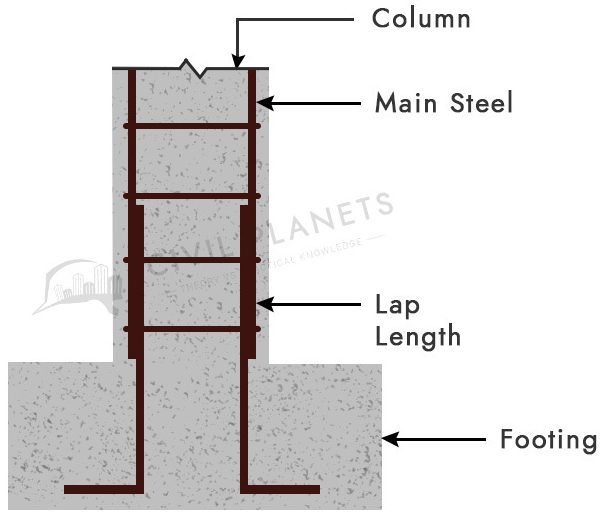

Steel Mesh Lap Length . Lapping zone and load path through reinforcements. Lap length is the minimum overlap required between two reinforcing bars or rebars that are spliced together to ensure structural stability and durability. A more optimal lap length may be calculated from. The building and housing group’s guidance on reinforcing mesh specifies a lap length of 40 deformed wire diameters. The lap length is calculated for those concrete sections whose length is greater than 12m. Therefore, determining the appropriate lap length is important for ensuring structural integrity and preventing premature. Usually, the stock length of steel bars is limited. It is required when bars are placed short of their required length, or when the bar diameter has to be changed along the length, as is sometimes done in columns. Lapping can be defined as the overlapping of two bars side by side to upto the design length. Mostly, 12m is the stock length which is fixed to. Simply, the lep length is to transfer the tensile or compression forces in the concrete.

from www.cannondigi.com

Lapping zone and load path through reinforcements. Mostly, 12m is the stock length which is fixed to. Lapping can be defined as the overlapping of two bars side by side to upto the design length. The lap length is calculated for those concrete sections whose length is greater than 12m. Therefore, determining the appropriate lap length is important for ensuring structural integrity and preventing premature. The building and housing group’s guidance on reinforcing mesh specifies a lap length of 40 deformed wire diameters. Lap length is the minimum overlap required between two reinforcing bars or rebars that are spliced together to ensure structural stability and durability. Usually, the stock length of steel bars is limited. Simply, the lep length is to transfer the tensile or compression forces in the concrete. A more optimal lap length may be calculated from.

Lap Length For Beam Column And Slab The Best Picture Of Beam

Steel Mesh Lap Length Usually, the stock length of steel bars is limited. Simply, the lep length is to transfer the tensile or compression forces in the concrete. Lap length is the minimum overlap required between two reinforcing bars or rebars that are spliced together to ensure structural stability and durability. Usually, the stock length of steel bars is limited. Therefore, determining the appropriate lap length is important for ensuring structural integrity and preventing premature. Lapping zone and load path through reinforcements. The building and housing group’s guidance on reinforcing mesh specifies a lap length of 40 deformed wire diameters. It is required when bars are placed short of their required length, or when the bar diameter has to be changed along the length, as is sometimes done in columns. The lap length is calculated for those concrete sections whose length is greater than 12m. Lapping can be defined as the overlapping of two bars side by side to upto the design length. Mostly, 12m is the stock length which is fixed to. A more optimal lap length may be calculated from.

From www.nmbsplicesleeve.com

For Cast In Place Connection SPLICE SLEEVE JAPAN, LTD. Steel Mesh Lap Length The lap length is calculated for those concrete sections whose length is greater than 12m. A more optimal lap length may be calculated from. Lapping can be defined as the overlapping of two bars side by side to upto the design length. Lap length is the minimum overlap required between two reinforcing bars or rebars that are spliced together to. Steel Mesh Lap Length.

From www.mdpi.com

Buildings Free FullText Compressive Performance of RC Columns Steel Mesh Lap Length A more optimal lap length may be calculated from. Therefore, determining the appropriate lap length is important for ensuring structural integrity and preventing premature. Lap length is the minimum overlap required between two reinforcing bars or rebars that are spliced together to ensure structural stability and durability. Simply, the lep length is to transfer the tensile or compression forces in. Steel Mesh Lap Length.

From www.cannondigi.com

Lap Length For Beam Column And Slab The Best Picture Of Beam Steel Mesh Lap Length Lapping zone and load path through reinforcements. Lapping can be defined as the overlapping of two bars side by side to upto the design length. The building and housing group’s guidance on reinforcing mesh specifies a lap length of 40 deformed wire diameters. Therefore, determining the appropriate lap length is important for ensuring structural integrity and preventing premature. A more. Steel Mesh Lap Length.

From rmreinforcingmesh.com

REINFORCING WELDED WIRE MESH (CUT AND BEND SOLUTION MESH) Australia Steel Mesh Lap Length The lap length is calculated for those concrete sections whose length is greater than 12m. Lap length is the minimum overlap required between two reinforcing bars or rebars that are spliced together to ensure structural stability and durability. Therefore, determining the appropriate lap length is important for ensuring structural integrity and preventing premature. A more optimal lap length may be. Steel Mesh Lap Length.

From www.vrogue.co

What Is Lap Length Overlapping Lap Splices In Beam Co vrogue.co Steel Mesh Lap Length Lapping can be defined as the overlapping of two bars side by side to upto the design length. A more optimal lap length may be calculated from. Lapping zone and load path through reinforcements. The lap length is calculated for those concrete sections whose length is greater than 12m. The building and housing group’s guidance on reinforcing mesh specifies a. Steel Mesh Lap Length.

From www.reinforcementproductsonline.co.uk

Lapping Mesh Reinforcement How to Calculate Overlap RPO Steel Mesh Lap Length Lap length is the minimum overlap required between two reinforcing bars or rebars that are spliced together to ensure structural stability and durability. Usually, the stock length of steel bars is limited. A more optimal lap length may be calculated from. Lapping zone and load path through reinforcements. Simply, the lep length is to transfer the tensile or compression forces. Steel Mesh Lap Length.

From www.youtube.com

Difference between Development Length and Lap Length YouTube Steel Mesh Lap Length Lap length is the minimum overlap required between two reinforcing bars or rebars that are spliced together to ensure structural stability and durability. Lapping can be defined as the overlapping of two bars side by side to upto the design length. Simply, the lep length is to transfer the tensile or compression forces in the concrete. It is required when. Steel Mesh Lap Length.

From www.youtube.com

Basic Knowledge of Lapping Length for Steel Rebars YouTube Steel Mesh Lap Length Lap length is the minimum overlap required between two reinforcing bars or rebars that are spliced together to ensure structural stability and durability. The building and housing group’s guidance on reinforcing mesh specifies a lap length of 40 deformed wire diameters. Therefore, determining the appropriate lap length is important for ensuring structural integrity and preventing premature. Lapping can be defined. Steel Mesh Lap Length.

From structx.com

StructX Reinforcement Details Steel Mesh Lap Length Lapping zone and load path through reinforcements. Lapping can be defined as the overlapping of two bars side by side to upto the design length. Therefore, determining the appropriate lap length is important for ensuring structural integrity and preventing premature. Mostly, 12m is the stock length which is fixed to. The building and housing group’s guidance on reinforcing mesh specifies. Steel Mesh Lap Length.

From hkrcdetails.blogspot.com

HK RC Typical Details A6. Laps of Steel Fabric Reinforcement Steel Mesh Lap Length Usually, the stock length of steel bars is limited. Lap length is the minimum overlap required between two reinforcing bars or rebars that are spliced together to ensure structural stability and durability. Lapping zone and load path through reinforcements. Simply, the lep length is to transfer the tensile or compression forces in the concrete. Lapping can be defined as the. Steel Mesh Lap Length.

From rmreinforcingmesh.com

REINFORCING WELDED WIRE MESH (CUT AND BEND SOLUTION MESH) Australia Steel Mesh Lap Length Usually, the stock length of steel bars is limited. Mostly, 12m is the stock length which is fixed to. Simply, the lep length is to transfer the tensile or compression forces in the concrete. A more optimal lap length may be calculated from. It is required when bars are placed short of their required length, or when the bar diameter. Steel Mesh Lap Length.

From www.youtube.com

Basic rules for Lap length in column Lap length in RCC column steel Steel Mesh Lap Length Mostly, 12m is the stock length which is fixed to. The lap length is calculated for those concrete sections whose length is greater than 12m. Lap length is the minimum overlap required between two reinforcing bars or rebars that are spliced together to ensure structural stability and durability. Simply, the lep length is to transfer the tensile or compression forces. Steel Mesh Lap Length.

From www.iqsdirectory.com

Basics of Wire Mesh Steel Mesh Lap Length The lap length is calculated for those concrete sections whose length is greater than 12m. A more optimal lap length may be calculated from. Lap length is the minimum overlap required between two reinforcing bars or rebars that are spliced together to ensure structural stability and durability. Lapping zone and load path through reinforcements. Lapping can be defined as the. Steel Mesh Lap Length.

From engindaily.com

Steel Bars OverLap Formulas Used In Column, slab and beams Engindaily Steel Mesh Lap Length Lapping can be defined as the overlapping of two bars side by side to upto the design length. Mostly, 12m is the stock length which is fixed to. Therefore, determining the appropriate lap length is important for ensuring structural integrity and preventing premature. Lap length is the minimum overlap required between two reinforcing bars or rebars that are spliced together. Steel Mesh Lap Length.

From ar.inspiredpencil.com

Lap Splice Reinforcement Steel Mesh Lap Length The building and housing group’s guidance on reinforcing mesh specifies a lap length of 40 deformed wire diameters. Lap length is the minimum overlap required between two reinforcing bars or rebars that are spliced together to ensure structural stability and durability. The lap length is calculated for those concrete sections whose length is greater than 12m. Usually, the stock length. Steel Mesh Lap Length.

From www.youtube.com

How to calculate lapping length of steel Overlapping of steel bars in Steel Mesh Lap Length Usually, the stock length of steel bars is limited. Lapping can be defined as the overlapping of two bars side by side to upto the design length. Simply, the lep length is to transfer the tensile or compression forces in the concrete. Mostly, 12m is the stock length which is fixed to. Therefore, determining the appropriate lap length is important. Steel Mesh Lap Length.

From www.riblathmesh.com

High Performance Expanded Metal Mesh / Expanded Steel Mesh Lath For Steel Mesh Lap Length Therefore, determining the appropriate lap length is important for ensuring structural integrity and preventing premature. The lap length is calculated for those concrete sections whose length is greater than 12m. Mostly, 12m is the stock length which is fixed to. Lap length is the minimum overlap required between two reinforcing bars or rebars that are spliced together to ensure structural. Steel Mesh Lap Length.

From www.pinterest.com

CETIPS 554 WHAT IS THE MINIMUM LAP LENGTH? Engineering notes, Civil Steel Mesh Lap Length The building and housing group’s guidance on reinforcing mesh specifies a lap length of 40 deformed wire diameters. Lapping zone and load path through reinforcements. It is required when bars are placed short of their required length, or when the bar diameter has to be changed along the length, as is sometimes done in columns. Therefore, determining the appropriate lap. Steel Mesh Lap Length.

From dailycivil.com

Difference Between Development Length And Lap Length Steel Mesh Lap Length Lapping can be defined as the overlapping of two bars side by side to upto the design length. The building and housing group’s guidance on reinforcing mesh specifies a lap length of 40 deformed wire diameters. Mostly, 12m is the stock length which is fixed to. Usually, the stock length of steel bars is limited. Therefore, determining the appropriate lap. Steel Mesh Lap Length.

From dailycivil.com

What Is Lap Length Of Reinforcement Bars Lapping Length of Steel Bars Steel Mesh Lap Length It is required when bars are placed short of their required length, or when the bar diameter has to be changed along the length, as is sometimes done in columns. Mostly, 12m is the stock length which is fixed to. Lap length is the minimum overlap required between two reinforcing bars or rebars that are spliced together to ensure structural. Steel Mesh Lap Length.

From www.specialistconstructionsupplies.online

Steel Reinforcement Sheets A Specialist Construction Supplies Steel Mesh Lap Length The lap length is calculated for those concrete sections whose length is greater than 12m. Lap length is the minimum overlap required between two reinforcing bars or rebars that are spliced together to ensure structural stability and durability. Usually, the stock length of steel bars is limited. The building and housing group’s guidance on reinforcing mesh specifies a lap length. Steel Mesh Lap Length.

From heatonmanufacturing.co.uk

Steel Reinforcing Mesh Sizes Chart Heaton Manufacturing Steel Mesh Lap Length The lap length is calculated for those concrete sections whose length is greater than 12m. Simply, the lep length is to transfer the tensile or compression forces in the concrete. Usually, the stock length of steel bars is limited. Lap length is the minimum overlap required between two reinforcing bars or rebars that are spliced together to ensure structural stability. Steel Mesh Lap Length.

From dreamcivil.com

Lap Length Lap length of Beams Lap Length of Slabs Lap Length of Steel Mesh Lap Length A more optimal lap length may be calculated from. Usually, the stock length of steel bars is limited. Therefore, determining the appropriate lap length is important for ensuring structural integrity and preventing premature. Lapping zone and load path through reinforcements. Lapping can be defined as the overlapping of two bars side by side to upto the design length. The lap. Steel Mesh Lap Length.

From www.mullerconstructionsupply.com

Mesh Wire 7′ X 4′ Sheets Muller Construction Supply Steel Mesh Lap Length Therefore, determining the appropriate lap length is important for ensuring structural integrity and preventing premature. The building and housing group’s guidance on reinforcing mesh specifies a lap length of 40 deformed wire diameters. Simply, the lep length is to transfer the tensile or compression forces in the concrete. The lap length is calculated for those concrete sections whose length is. Steel Mesh Lap Length.

From www.directmetals.com

Industrial Flattened Expanded Metal Direct Metals Steel Mesh Lap Length Lapping zone and load path through reinforcements. A more optimal lap length may be calculated from. Lap length is the minimum overlap required between two reinforcing bars or rebars that are spliced together to ensure structural stability and durability. Lapping can be defined as the overlapping of two bars side by side to upto the design length. Mostly, 12m is. Steel Mesh Lap Length.

From dreamcivil.com

Lap Length Lap length of Beams Lap Length of Slabs Lap Length of Steel Mesh Lap Length Therefore, determining the appropriate lap length is important for ensuring structural integrity and preventing premature. Lapping zone and load path through reinforcements. The building and housing group’s guidance on reinforcing mesh specifies a lap length of 40 deformed wire diameters. Mostly, 12m is the stock length which is fixed to. Lap length is the minimum overlap required between two reinforcing. Steel Mesh Lap Length.

From www.civilworkstudy.com

Calculation of Lap Length in RCC and Definition of Development Length Steel Mesh Lap Length Simply, the lep length is to transfer the tensile or compression forces in the concrete. Mostly, 12m is the stock length which is fixed to. Usually, the stock length of steel bars is limited. It is required when bars are placed short of their required length, or when the bar diameter has to be changed along the length, as is. Steel Mesh Lap Length.

From www.youtube.com

what is lap length How to calculate lap length Structural Design to Steel Mesh Lap Length Lapping zone and load path through reinforcements. It is required when bars are placed short of their required length, or when the bar diameter has to be changed along the length, as is sometimes done in columns. Lapping can be defined as the overlapping of two bars side by side to upto the design length. Mostly, 12m is the stock. Steel Mesh Lap Length.

From structx.com

StructX Reinforcement Details Steel Mesh Lap Length Mostly, 12m is the stock length which is fixed to. A more optimal lap length may be calculated from. Simply, the lep length is to transfer the tensile or compression forces in the concrete. Therefore, determining the appropriate lap length is important for ensuring structural integrity and preventing premature. Usually, the stock length of steel bars is limited. Lapping zone. Steel Mesh Lap Length.

From www.youtube.com

Over Lapping of Steel How to calculate lapping length of steel Bar Steel Mesh Lap Length It is required when bars are placed short of their required length, or when the bar diameter has to be changed along the length, as is sometimes done in columns. Therefore, determining the appropriate lap length is important for ensuring structural integrity and preventing premature. The lap length is calculated for those concrete sections whose length is greater than 12m.. Steel Mesh Lap Length.

From informacionpublica2021.svet.gob.gt

Lap Length Of Reinforcement Bars How To Calculate Lap, 42 OFF Steel Mesh Lap Length The building and housing group’s guidance on reinforcing mesh specifies a lap length of 40 deformed wire diameters. Mostly, 12m is the stock length which is fixed to. A more optimal lap length may be calculated from. It is required when bars are placed short of their required length, or when the bar diameter has to be changed along the. Steel Mesh Lap Length.

From eurocodeapplied.com

Table of reinforcement anchorage length & lap length Eurocode 2 Steel Mesh Lap Length The lap length is calculated for those concrete sections whose length is greater than 12m. A more optimal lap length may be calculated from. Mostly, 12m is the stock length which is fixed to. Lapping zone and load path through reinforcements. Lapping can be defined as the overlapping of two bars side by side to upto the design length. Lap. Steel Mesh Lap Length.

From kuudesign.com

28+ Aci Rebar Lap Splice Chart Design Gallery Steel Mesh Lap Length The building and housing group’s guidance on reinforcing mesh specifies a lap length of 40 deformed wire diameters. Lapping can be defined as the overlapping of two bars side by side to upto the design length. Therefore, determining the appropriate lap length is important for ensuring structural integrity and preventing premature. Lap length is the minimum overlap required between two. Steel Mesh Lap Length.

From www.youtube.com

How to calculate the overlapping length of steel bars in slab,column Steel Mesh Lap Length The lap length is calculated for those concrete sections whose length is greater than 12m. Usually, the stock length of steel bars is limited. Simply, the lep length is to transfer the tensile or compression forces in the concrete. Lapping can be defined as the overlapping of two bars side by side to upto the design length. A more optimal. Steel Mesh Lap Length.

From structville.com

How to Calculate the Anchorage and Lap Length of Steel Reinforcements Steel Mesh Lap Length The building and housing group’s guidance on reinforcing mesh specifies a lap length of 40 deformed wire diameters. A more optimal lap length may be calculated from. Therefore, determining the appropriate lap length is important for ensuring structural integrity and preventing premature. Usually, the stock length of steel bars is limited. The lap length is calculated for those concrete sections. Steel Mesh Lap Length.