Flange Taps Vs Corner Taps . They are often used for. corner taps must be used on small pipe diameters where the vena contracta is so close to the downstream face of the orifice plate that a downstream flange tap would sense pressure in the highly turbulent region (too far downstream). differential pressures are taken out in a corner tap system. corner taps ( less than 2 inches) flange taps: learn about different tap locations for orifice plates, such as flange, vena contracta, radius and corner taps. Corner taps are located right at the upstream side and downstream side faces of the orifice plates. Flange taps are the most common and are generally used for pipe sizes of 2 inches and greater. They are holes bored through the flanges located 1” upstream side and 1” downstream side from respective faces of the orifice plate. Flange taps should not be used in pipe sizes less than 2 inches. flange taps are positioned 25mm from the upstream face of the orifice plate and 25.4mm from the downstream face. corner taps are analogous to flange taps since the pressure tap is positioned within the orifice plate’s edges.

from www.jarviscuttingtools.com

differential pressures are taken out in a corner tap system. They are often used for. corner taps are analogous to flange taps since the pressure tap is positioned within the orifice plate’s edges. Flange taps should not be used in pipe sizes less than 2 inches. Corner taps are located right at the upstream side and downstream side faces of the orifice plates. flange taps are positioned 25mm from the upstream face of the orifice plate and 25.4mm from the downstream face. learn about different tap locations for orifice plates, such as flange, vena contracta, radius and corner taps. Flange taps are the most common and are generally used for pipe sizes of 2 inches and greater. corner taps ( less than 2 inches) flange taps: They are holes bored through the flanges located 1” upstream side and 1” downstream side from respective faces of the orifice plate.

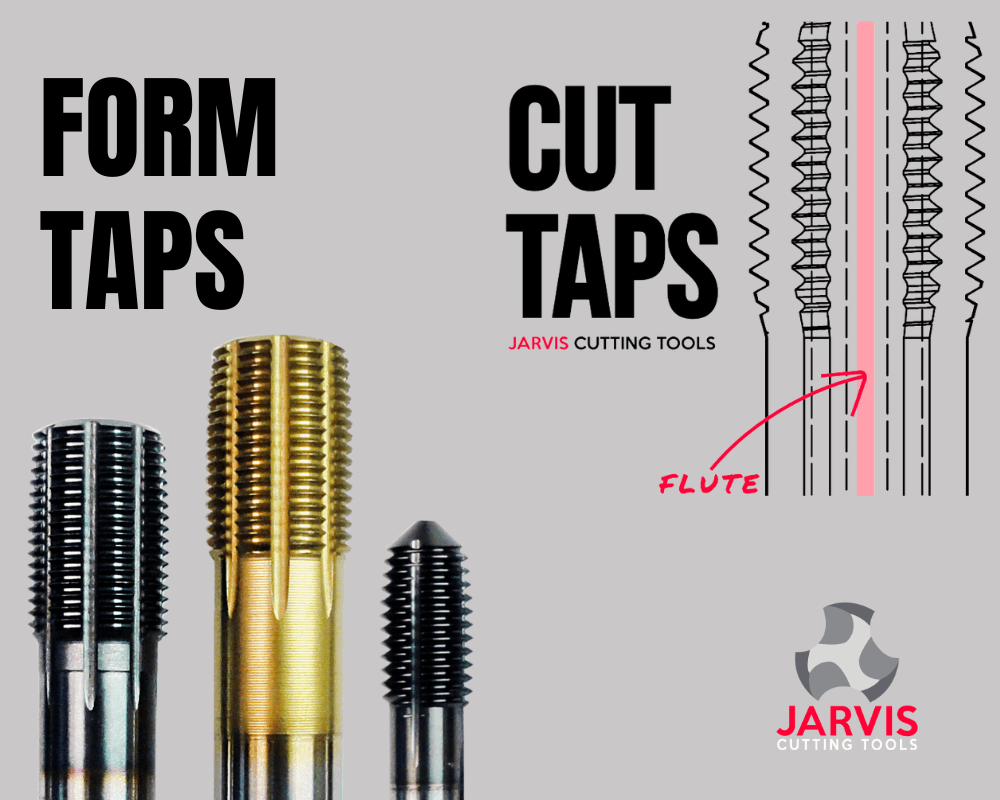

Cutting Taps vs. Forming Taps Difference Jarvis

Flange Taps Vs Corner Taps flange taps are positioned 25mm from the upstream face of the orifice plate and 25.4mm from the downstream face. differential pressures are taken out in a corner tap system. corner taps are analogous to flange taps since the pressure tap is positioned within the orifice plate’s edges. They are holes bored through the flanges located 1” upstream side and 1” downstream side from respective faces of the orifice plate. Flange taps should not be used in pipe sizes less than 2 inches. They are often used for. flange taps are positioned 25mm from the upstream face of the orifice plate and 25.4mm from the downstream face. Flange taps are the most common and are generally used for pipe sizes of 2 inches and greater. learn about different tap locations for orifice plates, such as flange, vena contracta, radius and corner taps. corner taps must be used on small pipe diameters where the vena contracta is so close to the downstream face of the orifice plate that a downstream flange tap would sense pressure in the highly turbulent region (too far downstream). corner taps ( less than 2 inches) flange taps: Corner taps are located right at the upstream side and downstream side faces of the orifice plates.

From hit.skku.edu

Piping Flanges Types Of Flanges In Piping Systems, 48 OFF Flange Taps Vs Corner Taps differential pressures are taken out in a corner tap system. Flange taps are the most common and are generally used for pipe sizes of 2 inches and greater. They are often used for. corner taps ( less than 2 inches) flange taps: learn about different tap locations for orifice plates, such as flange, vena contracta, radius and. Flange Taps Vs Corner Taps.

From engineeringlearner.com

Types of Flanges Design, Functions & Flange Face [with Pictures Flange Taps Vs Corner Taps Flange taps should not be used in pipe sizes less than 2 inches. They are often used for. They are holes bored through the flanges located 1” upstream side and 1” downstream side from respective faces of the orifice plate. Corner taps are located right at the upstream side and downstream side faces of the orifice plates. corner taps. Flange Taps Vs Corner Taps.

From www.promaxxtool.com

Different Types of Taps and When to Use Them ProMAXX Tool Flange Taps Vs Corner Taps They are holes bored through the flanges located 1” upstream side and 1” downstream side from respective faces of the orifice plate. differential pressures are taken out in a corner tap system. flange taps are positioned 25mm from the upstream face of the orifice plate and 25.4mm from the downstream face. corner taps are analogous to flange. Flange Taps Vs Corner Taps.

From www.studypool.com

SOLUTION Orifice assembly with corner taps and rtj flange facing Flange Taps Vs Corner Taps corner taps must be used on small pipe diameters where the vena contracta is so close to the downstream face of the orifice plate that a downstream flange tap would sense pressure in the highly turbulent region (too far downstream). Corner taps are located right at the upstream side and downstream side faces of the orifice plates. corner. Flange Taps Vs Corner Taps.

From www.sunnysteel.com

Orifice flange, flange, flanges, pipe flange, welding neck flange Flange Taps Vs Corner Taps differential pressures are taken out in a corner tap system. They are often used for. Corner taps are located right at the upstream side and downstream side faces of the orifice plates. Flange taps are the most common and are generally used for pipe sizes of 2 inches and greater. They are holes bored through the flanges located 1”. Flange Taps Vs Corner Taps.

From exogipowy.blob.core.windows.net

Difference Between Cutting And Forming Taps at Lashonda Johnson blog Flange Taps Vs Corner Taps They are often used for. Flange taps are the most common and are generally used for pipe sizes of 2 inches and greater. They are holes bored through the flanges located 1” upstream side and 1” downstream side from respective faces of the orifice plate. Corner taps are located right at the upstream side and downstream side faces of the. Flange Taps Vs Corner Taps.

From www.cncyangsen.com

What Are The Three Types of Flange Taps Vs Corner Taps flange taps are positioned 25mm from the upstream face of the orifice plate and 25.4mm from the downstream face. corner taps must be used on small pipe diameters where the vena contracta is so close to the downstream face of the orifice plate that a downstream flange tap would sense pressure in the highly turbulent region (too far. Flange Taps Vs Corner Taps.

From theinstrumentguru.com

Type of Orifice Tapping Connection THE INSTRUMENT GURU Flange Taps Vs Corner Taps flange taps are positioned 25mm from the upstream face of the orifice plate and 25.4mm from the downstream face. corner taps are analogous to flange taps since the pressure tap is positioned within the orifice plate’s edges. Flange taps are the most common and are generally used for pipe sizes of 2 inches and greater. They are often. Flange Taps Vs Corner Taps.

From forumautomation.com

Orifice plate Taps Flow Measurement Industrial Automation, PLC Flange Taps Vs Corner Taps flange taps are positioned 25mm from the upstream face of the orifice plate and 25.4mm from the downstream face. corner taps must be used on small pipe diameters where the vena contracta is so close to the downstream face of the orifice plate that a downstream flange tap would sense pressure in the highly turbulent region (too far. Flange Taps Vs Corner Taps.

From automationforum.co

Classification of Orifice Plates & Pressure Tappings Flange Taps Vs Corner Taps differential pressures are taken out in a corner tap system. They are often used for. flange taps are positioned 25mm from the upstream face of the orifice plate and 25.4mm from the downstream face. corner taps ( less than 2 inches) flange taps: Flange taps should not be used in pipe sizes less than 2 inches. Flange. Flange Taps Vs Corner Taps.

From www.slideserve.com

PPT Figure 10.1 Flow in a duct with area change. PowerPoint Flange Taps Vs Corner Taps They are often used for. flange taps are positioned 25mm from the upstream face of the orifice plate and 25.4mm from the downstream face. Corner taps are located right at the upstream side and downstream side faces of the orifice plates. Flange taps are the most common and are generally used for pipe sizes of 2 inches and greater.. Flange Taps Vs Corner Taps.

From www.youtube.com

Tap and Faucet City Singapore Your 1 Tap and Faucet Contractor YouTube Flange Taps Vs Corner Taps They are often used for. corner taps are analogous to flange taps since the pressure tap is positioned within the orifice plate’s edges. Flange taps are the most common and are generally used for pipe sizes of 2 inches and greater. Corner taps are located right at the upstream side and downstream side faces of the orifice plates. . Flange Taps Vs Corner Taps.

From atsduct.com

ats, inc » Tees and Taps Flange Taps Vs Corner Taps corner taps ( less than 2 inches) flange taps: corner taps are analogous to flange taps since the pressure tap is positioned within the orifice plate’s edges. flange taps are positioned 25mm from the upstream face of the orifice plate and 25.4mm from the downstream face. corner taps must be used on small pipe diameters where. Flange Taps Vs Corner Taps.

From www.cutwel.co.uk

Expert Guide on Threading Taps Cutwel Ltd Flange Taps Vs Corner Taps Flange taps should not be used in pipe sizes less than 2 inches. flange taps are positioned 25mm from the upstream face of the orifice plate and 25.4mm from the downstream face. Corner taps are located right at the upstream side and downstream side faces of the orifice plates. They are holes bored through the flanges located 1” upstream. Flange Taps Vs Corner Taps.

From www.imperialco.net

Orifice Flanges Flange Taps Vs Corner Taps flange taps are positioned 25mm from the upstream face of the orifice plate and 25.4mm from the downstream face. differential pressures are taken out in a corner tap system. They are holes bored through the flanges located 1” upstream side and 1” downstream side from respective faces of the orifice plate. learn about different tap locations for. Flange Taps Vs Corner Taps.

From www.instpedia.com

Flow Flange Taps Vs Corner Taps They are often used for. learn about different tap locations for orifice plates, such as flange, vena contracta, radius and corner taps. They are holes bored through the flanges located 1” upstream side and 1” downstream side from respective faces of the orifice plate. corner taps are analogous to flange taps since the pressure tap is positioned within. Flange Taps Vs Corner Taps.

From theinstrumentguru.com

Type of Orifice Tapping Connection THE INSTRUMENT GURU Flange Taps Vs Corner Taps learn about different tap locations for orifice plates, such as flange, vena contracta, radius and corner taps. They are often used for. Corner taps are located right at the upstream side and downstream side faces of the orifice plates. Flange taps should not be used in pipe sizes less than 2 inches. corner taps are analogous to flange. Flange Taps Vs Corner Taps.

From instrumentationtools.com

Readers Questions on Flow Transmitter Inst Tools Flange Taps Vs Corner Taps differential pressures are taken out in a corner tap system. Flange taps should not be used in pipe sizes less than 2 inches. They are often used for. corner taps ( less than 2 inches) flange taps: corner taps are analogous to flange taps since the pressure tap is positioned within the orifice plate’s edges. corner. Flange Taps Vs Corner Taps.

From www.oceanproperty.co.th

Orifice Flange Corner Taps Outlet UK www.oceanproperty.co.th Flange Taps Vs Corner Taps Flange taps should not be used in pipe sizes less than 2 inches. corner taps must be used on small pipe diameters where the vena contracta is so close to the downstream face of the orifice plate that a downstream flange tap would sense pressure in the highly turbulent region (too far downstream). differential pressures are taken out. Flange Taps Vs Corner Taps.

From flowmfg.com

Corner Tap Flange Manufacturers Imperial Flange and Fitting Company Flange Taps Vs Corner Taps flange taps are positioned 25mm from the upstream face of the orifice plate and 25.4mm from the downstream face. differential pressures are taken out in a corner tap system. corner taps ( less than 2 inches) flange taps: corner taps are analogous to flange taps since the pressure tap is positioned within the orifice plate’s edges.. Flange Taps Vs Corner Taps.

From www.pinterest.com

Pin on Process Technology Flange Taps Vs Corner Taps They are holes bored through the flanges located 1” upstream side and 1” downstream side from respective faces of the orifice plate. flange taps are positioned 25mm from the upstream face of the orifice plate and 25.4mm from the downstream face. differential pressures are taken out in a corner tap system. learn about different tap locations for. Flange Taps Vs Corner Taps.

From www.technoflow.co.za

Orifice flange Flange Taps Vs Corner Taps corner taps must be used on small pipe diameters where the vena contracta is so close to the downstream face of the orifice plate that a downstream flange tap would sense pressure in the highly turbulent region (too far downstream). Flange taps should not be used in pipe sizes less than 2 inches. They are often used for. . Flange Taps Vs Corner Taps.

From www.velosolar.com

Line Side Tap vs. Load Side Tap Everything You Need To Know Flange Taps Vs Corner Taps corner taps must be used on small pipe diameters where the vena contracta is so close to the downstream face of the orifice plate that a downstream flange tap would sense pressure in the highly turbulent region (too far downstream). Flange taps should not be used in pipe sizes less than 2 inches. corner taps are analogous to. Flange Taps Vs Corner Taps.

From dokumen.tips

(PPTX) Flange tap to Radius tap conversion Autorodder DOKUMEN.TIPS Flange Taps Vs Corner Taps differential pressures are taken out in a corner tap system. corner taps must be used on small pipe diameters where the vena contracta is so close to the downstream face of the orifice plate that a downstream flange tap would sense pressure in the highly turbulent region (too far downstream). Flange taps should not be used in pipe. Flange Taps Vs Corner Taps.

From pipingconstruction.blogspot.com

Piping Construction January 2016 Flange Taps Vs Corner Taps learn about different tap locations for orifice plates, such as flange, vena contracta, radius and corner taps. Flange taps should not be used in pipe sizes less than 2 inches. Flange taps are the most common and are generally used for pipe sizes of 2 inches and greater. corner taps must be used on small pipe diameters where. Flange Taps Vs Corner Taps.

From savree.com

Flange Assembly Explained saVRee Flange Taps Vs Corner Taps They are often used for. learn about different tap locations for orifice plates, such as flange, vena contracta, radius and corner taps. corner taps must be used on small pipe diameters where the vena contracta is so close to the downstream face of the orifice plate that a downstream flange tap would sense pressure in the highly turbulent. Flange Taps Vs Corner Taps.

From chempedia.info

Flange taps Big Chemical Encyclopedia Flange Taps Vs Corner Taps corner taps must be used on small pipe diameters where the vena contracta is so close to the downstream face of the orifice plate that a downstream flange tap would sense pressure in the highly turbulent region (too far downstream). differential pressures are taken out in a corner tap system. flange taps are positioned 25mm from the. Flange Taps Vs Corner Taps.

From forumautomation.com

Orifice plate Taps Flow Measurement Industrial Automation, PLC Flange Taps Vs Corner Taps Flange taps should not be used in pipe sizes less than 2 inches. learn about different tap locations for orifice plates, such as flange, vena contracta, radius and corner taps. corner taps must be used on small pipe diameters where the vena contracta is so close to the downstream face of the orifice plate that a downstream flange. Flange Taps Vs Corner Taps.

From www.evdesignandmanufacturing.com

Forming taps vs. cutting taps Which one should you choose? EV Flange Taps Vs Corner Taps learn about different tap locations for orifice plates, such as flange, vena contracta, radius and corner taps. flange taps are positioned 25mm from the upstream face of the orifice plate and 25.4mm from the downstream face. Corner taps are located right at the upstream side and downstream side faces of the orifice plates. corner taps are analogous. Flange Taps Vs Corner Taps.

From www.instpedia.com

Flow Flange Taps Vs Corner Taps flange taps are positioned 25mm from the upstream face of the orifice plate and 25.4mm from the downstream face. Flange taps are the most common and are generally used for pipe sizes of 2 inches and greater. differential pressures are taken out in a corner tap system. Corner taps are located right at the upstream side and downstream. Flange Taps Vs Corner Taps.

From hardhatengineer.com

What are the Orifice Flange and Long Weld Neck? Flange Taps Vs Corner Taps Corner taps are located right at the upstream side and downstream side faces of the orifice plates. corner taps are analogous to flange taps since the pressure tap is positioned within the orifice plate’s edges. differential pressures are taken out in a corner tap system. They are often used for. They are holes bored through the flanges located. Flange Taps Vs Corner Taps.

From www.cutwel.co.uk

Expert Guide on Threading Taps Cutwel Ltd Flange Taps Vs Corner Taps Flange taps are the most common and are generally used for pipe sizes of 2 inches and greater. corner taps ( less than 2 inches) flange taps: corner taps are analogous to flange taps since the pressure tap is positioned within the orifice plate’s edges. differential pressures are taken out in a corner tap system. They are. Flange Taps Vs Corner Taps.

From www.nandantechnicals.com

What is Flange Taps Flange Taps Vs Corner Taps differential pressures are taken out in a corner tap system. learn about different tap locations for orifice plates, such as flange, vena contracta, radius and corner taps. They are holes bored through the flanges located 1” upstream side and 1” downstream side from respective faces of the orifice plate. Flange taps are the most common and are generally. Flange Taps Vs Corner Taps.

From www.aiophotoz.com

The 7 Types Of Flanges Explained Images and Photos finder Flange Taps Vs Corner Taps corner taps ( less than 2 inches) flange taps: They are holes bored through the flanges located 1” upstream side and 1” downstream side from respective faces of the orifice plate. corner taps must be used on small pipe diameters where the vena contracta is so close to the downstream face of the orifice plate that a downstream. Flange Taps Vs Corner Taps.

From www.jarviscuttingtools.com

Cutting Taps vs. Forming Taps Difference Jarvis Flange Taps Vs Corner Taps Flange taps should not be used in pipe sizes less than 2 inches. flange taps are positioned 25mm from the upstream face of the orifice plate and 25.4mm from the downstream face. Flange taps are the most common and are generally used for pipe sizes of 2 inches and greater. learn about different tap locations for orifice plates,. Flange Taps Vs Corner Taps.