How To Make A Cast Mold For Metal . Here are the general steps to make a casting mold for metal: Create a sprue hole using a dowel rod next to your casting object. Sand casting is very basic, but it allows you to quickly make complex objects in solid silver. Rub the dowel rod into the sand until you create an approximately 0.5 in (1.3 cm) wide hole that runs from one end of the mold to the other. You’ll need some kind of mold and clay or sand setup to begin. This is the process i use to make an aluminum mold in petrobond sand for casting aluminum. Metal casting is an ancient crafting process where you pour molten metal into a custom mold to create objects like coins, swords, and jewelry. Want to learn sand casting using your 3d printer? The metal and mold are cooled, and the metal object is removed and finished.

from www.youtube.com

Sand casting is very basic, but it allows you to quickly make complex objects in solid silver. You’ll need some kind of mold and clay or sand setup to begin. This is the process i use to make an aluminum mold in petrobond sand for casting aluminum. Create a sprue hole using a dowel rod next to your casting object. Want to learn sand casting using your 3d printer? The metal and mold are cooled, and the metal object is removed and finished. Rub the dowel rod into the sand until you create an approximately 0.5 in (1.3 cm) wide hole that runs from one end of the mold to the other. Here are the general steps to make a casting mold for metal: Metal casting is an ancient crafting process where you pour molten metal into a custom mold to create objects like coins, swords, and jewelry.

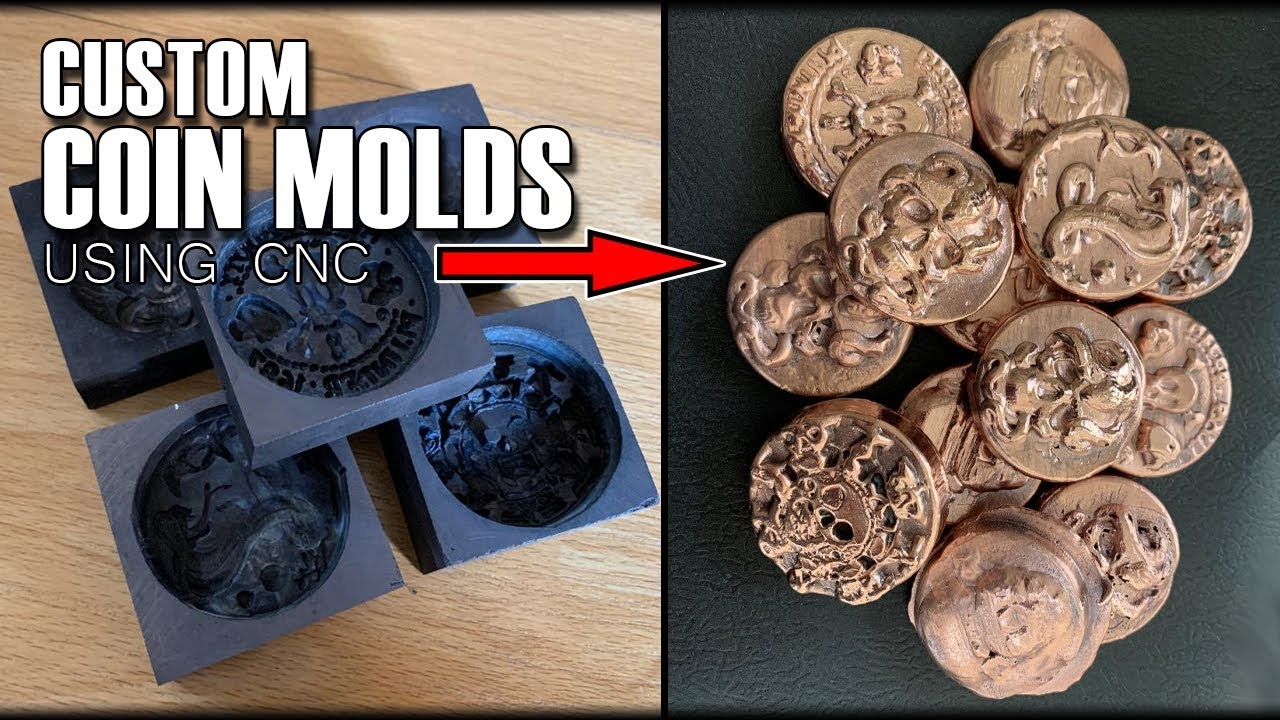

Casting COPPER Coins Using CUSTOM Made CNC Molds Melting Rubish To

How To Make A Cast Mold For Metal Sand casting is very basic, but it allows you to quickly make complex objects in solid silver. This is the process i use to make an aluminum mold in petrobond sand for casting aluminum. You’ll need some kind of mold and clay or sand setup to begin. Create a sprue hole using a dowel rod next to your casting object. Sand casting is very basic, but it allows you to quickly make complex objects in solid silver. The metal and mold are cooled, and the metal object is removed and finished. Rub the dowel rod into the sand until you create an approximately 0.5 in (1.3 cm) wide hole that runs from one end of the mold to the other. Want to learn sand casting using your 3d printer? Metal casting is an ancient crafting process where you pour molten metal into a custom mold to create objects like coins, swords, and jewelry. Here are the general steps to make a casting mold for metal:

From prototechasia.com

What is Plastic Injection Molding? Our Comprehensive Overview How To Make A Cast Mold For Metal Create a sprue hole using a dowel rod next to your casting object. Want to learn sand casting using your 3d printer? Sand casting is very basic, but it allows you to quickly make complex objects in solid silver. Rub the dowel rod into the sand until you create an approximately 0.5 in (1.3 cm) wide hole that runs from. How To Make A Cast Mold For Metal.

From hackaday.io

A simple casting mould for hot metal key copying Hackaday.io How To Make A Cast Mold For Metal Create a sprue hole using a dowel rod next to your casting object. This is the process i use to make an aluminum mold in petrobond sand for casting aluminum. Rub the dowel rod into the sand until you create an approximately 0.5 in (1.3 cm) wide hole that runs from one end of the mold to the other. Sand. How To Make A Cast Mold For Metal.

From veenaengicast.com

Metal Casting Guide for Beginners Veena Enterprise How To Make A Cast Mold For Metal Create a sprue hole using a dowel rod next to your casting object. Metal casting is an ancient crafting process where you pour molten metal into a custom mold to create objects like coins, swords, and jewelry. You’ll need some kind of mold and clay or sand setup to begin. Here are the general steps to make a casting mold. How To Make A Cast Mold For Metal.

From www.pinterest.com

We make your CUSTOM graphite Molds in 2020 Art jewelry elements, How How To Make A Cast Mold For Metal This is the process i use to make an aluminum mold in petrobond sand for casting aluminum. Want to learn sand casting using your 3d printer? The metal and mold are cooled, and the metal object is removed and finished. Create a sprue hole using a dowel rod next to your casting object. Here are the general steps to make. How To Make A Cast Mold For Metal.

From formlabs.com

Introduction to Metal Casting and Ways to Combine 3D Printing With How To Make A Cast Mold For Metal Sand casting is very basic, but it allows you to quickly make complex objects in solid silver. The metal and mold are cooled, and the metal object is removed and finished. Here are the general steps to make a casting mold for metal: Metal casting is an ancient crafting process where you pour molten metal into a custom mold to. How To Make A Cast Mold For Metal.

From www.youtube.com

DIY Casting lead into plaster mold YouTube How To Make A Cast Mold For Metal Create a sprue hole using a dowel rod next to your casting object. Want to learn sand casting using your 3d printer? Here are the general steps to make a casting mold for metal: Metal casting is an ancient crafting process where you pour molten metal into a custom mold to create objects like coins, swords, and jewelry. You’ll need. How To Make A Cast Mold For Metal.

From www.alibaba.com

Aluminum Die Casting Making As 3d Drawing & Sample Cast Lead Mold Lead How To Make A Cast Mold For Metal This is the process i use to make an aluminum mold in petrobond sand for casting aluminum. Create a sprue hole using a dowel rod next to your casting object. Sand casting is very basic, but it allows you to quickly make complex objects in solid silver. Metal casting is an ancient crafting process where you pour molten metal into. How To Make A Cast Mold For Metal.

From goodtuto-rial.blogspot.com

How To Make A Cast Mold For Silver How To Make A Cast Mold For Metal Sand casting is very basic, but it allows you to quickly make complex objects in solid silver. Metal casting is an ancient crafting process where you pour molten metal into a custom mold to create objects like coins, swords, and jewelry. This is the process i use to make an aluminum mold in petrobond sand for casting aluminum. Here are. How To Make A Cast Mold For Metal.

From www.youtube.com

How to make a sand mold for casting metal YouTube How To Make A Cast Mold For Metal Rub the dowel rod into the sand until you create an approximately 0.5 in (1.3 cm) wide hole that runs from one end of the mold to the other. Create a sprue hole using a dowel rod next to your casting object. Metal casting is an ancient crafting process where you pour molten metal into a custom mold to create. How To Make A Cast Mold For Metal.

From learnglassblowing.com

The Process Of Creating A Mold For Glass Blowing Learn Glass Blowing How To Make A Cast Mold For Metal Sand casting is very basic, but it allows you to quickly make complex objects in solid silver. Rub the dowel rod into the sand until you create an approximately 0.5 in (1.3 cm) wide hole that runs from one end of the mold to the other. Create a sprue hole using a dowel rod next to your casting object. Want. How To Make A Cast Mold For Metal.

From www.youtube.com

Unlock the Secrets to Metal Casting with a Simple Studio Setup YouTube How To Make A Cast Mold For Metal Metal casting is an ancient crafting process where you pour molten metal into a custom mold to create objects like coins, swords, and jewelry. Create a sprue hole using a dowel rod next to your casting object. This is the process i use to make an aluminum mold in petrobond sand for casting aluminum. Here are the general steps to. How To Make A Cast Mold For Metal.

From goodtuto-rial.blogspot.com

How To Make A Cast Mold For Silver How To Make A Cast Mold For Metal Metal casting is an ancient crafting process where you pour molten metal into a custom mold to create objects like coins, swords, and jewelry. Sand casting is very basic, but it allows you to quickly make complex objects in solid silver. The metal and mold are cooled, and the metal object is removed and finished. Create a sprue hole using. How To Make A Cast Mold For Metal.

From riversofsteel.com

Aluminum Casting Session — Rivers of Steel How To Make A Cast Mold For Metal Sand casting is very basic, but it allows you to quickly make complex objects in solid silver. You’ll need some kind of mold and clay or sand setup to begin. Create a sprue hole using a dowel rod next to your casting object. Metal casting is an ancient crafting process where you pour molten metal into a custom mold to. How To Make A Cast Mold For Metal.

From www.youtube.com

Mold Making and Casting Tutorials From SmoothOn YouTube How To Make A Cast Mold For Metal Create a sprue hole using a dowel rod next to your casting object. Metal casting is an ancient crafting process where you pour molten metal into a custom mold to create objects like coins, swords, and jewelry. This is the process i use to make an aluminum mold in petrobond sand for casting aluminum. Here are the general steps to. How To Make A Cast Mold For Metal.

From www.youtube.com

How to Mold and Cast Your Hand! Lifecasting a Hand with Alginate and How To Make A Cast Mold For Metal Here are the general steps to make a casting mold for metal: Create a sprue hole using a dowel rod next to your casting object. Metal casting is an ancient crafting process where you pour molten metal into a custom mold to create objects like coins, swords, and jewelry. Want to learn sand casting using your 3d printer? This is. How To Make A Cast Mold For Metal.

From www.youtube.com

Casting COPPER Coins Using CUSTOM Made CNC Molds Melting Rubish To How To Make A Cast Mold For Metal Here are the general steps to make a casting mold for metal: Want to learn sand casting using your 3d printer? The metal and mold are cooled, and the metal object is removed and finished. This is the process i use to make an aluminum mold in petrobond sand for casting aluminum. Metal casting is an ancient crafting process where. How To Make A Cast Mold For Metal.

From www.youtube.com

Machining a Custom Graphite Mold for Metal Casting MaterialMonday How To Make A Cast Mold For Metal Here are the general steps to make a casting mold for metal: Rub the dowel rod into the sand until you create an approximately 0.5 in (1.3 cm) wide hole that runs from one end of the mold to the other. Metal casting is an ancient crafting process where you pour molten metal into a custom mold to create objects. How To Make A Cast Mold For Metal.

From formlabs.com

How to Make Silicone Molds A Practical Guide Formlabs How To Make A Cast Mold For Metal Create a sprue hole using a dowel rod next to your casting object. Rub the dowel rod into the sand until you create an approximately 0.5 in (1.3 cm) wide hole that runs from one end of the mold to the other. Metal casting is an ancient crafting process where you pour molten metal into a custom mold to create. How To Make A Cast Mold For Metal.

From www.youtube.com

Casting Metal Parts into 3D Printed Molds YouTube How To Make A Cast Mold For Metal Sand casting is very basic, but it allows you to quickly make complex objects in solid silver. Here are the general steps to make a casting mold for metal: The metal and mold are cooled, and the metal object is removed and finished. You’ll need some kind of mold and clay or sand setup to begin. Want to learn sand. How To Make A Cast Mold For Metal.

From www.youtube.com

Easy Metal Casting with a Silicone Mold and Pewter Prop Live from How To Make A Cast Mold For Metal Here are the general steps to make a casting mold for metal: The metal and mold are cooled, and the metal object is removed and finished. This is the process i use to make an aluminum mold in petrobond sand for casting aluminum. You’ll need some kind of mold and clay or sand setup to begin. Sand casting is very. How To Make A Cast Mold For Metal.

From www.youtube.com

Casting Iron Mold for Ingots! 2000°+ (MattMakes Mold Part 1/4) YouTube How To Make A Cast Mold For Metal You’ll need some kind of mold and clay or sand setup to begin. Here are the general steps to make a casting mold for metal: Sand casting is very basic, but it allows you to quickly make complex objects in solid silver. The metal and mold are cooled, and the metal object is removed and finished. Rub the dowel rod. How To Make A Cast Mold For Metal.

From www.youtube.com

Casting Metal the Basics YouTube How To Make A Cast Mold For Metal You’ll need some kind of mold and clay or sand setup to begin. Metal casting is an ancient crafting process where you pour molten metal into a custom mold to create objects like coins, swords, and jewelry. Here are the general steps to make a casting mold for metal: The metal and mold are cooled, and the metal object is. How To Make A Cast Mold For Metal.

From www.aniwaa.com

Guide to 3D printing molds for metal casting Aniwaa How To Make A Cast Mold For Metal Create a sprue hole using a dowel rod next to your casting object. Sand casting is very basic, but it allows you to quickly make complex objects in solid silver. The metal and mold are cooled, and the metal object is removed and finished. Here are the general steps to make a casting mold for metal: Rub the dowel rod. How To Make A Cast Mold For Metal.

From www.youtube.com

How To Make Silicone Molds & Cast Plaster YouTube How To Make A Cast Mold For Metal This is the process i use to make an aluminum mold in petrobond sand for casting aluminum. You’ll need some kind of mold and clay or sand setup to begin. Here are the general steps to make a casting mold for metal: Want to learn sand casting using your 3d printer? The metal and mold are cooled, and the metal. How To Make A Cast Mold For Metal.

From www.pinterest.com

handverker readymake sand molds Mold making, Molding clay, Diy metal How To Make A Cast Mold For Metal This is the process i use to make an aluminum mold in petrobond sand for casting aluminum. Here are the general steps to make a casting mold for metal: Create a sprue hole using a dowel rod next to your casting object. Rub the dowel rod into the sand until you create an approximately 0.5 in (1.3 cm) wide hole. How To Make A Cast Mold For Metal.

From www.pinterest.com

Metal Casting Process Metal casting process, Metal casting, It cast How To Make A Cast Mold For Metal Here are the general steps to make a casting mold for metal: The metal and mold are cooled, and the metal object is removed and finished. Want to learn sand casting using your 3d printer? Metal casting is an ancient crafting process where you pour molten metal into a custom mold to create objects like coins, swords, and jewelry. Sand. How To Make A Cast Mold For Metal.

From www.thecrucible.org

Metal Casting 101 Learn To Cast Metal [Types & Processes] How To Make A Cast Mold For Metal You’ll need some kind of mold and clay or sand setup to begin. Metal casting is an ancient crafting process where you pour molten metal into a custom mold to create objects like coins, swords, and jewelry. Sand casting is very basic, but it allows you to quickly make complex objects in solid silver. Here are the general steps to. How To Make A Cast Mold For Metal.

From www.omicroncasting.com

5 Different Methods Used in Casting How To Make A Cast Mold For Metal This is the process i use to make an aluminum mold in petrobond sand for casting aluminum. Create a sprue hole using a dowel rod next to your casting object. Sand casting is very basic, but it allows you to quickly make complex objects in solid silver. Rub the dowel rod into the sand until you create an approximately 0.5. How To Make A Cast Mold For Metal.

From www.pinterest.es

Pewter mold carving and casting class examples Casting jewelry How To Make A Cast Mold For Metal Metal casting is an ancient crafting process where you pour molten metal into a custom mold to create objects like coins, swords, and jewelry. Create a sprue hole using a dowel rod next to your casting object. Here are the general steps to make a casting mold for metal: The metal and mold are cooled, and the metal object is. How To Make A Cast Mold For Metal.

From startup-buzz.com

The Beginner’s Guide to Permanent Mold Casting Startup Buzz How To Make A Cast Mold For Metal Sand casting is very basic, but it allows you to quickly make complex objects in solid silver. Here are the general steps to make a casting mold for metal: The metal and mold are cooled, and the metal object is removed and finished. You’ll need some kind of mold and clay or sand setup to begin. Create a sprue hole. How To Make A Cast Mold For Metal.

From mungfali.com

How To Make 3D Printed Molds How To Make A Cast Mold For Metal Metal casting is an ancient crafting process where you pour molten metal into a custom mold to create objects like coins, swords, and jewelry. This is the process i use to make an aluminum mold in petrobond sand for casting aluminum. The metal and mold are cooled, and the metal object is removed and finished. Here are the general steps. How To Make A Cast Mold For Metal.

From donkeymud.com

Slip Casting Dan’s Quick Glimpse HowTo Dan Pearce Pottery How To Make A Cast Mold For Metal Metal casting is an ancient crafting process where you pour molten metal into a custom mold to create objects like coins, swords, and jewelry. Create a sprue hole using a dowel rod next to your casting object. This is the process i use to make an aluminum mold in petrobond sand for casting aluminum. The metal and mold are cooled,. How To Make A Cast Mold For Metal.

From www.foundrymag.com

A Practical Guide to Placing Chills in Large Molds Foundry Management How To Make A Cast Mold For Metal Create a sprue hole using a dowel rod next to your casting object. Want to learn sand casting using your 3d printer? This is the process i use to make an aluminum mold in petrobond sand for casting aluminum. You’ll need some kind of mold and clay or sand setup to begin. Rub the dowel rod into the sand until. How To Make A Cast Mold For Metal.

From www.youtube.com

HOW TO... PART 1 'SILICONE MOULDS FOR METAL' YouTube How To Make A Cast Mold For Metal This is the process i use to make an aluminum mold in petrobond sand for casting aluminum. Want to learn sand casting using your 3d printer? You’ll need some kind of mold and clay or sand setup to begin. Create a sprue hole using a dowel rod next to your casting object. Rub the dowel rod into the sand until. How To Make A Cast Mold For Metal.

From dragomet.com

Melting point of silver Top 10 ways to melt silver at home, melting in How To Make A Cast Mold For Metal Sand casting is very basic, but it allows you to quickly make complex objects in solid silver. Create a sprue hole using a dowel rod next to your casting object. Rub the dowel rod into the sand until you create an approximately 0.5 in (1.3 cm) wide hole that runs from one end of the mold to the other. This. How To Make A Cast Mold For Metal.