Wire Welding Gas Pressure . The shielding gas provides the gas needed for mig welding. the typical gas pressure when welding with mig tends to be around 3 to 8 psi, this is very low compared to other types of welding. These settings determine the heat, wire deposition rate, and protection from atmospheric contamination, respectively, crucial for producing strong and clean welds. low gas pressure weakens the weld, reduces penetration and increases spatter. When starting, it is important to make sure the gas bottle is properly installed into the holder. this article will show you how to set the flow rate of gas, the minimum and maximum values and the optimal gas. If you’re creating a weld that is too weak or. mig welding is an arc welding process in which a continuous solid wire electrode is fed through a welding gun and into the weld pool, joining the two. usually, you should set your mig welding gas pressure based on what metal type you’re working with. the most important mig welder settings are voltage, wire feed speed, and shielding gas flow rate. know the thickness of the metal so you know if your welder has the power to get the job done, you can choose the right electrode wire and the proper shielding gas. You can make plans for how you approach your project concerning clamping, angle of approach, cooling, dealing with your welder’s duty cycle, and other practical solutions.

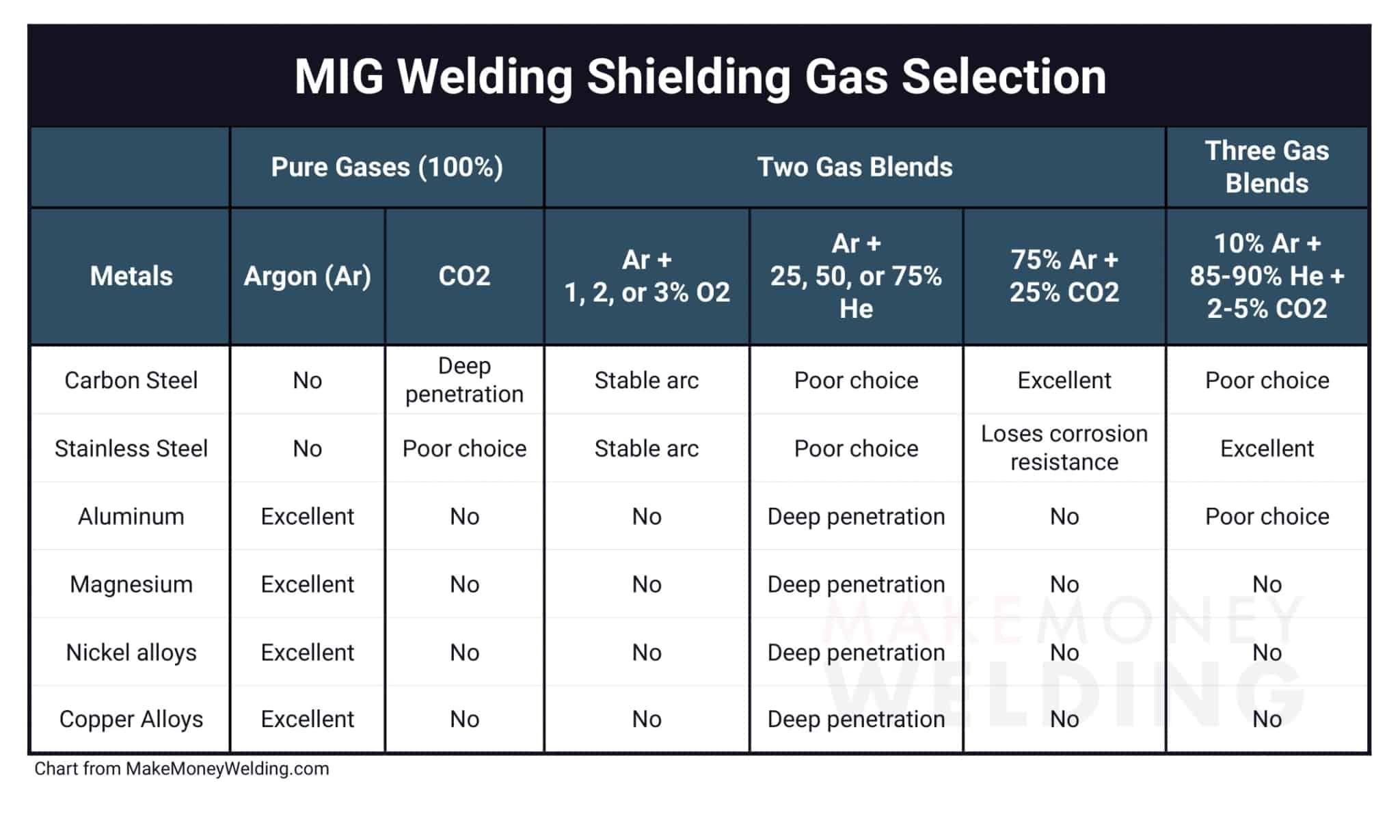

from makemoneywelding.com

When starting, it is important to make sure the gas bottle is properly installed into the holder. the typical gas pressure when welding with mig tends to be around 3 to 8 psi, this is very low compared to other types of welding. You can make plans for how you approach your project concerning clamping, angle of approach, cooling, dealing with your welder’s duty cycle, and other practical solutions. If you’re creating a weld that is too weak or. usually, you should set your mig welding gas pressure based on what metal type you’re working with. These settings determine the heat, wire deposition rate, and protection from atmospheric contamination, respectively, crucial for producing strong and clean welds. mig welding is an arc welding process in which a continuous solid wire electrode is fed through a welding gun and into the weld pool, joining the two. The shielding gas provides the gas needed for mig welding. this article will show you how to set the flow rate of gas, the minimum and maximum values and the optimal gas. low gas pressure weakens the weld, reduces penetration and increases spatter.

Explained Best MIG Welding Shielding Gas To Use

Wire Welding Gas Pressure The shielding gas provides the gas needed for mig welding. When starting, it is important to make sure the gas bottle is properly installed into the holder. These settings determine the heat, wire deposition rate, and protection from atmospheric contamination, respectively, crucial for producing strong and clean welds. the most important mig welder settings are voltage, wire feed speed, and shielding gas flow rate. usually, you should set your mig welding gas pressure based on what metal type you’re working with. the typical gas pressure when welding with mig tends to be around 3 to 8 psi, this is very low compared to other types of welding. If you’re creating a weld that is too weak or. know the thickness of the metal so you know if your welder has the power to get the job done, you can choose the right electrode wire and the proper shielding gas. You can make plans for how you approach your project concerning clamping, angle of approach, cooling, dealing with your welder’s duty cycle, and other practical solutions. low gas pressure weakens the weld, reduces penetration and increases spatter. mig welding is an arc welding process in which a continuous solid wire electrode is fed through a welding gun and into the weld pool, joining the two. this article will show you how to set the flow rate of gas, the minimum and maximum values and the optimal gas. The shielding gas provides the gas needed for mig welding.

From www.slideserve.com

PPT Let’s Look at the Processes COLD WELDING PRESSURE GAS WELDING Wire Welding Gas Pressure the typical gas pressure when welding with mig tends to be around 3 to 8 psi, this is very low compared to other types of welding. know the thickness of the metal so you know if your welder has the power to get the job done, you can choose the right electrode wire and the proper shielding gas.. Wire Welding Gas Pressure.

From sparkerweld.com

What Is Mıg Weldıng /Gas Metal Arc Welding Sparker Electric Ltd. Wire Welding Gas Pressure These settings determine the heat, wire deposition rate, and protection from atmospheric contamination, respectively, crucial for producing strong and clean welds. You can make plans for how you approach your project concerning clamping, angle of approach, cooling, dealing with your welder’s duty cycle, and other practical solutions. know the thickness of the metal so you know if your welder. Wire Welding Gas Pressure.

From itstillruns.com

How to Set the Gas on an MIG Welder It Still Runs Wire Welding Gas Pressure These settings determine the heat, wire deposition rate, and protection from atmospheric contamination, respectively, crucial for producing strong and clean welds. The shielding gas provides the gas needed for mig welding. know the thickness of the metal so you know if your welder has the power to get the job done, you can choose the right electrode wire and. Wire Welding Gas Pressure.

From itstillruns.com

How to Set the Gas on an MIG Welder It Still Runs Wire Welding Gas Pressure mig welding is an arc welding process in which a continuous solid wire electrode is fed through a welding gun and into the weld pool, joining the two. These settings determine the heat, wire deposition rate, and protection from atmospheric contamination, respectively, crucial for producing strong and clean welds. The shielding gas provides the gas needed for mig welding.. Wire Welding Gas Pressure.

From www.youtube.com

Reinforcement Lap Joint Welding Gas Pressure Welding System YouTube Wire Welding Gas Pressure You can make plans for how you approach your project concerning clamping, angle of approach, cooling, dealing with your welder’s duty cycle, and other practical solutions. mig welding is an arc welding process in which a continuous solid wire electrode is fed through a welding gun and into the weld pool, joining the two. When starting, it is important. Wire Welding Gas Pressure.

From mubashirghori.blogspot.com

Muhammad Mubashir Ghori Understand the Pressure Gas Welding Wire Welding Gas Pressure These settings determine the heat, wire deposition rate, and protection from atmospheric contamination, respectively, crucial for producing strong and clean welds. If you’re creating a weld that is too weak or. The shielding gas provides the gas needed for mig welding. the typical gas pressure when welding with mig tends to be around 3 to 8 psi, this is. Wire Welding Gas Pressure.

From blog.thepipingmart.com

Gas Pressure Welding Advantages and Disadvantages Wire Welding Gas Pressure When starting, it is important to make sure the gas bottle is properly installed into the holder. low gas pressure weakens the weld, reduces penetration and increases spatter. mig welding is an arc welding process in which a continuous solid wire electrode is fed through a welding gun and into the weld pool, joining the two. If you’re. Wire Welding Gas Pressure.

From www.youtube.com

Welding a live natural gas line! YouTube Wire Welding Gas Pressure know the thickness of the metal so you know if your welder has the power to get the job done, you can choose the right electrode wire and the proper shielding gas. mig welding is an arc welding process in which a continuous solid wire electrode is fed through a welding gun and into the weld pool, joining. Wire Welding Gas Pressure.

From makemoneywelding.com

MIG Welding Gas Pressure Settings Wire Welding Gas Pressure usually, you should set your mig welding gas pressure based on what metal type you’re working with. The shielding gas provides the gas needed for mig welding. low gas pressure weakens the weld, reduces penetration and increases spatter. These settings determine the heat, wire deposition rate, and protection from atmospheric contamination, respectively, crucial for producing strong and clean. Wire Welding Gas Pressure.

From exoahgqnb.blob.core.windows.net

Welding Techniques For Gas at Ashley Weiner blog Wire Welding Gas Pressure mig welding is an arc welding process in which a continuous solid wire electrode is fed through a welding gun and into the weld pool, joining the two. When starting, it is important to make sure the gas bottle is properly installed into the holder. You can make plans for how you approach your project concerning clamping, angle of. Wire Welding Gas Pressure.

From weldingzilla.com

MIG Welding Gas Pressure Settings (with Charts) Wire Welding Gas Pressure These settings determine the heat, wire deposition rate, and protection from atmospheric contamination, respectively, crucial for producing strong and clean welds. the typical gas pressure when welding with mig tends to be around 3 to 8 psi, this is very low compared to other types of welding. If you’re creating a weld that is too weak or. the. Wire Welding Gas Pressure.

From blog.thepipingmart.com

Everything You Need To Know About Gas Welding ThePipingMart Blog Wire Welding Gas Pressure When starting, it is important to make sure the gas bottle is properly installed into the holder. low gas pressure weakens the weld, reduces penetration and increases spatter. this article will show you how to set the flow rate of gas, the minimum and maximum values and the optimal gas. You can make plans for how you approach. Wire Welding Gas Pressure.

From weldingzilla.com

MIG Welding Gas Pressure Settings (with Charts) Wire Welding Gas Pressure You can make plans for how you approach your project concerning clamping, angle of approach, cooling, dealing with your welder’s duty cycle, and other practical solutions. this article will show you how to set the flow rate of gas, the minimum and maximum values and the optimal gas. mig welding is an arc welding process in which a. Wire Welding Gas Pressure.

From waterwelders.com

What Should My MIG Welding Gas Pressure Be? WaterWelders Wire Welding Gas Pressure the most important mig welder settings are voltage, wire feed speed, and shielding gas flow rate. When starting, it is important to make sure the gas bottle is properly installed into the holder. These settings determine the heat, wire deposition rate, and protection from atmospheric contamination, respectively, crucial for producing strong and clean welds. mig welding is an. Wire Welding Gas Pressure.

From weldguru.com

What is FluxCore Arc Welding (FCAW) & How Does it Work? Wire Welding Gas Pressure These settings determine the heat, wire deposition rate, and protection from atmospheric contamination, respectively, crucial for producing strong and clean welds. mig welding is an arc welding process in which a continuous solid wire electrode is fed through a welding gun and into the weld pool, joining the two. the typical gas pressure when welding with mig tends. Wire Welding Gas Pressure.

From dxosrnjtq.blob.core.windows.net

Gas Metal Reactions In Welding at Kathy Fredrick blog Wire Welding Gas Pressure If you’re creating a weld that is too weak or. this article will show you how to set the flow rate of gas, the minimum and maximum values and the optimal gas. The shielding gas provides the gas needed for mig welding. You can make plans for how you approach your project concerning clamping, angle of approach, cooling, dealing. Wire Welding Gas Pressure.

From guidelibmisjoinder.z22.web.core.windows.net

Diagram Of Mig Welding Wire Welding Gas Pressure the most important mig welder settings are voltage, wire feed speed, and shielding gas flow rate. These settings determine the heat, wire deposition rate, and protection from atmospheric contamination, respectively, crucial for producing strong and clean welds. mig welding is an arc welding process in which a continuous solid wire electrode is fed through a welding gun and. Wire Welding Gas Pressure.

From www.youtube.com

BOC Setting Up for Gas Welding and Brazing YouTube Wire Welding Gas Pressure know the thickness of the metal so you know if your welder has the power to get the job done, you can choose the right electrode wire and the proper shielding gas. mig welding is an arc welding process in which a continuous solid wire electrode is fed through a welding gun and into the weld pool, joining. Wire Welding Gas Pressure.

From weldguru.com

MIG Welding Gas Pressure Settings (with Charts) Wire Welding Gas Pressure low gas pressure weakens the weld, reduces penetration and increases spatter. If you’re creating a weld that is too weak or. this article will show you how to set the flow rate of gas, the minimum and maximum values and the optimal gas. the most important mig welder settings are voltage, wire feed speed, and shielding gas. Wire Welding Gas Pressure.

From weldempire.com

What Should Be the Gas Pressure for MIG Welding? Weld Empire Wire Welding Gas Pressure low gas pressure weakens the weld, reduces penetration and increases spatter. These settings determine the heat, wire deposition rate, and protection from atmospheric contamination, respectively, crucial for producing strong and clean welds. know the thickness of the metal so you know if your welder has the power to get the job done, you can choose the right electrode. Wire Welding Gas Pressure.

From www.dreamstime.com

Closeup White Dial Pressure Gauge of Gas and Laser Welding Wire Stock Wire Welding Gas Pressure If you’re creating a weld that is too weak or. usually, you should set your mig welding gas pressure based on what metal type you’re working with. the most important mig welder settings are voltage, wire feed speed, and shielding gas flow rate. When starting, it is important to make sure the gas bottle is properly installed into. Wire Welding Gas Pressure.

From www.perfectwelders.com

How To Optimize MIG Welding Shielding Gas Pressure PERFECT POWER Wire Welding Gas Pressure These settings determine the heat, wire deposition rate, and protection from atmospheric contamination, respectively, crucial for producing strong and clean welds. this article will show you how to set the flow rate of gas, the minimum and maximum values and the optimal gas. the most important mig welder settings are voltage, wire feed speed, and shielding gas flow. Wire Welding Gas Pressure.

From blog.thepipingmart.com

What is Gas Pressure Welding Machine? Uses and Working Wire Welding Gas Pressure If you’re creating a weld that is too weak or. You can make plans for how you approach your project concerning clamping, angle of approach, cooling, dealing with your welder’s duty cycle, and other practical solutions. the typical gas pressure when welding with mig tends to be around 3 to 8 psi, this is very low compared to other. Wire Welding Gas Pressure.

From www.mech4study.com

Gas Welding Principle, Working, Equipment, Application, Advantages Wire Welding Gas Pressure know the thickness of the metal so you know if your welder has the power to get the job done, you can choose the right electrode wire and the proper shielding gas. the most important mig welder settings are voltage, wire feed speed, and shielding gas flow rate. the typical gas pressure when welding with mig tends. Wire Welding Gas Pressure.

From informacionpublica.svet.gob.gt

MIG Gas Settings How To Set Gas On MIG Welder Welding Wire Welding Gas Pressure If you’re creating a weld that is too weak or. the typical gas pressure when welding with mig tends to be around 3 to 8 psi, this is very low compared to other types of welding. know the thickness of the metal so you know if your welder has the power to get the job done, you can. Wire Welding Gas Pressure.

From weldguru.com

MIG Welding Gas Pressure Settings (with Charts) Wire Welding Gas Pressure mig welding is an arc welding process in which a continuous solid wire electrode is fed through a welding gun and into the weld pool, joining the two. this article will show you how to set the flow rate of gas, the minimum and maximum values and the optimal gas. know the thickness of the metal so. Wire Welding Gas Pressure.

From www.wcwelding.com

Mig Welding Tutorial Wire Welding Gas Pressure this article will show you how to set the flow rate of gas, the minimum and maximum values and the optimal gas. The shielding gas provides the gas needed for mig welding. When starting, it is important to make sure the gas bottle is properly installed into the holder. usually, you should set your mig welding gas pressure. Wire Welding Gas Pressure.

From weldguru.com

What Gas Should You Use for TIG Welding? (with Chart) Wire Welding Gas Pressure These settings determine the heat, wire deposition rate, and protection from atmospheric contamination, respectively, crucial for producing strong and clean welds. mig welding is an arc welding process in which a continuous solid wire electrode is fed through a welding gun and into the weld pool, joining the two. The shielding gas provides the gas needed for mig welding.. Wire Welding Gas Pressure.

From weldguru.com

MIG Welding Gas Pressure Settings (with Charts) Wire Welding Gas Pressure mig welding is an arc welding process in which a continuous solid wire electrode is fed through a welding gun and into the weld pool, joining the two. the most important mig welder settings are voltage, wire feed speed, and shielding gas flow rate. These settings determine the heat, wire deposition rate, and protection from atmospheric contamination, respectively,. Wire Welding Gas Pressure.

From rst-web.com

Selecting the Right Shielding Gas For Your Welding Process RonSon's Wire Welding Gas Pressure know the thickness of the metal so you know if your welder has the power to get the job done, you can choose the right electrode wire and the proper shielding gas. If you’re creating a weld that is too weak or. These settings determine the heat, wire deposition rate, and protection from atmospheric contamination, respectively, crucial for producing. Wire Welding Gas Pressure.

From mavink.com

Welding Gas Pressure Chart Wire Welding Gas Pressure know the thickness of the metal so you know if your welder has the power to get the job done, you can choose the right electrode wire and the proper shielding gas. the most important mig welder settings are voltage, wire feed speed, and shielding gas flow rate. mig welding is an arc welding process in which. Wire Welding Gas Pressure.

From makemoneywelding.com

MIG Welding Gas Pressure Settings Wire Welding Gas Pressure These settings determine the heat, wire deposition rate, and protection from atmospheric contamination, respectively, crucial for producing strong and clean welds. When starting, it is important to make sure the gas bottle is properly installed into the holder. this article will show you how to set the flow rate of gas, the minimum and maximum values and the optimal. Wire Welding Gas Pressure.

From beststudwelders.com

MIG Welding Gas Pressure Settings Complete Guide best stud welders Wire Welding Gas Pressure These settings determine the heat, wire deposition rate, and protection from atmospheric contamination, respectively, crucial for producing strong and clean welds. the typical gas pressure when welding with mig tends to be around 3 to 8 psi, this is very low compared to other types of welding. know the thickness of the metal so you know if your. Wire Welding Gas Pressure.

From www.machines4u.com.au

The Beginner's Guide To Gas Welding Wire Welding Gas Pressure mig welding is an arc welding process in which a continuous solid wire electrode is fed through a welding gun and into the weld pool, joining the two. The shielding gas provides the gas needed for mig welding. You can make plans for how you approach your project concerning clamping, angle of approach, cooling, dealing with your welder’s duty. Wire Welding Gas Pressure.

From makemoneywelding.com

Explained Best MIG Welding Shielding Gas To Use Wire Welding Gas Pressure mig welding is an arc welding process in which a continuous solid wire electrode is fed through a welding gun and into the weld pool, joining the two. These settings determine the heat, wire deposition rate, and protection from atmospheric contamination, respectively, crucial for producing strong and clean welds. low gas pressure weakens the weld, reduces penetration and. Wire Welding Gas Pressure.