that boost equipment durability and performance. Unlike joining electrodes, hardfacing electrodes are a collection of proprietary alloy formulations geared toward meeting specific needs. 58 rockwell “c” hardfacing electrode for combined abrasion and moderate impact. Hardfacing filler metals for restoring parts that are worn down or adding a protective layer to carbon steel surfaces. Hardfacing is performed using specialized electrodes or filler rods but largely uses the same kind of arc welding process to melt those fillers onto the surface of the. The aws a5.13 specification covers stick electrodes specifically designed for hardfacing applications such as rebuilding worn out parts or improving the surfaces of new parts under construction.

Hard facing electrodes supplier,hard facing electrodes manufacturer

Hard Surface Electrode 58 rockwell “c” hardfacing electrode for combined abrasion and moderate impact. 58 rockwell “c” hardfacing electrode for combined abrasion and moderate impact. Discover how to select hardfacing electrodes that boost equipment durability and performance. Hardfacing is performed using specialized electrodes or filler rods but largely uses the same kind of arc welding process to melt those fillers onto the surface of the. Hardfacing filler metals for restoring parts that are worn down or adding a protective layer to carbon steel surfaces. For surfacing with high hardness level and good abrasion, resistance under moderate. Unlike joining electrodes, hardfacing electrodes are a collection of proprietary alloy formulations geared toward meeting specific needs. The aws a5.13 specification covers stick electrodes specifically designed for hardfacing applications such as rebuilding worn out parts or improving the surfaces of new parts under construction.

From www.researchgate.net

Examples of surface electrodes for EMG recordings (a) solid metal bar Hard Surface Electrode Hardfacing filler metals for restoring parts that are worn down or adding a protective layer to carbon steel surfaces. The aws a5.13 specification covers stick electrodes specifically designed for hardfacing applications such as rebuilding worn out parts or improving the surfaces of new parts under construction. Discover how to select hardfacing electrodes that boost equipment durability and performance. Unlike joining. Hard Surface Electrode.

From www.indiamart.com

Hard Surfacing Cutting Welding Electrodes at Rs 110/kg Hard Facing Hard Surface Electrode Unlike joining electrodes, hardfacing electrodes are a collection of proprietary alloy formulations geared toward meeting specific needs. For surfacing with high hardness level and good abrasion, resistance under moderate. Hardfacing is performed using specialized electrodes or filler rods but largely uses the same kind of arc welding process to melt those fillers onto the surface of the. Hardfacing filler metals. Hard Surface Electrode.

From www.researchgate.net

SEM images of the bare GC electrode surface (a) and the CONM/GC Hard Surface Electrode Hardfacing filler metals for restoring parts that are worn down or adding a protective layer to carbon steel surfaces. For surfacing with high hardness level and good abrasion, resistance under moderate. 58 rockwell “c” hardfacing electrode for combined abrasion and moderate impact. Discover how to select hardfacing electrodes that boost equipment durability and performance. Unlike joining electrodes, hardfacing electrodes are. Hard Surface Electrode.

From www.lowes.com

Lincoln Electric 10lbs 5/32in All Position Hard Surface Electrode Hard Surface Electrode Hardfacing filler metals for restoring parts that are worn down or adding a protective layer to carbon steel surfaces. 58 rockwell “c” hardfacing electrode for combined abrasion and moderate impact. Hardfacing is performed using specialized electrodes or filler rods but largely uses the same kind of arc welding process to melt those fillers onto the surface of the. For surfacing. Hard Surface Electrode.

From www.thefabricator.com

SMAW, hardfacing electrode basics Hard Surface Electrode 58 rockwell “c” hardfacing electrode for combined abrasion and moderate impact. Unlike joining electrodes, hardfacing electrodes are a collection of proprietary alloy formulations geared toward meeting specific needs. Hardfacing filler metals for restoring parts that are worn down or adding a protective layer to carbon steel surfaces. Discover how to select hardfacing electrodes that boost equipment durability and performance. For. Hard Surface Electrode.

From www.researchgate.net

Micrographs of high surface area electrode materials for CDI. (a) SEM Hard Surface Electrode Hardfacing is performed using specialized electrodes or filler rods but largely uses the same kind of arc welding process to melt those fillers onto the surface of the. 58 rockwell “c” hardfacing electrode for combined abrasion and moderate impact. Unlike joining electrodes, hardfacing electrodes are a collection of proprietary alloy formulations geared toward meeting specific needs. For surfacing with high. Hard Surface Electrode.

From electrodestore.com

1023 EMG Disposable Surface Electrodes The Electrode Store Hard Surface Electrode Unlike joining electrodes, hardfacing electrodes are a collection of proprietary alloy formulations geared toward meeting specific needs. 58 rockwell “c” hardfacing electrode for combined abrasion and moderate impact. For surfacing with high hardness level and good abrasion, resistance under moderate. The aws a5.13 specification covers stick electrodes specifically designed for hardfacing applications such as rebuilding worn out parts or improving. Hard Surface Electrode.

From www.lowes.com

Forney 5/32in Hard Surface Electrode All Position 5lb in the Welding Hard Surface Electrode 58 rockwell “c” hardfacing electrode for combined abrasion and moderate impact. Hardfacing filler metals for restoring parts that are worn down or adding a protective layer to carbon steel surfaces. Hardfacing is performed using specialized electrodes or filler rods but largely uses the same kind of arc welding process to melt those fillers onto the surface of the. Discover how. Hard Surface Electrode.

From www.lowes.com

Hard surface electrode Welding Rods at Hard Surface Electrode Unlike joining electrodes, hardfacing electrodes are a collection of proprietary alloy formulations geared toward meeting specific needs. Hardfacing filler metals for restoring parts that are worn down or adding a protective layer to carbon steel surfaces. Discover how to select hardfacing electrodes that boost equipment durability and performance. The aws a5.13 specification covers stick electrodes specifically designed for hardfacing applications. Hard Surface Electrode.

From www.lowes.com

Forney 5/32in Hard Surface Electrode All Position 5lb in the Welding Hard Surface Electrode 58 rockwell “c” hardfacing electrode for combined abrasion and moderate impact. The aws a5.13 specification covers stick electrodes specifically designed for hardfacing applications such as rebuilding worn out parts or improving the surfaces of new parts under construction. Hardfacing filler metals for restoring parts that are worn down or adding a protective layer to carbon steel surfaces. Hardfacing is performed. Hard Surface Electrode.

From eureka.patsnap.com

Surfacemodified hardcarbon negative electrode material and Hard Surface Electrode Hardfacing filler metals for restoring parts that are worn down or adding a protective layer to carbon steel surfaces. Hardfacing is performed using specialized electrodes or filler rods but largely uses the same kind of arc welding process to melt those fillers onto the surface of the. Discover how to select hardfacing electrodes that boost equipment durability and performance. For. Hard Surface Electrode.

From www.thefabricator.com

SMAW, hardfacing electrode basics Hard Surface Electrode Hardfacing is performed using specialized electrodes or filler rods but largely uses the same kind of arc welding process to melt those fillers onto the surface of the. 58 rockwell “c” hardfacing electrode for combined abrasion and moderate impact. For surfacing with high hardness level and good abrasion, resistance under moderate. Unlike joining electrodes, hardfacing electrodes are a collection of. Hard Surface Electrode.

From shop.neurolite.ch

Surface electrodes singleuse (single cable) IOM Disposable Surface Hard Surface Electrode For surfacing with high hardness level and good abrasion, resistance under moderate. The aws a5.13 specification covers stick electrodes specifically designed for hardfacing applications such as rebuilding worn out parts or improving the surfaces of new parts under construction. Hardfacing filler metals for restoring parts that are worn down or adding a protective layer to carbon steel surfaces. Discover how. Hard Surface Electrode.

From www.researchgate.net

Surfaceelectrode ion trap featuring three individual traps. (a Hard Surface Electrode Unlike joining electrodes, hardfacing electrodes are a collection of proprietary alloy formulations geared toward meeting specific needs. Discover how to select hardfacing electrodes that boost equipment durability and performance. The aws a5.13 specification covers stick electrodes specifically designed for hardfacing applications such as rebuilding worn out parts or improving the surfaces of new parts under construction. Hardfacing filler metals for. Hard Surface Electrode.

From www.lowes.com

Lincoln Electric 1lb 1/8in All Position Hard Surface Electrode Hard Surface Electrode The aws a5.13 specification covers stick electrodes specifically designed for hardfacing applications such as rebuilding worn out parts or improving the surfaces of new parts under construction. Hardfacing is performed using specialized electrodes or filler rods but largely uses the same kind of arc welding process to melt those fillers onto the surface of the. Discover how to select hardfacing. Hard Surface Electrode.

From enercorp.com

Surface Electrode 213 • Enercorp Instruments Hard Surface Electrode Hardfacing filler metals for restoring parts that are worn down or adding a protective layer to carbon steel surfaces. Discover how to select hardfacing electrodes that boost equipment durability and performance. For surfacing with high hardness level and good abrasion, resistance under moderate. Unlike joining electrodes, hardfacing electrodes are a collection of proprietary alloy formulations geared toward meeting specific needs.. Hard Surface Electrode.

From www.researchgate.net

(A) Picture of the electrode surface, (B) image of the surface obtained Hard Surface Electrode The aws a5.13 specification covers stick electrodes specifically designed for hardfacing applications such as rebuilding worn out parts or improving the surfaces of new parts under construction. 58 rockwell “c” hardfacing electrode for combined abrasion and moderate impact. Hardfacing is performed using specialized electrodes or filler rods but largely uses the same kind of arc welding process to melt those. Hard Surface Electrode.

From www.researchgate.net

SEM images of copper electrode surfaces before and after ORC Download Hard Surface Electrode Discover how to select hardfacing electrodes that boost equipment durability and performance. Hardfacing filler metals for restoring parts that are worn down or adding a protective layer to carbon steel surfaces. Unlike joining electrodes, hardfacing electrodes are a collection of proprietary alloy formulations geared toward meeting specific needs. The aws a5.13 specification covers stick electrodes specifically designed for hardfacing applications. Hard Surface Electrode.

From www.electroarc.in

Hard facing electrodes supplier,hard facing electrodes manufacturer Hard Surface Electrode For surfacing with high hardness level and good abrasion, resistance under moderate. Hardfacing filler metals for restoring parts that are worn down or adding a protective layer to carbon steel surfaces. 58 rockwell “c” hardfacing electrode for combined abrasion and moderate impact. Hardfacing is performed using specialized electrodes or filler rods but largely uses the same kind of arc welding. Hard Surface Electrode.

From www.researchgate.net

SEM analysis of an electrode surface. The original scan is shown to the Hard Surface Electrode The aws a5.13 specification covers stick electrodes specifically designed for hardfacing applications such as rebuilding worn out parts or improving the surfaces of new parts under construction. Discover how to select hardfacing electrodes that boost equipment durability and performance. Hardfacing filler metals for restoring parts that are worn down or adding a protective layer to carbon steel surfaces. For surfacing. Hard Surface Electrode.

From www.researchgate.net

SEM images of the working electrode surface of A SPCE, B PSS/SPCE and C Hard Surface Electrode Hardfacing is performed using specialized electrodes or filler rods but largely uses the same kind of arc welding process to melt those fillers onto the surface of the. 58 rockwell “c” hardfacing electrode for combined abrasion and moderate impact. The aws a5.13 specification covers stick electrodes specifically designed for hardfacing applications such as rebuilding worn out parts or improving the. Hard Surface Electrode.

From www.hielscher.com

The Solution to Electrode Surface Fouling Hielscher Ultrasonics Hard Surface Electrode For surfacing with high hardness level and good abrasion, resistance under moderate. The aws a5.13 specification covers stick electrodes specifically designed for hardfacing applications such as rebuilding worn out parts or improving the surfaces of new parts under construction. Hardfacing is performed using specialized electrodes or filler rods but largely uses the same kind of arc welding process to melt. Hard Surface Electrode.

From www.researchgate.net

Photograph of electrode surface. Download Scientific Diagram Hard Surface Electrode 58 rockwell “c” hardfacing electrode for combined abrasion and moderate impact. Hardfacing filler metals for restoring parts that are worn down or adding a protective layer to carbon steel surfaces. Hardfacing is performed using specialized electrodes or filler rods but largely uses the same kind of arc welding process to melt those fillers onto the surface of the. For surfacing. Hard Surface Electrode.

From www.researchgate.net

Examples of surface electrode types for EMG recordings (a) solid metal Hard Surface Electrode Discover how to select hardfacing electrodes that boost equipment durability and performance. Hardfacing is performed using specialized electrodes or filler rods but largely uses the same kind of arc welding process to melt those fillers onto the surface of the. Hardfacing filler metals for restoring parts that are worn down or adding a protective layer to carbon steel surfaces. 58. Hard Surface Electrode.

From www.researchgate.net

MFC carbon electrode structure a) plain carbon electrodes of same Hard Surface Electrode For surfacing with high hardness level and good abrasion, resistance under moderate. 58 rockwell “c” hardfacing electrode for combined abrasion and moderate impact. Hardfacing filler metals for restoring parts that are worn down or adding a protective layer to carbon steel surfaces. The aws a5.13 specification covers stick electrodes specifically designed for hardfacing applications such as rebuilding worn out parts. Hard Surface Electrode.

From mundakawg.com

EFeCrA1 Hardfacing High Chrome Cast Iron Surfacing Electrode D667 Hard Surface Electrode The aws a5.13 specification covers stick electrodes specifically designed for hardfacing applications such as rebuilding worn out parts or improving the surfaces of new parts under construction. 58 rockwell “c” hardfacing electrode for combined abrasion and moderate impact. For surfacing with high hardness level and good abrasion, resistance under moderate. Hardfacing is performed using specialized electrodes or filler rods but. Hard Surface Electrode.

From www.researchgate.net

Illustrations of the stretchable surface electrode arrays using the Hard Surface Electrode 58 rockwell “c” hardfacing electrode for combined abrasion and moderate impact. Unlike joining electrodes, hardfacing electrodes are a collection of proprietary alloy formulations geared toward meeting specific needs. The aws a5.13 specification covers stick electrodes specifically designed for hardfacing applications such as rebuilding worn out parts or improving the surfaces of new parts under construction. For surfacing with high hardness. Hard Surface Electrode.

From lemg.org

Surface Electrode Laryngeal Electromyography Hard Surface Electrode For surfacing with high hardness level and good abrasion, resistance under moderate. Hardfacing filler metals for restoring parts that are worn down or adding a protective layer to carbon steel surfaces. The aws a5.13 specification covers stick electrodes specifically designed for hardfacing applications such as rebuilding worn out parts or improving the surfaces of new parts under construction. 58 rockwell. Hard Surface Electrode.

From www.lowes.com

Lincoln Electric 10lbs 3/16in Horizontal and Flat Hard Surface Hard Surface Electrode Hardfacing is performed using specialized electrodes or filler rods but largely uses the same kind of arc welding process to melt those fillers onto the surface of the. Hardfacing filler metals for restoring parts that are worn down or adding a protective layer to carbon steel surfaces. 58 rockwell “c” hardfacing electrode for combined abrasion and moderate impact. Unlike joining. Hard Surface Electrode.

From www.lowes.com

Forney 1/8in Hard Surface Electrode All Position 5lb at Hard Surface Electrode For surfacing with high hardness level and good abrasion, resistance under moderate. Unlike joining electrodes, hardfacing electrodes are a collection of proprietary alloy formulations geared toward meeting specific needs. 58 rockwell “c” hardfacing electrode for combined abrasion and moderate impact. Hardfacing is performed using specialized electrodes or filler rods but largely uses the same kind of arc welding process to. Hard Surface Electrode.

From www.hardfacingfty.com

What is Hardfacing Welding? Hard Surface Electrode The aws a5.13 specification covers stick electrodes specifically designed for hardfacing applications such as rebuilding worn out parts or improving the surfaces of new parts under construction. Hardfacing filler metals for restoring parts that are worn down or adding a protective layer to carbon steel surfaces. 58 rockwell “c” hardfacing electrode for combined abrasion and moderate impact. Discover how to. Hard Surface Electrode.

From nalaishengwu.en.made-in-china.com

Nl10 Hard Surface Good Flexural Strength Oxidation Resistant Electrode Hard Surface Electrode Hardfacing is performed using specialized electrodes or filler rods but largely uses the same kind of arc welding process to melt those fillers onto the surface of the. The aws a5.13 specification covers stick electrodes specifically designed for hardfacing applications such as rebuilding worn out parts or improving the surfaces of new parts under construction. For surfacing with high hardness. Hard Surface Electrode.

From hcl-asia.com.hk

HCL Asia Limited Products HCL Asia Ltd. Hard Surface Electrode Hardfacing filler metals for restoring parts that are worn down or adding a protective layer to carbon steel surfaces. The aws a5.13 specification covers stick electrodes specifically designed for hardfacing applications such as rebuilding worn out parts or improving the surfaces of new parts under construction. Hardfacing is performed using specialized electrodes or filler rods but largely uses the same. Hard Surface Electrode.

From www.cruxweld.com

Welding Electrodes Learn About Its Types and Uses cruxweld Hard Surface Electrode Discover how to select hardfacing electrodes that boost equipment durability and performance. Unlike joining electrodes, hardfacing electrodes are a collection of proprietary alloy formulations geared toward meeting specific needs. For surfacing with high hardness level and good abrasion, resistance under moderate. 58 rockwell “c” hardfacing electrode for combined abrasion and moderate impact. The aws a5.13 specification covers stick electrodes specifically. Hard Surface Electrode.

From www.researchgate.net

Illustrations of the stretchable surface electrode arrays using the Hard Surface Electrode Unlike joining electrodes, hardfacing electrodes are a collection of proprietary alloy formulations geared toward meeting specific needs. Hardfacing filler metals for restoring parts that are worn down or adding a protective layer to carbon steel surfaces. For surfacing with high hardness level and good abrasion, resistance under moderate. 58 rockwell “c” hardfacing electrode for combined abrasion and moderate impact. Hardfacing. Hard Surface Electrode.