Zinc And Mold . As the molten zinc cools and solidifies, it takes on the exact shape and features of the mold. It involves injecting molten zinc into custom tools with die cast die cavities at high pressures. Reports have demonstrated that zinc oxide nanoparticles (zno nps) can control postharvest mold, plant wilts, and grey mold. In die casting, zinc alloys are melted and injected into steel molds under high pressure. The moisture retained by moss can promote mold growth both on the roof and in the underlying structure, which can pose health risks and lead to costly repairs. This process allows the molten metal. Zinc die casting is a process involving the injection of liquid zinc metal under pressure into a mold and left to solidify. Moss can accelerate the deterioration of roofing materials, shortening the lifespan of your roof and leading to the need for premature replacement.

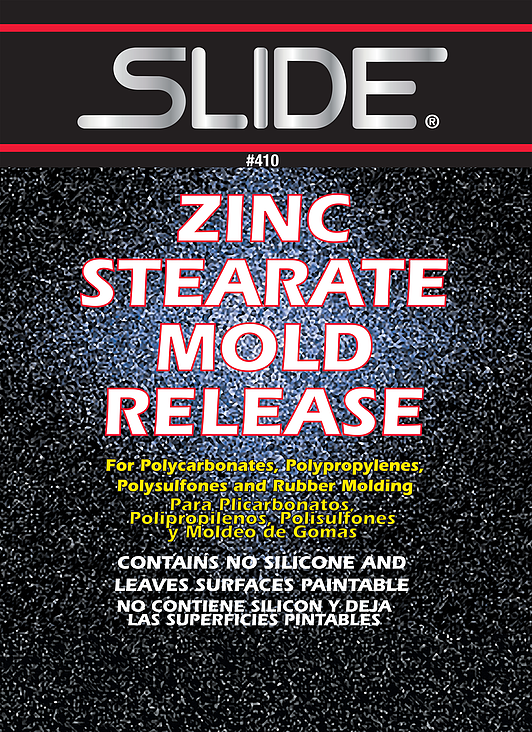

from www.slideproducts.com

The moisture retained by moss can promote mold growth both on the roof and in the underlying structure, which can pose health risks and lead to costly repairs. Reports have demonstrated that zinc oxide nanoparticles (zno nps) can control postharvest mold, plant wilts, and grey mold. As the molten zinc cools and solidifies, it takes on the exact shape and features of the mold. Zinc die casting is a process involving the injection of liquid zinc metal under pressure into a mold and left to solidify. In die casting, zinc alloys are melted and injected into steel molds under high pressure. This process allows the molten metal. Moss can accelerate the deterioration of roofing materials, shortening the lifespan of your roof and leading to the need for premature replacement. It involves injecting molten zinc into custom tools with die cast die cavities at high pressures.

Zinc Stearate Mold Release Spray Paintable Water Repellant

Zinc And Mold As the molten zinc cools and solidifies, it takes on the exact shape and features of the mold. Moss can accelerate the deterioration of roofing materials, shortening the lifespan of your roof and leading to the need for premature replacement. This process allows the molten metal. In die casting, zinc alloys are melted and injected into steel molds under high pressure. It involves injecting molten zinc into custom tools with die cast die cavities at high pressures. As the molten zinc cools and solidifies, it takes on the exact shape and features of the mold. The moisture retained by moss can promote mold growth both on the roof and in the underlying structure, which can pose health risks and lead to costly repairs. Reports have demonstrated that zinc oxide nanoparticles (zno nps) can control postharvest mold, plant wilts, and grey mold. Zinc die casting is a process involving the injection of liquid zinc metal under pressure into a mold and left to solidify.

From www.youtube.com

How to Make a DIY Ingot Mold for Aluminum, Lead or Zinc Casting YouTube Zinc And Mold Zinc die casting is a process involving the injection of liquid zinc metal under pressure into a mold and left to solidify. As the molten zinc cools and solidifies, it takes on the exact shape and features of the mold. The moisture retained by moss can promote mold growth both on the roof and in the underlying structure, which can. Zinc And Mold.

From store.goengineer.com

Zinc Stearate Mold Release Aerosol GoEngineer Store Zinc And Mold Moss can accelerate the deterioration of roofing materials, shortening the lifespan of your roof and leading to the need for premature replacement. It involves injecting molten zinc into custom tools with die cast die cavities at high pressures. As the molten zinc cools and solidifies, it takes on the exact shape and features of the mold. Zinc die casting is. Zinc And Mold.

From www.injectionmouldingparts.com

Polishing Zinc Alloy Die Casting Parts Keys HASCO Mold Standard Zinc And Mold Moss can accelerate the deterioration of roofing materials, shortening the lifespan of your roof and leading to the need for premature replacement. The moisture retained by moss can promote mold growth both on the roof and in the underlying structure, which can pose health risks and lead to costly repairs. This process allows the molten metal. It involves injecting molten. Zinc And Mold.

From www.made-in-china.com

China Steel Casting Aluminum Sow Ingot Mold with Fork Slots China OEM Zinc And Mold In die casting, zinc alloys are melted and injected into steel molds under high pressure. Reports have demonstrated that zinc oxide nanoparticles (zno nps) can control postharvest mold, plant wilts, and grey mold. It involves injecting molten zinc into custom tools with die cast die cavities at high pressures. As the molten zinc cools and solidifies, it takes on the. Zinc And Mold.

From www.taiwantrade.com

Quotation for Aluminum,magnesium,zinc die casting mold/parts Zinc And Mold Moss can accelerate the deterioration of roofing materials, shortening the lifespan of your roof and leading to the need for premature replacement. Zinc die casting is a process involving the injection of liquid zinc metal under pressure into a mold and left to solidify. Reports have demonstrated that zinc oxide nanoparticles (zno nps) can control postharvest mold, plant wilts, and. Zinc And Mold.

From www.die-casting-china.com

Case Studyaluminum/magnesium/zinc die casting and sand casting Zinc And Mold Moss can accelerate the deterioration of roofing materials, shortening the lifespan of your roof and leading to the need for premature replacement. Reports have demonstrated that zinc oxide nanoparticles (zno nps) can control postharvest mold, plant wilts, and grey mold. The moisture retained by moss can promote mold growth both on the roof and in the underlying structure, which can. Zinc And Mold.

From chinametalcastings.com

Die casting mold Aluminum & Zinc Die casting China Zinc And Mold It involves injecting molten zinc into custom tools with die cast die cavities at high pressures. Moss can accelerate the deterioration of roofing materials, shortening the lifespan of your roof and leading to the need for premature replacement. In die casting, zinc alloys are melted and injected into steel molds under high pressure. The moisture retained by moss can promote. Zinc And Mold.

From www.injectionmouldingparts.com

OEM Zinc Alloy Die Casting Mold Hot Chamber / Cast Aluminum Mold Zinc And Mold It involves injecting molten zinc into custom tools with die cast die cavities at high pressures. This process allows the molten metal. As the molten zinc cools and solidifies, it takes on the exact shape and features of the mold. Moss can accelerate the deterioration of roofing materials, shortening the lifespan of your roof and leading to the need for. Zinc And Mold.

From www.diecasting-mould.com

How To Solve The Problem Of Sticking Mold Of Zinc Alloy Die Casting Zinc And Mold Moss can accelerate the deterioration of roofing materials, shortening the lifespan of your roof and leading to the need for premature replacement. This process allows the molten metal. Reports have demonstrated that zinc oxide nanoparticles (zno nps) can control postharvest mold, plant wilts, and grey mold. Zinc die casting is a process involving the injection of liquid zinc metal under. Zinc And Mold.

From www.usamm.net

DieCast Mold for Zinc parts, OEM/ODM Orders are Accepted Material use Zinc And Mold The moisture retained by moss can promote mold growth both on the roof and in the underlying structure, which can pose health risks and lead to costly repairs. Reports have demonstrated that zinc oxide nanoparticles (zno nps) can control postharvest mold, plant wilts, and grey mold. It involves injecting molten zinc into custom tools with die cast die cavities at. Zinc And Mold.

From www.themouldinfo.com

Zinc Die Casting Mold Mould Products, Mould Manufacturers, Mould Zinc And Mold In die casting, zinc alloys are melted and injected into steel molds under high pressure. It involves injecting molten zinc into custom tools with die cast die cavities at high pressures. This process allows the molten metal. The moisture retained by moss can promote mold growth both on the roof and in the underlying structure, which can pose health risks. Zinc And Mold.

From www.pinterest.com

Zinc ingot mold Mould design, Zinc, Ingot Zinc And Mold This process allows the molten metal. It involves injecting molten zinc into custom tools with die cast die cavities at high pressures. Zinc die casting is a process involving the injection of liquid zinc metal under pressure into a mold and left to solidify. As the molten zinc cools and solidifies, it takes on the exact shape and features of. Zinc And Mold.

From store.goengineer.com

Zinc Stearate Mold Release Aerosol GoEngineer Store Zinc And Mold Zinc die casting is a process involving the injection of liquid zinc metal under pressure into a mold and left to solidify. The moisture retained by moss can promote mold growth both on the roof and in the underlying structure, which can pose health risks and lead to costly repairs. It involves injecting molten zinc into custom tools with die. Zinc And Mold.

From www.plastopialtd.com

Mold Polish for Zinc Die Casting Mold Plastopia Zinc And Mold It involves injecting molten zinc into custom tools with die cast die cavities at high pressures. The moisture retained by moss can promote mold growth both on the roof and in the underlying structure, which can pose health risks and lead to costly repairs. As the molten zinc cools and solidifies, it takes on the exact shape and features of. Zinc And Mold.

From www.istockphoto.com

Silver Zinc Bread Mold Aluminum Stainless Steel Square Mold Isolated Zinc And Mold Moss can accelerate the deterioration of roofing materials, shortening the lifespan of your roof and leading to the need for premature replacement. Reports have demonstrated that zinc oxide nanoparticles (zno nps) can control postharvest mold, plant wilts, and grey mold. As the molten zinc cools and solidifies, it takes on the exact shape and features of the mold. It involves. Zinc And Mold.

From www.sylprotec.com

Encapsulating product for mold control & prevention Zinc And Mold The moisture retained by moss can promote mold growth both on the roof and in the underlying structure, which can pose health risks and lead to costly repairs. In die casting, zinc alloys are melted and injected into steel molds under high pressure. This process allows the molten metal. Zinc die casting is a process involving the injection of liquid. Zinc And Mold.

From store.goengineer.com

Zinc Stearate Mold Release Aerosol GoEngineer Store Zinc And Mold The moisture retained by moss can promote mold growth both on the roof and in the underlying structure, which can pose health risks and lead to costly repairs. Reports have demonstrated that zinc oxide nanoparticles (zno nps) can control postharvest mold, plant wilts, and grey mold. Zinc die casting is a process involving the injection of liquid zinc metal under. Zinc And Mold.

From decoprod.com

Zinc Alloy Precision with Die Casting Molds Deco Products Zinc And Mold In die casting, zinc alloys are melted and injected into steel molds under high pressure. Reports have demonstrated that zinc oxide nanoparticles (zno nps) can control postharvest mold, plant wilts, and grey mold. Zinc die casting is a process involving the injection of liquid zinc metal under pressure into a mold and left to solidify. This process allows the molten. Zinc And Mold.

From www.alibaba.com

China Factory Zinc Die Casting Mold Buy Die Casting Mold,Zinc Die Zinc And Mold It involves injecting molten zinc into custom tools with die cast die cavities at high pressures. This process allows the molten metal. Reports have demonstrated that zinc oxide nanoparticles (zno nps) can control postharvest mold, plant wilts, and grey mold. Moss can accelerate the deterioration of roofing materials, shortening the lifespan of your roof and leading to the need for. Zinc And Mold.

From www.alibaba.com

Customized Zinc And Aluminum Alloy Die Casting Mold Making Buy Zinc Zinc And Mold Moss can accelerate the deterioration of roofing materials, shortening the lifespan of your roof and leading to the need for premature replacement. In die casting, zinc alloys are melted and injected into steel molds under high pressure. The moisture retained by moss can promote mold growth both on the roof and in the underlying structure, which can pose health risks. Zinc And Mold.

From www.marketingthiink.com

Plastic gears molding and moldmaking service CNC MachiningCNC Zinc And Mold This process allows the molten metal. As the molten zinc cools and solidifies, it takes on the exact shape and features of the mold. The moisture retained by moss can promote mold growth both on the roof and in the underlying structure, which can pose health risks and lead to costly repairs. In die casting, zinc alloys are melted and. Zinc And Mold.

From www.iqsdirectory.com

Zinc Die Casting What Is It? How Is it Made? Advantages Zinc And Mold As the molten zinc cools and solidifies, it takes on the exact shape and features of the mold. Reports have demonstrated that zinc oxide nanoparticles (zno nps) can control postharvest mold, plant wilts, and grey mold. The moisture retained by moss can promote mold growth both on the roof and in the underlying structure, which can pose health risks and. Zinc And Mold.

From www.aluminumingotmold.com

Lead Zinc Ingot Casting Molds Impacts Out Surface And Inner OEM Zinc And Mold It involves injecting molten zinc into custom tools with die cast die cavities at high pressures. In die casting, zinc alloys are melted and injected into steel molds under high pressure. This process allows the molten metal. As the molten zinc cools and solidifies, it takes on the exact shape and features of the mold. Reports have demonstrated that zinc. Zinc And Mold.

From www.adtcmold.com

Injection mold principle and structure knowledge Zinc And Mold It involves injecting molten zinc into custom tools with die cast die cavities at high pressures. Reports have demonstrated that zinc oxide nanoparticles (zno nps) can control postharvest mold, plant wilts, and grey mold. As the molten zinc cools and solidifies, it takes on the exact shape and features of the mold. Moss can accelerate the deterioration of roofing materials,. Zinc And Mold.

From oeform.com

Die casting mold design Alu; Zinc;Mg Die casting OEFORM Zinc And Mold As the molten zinc cools and solidifies, it takes on the exact shape and features of the mold. In die casting, zinc alloys are melted and injected into steel molds under high pressure. It involves injecting molten zinc into custom tools with die cast die cavities at high pressures. Zinc die casting is a process involving the injection of liquid. Zinc And Mold.

From www.bruschitech.com

How to optimize die casting mold design Zinc And Mold In die casting, zinc alloys are melted and injected into steel molds under high pressure. Reports have demonstrated that zinc oxide nanoparticles (zno nps) can control postharvest mold, plant wilts, and grey mold. Zinc die casting is a process involving the injection of liquid zinc metal under pressure into a mold and left to solidify. It involves injecting molten zinc. Zinc And Mold.

From pluxindustry.en.made-in-china.com

Zinc Alloy High Pressure Die Cast Mold Mould Injection Mould China Zinc And Mold As the molten zinc cools and solidifies, it takes on the exact shape and features of the mold. In die casting, zinc alloys are melted and injected into steel molds under high pressure. Reports have demonstrated that zinc oxide nanoparticles (zno nps) can control postharvest mold, plant wilts, and grey mold. It involves injecting molten zinc into custom tools with. Zinc And Mold.

From www.zoro.com

Stoner Zinc Stearate Mold Release, 12 oz. E474 Zoro Zinc And Mold In die casting, zinc alloys are melted and injected into steel molds under high pressure. Moss can accelerate the deterioration of roofing materials, shortening the lifespan of your roof and leading to the need for premature replacement. This process allows the molten metal. The moisture retained by moss can promote mold growth both on the roof and in the underlying. Zinc And Mold.

From imscompany.com

IMS Company Mold Release, Zinc Stearate, Paintable, A4, DryPowder Zinc And Mold This process allows the molten metal. Moss can accelerate the deterioration of roofing materials, shortening the lifespan of your roof and leading to the need for premature replacement. Zinc die casting is a process involving the injection of liquid zinc metal under pressure into a mold and left to solidify. The moisture retained by moss can promote mold growth both. Zinc And Mold.

From www.slideproducts.com

Zinc Stearate Mold Release Spray Paintable Water Repellant Zinc And Mold Reports have demonstrated that zinc oxide nanoparticles (zno nps) can control postharvest mold, plant wilts, and grey mold. In die casting, zinc alloys are melted and injected into steel molds under high pressure. This process allows the molten metal. It involves injecting molten zinc into custom tools with die cast die cavities at high pressures. Zinc die casting is a. Zinc And Mold.

From etmold.en.made-in-china.com

Die Casting Mold and Molding Plastic Injection Mold and Mould Main Zinc And Mold Reports have demonstrated that zinc oxide nanoparticles (zno nps) can control postharvest mold, plant wilts, and grey mold. It involves injecting molten zinc into custom tools with die cast die cavities at high pressures. Zinc die casting is a process involving the injection of liquid zinc metal under pressure into a mold and left to solidify. The moisture retained by. Zinc And Mold.

From www.grefeemold.com

Zinc alloy die casting mold machining grefee mold company Zinc And Mold Reports have demonstrated that zinc oxide nanoparticles (zno nps) can control postharvest mold, plant wilts, and grey mold. Moss can accelerate the deterioration of roofing materials, shortening the lifespan of your roof and leading to the need for premature replacement. As the molten zinc cools and solidifies, it takes on the exact shape and features of the mold. In die. Zinc And Mold.

From www.thompsonfoundry.com

6 cavity zinc ingot mold Thompson Foundry Zinc And Mold It involves injecting molten zinc into custom tools with die cast die cavities at high pressures. In die casting, zinc alloys are melted and injected into steel molds under high pressure. As the molten zinc cools and solidifies, it takes on the exact shape and features of the mold. Zinc die casting is a process involving the injection of liquid. Zinc And Mold.

From www.istockphoto.com

Silver Zinc Bread Mold Aluminum Stainless Steel Square Mold Isolated Zinc And Mold Zinc die casting is a process involving the injection of liquid zinc metal under pressure into a mold and left to solidify. Reports have demonstrated that zinc oxide nanoparticles (zno nps) can control postharvest mold, plant wilts, and grey mold. As the molten zinc cools and solidifies, it takes on the exact shape and features of the mold. The moisture. Zinc And Mold.

From mrocrib.com

Slide 41012N Zinc Stearate Mold Release Zinc And Mold This process allows the molten metal. Moss can accelerate the deterioration of roofing materials, shortening the lifespan of your roof and leading to the need for premature replacement. In die casting, zinc alloys are melted and injected into steel molds under high pressure. Reports have demonstrated that zinc oxide nanoparticles (zno nps) can control postharvest mold, plant wilts, and grey. Zinc And Mold.