Vacuum Former Examples . In its advanced form, the vacuum forming process utilizes. a vacuum is applied sucking the sheet into the mould. With pressure forming, compressed air pushes the plastic down. vacuum forming, also known as vacuum molding, is a flexible plastic manufacturing process where a heated. examples of vacuum forming products from golf trolleys, land yachts to baths and dashboards. vacuum forming is a type of thermoforming process where a plastic sheet is heated until it becomes pliable, then shaped over a mold using vacuum pressure. the solid shape that goes in the vacuum former is called a former; with vacuum forming, a vacuum pump sucks the plastic into the mould. The hollow part that has been vacuum formed is called a mould. The sheet is then ejected from the mould. This method is favored for its ability to create detailed and large parts efficiently, making it indispensable in various industries.

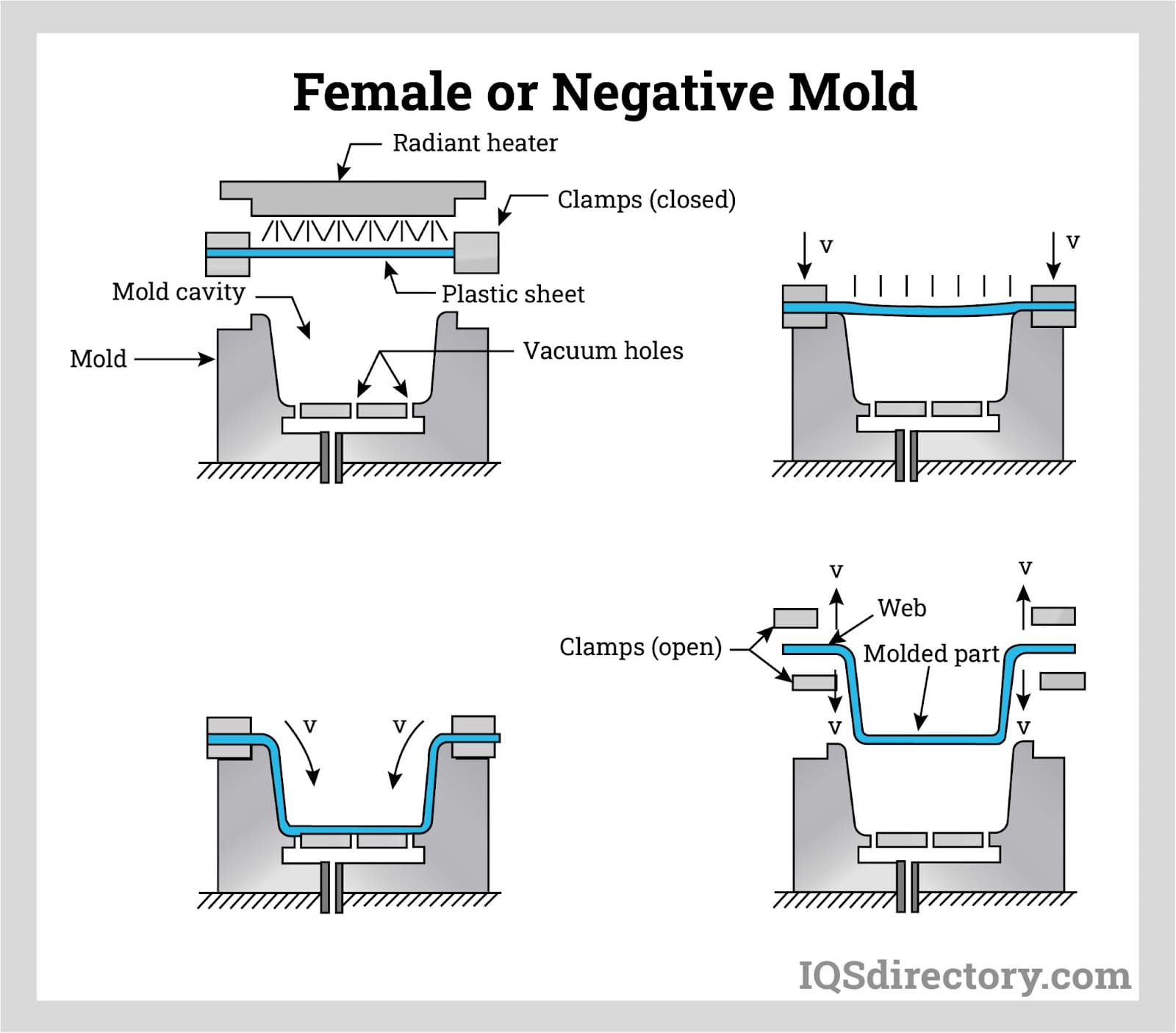

from www.iqsdirectory.com

vacuum forming is a type of thermoforming process where a plastic sheet is heated until it becomes pliable, then shaped over a mold using vacuum pressure. With pressure forming, compressed air pushes the plastic down. In its advanced form, the vacuum forming process utilizes. This method is favored for its ability to create detailed and large parts efficiently, making it indispensable in various industries. vacuum forming, also known as vacuum molding, is a flexible plastic manufacturing process where a heated. with vacuum forming, a vacuum pump sucks the plastic into the mould. The sheet is then ejected from the mould. a vacuum is applied sucking the sheet into the mould. The hollow part that has been vacuum formed is called a mould. the solid shape that goes in the vacuum former is called a former;

Vacuum Forming Types, Uses, Features and Benefits

Vacuum Former Examples with vacuum forming, a vacuum pump sucks the plastic into the mould. the solid shape that goes in the vacuum former is called a former; examples of vacuum forming products from golf trolleys, land yachts to baths and dashboards. a vacuum is applied sucking the sheet into the mould. vacuum forming, also known as vacuum molding, is a flexible plastic manufacturing process where a heated. with vacuum forming, a vacuum pump sucks the plastic into the mould. The sheet is then ejected from the mould. vacuum forming is a type of thermoforming process where a plastic sheet is heated until it becomes pliable, then shaped over a mold using vacuum pressure. In its advanced form, the vacuum forming process utilizes. With pressure forming, compressed air pushes the plastic down. The hollow part that has been vacuum formed is called a mould. This method is favored for its ability to create detailed and large parts efficiently, making it indispensable in various industries.

From www.youtube.com

How to Make a Larger Vacuum Former I Like To Make Stuff YouTube Vacuum Former Examples In its advanced form, the vacuum forming process utilizes. the solid shape that goes in the vacuum former is called a former; a vacuum is applied sucking the sheet into the mould. vacuum forming, also known as vacuum molding, is a flexible plastic manufacturing process where a heated. vacuum forming is a type of thermoforming process. Vacuum Former Examples.

From www.youtube.com

Vacuum forming 01 main process YouTube Vacuum Former Examples a vacuum is applied sucking the sheet into the mould. examples of vacuum forming products from golf trolleys, land yachts to baths and dashboards. the solid shape that goes in the vacuum former is called a former; vacuum forming, also known as vacuum molding, is a flexible plastic manufacturing process where a heated. In its advanced. Vacuum Former Examples.

From www.techsoft.co.uk

Vacuum Forming TechSoft Vacuum Former Examples with vacuum forming, a vacuum pump sucks the plastic into the mould. With pressure forming, compressed air pushes the plastic down. The sheet is then ejected from the mould. vacuum forming, also known as vacuum molding, is a flexible plastic manufacturing process where a heated. In its advanced form, the vacuum forming process utilizes. examples of vacuum. Vacuum Former Examples.

From www.pinterest.com.mx

Formech Vacuum Former FM660 Signage design, Vacuum, Acrylic display Vacuum Former Examples In its advanced form, the vacuum forming process utilizes. The sheet is then ejected from the mould. examples of vacuum forming products from golf trolleys, land yachts to baths and dashboards. The hollow part that has been vacuum formed is called a mould. This method is favored for its ability to create detailed and large parts efficiently, making it. Vacuum Former Examples.

From www.brayplastics.co.uk

Vacuum Forming Bray Plastics Vacuum Former Examples the solid shape that goes in the vacuum former is called a former; This method is favored for its ability to create detailed and large parts efficiently, making it indispensable in various industries. With pressure forming, compressed air pushes the plastic down. a vacuum is applied sucking the sheet into the mould. vacuum forming is a type. Vacuum Former Examples.

From www.alplastics.ca

VACUUM FORMING Vacuum Former Examples examples of vacuum forming products from golf trolleys, land yachts to baths and dashboards. With pressure forming, compressed air pushes the plastic down. In its advanced form, the vacuum forming process utilizes. vacuum forming, also known as vacuum molding, is a flexible plastic manufacturing process where a heated. The hollow part that has been vacuum formed is called. Vacuum Former Examples.

From vacmoulddisplays.com.au

Plastic Vacuum Forming ABS Forming Vacmould Vacuum Former Examples with vacuum forming, a vacuum pump sucks the plastic into the mould. the solid shape that goes in the vacuum former is called a former; In its advanced form, the vacuum forming process utilizes. The sheet is then ejected from the mould. a vacuum is applied sucking the sheet into the mould. examples of vacuum forming. Vacuum Former Examples.

From www.iqsdirectory.com

Vacuum Forming Types, Uses, Features and Benefits Vacuum Former Examples In its advanced form, the vacuum forming process utilizes. With pressure forming, compressed air pushes the plastic down. examples of vacuum forming products from golf trolleys, land yachts to baths and dashboards. with vacuum forming, a vacuum pump sucks the plastic into the mould. a vacuum is applied sucking the sheet into the mould. The hollow part. Vacuum Former Examples.

From www.iqsdirectory.com

Vacuum Forming Types, Uses, Features and Benefits Vacuum Former Examples This method is favored for its ability to create detailed and large parts efficiently, making it indispensable in various industries. In its advanced form, the vacuum forming process utilizes. the solid shape that goes in the vacuum former is called a former; vacuum forming, also known as vacuum molding, is a flexible plastic manufacturing process where a heated.. Vacuum Former Examples.

From www.youtube.com

Formech explores how vacuum forming is innovating design at Pratt Vacuum Former Examples the solid shape that goes in the vacuum former is called a former; vacuum forming, also known as vacuum molding, is a flexible plastic manufacturing process where a heated. With pressure forming, compressed air pushes the plastic down. In its advanced form, the vacuum forming process utilizes. The sheet is then ejected from the mould. examples of. Vacuum Former Examples.

From www.slideshare.net

Vacuum forming Vacuum Former Examples examples of vacuum forming products from golf trolleys, land yachts to baths and dashboards. vacuum forming is a type of thermoforming process where a plastic sheet is heated until it becomes pliable, then shaped over a mold using vacuum pressure. With pressure forming, compressed air pushes the plastic down. a vacuum is applied sucking the sheet into. Vacuum Former Examples.

From vacmoulddisplays.com.au

Plastic Vacuum Forming ABS Forming Vacmould Vacuum Former Examples This method is favored for its ability to create detailed and large parts efficiently, making it indispensable in various industries. vacuum forming is a type of thermoforming process where a plastic sheet is heated until it becomes pliable, then shaped over a mold using vacuum pressure. With pressure forming, compressed air pushes the plastic down. with vacuum forming,. Vacuum Former Examples.

From www.slideserve.com

PPT VACUUM FORMING PowerPoint Presentation, free download ID6902792 Vacuum Former Examples This method is favored for its ability to create detailed and large parts efficiently, making it indispensable in various industries. the solid shape that goes in the vacuum former is called a former; vacuum forming is a type of thermoforming process where a plastic sheet is heated until it becomes pliable, then shaped over a mold using vacuum. Vacuum Former Examples.

From www.manufacturingguide.com

Vacuum forming Find suppliers, processes & material Vacuum Former Examples with vacuum forming, a vacuum pump sucks the plastic into the mould. vacuum forming, also known as vacuum molding, is a flexible plastic manufacturing process where a heated. vacuum forming is a type of thermoforming process where a plastic sheet is heated until it becomes pliable, then shaped over a mold using vacuum pressure. The hollow part. Vacuum Former Examples.

From ryobe.co.uk

Vacuum Forming Service Variety of materials Ryobe UK LTD Vacuum Former Examples the solid shape that goes in the vacuum former is called a former; In its advanced form, the vacuum forming process utilizes. With pressure forming, compressed air pushes the plastic down. with vacuum forming, a vacuum pump sucks the plastic into the mould. a vacuum is applied sucking the sheet into the mould. The hollow part that. Vacuum Former Examples.

From www.brayplastics.co.uk

Vacuum Forming Bray Plastics Limited Vacuum Former Examples With pressure forming, compressed air pushes the plastic down. This method is favored for its ability to create detailed and large parts efficiently, making it indispensable in various industries. a vacuum is applied sucking the sheet into the mould. examples of vacuum forming products from golf trolleys, land yachts to baths and dashboards. The hollow part that has. Vacuum Former Examples.

From mindworks.shoutwiki.com

Vacuum Forming Mindworks Vacuum Former Examples This method is favored for its ability to create detailed and large parts efficiently, making it indispensable in various industries. the solid shape that goes in the vacuum former is called a former; examples of vacuum forming products from golf trolleys, land yachts to baths and dashboards. The sheet is then ejected from the mould. With pressure forming,. Vacuum Former Examples.

From www.youtube.com

vacuum forming YouTube Vacuum Former Examples vacuum forming is a type of thermoforming process where a plastic sheet is heated until it becomes pliable, then shaped over a mold using vacuum pressure. the solid shape that goes in the vacuum former is called a former; The sheet is then ejected from the mould. This method is favored for its ability to create detailed and. Vacuum Former Examples.

From sites.wit.edu

stepbystep guide to vacuum forming Center for Applied Research Vacuum Former Examples vacuum forming, also known as vacuum molding, is a flexible plastic manufacturing process where a heated. with vacuum forming, a vacuum pump sucks the plastic into the mould. The hollow part that has been vacuum formed is called a mould. a vacuum is applied sucking the sheet into the mould. The sheet is then ejected from the. Vacuum Former Examples.

From sites.wit.edu

stepbystep guide to vacuum forming Center for Applied Research Vacuum Former Examples examples of vacuum forming products from golf trolleys, land yachts to baths and dashboards. The sheet is then ejected from the mould. a vacuum is applied sucking the sheet into the mould. The hollow part that has been vacuum formed is called a mould. vacuum forming is a type of thermoforming process where a plastic sheet is. Vacuum Former Examples.

From blog.adafruit.com

How to Make a Vacuum Forming Machine « Adafruit Industries Makers Vacuum Former Examples With pressure forming, compressed air pushes the plastic down. This method is favored for its ability to create detailed and large parts efficiently, making it indispensable in various industries. the solid shape that goes in the vacuum former is called a former; with vacuum forming, a vacuum pump sucks the plastic into the mould. The hollow part that. Vacuum Former Examples.

From www.hotrod.com

How to build a vacuum forming mold to make your own plastic parts Vacuum Former Examples a vacuum is applied sucking the sheet into the mould. This method is favored for its ability to create detailed and large parts efficiently, making it indispensable in various industries. The sheet is then ejected from the mould. vacuum forming is a type of thermoforming process where a plastic sheet is heated until it becomes pliable, then shaped. Vacuum Former Examples.

From www.techsoft.co.uk

Vacuum Forming TechSoft Vacuum Former Examples examples of vacuum forming products from golf trolleys, land yachts to baths and dashboards. vacuum forming, also known as vacuum molding, is a flexible plastic manufacturing process where a heated. In its advanced form, the vacuum forming process utilizes. vacuum forming is a type of thermoforming process where a plastic sheet is heated until it becomes pliable,. Vacuum Former Examples.

From www.pinterest.co.uk

vacuum forming Technology projects, Display boards for school Vacuum Former Examples a vacuum is applied sucking the sheet into the mould. With pressure forming, compressed air pushes the plastic down. The hollow part that has been vacuum formed is called a mould. vacuum forming is a type of thermoforming process where a plastic sheet is heated until it becomes pliable, then shaped over a mold using vacuum pressure. This. Vacuum Former Examples.

From www.crclarke.co.uk

Vacuum Former 725FLB C R Clarke & Co C R Clarke & Co Vacuum Former Examples with vacuum forming, a vacuum pump sucks the plastic into the mould. vacuum forming is a type of thermoforming process where a plastic sheet is heated until it becomes pliable, then shaped over a mold using vacuum pressure. a vacuum is applied sucking the sheet into the mould. This method is favored for its ability to create. Vacuum Former Examples.

From www.rapidonline.com

C R Clarke 1210 115V Vacuum Former Rapid Online Vacuum Former Examples examples of vacuum forming products from golf trolleys, land yachts to baths and dashboards. vacuum forming, also known as vacuum molding, is a flexible plastic manufacturing process where a heated. with vacuum forming, a vacuum pump sucks the plastic into the mould. With pressure forming, compressed air pushes the plastic down. In its advanced form, the vacuum. Vacuum Former Examples.

From www.petervaldivia.com

Fabrication of Plastics. Tecnología ESO en Ingles Vacuum Former Examples with vacuum forming, a vacuum pump sucks the plastic into the mould. examples of vacuum forming products from golf trolleys, land yachts to baths and dashboards. In its advanced form, the vacuum forming process utilizes. vacuum forming, also known as vacuum molding, is a flexible plastic manufacturing process where a heated. The sheet is then ejected from. Vacuum Former Examples.

From foammolders.com

Vacuum Forming The Processes Foam Molders Uses To Create HighQuality Vacuum Former Examples The sheet is then ejected from the mould. the solid shape that goes in the vacuum former is called a former; In its advanced form, the vacuum forming process utilizes. vacuum forming is a type of thermoforming process where a plastic sheet is heated until it becomes pliable, then shaped over a mold using vacuum pressure. a. Vacuum Former Examples.

From www.la-plastic.com

What are the 6 stages of vacuum forming? Vacuum Former Examples with vacuum forming, a vacuum pump sucks the plastic into the mould. In its advanced form, the vacuum forming process utilizes. vacuum forming is a type of thermoforming process where a plastic sheet is heated until it becomes pliable, then shaped over a mold using vacuum pressure. vacuum forming, also known as vacuum molding, is a flexible. Vacuum Former Examples.

From formlabs.com

Introduction to Vacuum Forming Vacuum Former Examples The sheet is then ejected from the mould. The hollow part that has been vacuum formed is called a mould. In its advanced form, the vacuum forming process utilizes. This method is favored for its ability to create detailed and large parts efficiently, making it indispensable in various industries. examples of vacuum forming products from golf trolleys, land yachts. Vacuum Former Examples.

From www.youtube.com

Formech 508FS (with new PLC) Floor Standing Vacuum Forming Machine Vacuum Former Examples with vacuum forming, a vacuum pump sucks the plastic into the mould. vacuum forming, also known as vacuum molding, is a flexible plastic manufacturing process where a heated. The sheet is then ejected from the mould. vacuum forming is a type of thermoforming process where a plastic sheet is heated until it becomes pliable, then shaped over. Vacuum Former Examples.

From formlabs.com

Introduction to Vacuum Forming Vacuum Former Examples vacuum forming is a type of thermoforming process where a plastic sheet is heated until it becomes pliable, then shaped over a mold using vacuum pressure. With pressure forming, compressed air pushes the plastic down. vacuum forming, also known as vacuum molding, is a flexible plastic manufacturing process where a heated. In its advanced form, the vacuum forming. Vacuum Former Examples.

From designitforyou.com

WHAT IS VACUUM FORMING Vacuum Former Examples The sheet is then ejected from the mould. This method is favored for its ability to create detailed and large parts efficiently, making it indispensable in various industries. vacuum forming is a type of thermoforming process where a plastic sheet is heated until it becomes pliable, then shaped over a mold using vacuum pressure. examples of vacuum forming. Vacuum Former Examples.

From www.iqsdirectory.com

Vacuum Forming Types, Uses, Features and Benefits Vacuum Former Examples vacuum forming, also known as vacuum molding, is a flexible plastic manufacturing process where a heated. vacuum forming is a type of thermoforming process where a plastic sheet is heated until it becomes pliable, then shaped over a mold using vacuum pressure. with vacuum forming, a vacuum pump sucks the plastic into the mould. With pressure forming,. Vacuum Former Examples.

From ceznlwqf.blob.core.windows.net

Vacuum Forming Plastic Bottles at Alicia Moreno blog Vacuum Former Examples With pressure forming, compressed air pushes the plastic down. vacuum forming, also known as vacuum molding, is a flexible plastic manufacturing process where a heated. This method is favored for its ability to create detailed and large parts efficiently, making it indispensable in various industries. with vacuum forming, a vacuum pump sucks the plastic into the mould. In. Vacuum Former Examples.