Spiral Bevel Gear Rotation Direction . However, the axes always intersect, which means they have, at their crossing. this type of gear is beginning to supersede straight bevel gears in many applications. They have the advantage of ensuring evenly distributed tooth loads and carry more load without surface fatigue. Would you expect an increase in the torque required to turn a spiral bevel gearset in one direction (say clockwise) vs. the axes of spiral bevel gears in most cases intersect under an angle of 90°. The octoid provides a constant ratio and makes the gears insensitive to displacements perpendicular to the pitch line. The formulas that i can find say that the. Bevel gears are widely used in industrial machinery for their ability to change the. for any spiral tooth spiral bevel gear combination, the mating pinion and the spiral bevel gear must be the same pitch, the same pressure angle, the same spiral angle, but opposite spiral direction. In addition to standard spiral bevel gears, there are modified versions designed for specific applications. the standard convention for speed reducing drives is for the gear convex flank of a spiral bevel or zerol bevel set to be the “forward driven flank” and for the concave side to be the “reverse driven flank.”.

from en.wikipedia.org

The formulas that i can find say that the. In addition to standard spiral bevel gears, there are modified versions designed for specific applications. However, the axes always intersect, which means they have, at their crossing. the axes of spiral bevel gears in most cases intersect under an angle of 90°. Would you expect an increase in the torque required to turn a spiral bevel gearset in one direction (say clockwise) vs. the standard convention for speed reducing drives is for the gear convex flank of a spiral bevel or zerol bevel set to be the “forward driven flank” and for the concave side to be the “reverse driven flank.”. The octoid provides a constant ratio and makes the gears insensitive to displacements perpendicular to the pitch line. They have the advantage of ensuring evenly distributed tooth loads and carry more load without surface fatigue. this type of gear is beginning to supersede straight bevel gears in many applications. for any spiral tooth spiral bevel gear combination, the mating pinion and the spiral bevel gear must be the same pitch, the same pressure angle, the same spiral angle, but opposite spiral direction.

Spiral bevel gear Wikipedia

Spiral Bevel Gear Rotation Direction They have the advantage of ensuring evenly distributed tooth loads and carry more load without surface fatigue. this type of gear is beginning to supersede straight bevel gears in many applications. the standard convention for speed reducing drives is for the gear convex flank of a spiral bevel or zerol bevel set to be the “forward driven flank” and for the concave side to be the “reverse driven flank.”. The formulas that i can find say that the. for any spiral tooth spiral bevel gear combination, the mating pinion and the spiral bevel gear must be the same pitch, the same pressure angle, the same spiral angle, but opposite spiral direction. The octoid provides a constant ratio and makes the gears insensitive to displacements perpendicular to the pitch line. However, the axes always intersect, which means they have, at their crossing. Would you expect an increase in the torque required to turn a spiral bevel gearset in one direction (say clockwise) vs. In addition to standard spiral bevel gears, there are modified versions designed for specific applications. the axes of spiral bevel gears in most cases intersect under an angle of 90°. They have the advantage of ensuring evenly distributed tooth loads and carry more load without surface fatigue. Bevel gears are widely used in industrial machinery for their ability to change the.

From www.researchgate.net

Direction of thrust and rotational forces in a spiral bevel gear Spiral Bevel Gear Rotation Direction the axes of spiral bevel gears in most cases intersect under an angle of 90°. They have the advantage of ensuring evenly distributed tooth loads and carry more load without surface fatigue. The formulas that i can find say that the. However, the axes always intersect, which means they have, at their crossing. the standard convention for speed. Spiral Bevel Gear Rotation Direction.

From www.turbosquid.com

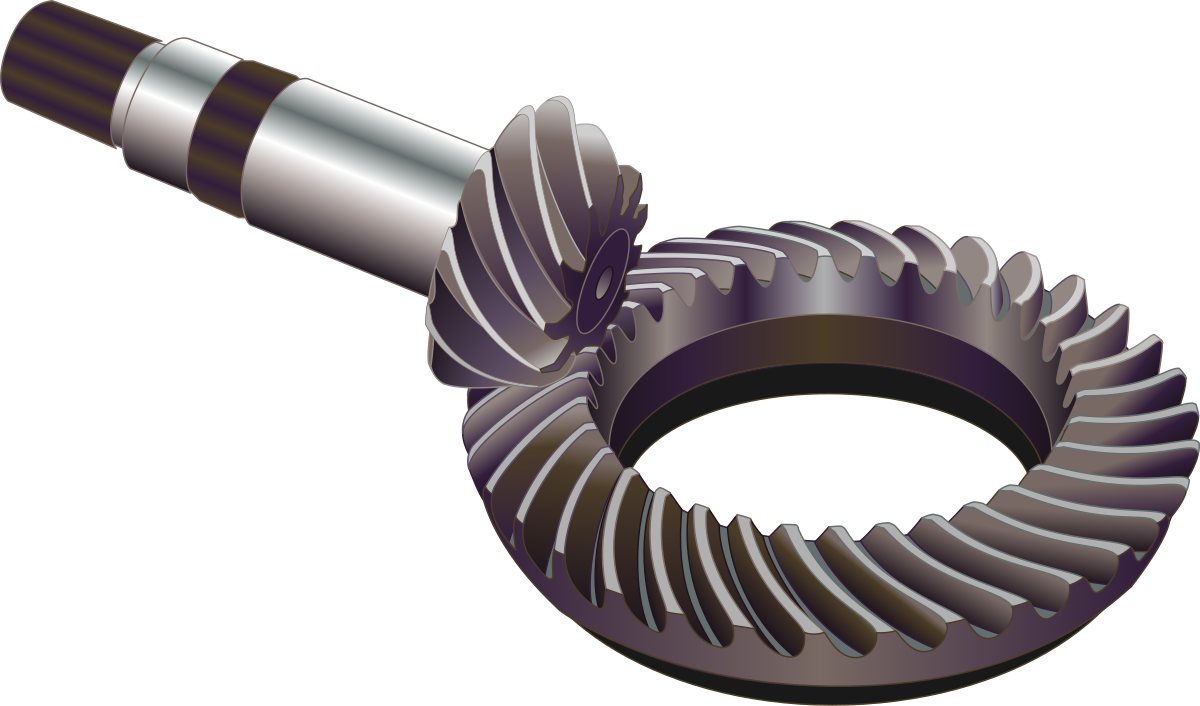

spiral bevel gear 3d model Spiral Bevel Gear Rotation Direction The formulas that i can find say that the. The octoid provides a constant ratio and makes the gears insensitive to displacements perpendicular to the pitch line. In addition to standard spiral bevel gears, there are modified versions designed for specific applications. Would you expect an increase in the torque required to turn a spiral bevel gearset in one direction. Spiral Bevel Gear Rotation Direction.

From www.zhygear.com

Understanding the Dynamics of Spiral Bevel Gears ZHY Gear Spiral Bevel Gear Rotation Direction They have the advantage of ensuring evenly distributed tooth loads and carry more load without surface fatigue. Bevel gears are widely used in industrial machinery for their ability to change the. this type of gear is beginning to supersede straight bevel gears in many applications. Would you expect an increase in the torque required to turn a spiral bevel. Spiral Bevel Gear Rotation Direction.

From www.zhygear.com

Construction of contact finite element model of spiral bevel gear ZHY Spiral Bevel Gear Rotation Direction this type of gear is beginning to supersede straight bevel gears in many applications. In addition to standard spiral bevel gears, there are modified versions designed for specific applications. Bevel gears are widely used in industrial machinery for their ability to change the. However, the axes always intersect, which means they have, at their crossing. They have the advantage. Spiral Bevel Gear Rotation Direction.

From www.pinterest.com

Close up view of brand new engine gears Stock Photo Alamy Spiral Bevel Gear Rotation Direction this type of gear is beginning to supersede straight bevel gears in many applications. the axes of spiral bevel gears in most cases intersect under an angle of 90°. the standard convention for speed reducing drives is for the gear convex flank of a spiral bevel or zerol bevel set to be the “forward driven flank” and. Spiral Bevel Gear Rotation Direction.

From www.needpix.com

Gears,spiral bevel gears,bevel gear,toothed wheels,rotation free Spiral Bevel Gear Rotation Direction the standard convention for speed reducing drives is for the gear convex flank of a spiral bevel or zerol bevel set to be the “forward driven flank” and for the concave side to be the “reverse driven flank.”. In addition to standard spiral bevel gears, there are modified versions designed for specific applications. Would you expect an increase in. Spiral Bevel Gear Rotation Direction.

From www.tandler.co.uk

Spiral Bevel Reversing Gearbox — Tandler Precision Spiral Bevel Gear Rotation Direction In addition to standard spiral bevel gears, there are modified versions designed for specific applications. the standard convention for speed reducing drives is for the gear convex flank of a spiral bevel or zerol bevel set to be the “forward driven flank” and for the concave side to be the “reverse driven flank.”. the axes of spiral bevel. Spiral Bevel Gear Rotation Direction.

From en.wikipedia.org

Spiral bevel gear Wikipedia Spiral Bevel Gear Rotation Direction However, the axes always intersect, which means they have, at their crossing. They have the advantage of ensuring evenly distributed tooth loads and carry more load without surface fatigue. for any spiral tooth spiral bevel gear combination, the mating pinion and the spiral bevel gear must be the same pitch, the same pressure angle, the same spiral angle, but. Spiral Bevel Gear Rotation Direction.

From www.grainger.com

Spiral, Gear Ratio 3, Ground Spiral Bevel Gear 793DF6SBSG2.54515R Spiral Bevel Gear Rotation Direction The formulas that i can find say that the. They have the advantage of ensuring evenly distributed tooth loads and carry more load without surface fatigue. However, the axes always intersect, which means they have, at their crossing. for any spiral tooth spiral bevel gear combination, the mating pinion and the spiral bevel gear must be the same pitch,. Spiral Bevel Gear Rotation Direction.

From www.youtube.com

How to make spiral bevel gear in SolidWorks YouTube Spiral Bevel Gear Rotation Direction Bevel gears are widely used in industrial machinery for their ability to change the. the standard convention for speed reducing drives is for the gear convex flank of a spiral bevel or zerol bevel set to be the “forward driven flank” and for the concave side to be the “reverse driven flank.”. the axes of spiral bevel gears. Spiral Bevel Gear Rotation Direction.

From www.researchgate.net

Concept of spiral bevel gear hobbing. Download Scientific Diagram Spiral Bevel Gear Rotation Direction the axes of spiral bevel gears in most cases intersect under an angle of 90°. The formulas that i can find say that the. for any spiral tooth spiral bevel gear combination, the mating pinion and the spiral bevel gear must be the same pitch, the same pressure angle, the same spiral angle, but opposite spiral direction. However,. Spiral Bevel Gear Rotation Direction.

From www.researchgate.net

Sketch of the gear alignment curve of the spiral bevel gear Download Spiral Bevel Gear Rotation Direction the axes of spiral bevel gears in most cases intersect under an angle of 90°. They have the advantage of ensuring evenly distributed tooth loads and carry more load without surface fatigue. However, the axes always intersect, which means they have, at their crossing. for any spiral tooth spiral bevel gear combination, the mating pinion and the spiral. Spiral Bevel Gear Rotation Direction.

From www.lampin.com

Rotation Guide for MITRPAK Right Angle Gearboxes Spiral Bevel Gear Rotation Direction They have the advantage of ensuring evenly distributed tooth loads and carry more load without surface fatigue. Bevel gears are widely used in industrial machinery for their ability to change the. the axes of spiral bevel gears in most cases intersect under an angle of 90°. However, the axes always intersect, which means they have, at their crossing. Would. Spiral Bevel Gear Rotation Direction.

From www.renowngears.co.uk

Spiral Bevel Gears Renown Gears Spiral Bevel Gear Rotation Direction for any spiral tooth spiral bevel gear combination, the mating pinion and the spiral bevel gear must be the same pitch, the same pressure angle, the same spiral angle, but opposite spiral direction. They have the advantage of ensuring evenly distributed tooth loads and carry more load without surface fatigue. However, the axes always intersect, which means they have,. Spiral Bevel Gear Rotation Direction.

From ar.inspiredpencil.com

Bevel Gear Examples Spiral Bevel Gear Rotation Direction for any spiral tooth spiral bevel gear combination, the mating pinion and the spiral bevel gear must be the same pitch, the same pressure angle, the same spiral angle, but opposite spiral direction. However, the axes always intersect, which means they have, at their crossing. the axes of spiral bevel gears in most cases intersect under an angle. Spiral Bevel Gear Rotation Direction.

From www.zhygear.com

Modeling of cutting force in machining spiral bevel gear with forming Spiral Bevel Gear Rotation Direction Bevel gears are widely used in industrial machinery for their ability to change the. The formulas that i can find say that the. In addition to standard spiral bevel gears, there are modified versions designed for specific applications. They have the advantage of ensuring evenly distributed tooth loads and carry more load without surface fatigue. this type of gear. Spiral Bevel Gear Rotation Direction.

From www.zhygear.com

Machining spiral bevel gears and hypoid gears based on the principle of Spiral Bevel Gear Rotation Direction The formulas that i can find say that the. the standard convention for speed reducing drives is for the gear convex flank of a spiral bevel or zerol bevel set to be the “forward driven flank” and for the concave side to be the “reverse driven flank.”. the axes of spiral bevel gears in most cases intersect under. Spiral Bevel Gear Rotation Direction.

From inhisfootprint.blogspot.com

zerol bevel gear design inhisfootprint Spiral Bevel Gear Rotation Direction for any spiral tooth spiral bevel gear combination, the mating pinion and the spiral bevel gear must be the same pitch, the same pressure angle, the same spiral angle, but opposite spiral direction. In addition to standard spiral bevel gears, there are modified versions designed for specific applications. Bevel gears are widely used in industrial machinery for their ability. Spiral Bevel Gear Rotation Direction.

From www.turbosquid.com

spiral bevel gear 3d model Spiral Bevel Gear Rotation Direction Bevel gears are widely used in industrial machinery for their ability to change the. In addition to standard spiral bevel gears, there are modified versions designed for specific applications. Would you expect an increase in the torque required to turn a spiral bevel gearset in one direction (say clockwise) vs. for any spiral tooth spiral bevel gear combination, the. Spiral Bevel Gear Rotation Direction.

From www.mdpi.com

Applied Sciences Free FullText Theoretical and Experimental Study Spiral Bevel Gear Rotation Direction The formulas that i can find say that the. this type of gear is beginning to supersede straight bevel gears in many applications. the axes of spiral bevel gears in most cases intersect under an angle of 90°. Would you expect an increase in the torque required to turn a spiral bevel gearset in one direction (say clockwise). Spiral Bevel Gear Rotation Direction.

From www.iqsdirectory.com

Bevel Gear What Is It? How Does It Work? Types, Uses Spiral Bevel Gear Rotation Direction the axes of spiral bevel gears in most cases intersect under an angle of 90°. The octoid provides a constant ratio and makes the gears insensitive to displacements perpendicular to the pitch line. the standard convention for speed reducing drives is for the gear convex flank of a spiral bevel or zerol bevel set to be the “forward. Spiral Bevel Gear Rotation Direction.

From blogs.sw.siemens.com

Simulate Bevel Gears Accurately and Efficiently Simcenter Spiral Bevel Gear Rotation Direction They have the advantage of ensuring evenly distributed tooth loads and carry more load without surface fatigue. for any spiral tooth spiral bevel gear combination, the mating pinion and the spiral bevel gear must be the same pitch, the same pressure angle, the same spiral angle, but opposite spiral direction. The octoid provides a constant ratio and makes the. Spiral Bevel Gear Rotation Direction.

From www.iqsdirectory.com

Bevel Gear What Are They? How Do They Work? Types and Uses Spiral Bevel Gear Rotation Direction They have the advantage of ensuring evenly distributed tooth loads and carry more load without surface fatigue. Would you expect an increase in the torque required to turn a spiral bevel gearset in one direction (say clockwise) vs. In addition to standard spiral bevel gears, there are modified versions designed for specific applications. The octoid provides a constant ratio and. Spiral Bevel Gear Rotation Direction.

From www.zuazo.net

Spiral Bevel Gears BSG ZUAZO Spiral Bevel Gear Rotation Direction Would you expect an increase in the torque required to turn a spiral bevel gearset in one direction (say clockwise) vs. for any spiral tooth spiral bevel gear combination, the mating pinion and the spiral bevel gear must be the same pitch, the same pressure angle, the same spiral angle, but opposite spiral direction. this type of gear. Spiral Bevel Gear Rotation Direction.

From www.tec-science.com

How does a differential gear work? tecscience Spiral Bevel Gear Rotation Direction the standard convention for speed reducing drives is for the gear convex flank of a spiral bevel or zerol bevel set to be the “forward driven flank” and for the concave side to be the “reverse driven flank.”. In addition to standard spiral bevel gears, there are modified versions designed for specific applications. Would you expect an increase in. Spiral Bevel Gear Rotation Direction.

From www.zhygear.com

Spiral Bevel Gears Driving Force Behind Wind Turbine Efficiency ZHY Gear Spiral Bevel Gear Rotation Direction Bevel gears are widely used in industrial machinery for their ability to change the. the standard convention for speed reducing drives is for the gear convex flank of a spiral bevel or zerol bevel set to be the “forward driven flank” and for the concave side to be the “reverse driven flank.”. The octoid provides a constant ratio and. Spiral Bevel Gear Rotation Direction.

From www.sdprecision.co.za

Spiral Bevel Gear S&D Precision Toolmakers Spiral Bevel Gear Rotation Direction They have the advantage of ensuring evenly distributed tooth loads and carry more load without surface fatigue. the axes of spiral bevel gears in most cases intersect under an angle of 90°. Would you expect an increase in the torque required to turn a spiral bevel gearset in one direction (say clockwise) vs. Bevel gears are widely used in. Spiral Bevel Gear Rotation Direction.

From www.slideserve.com

PPT MANUAL TRANSMISSIONS/TRANSAXLES PowerPoint Presentation, free Spiral Bevel Gear Rotation Direction In addition to standard spiral bevel gears, there are modified versions designed for specific applications. The octoid provides a constant ratio and makes the gears insensitive to displacements perpendicular to the pitch line. Bevel gears are widely used in industrial machinery for their ability to change the. the axes of spiral bevel gears in most cases intersect under an. Spiral Bevel Gear Rotation Direction.

From library3dengineer.blogspot.com

30. Spiral Bevel Gear Pair in SolidWorks free download 3D model Spiral Bevel Gear Rotation Direction the axes of spiral bevel gears in most cases intersect under an angle of 90°. However, the axes always intersect, which means they have, at their crossing. for any spiral tooth spiral bevel gear combination, the mating pinion and the spiral bevel gear must be the same pitch, the same pressure angle, the same spiral angle, but opposite. Spiral Bevel Gear Rotation Direction.

From www.semanticscholar.org

Figure 7 from Design and Analysis of a Spiral Bevel Gear Semantic Scholar Spiral Bevel Gear Rotation Direction the axes of spiral bevel gears in most cases intersect under an angle of 90°. They have the advantage of ensuring evenly distributed tooth loads and carry more load without surface fatigue. In addition to standard spiral bevel gears, there are modified versions designed for specific applications. Bevel gears are widely used in industrial machinery for their ability to. Spiral Bevel Gear Rotation Direction.

From www.lampin.com

The Top 4 Advantages of Spiral Bevel Gears for Engineers Lampin Spiral Bevel Gear Rotation Direction In addition to standard spiral bevel gears, there are modified versions designed for specific applications. the axes of spiral bevel gears in most cases intersect under an angle of 90°. Would you expect an increase in the torque required to turn a spiral bevel gearset in one direction (say clockwise) vs. The formulas that i can find say that. Spiral Bevel Gear Rotation Direction.

From atbautomation.eu

Reversing spiral bevel gearbox Tandler W ATB Automation Spiral Bevel Gear Rotation Direction The octoid provides a constant ratio and makes the gears insensitive to displacements perpendicular to the pitch line. Would you expect an increase in the torque required to turn a spiral bevel gearset in one direction (say clockwise) vs. this type of gear is beginning to supersede straight bevel gears in many applications. for any spiral tooth spiral. Spiral Bevel Gear Rotation Direction.

From www.zhygear.com

Research conclusion of reverse engineering of logarithmic spiral bevel Spiral Bevel Gear Rotation Direction this type of gear is beginning to supersede straight bevel gears in many applications. the axes of spiral bevel gears in most cases intersect under an angle of 90°. The formulas that i can find say that the. However, the axes always intersect, which means they have, at their crossing. Bevel gears are widely used in industrial machinery. Spiral Bevel Gear Rotation Direction.

From blog.wcbranham.com

What's Better? Straight or Spiral Bevel Gearbox? Spiral Bevel Gear Rotation Direction Would you expect an increase in the torque required to turn a spiral bevel gearset in one direction (say clockwise) vs. this type of gear is beginning to supersede straight bevel gears in many applications. The octoid provides a constant ratio and makes the gears insensitive to displacements perpendicular to the pitch line. They have the advantage of ensuring. Spiral Bevel Gear Rotation Direction.

From www.researchgate.net

The dynamic model of a spiral bevel gear system with rotational degrees Spiral Bevel Gear Rotation Direction The octoid provides a constant ratio and makes the gears insensitive to displacements perpendicular to the pitch line. Bevel gears are widely used in industrial machinery for their ability to change the. However, the axes always intersect, which means they have, at their crossing. this type of gear is beginning to supersede straight bevel gears in many applications. They. Spiral Bevel Gear Rotation Direction.