Belt Design Roller . Designing a belt conveyor involves several key steps to ensure the system is efficient,. Flexco expert explains the five factors to consider when selecting belt conveyor rollers to increase roller longevity and downtime and decrease maintenance costs. For powered roller conveyors, either individual rollers are motorized or a motor drives the conveyor belt that moves the rollers, thus propelling objects along the conveyor’s. These material handling systems come in numerous designs, with the incorporation of rollers, chains, and more commonly, belts. These are rollers employed along the length of the belt to support the belt and load, prevent sagging, align the. Central to these systems is the concept of conveyor idler roller design, which plays a crucial role in ensuring the smooth and reliable. How to design a belt conveyor? Conveyor belt centered on the conveyor when temporary or transient conditions could result in belt misalignment.

from www.ammeraalbeltech.com

These material handling systems come in numerous designs, with the incorporation of rollers, chains, and more commonly, belts. How to design a belt conveyor? Designing a belt conveyor involves several key steps to ensure the system is efficient,. Flexco expert explains the five factors to consider when selecting belt conveyor rollers to increase roller longevity and downtime and decrease maintenance costs. These are rollers employed along the length of the belt to support the belt and load, prevent sagging, align the. Conveyor belt centered on the conveyor when temporary or transient conditions could result in belt misalignment. Central to these systems is the concept of conveyor idler roller design, which plays a crucial role in ensuring the smooth and reliable. For powered roller conveyors, either individual rollers are motorized or a motor drives the conveyor belt that moves the rollers, thus propelling objects along the conveyor’s.

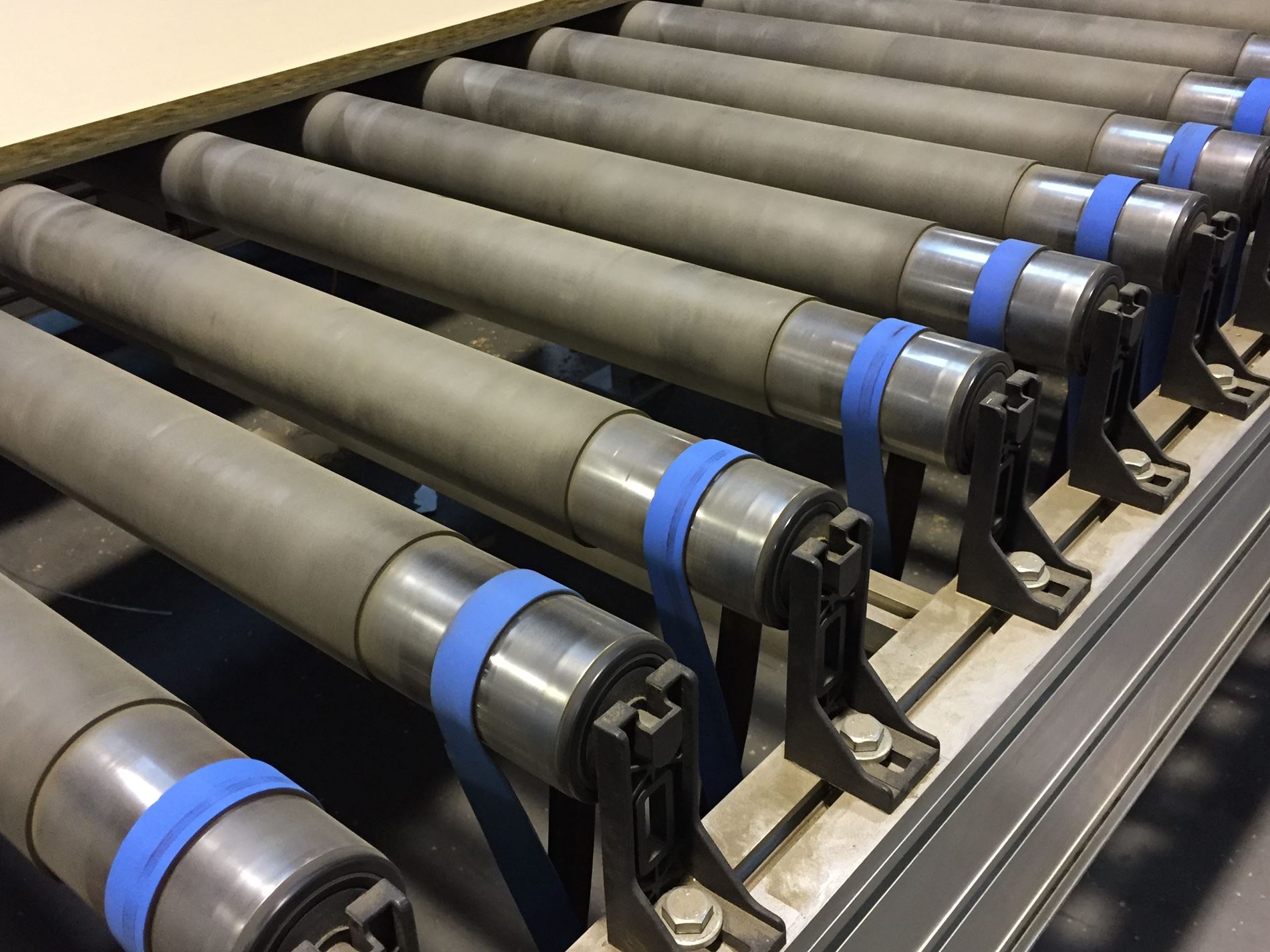

Roller Drive Belts Ammeraal Beltech

Belt Design Roller Central to these systems is the concept of conveyor idler roller design, which plays a crucial role in ensuring the smooth and reliable. Designing a belt conveyor involves several key steps to ensure the system is efficient,. Conveyor belt centered on the conveyor when temporary or transient conditions could result in belt misalignment. How to design a belt conveyor? These are rollers employed along the length of the belt to support the belt and load, prevent sagging, align the. For powered roller conveyors, either individual rollers are motorized or a motor drives the conveyor belt that moves the rollers, thus propelling objects along the conveyor’s. Flexco expert explains the five factors to consider when selecting belt conveyor rollers to increase roller longevity and downtime and decrease maintenance costs. These material handling systems come in numerous designs, with the incorporation of rollers, chains, and more commonly, belts. Central to these systems is the concept of conveyor idler roller design, which plays a crucial role in ensuring the smooth and reliable.

From www.dornerconveyors.com

Intralox Activated Roller Belt™ (ARB) Technology Dorner Conveyors Belt Design Roller These material handling systems come in numerous designs, with the incorporation of rollers, chains, and more commonly, belts. How to design a belt conveyor? For powered roller conveyors, either individual rollers are motorized or a motor drives the conveyor belt that moves the rollers, thus propelling objects along the conveyor’s. Flexco expert explains the five factors to consider when selecting. Belt Design Roller.

From www.truckloader.in

Roller Belt Conveyors, Belt Conveyors, Manufacturer, Supplier, India Belt Design Roller Designing a belt conveyor involves several key steps to ensure the system is efficient,. Central to these systems is the concept of conveyor idler roller design, which plays a crucial role in ensuring the smooth and reliable. These material handling systems come in numerous designs, with the incorporation of rollers, chains, and more commonly, belts. For powered roller conveyors, either. Belt Design Roller.

From dyno.co.nz

Tranzband (Lineshaft) Powered Roller Conveyor Dyno Conveyors NZ Belt Design Roller Flexco expert explains the five factors to consider when selecting belt conveyor rollers to increase roller longevity and downtime and decrease maintenance costs. For powered roller conveyors, either individual rollers are motorized or a motor drives the conveyor belt that moves the rollers, thus propelling objects along the conveyor’s. These material handling systems come in numerous designs, with the incorporation. Belt Design Roller.

From www.indiamart.com

Mild Steel OGroove Rollers Powered Roller Conveyor Belt, Rs 125000. Belt Design Roller Conveyor belt centered on the conveyor when temporary or transient conditions could result in belt misalignment. Central to these systems is the concept of conveyor idler roller design, which plays a crucial role in ensuring the smooth and reliable. These material handling systems come in numerous designs, with the incorporation of rollers, chains, and more commonly, belts. Flexco expert explains. Belt Design Roller.

From www.coastcontrols.com

Idler Rollers Steel, Stainless Steel, Aluminum Belt Design Roller Central to these systems is the concept of conveyor idler roller design, which plays a crucial role in ensuring the smooth and reliable. How to design a belt conveyor? For powered roller conveyors, either individual rollers are motorized or a motor drives the conveyor belt that moves the rollers, thus propelling objects along the conveyor’s. These material handling systems come. Belt Design Roller.

From www.red-dot.org

Red Dot Design Award Roller and Belt Conveyor System Belt Design Roller Designing a belt conveyor involves several key steps to ensure the system is efficient,. For powered roller conveyors, either individual rollers are motorized or a motor drives the conveyor belt that moves the rollers, thus propelling objects along the conveyor’s. Central to these systems is the concept of conveyor idler roller design, which plays a crucial role in ensuring the. Belt Design Roller.

From accurateindustrial.com

Live Roller Belting Accurate Industrial Belt Design Roller Designing a belt conveyor involves several key steps to ensure the system is efficient,. Central to these systems is the concept of conveyor idler roller design, which plays a crucial role in ensuring the smooth and reliable. How to design a belt conveyor? For powered roller conveyors, either individual rollers are motorized or a motor drives the conveyor belt that. Belt Design Roller.

From www.youtube.com

Belt Roller Support Assembly Autodesk Inventor Tutorial YouTube Belt Design Roller Flexco expert explains the five factors to consider when selecting belt conveyor rollers to increase roller longevity and downtime and decrease maintenance costs. These are rollers employed along the length of the belt to support the belt and load, prevent sagging, align the. These material handling systems come in numerous designs, with the incorporation of rollers, chains, and more commonly,. Belt Design Roller.

From www.truckloader.in

Roller Belt Conveyors, Belt Conveyors, Manufacturer, Supplier, India Belt Design Roller For powered roller conveyors, either individual rollers are motorized or a motor drives the conveyor belt that moves the rollers, thus propelling objects along the conveyor’s. Conveyor belt centered on the conveyor when temporary or transient conditions could result in belt misalignment. These are rollers employed along the length of the belt to support the belt and load, prevent sagging,. Belt Design Roller.

From conveyors.lewcoinc.com

Modular Plastic Belt Conveyor with Series 1000 Insert Roller Top Belt Design Roller These are rollers employed along the length of the belt to support the belt and load, prevent sagging, align the. Flexco expert explains the five factors to consider when selecting belt conveyor rollers to increase roller longevity and downtime and decrease maintenance costs. How to design a belt conveyor? Central to these systems is the concept of conveyor idler roller. Belt Design Roller.

From www.youtube.com

90 Degree Curved/Bend Roller Conveyor Designing and Motion Study in Belt Design Roller Central to these systems is the concept of conveyor idler roller design, which plays a crucial role in ensuring the smooth and reliable. These material handling systems come in numerous designs, with the incorporation of rollers, chains, and more commonly, belts. How to design a belt conveyor? Conveyor belt centered on the conveyor when temporary or transient conditions could result. Belt Design Roller.

From www.tyma.eu

News » PolyVBelts for Roller Conveyors in Stock TYMA CZ Belt Design Roller How to design a belt conveyor? Flexco expert explains the five factors to consider when selecting belt conveyor rollers to increase roller longevity and downtime and decrease maintenance costs. These are rollers employed along the length of the belt to support the belt and load, prevent sagging, align the. These material handling systems come in numerous designs, with the incorporation. Belt Design Roller.

From mobilityengineering.co.uk

Active Roller Belt Conveyor Mobility Engineering (Cheshire) Ltd Belt Design Roller How to design a belt conveyor? Central to these systems is the concept of conveyor idler roller design, which plays a crucial role in ensuring the smooth and reliable. Designing a belt conveyor involves several key steps to ensure the system is efficient,. Conveyor belt centered on the conveyor when temporary or transient conditions could result in belt misalignment. These. Belt Design Roller.

From www.pinterest.co.uk

Sorting Conveyor Activated Roller Belt Sortation Systems https Belt Design Roller Central to these systems is the concept of conveyor idler roller design, which plays a crucial role in ensuring the smooth and reliable. These are rollers employed along the length of the belt to support the belt and load, prevent sagging, align the. These material handling systems come in numerous designs, with the incorporation of rollers, chains, and more commonly,. Belt Design Roller.

From www.mknorthamerica.com

Plastic Modular Belt Conveyor MBFP 2040 mk Belt Design Roller Flexco expert explains the five factors to consider when selecting belt conveyor rollers to increase roller longevity and downtime and decrease maintenance costs. These are rollers employed along the length of the belt to support the belt and load, prevent sagging, align the. How to design a belt conveyor? These material handling systems come in numerous designs, with the incorporation. Belt Design Roller.

From proguideroller.com

Guide Roller for Belt Conveyor (Steel) ProGuide Belt Design Roller Central to these systems is the concept of conveyor idler roller design, which plays a crucial role in ensuring the smooth and reliable. For powered roller conveyors, either individual rollers are motorized or a motor drives the conveyor belt that moves the rollers, thus propelling objects along the conveyor’s. These material handling systems come in numerous designs, with the incorporation. Belt Design Roller.

From foundations.martin-eng.com

Crowned pulleys are used in low tension areas Martin Engineering Belt Design Roller Central to these systems is the concept of conveyor idler roller design, which plays a crucial role in ensuring the smooth and reliable. These are rollers employed along the length of the belt to support the belt and load, prevent sagging, align the. Conveyor belt centered on the conveyor when temporary or transient conditions could result in belt misalignment. Flexco. Belt Design Roller.

From www.artstation.com

ArtStation Belt Roller Support Belt Design Roller Central to these systems is the concept of conveyor idler roller design, which plays a crucial role in ensuring the smooth and reliable. For powered roller conveyors, either individual rollers are motorized or a motor drives the conveyor belt that moves the rollers, thus propelling objects along the conveyor’s. These are rollers employed along the length of the belt to. Belt Design Roller.

From dyno.co.nz

Pallet Roller Conveyor Systems » DYNO Belt Design Roller Conveyor belt centered on the conveyor when temporary or transient conditions could result in belt misalignment. Central to these systems is the concept of conveyor idler roller design, which plays a crucial role in ensuring the smooth and reliable. Designing a belt conveyor involves several key steps to ensure the system is efficient,. For powered roller conveyors, either individual rollers. Belt Design Roller.

From www.brockgrain.com

Enclosed RollerBelt Conveyors Brock Grain Belt Design Roller These are rollers employed along the length of the belt to support the belt and load, prevent sagging, align the. How to design a belt conveyor? These material handling systems come in numerous designs, with the incorporation of rollers, chains, and more commonly, belts. Conveyor belt centered on the conveyor when temporary or transient conditions could result in belt misalignment.. Belt Design Roller.

From www.youtube.com

Belt Roller Support Assembly in Solidworks YouTube Belt Design Roller Central to these systems is the concept of conveyor idler roller design, which plays a crucial role in ensuring the smooth and reliable. Conveyor belt centered on the conveyor when temporary or transient conditions could result in belt misalignment. How to design a belt conveyor? These are rollers employed along the length of the belt to support the belt and. Belt Design Roller.

From www.conveyorrollers.co.uk

Lineshaft driven roller conveyor Fastrax Conveyor Rollers Belt Design Roller How to design a belt conveyor? Designing a belt conveyor involves several key steps to ensure the system is efficient,. Central to these systems is the concept of conveyor idler roller design, which plays a crucial role in ensuring the smooth and reliable. For powered roller conveyors, either individual rollers are motorized or a motor drives the conveyor belt that. Belt Design Roller.

From dphengg.com

All about Idler Roller Belts Belt Design Roller Central to these systems is the concept of conveyor idler roller design, which plays a crucial role in ensuring the smooth and reliable. Conveyor belt centered on the conveyor when temporary or transient conditions could result in belt misalignment. These material handling systems come in numerous designs, with the incorporation of rollers, chains, and more commonly, belts. How to design. Belt Design Roller.

From www.bellebannecp.com.au

Conveyor Belt Hold Down Rollers Belle Banne Conveyor Products Belt Design Roller These are rollers employed along the length of the belt to support the belt and load, prevent sagging, align the. Flexco expert explains the five factors to consider when selecting belt conveyor rollers to increase roller longevity and downtime and decrease maintenance costs. Central to these systems is the concept of conveyor idler roller design, which plays a crucial role. Belt Design Roller.

From conveyors.lewcoinc.com

Modular Plastic Belt Conveyor with Series 1000 Insert Roller Top Belt Design Roller Central to these systems is the concept of conveyor idler roller design, which plays a crucial role in ensuring the smooth and reliable. Conveyor belt centered on the conveyor when temporary or transient conditions could result in belt misalignment. Flexco expert explains the five factors to consider when selecting belt conveyor rollers to increase roller longevity and downtime and decrease. Belt Design Roller.

From dyno.co.nz

Tranzband (Lineshaft) Powered Roller Conveyor Dyno Conveyors NZ Belt Design Roller Conveyor belt centered on the conveyor when temporary or transient conditions could result in belt misalignment. These are rollers employed along the length of the belt to support the belt and load, prevent sagging, align the. For powered roller conveyors, either individual rollers are motorized or a motor drives the conveyor belt that moves the rollers, thus propelling objects along. Belt Design Roller.

From www.indiamart.com

Conveyor Guide Roller at Rs 150/piece Conveyor Rollers ID 2221255012 Belt Design Roller For powered roller conveyors, either individual rollers are motorized or a motor drives the conveyor belt that moves the rollers, thus propelling objects along the conveyor’s. These material handling systems come in numerous designs, with the incorporation of rollers, chains, and more commonly, belts. How to design a belt conveyor? Central to these systems is the concept of conveyor idler. Belt Design Roller.

From www.iqsdirectory.com

Belt Conveyors Components, Types, Design, and Applications Belt Design Roller These are rollers employed along the length of the belt to support the belt and load, prevent sagging, align the. Flexco expert explains the five factors to consider when selecting belt conveyor rollers to increase roller longevity and downtime and decrease maintenance costs. How to design a belt conveyor? Designing a belt conveyor involves several key steps to ensure the. Belt Design Roller.

From www.iqsdirectory.com

Belt Conveyors Components, Types, Design, and Applications Belt Design Roller How to design a belt conveyor? Flexco expert explains the five factors to consider when selecting belt conveyor rollers to increase roller longevity and downtime and decrease maintenance costs. Designing a belt conveyor involves several key steps to ensure the system is efficient,. Central to these systems is the concept of conveyor idler roller design, which plays a crucial role. Belt Design Roller.

From www.sciencechannel.com

Roller Conveyors Science Channel How It's Made Discovery Science Belt Design Roller Conveyor belt centered on the conveyor when temporary or transient conditions could result in belt misalignment. Central to these systems is the concept of conveyor idler roller design, which plays a crucial role in ensuring the smooth and reliable. These are rollers employed along the length of the belt to support the belt and load, prevent sagging, align the. These. Belt Design Roller.

From www.gcsconveyor.com

News Articles conveyors beltconveyors Belt Design Roller Designing a belt conveyor involves several key steps to ensure the system is efficient,. These are rollers employed along the length of the belt to support the belt and load, prevent sagging, align the. Flexco expert explains the five factors to consider when selecting belt conveyor rollers to increase roller longevity and downtime and decrease maintenance costs. How to design. Belt Design Roller.

From www.beltpower.com

Conveyor Pulleys Conveyor Rollers Belt Power Belt Design Roller Designing a belt conveyor involves several key steps to ensure the system is efficient,. Flexco expert explains the five factors to consider when selecting belt conveyor rollers to increase roller longevity and downtime and decrease maintenance costs. Conveyor belt centered on the conveyor when temporary or transient conditions could result in belt misalignment. These are rollers employed along the length. Belt Design Roller.

From www.conveyorrollers.co.uk

Steel Rollers and stainless steel roller conveyors, Manufactured in UK Belt Design Roller For powered roller conveyors, either individual rollers are motorized or a motor drives the conveyor belt that moves the rollers, thus propelling objects along the conveyor’s. These material handling systems come in numerous designs, with the incorporation of rollers, chains, and more commonly, belts. How to design a belt conveyor? Designing a belt conveyor involves several key steps to ensure. Belt Design Roller.

From www.ammeraalbeltech.com

Roller Drive Belts Ammeraal Beltech Belt Design Roller These are rollers employed along the length of the belt to support the belt and load, prevent sagging, align the. Conveyor belt centered on the conveyor when temporary or transient conditions could result in belt misalignment. How to design a belt conveyor? These material handling systems come in numerous designs, with the incorporation of rollers, chains, and more commonly, belts.. Belt Design Roller.

From rulmeca.com

Material handling components for conveyor Rulmeca Belt Design Roller These are rollers employed along the length of the belt to support the belt and load, prevent sagging, align the. These material handling systems come in numerous designs, with the incorporation of rollers, chains, and more commonly, belts. Designing a belt conveyor involves several key steps to ensure the system is efficient,. How to design a belt conveyor? Central to. Belt Design Roller.