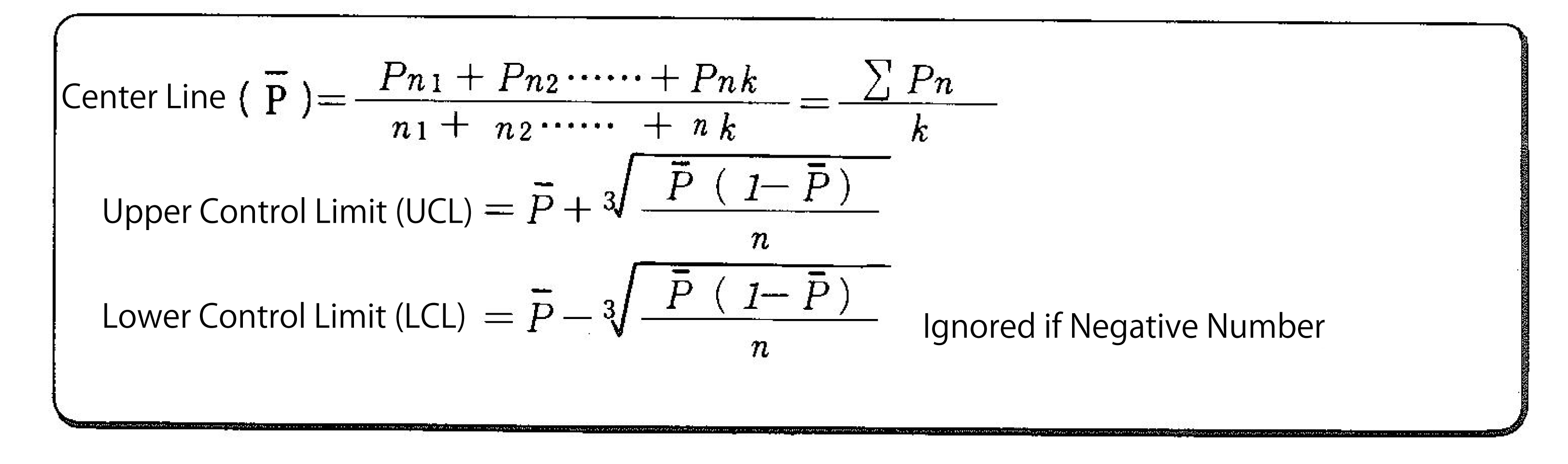

Lower Control Limit Calculator . calculate the upper and lower control limits (ucl and lcl) for a process using the average and range of sample data. control limits are statistical boundaries used in quality control to monitor and manage a process. Ucl = cl + 3 * √cl in c control charts, the center line (cl) represents the average count of defects per sample. They consist of upper and lower limits. Cl = σ(count of defects per sample) / n; find the lower and upper control limits (lcl and ucl) of a process using the control mean, standard deviation and the control. The upper control limit (ucl) and lower control limit (lcl) are calculated based on the average count of defects and the number of samples (n) using the following formulas: learn how to calculate the upper control limit (ucl) of your process dataset and use it to detect variation caused by special causes. calculate the upper and lower control limits for a process based on mean, standard deviation and control limit factor.

from www.asprova.jp

learn how to calculate the upper control limit (ucl) of your process dataset and use it to detect variation caused by special causes. Cl = σ(count of defects per sample) / n; in c control charts, the center line (cl) represents the average count of defects per sample. Ucl = cl + 3 * √cl find the lower and upper control limits (lcl and ucl) of a process using the control mean, standard deviation and the control. They consist of upper and lower limits. calculate the upper and lower control limits for a process based on mean, standard deviation and control limit factor. calculate the upper and lower control limits (ucl and lcl) for a process using the average and range of sample data. The upper control limit (ucl) and lower control limit (lcl) are calculated based on the average count of defects and the number of samples (n) using the following formulas: control limits are statistical boundaries used in quality control to monitor and manage a process.

P Chart Quality Control MRP glossary of Production scheduler Asprova

Lower Control Limit Calculator calculate the upper and lower control limits (ucl and lcl) for a process using the average and range of sample data. calculate the upper and lower control limits for a process based on mean, standard deviation and control limit factor. Cl = σ(count of defects per sample) / n; learn how to calculate the upper control limit (ucl) of your process dataset and use it to detect variation caused by special causes. The upper control limit (ucl) and lower control limit (lcl) are calculated based on the average count of defects and the number of samples (n) using the following formulas: calculate the upper and lower control limits (ucl and lcl) for a process using the average and range of sample data. find the lower and upper control limits (lcl and ucl) of a process using the control mean, standard deviation and the control. in c control charts, the center line (cl) represents the average count of defects per sample. They consist of upper and lower limits. control limits are statistical boundaries used in quality control to monitor and manage a process. Ucl = cl + 3 * √cl

From www.youtube.com

Control Limits for pchart by hand YouTube Lower Control Limit Calculator Ucl = cl + 3 * √cl control limits are statistical boundaries used in quality control to monitor and manage a process. The upper control limit (ucl) and lower control limit (lcl) are calculated based on the average count of defects and the number of samples (n) using the following formulas: in c control charts, the center line. Lower Control Limit Calculator.

From www.youtube.com

Calculating Control Limits for a c chart by hand YouTube Lower Control Limit Calculator calculate the upper and lower control limits for a process based on mean, standard deviation and control limit factor. learn how to calculate the upper control limit (ucl) of your process dataset and use it to detect variation caused by special causes. calculate the upper and lower control limits (ucl and lcl) for a process using the. Lower Control Limit Calculator.

From www.learnleansigma.com

Control Limits Calculator (UCL and LCL) Learn Lean Sigma Lower Control Limit Calculator find the lower and upper control limits (lcl and ucl) of a process using the control mean, standard deviation and the control. They consist of upper and lower limits. Ucl = cl + 3 * √cl in c control charts, the center line (cl) represents the average count of defects per sample. calculate the upper and lower. Lower Control Limit Calculator.

From www.slideserve.com

PPT Control Charts PowerPoint Presentation ID996623 Lower Control Limit Calculator They consist of upper and lower limits. find the lower and upper control limits (lcl and ucl) of a process using the control mean, standard deviation and the control. learn how to calculate the upper control limit (ucl) of your process dataset and use it to detect variation caused by special causes. Ucl = cl + 3 *. Lower Control Limit Calculator.

From www.investopedia.com

Three Sigma Limits Statistical Calculation With Example Lower Control Limit Calculator Ucl = cl + 3 * √cl calculate the upper and lower control limits (ucl and lcl) for a process using the average and range of sample data. Cl = σ(count of defects per sample) / n; control limits are statistical boundaries used in quality control to monitor and manage a process. in c control charts, the. Lower Control Limit Calculator.

From mazafargabija.blogspot.com

Evaluate limit calculator MazafarGabija Lower Control Limit Calculator find the lower and upper control limits (lcl and ucl) of a process using the control mean, standard deviation and the control. They consist of upper and lower limits. learn how to calculate the upper control limit (ucl) of your process dataset and use it to detect variation caused by special causes. calculate the upper and lower. Lower Control Limit Calculator.

From chartwalls.blogspot.com

Factors For Computing Control Chart Limits 3 Sigma Chart Walls Lower Control Limit Calculator calculate the upper and lower control limits for a process based on mean, standard deviation and control limit factor. find the lower and upper control limits (lcl and ucl) of a process using the control mean, standard deviation and the control. in c control charts, the center line (cl) represents the average count of defects per sample.. Lower Control Limit Calculator.

From calculatorshub.net

Upper and Lower Control Limit Calculator Online Lower Control Limit Calculator control limits are statistical boundaries used in quality control to monitor and manage a process. calculate the upper and lower control limits for a process based on mean, standard deviation and control limit factor. Cl = σ(count of defects per sample) / n; find the lower and upper control limits (lcl and ucl) of a process using. Lower Control Limit Calculator.

From www.slideserve.com

PPT Six Sigma and Statistical Quality Control PowerPoint Presentation Lower Control Limit Calculator calculate the upper and lower control limits for a process based on mean, standard deviation and control limit factor. Ucl = cl + 3 * √cl The upper control limit (ucl) and lower control limit (lcl) are calculated based on the average count of defects and the number of samples (n) using the following formulas: find the lower. Lower Control Limit Calculator.

From www.chegg.com

Solved Upper control limit for X X+AR Lower control limit Lower Control Limit Calculator find the lower and upper control limits (lcl and ucl) of a process using the control mean, standard deviation and the control. Ucl = cl + 3 * √cl in c control charts, the center line (cl) represents the average count of defects per sample. calculate the upper and lower control limits for a process based on. Lower Control Limit Calculator.

From www.exceldemy.com

How to Find Upper and Lower Limits of Confidence Interval in Excel Lower Control Limit Calculator calculate the upper and lower control limits (ucl and lcl) for a process using the average and range of sample data. find the lower and upper control limits (lcl and ucl) of a process using the control mean, standard deviation and the control. in c control charts, the center line (cl) represents the average count of defects. Lower Control Limit Calculator.

From calculator.academy

Control Limit Calculator Calculator Academy Lower Control Limit Calculator The upper control limit (ucl) and lower control limit (lcl) are calculated based on the average count of defects and the number of samples (n) using the following formulas: control limits are statistical boundaries used in quality control to monitor and manage a process. learn how to calculate the upper control limit (ucl) of your process dataset and. Lower Control Limit Calculator.

From www.scribd.com

How To Calculate Upper & Lower Control Limits PDF Standard Lower Control Limit Calculator calculate the upper and lower control limits (ucl and lcl) for a process using the average and range of sample data. control limits are statistical boundaries used in quality control to monitor and manage a process. They consist of upper and lower limits. in c control charts, the center line (cl) represents the average count of defects. Lower Control Limit Calculator.

From www.presentationeze.com

C chart control limits PresentationEZE Lower Control Limit Calculator Ucl = cl + 3 * √cl learn how to calculate the upper control limit (ucl) of your process dataset and use it to detect variation caused by special causes. Cl = σ(count of defects per sample) / n; calculate the upper and lower control limits for a process based on mean, standard deviation and control limit factor.. Lower Control Limit Calculator.

From www.chegg.com

Solved a) Establish 3σ upper and lower control limits. UCLp= Lower Control Limit Calculator Cl = σ(count of defects per sample) / n; Ucl = cl + 3 * √cl calculate the upper and lower control limits (ucl and lcl) for a process using the average and range of sample data. control limits are statistical boundaries used in quality control to monitor and manage a process. calculate the upper and lower. Lower Control Limit Calculator.

From www.slideserve.com

PPT Control Charts for Variables PowerPoint Presentation, free Lower Control Limit Calculator learn how to calculate the upper control limit (ucl) of your process dataset and use it to detect variation caused by special causes. They consist of upper and lower limits. Cl = σ(count of defects per sample) / n; calculate the upper and lower control limits for a process based on mean, standard deviation and control limit factor.. Lower Control Limit Calculator.

From syque.com

Calculation detail for XMR, Xbar/R and Xbar/S Control Charts Lower Control Limit Calculator The upper control limit (ucl) and lower control limit (lcl) are calculated based on the average count of defects and the number of samples (n) using the following formulas: calculate the upper and lower control limits for a process based on mean, standard deviation and control limit factor. find the lower and upper control limits (lcl and ucl). Lower Control Limit Calculator.

From www.slideserve.com

PPT Statistical Process Control (SPC) PowerPoint Presentation, free Lower Control Limit Calculator They consist of upper and lower limits. control limits are statistical boundaries used in quality control to monitor and manage a process. calculate the upper and lower control limits (ucl and lcl) for a process using the average and range of sample data. The upper control limit (ucl) and lower control limit (lcl) are calculated based on the. Lower Control Limit Calculator.

From www.asprova.jp

P Chart Quality Control MRP glossary of Production scheduler Asprova Lower Control Limit Calculator calculate the upper and lower control limits (ucl and lcl) for a process using the average and range of sample data. learn how to calculate the upper control limit (ucl) of your process dataset and use it to detect variation caused by special causes. They consist of upper and lower limits. The upper control limit (ucl) and lower. Lower Control Limit Calculator.

From sciencing.com

How to Calculate Upper & Lower Control Limits Sciencing Lower Control Limit Calculator find the lower and upper control limits (lcl and ucl) of a process using the control mean, standard deviation and the control. Cl = σ(count of defects per sample) / n; learn how to calculate the upper control limit (ucl) of your process dataset and use it to detect variation caused by special causes. calculate the upper. Lower Control Limit Calculator.

From spreadcheaters.com

How To Calculate The Upper And Lower Control Limits In Microsoft Excel Lower Control Limit Calculator find the lower and upper control limits (lcl and ucl) of a process using the control mean, standard deviation and the control. in c control charts, the center line (cl) represents the average count of defects per sample. calculate the upper and lower control limits (ucl and lcl) for a process using the average and range of. Lower Control Limit Calculator.

From www.youtube.com

SPC Calculating Upper/Lower Control Limits YouTube Lower Control Limit Calculator find the lower and upper control limits (lcl and ucl) of a process using the control mean, standard deviation and the control. control limits are statistical boundaries used in quality control to monitor and manage a process. calculate the upper and lower control limits (ucl and lcl) for a process using the average and range of sample. Lower Control Limit Calculator.

From www.slideserve.com

PPT Control Charts PowerPoint Presentation, free download ID996623 Lower Control Limit Calculator control limits are statistical boundaries used in quality control to monitor and manage a process. They consist of upper and lower limits. in c control charts, the center line (cl) represents the average count of defects per sample. Cl = σ(count of defects per sample) / n; learn how to calculate the upper control limit (ucl) of. Lower Control Limit Calculator.

From www.sixsigmadaily.com

Control Chart Construction Formulas for Control Limits Lower Control Limit Calculator learn how to calculate the upper control limit (ucl) of your process dataset and use it to detect variation caused by special causes. calculate the upper and lower control limits for a process based on mean, standard deviation and control limit factor. Ucl = cl + 3 * √cl control limits are statistical boundaries used in quality. Lower Control Limit Calculator.

From nibhtpb.weebly.com

nibhtpb Blog Lower Control Limit Calculator calculate the upper and lower control limits (ucl and lcl) for a process using the average and range of sample data. Cl = σ(count of defects per sample) / n; They consist of upper and lower limits. find the lower and upper control limits (lcl and ucl) of a process using the control mean, standard deviation and the. Lower Control Limit Calculator.

From www.numerade.com

SOLVED Suppose that p̅=.1 and n=100 . Calculate the upper and lower Lower Control Limit Calculator calculate the upper and lower control limits for a process based on mean, standard deviation and control limit factor. find the lower and upper control limits (lcl and ucl) of a process using the control mean, standard deviation and the control. calculate the upper and lower control limits (ucl and lcl) for a process using the average. Lower Control Limit Calculator.

From spreadcheaters.com

How To Calculate The Upper And Lower Control Limits In Microsoft Excel Lower Control Limit Calculator in c control charts, the center line (cl) represents the average count of defects per sample. learn how to calculate the upper control limit (ucl) of your process dataset and use it to detect variation caused by special causes. The upper control limit (ucl) and lower control limit (lcl) are calculated based on the average count of defects. Lower Control Limit Calculator.

From qualityamerica.com

P Chart Calculations P Chart Formula Quality America Lower Control Limit Calculator Ucl = cl + 3 * √cl learn how to calculate the upper control limit (ucl) of your process dataset and use it to detect variation caused by special causes. find the lower and upper control limits (lcl and ucl) of a process using the control mean, standard deviation and the control. They consist of upper and lower. Lower Control Limit Calculator.

From mavink.com

Calculate Upper And Lower Control Limits Lower Control Limit Calculator They consist of upper and lower limits. in c control charts, the center line (cl) represents the average count of defects per sample. calculate the upper and lower control limits (ucl and lcl) for a process using the average and range of sample data. find the lower and upper control limits (lcl and ucl) of a process. Lower Control Limit Calculator.

From gbu-taganskij.ru

Control Chart Limits UCL LCL How To Calculate Control, 57 OFF Lower Control Limit Calculator The upper control limit (ucl) and lower control limit (lcl) are calculated based on the average count of defects and the number of samples (n) using the following formulas: in c control charts, the center line (cl) represents the average count of defects per sample. control limits are statistical boundaries used in quality control to monitor and manage. Lower Control Limit Calculator.

From www.omnicalculator.com

Upper & Lower Control Limit Calculator Lower Control Limit Calculator calculate the upper and lower control limits (ucl and lcl) for a process using the average and range of sample data. They consist of upper and lower limits. control limits are statistical boundaries used in quality control to monitor and manage a process. find the lower and upper control limits (lcl and ucl) of a process using. Lower Control Limit Calculator.

From www.chegg.com

Solved (7 pts) Calculate the upper and lower control limits Lower Control Limit Calculator The upper control limit (ucl) and lower control limit (lcl) are calculated based on the average count of defects and the number of samples (n) using the following formulas: Cl = σ(count of defects per sample) / n; They consist of upper and lower limits. in c control charts, the center line (cl) represents the average count of defects. Lower Control Limit Calculator.

From desiraeadele.blogspot.com

Lcl and ucl calculator DesiraeAdele Lower Control Limit Calculator calculate the upper and lower control limits (ucl and lcl) for a process using the average and range of sample data. find the lower and upper control limits (lcl and ucl) of a process using the control mean, standard deviation and the control. They consist of upper and lower limits. The upper control limit (ucl) and lower control. Lower Control Limit Calculator.

From www.isixsigma.com

Lower Control Limit (LCL) Definition Lower Control Limit Calculator find the lower and upper control limits (lcl and ucl) of a process using the control mean, standard deviation and the control. calculate the upper and lower control limits for a process based on mean, standard deviation and control limit factor. They consist of upper and lower limits. calculate the upper and lower control limits (ucl and. Lower Control Limit Calculator.

From www.slideserve.com

PPT Introduction to Control Charts XmR Chart PowerPoint Presentation Lower Control Limit Calculator calculate the upper and lower control limits (ucl and lcl) for a process using the average and range of sample data. calculate the upper and lower control limits for a process based on mean, standard deviation and control limit factor. The upper control limit (ucl) and lower control limit (lcl) are calculated based on the average count of. Lower Control Limit Calculator.